Patent Dr.-Ing. Ludwig Herzog

Head of Mechatronics

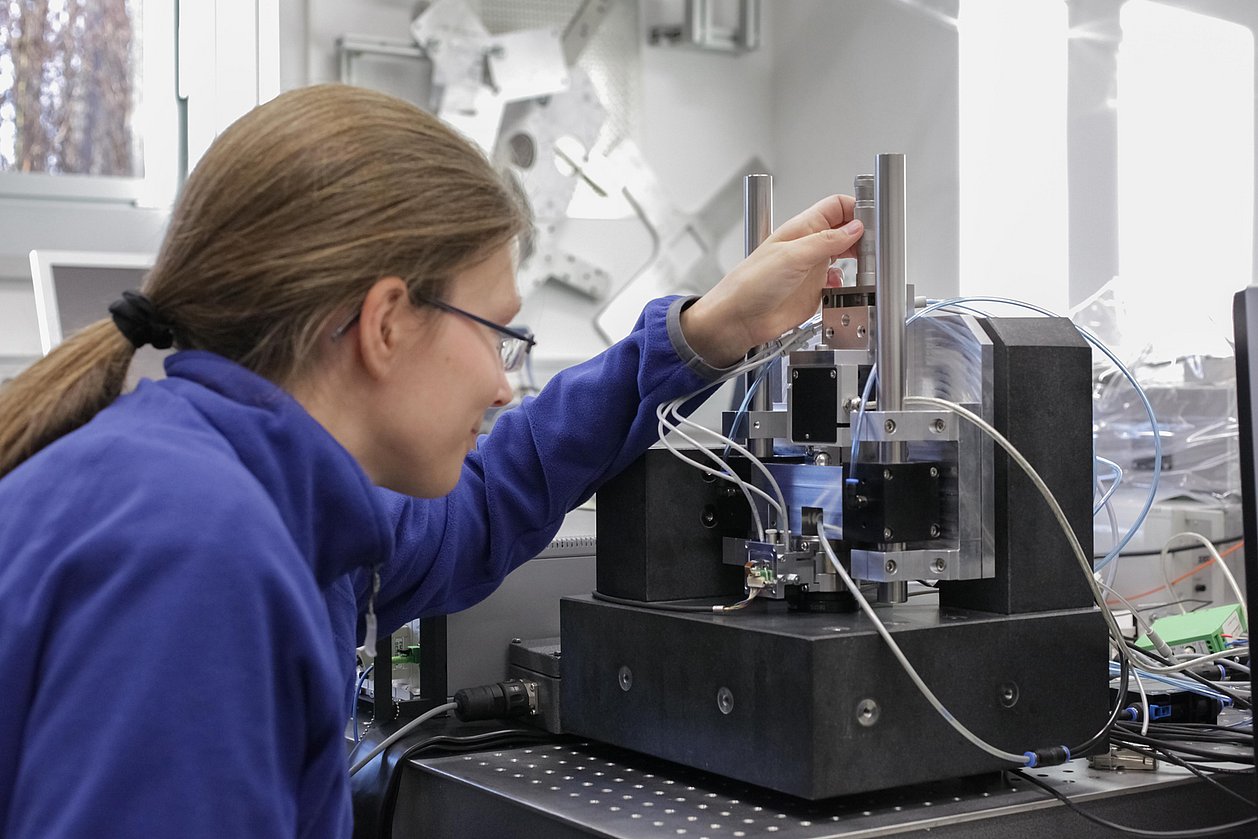

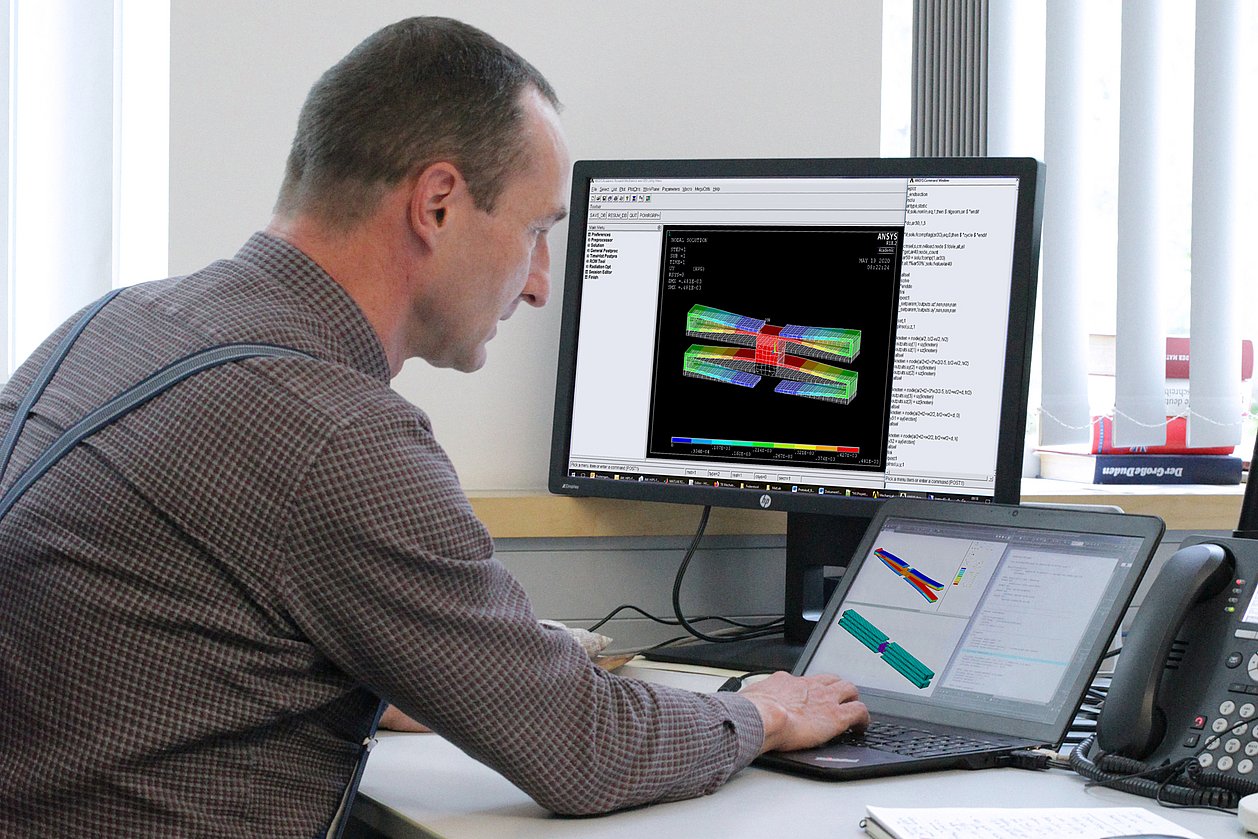

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Patent No.:Dr.-Ing. Ludwig Herzog

Inventor:

Research field:Magnetic 6D-direct drives with nanometre precision

Date of first publication:10 November 2014

Related content

Project

OptoMed vacuum air bearings

Air bearings in high-precision vacuum applications? Together with our partners, we are exploring the technical feasibility of this (apparent) contradiction.

Project

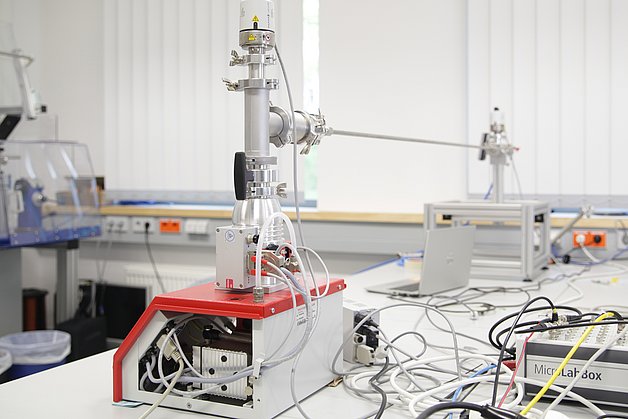

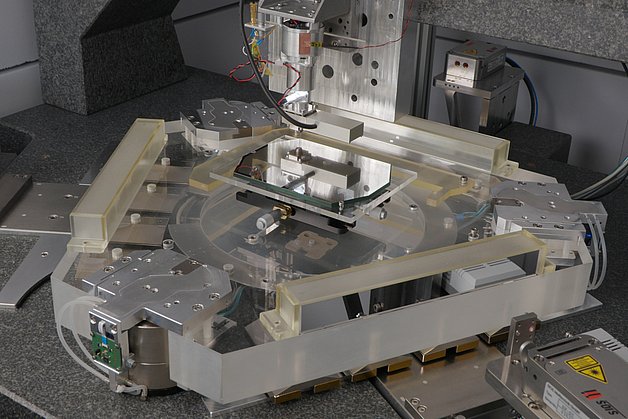

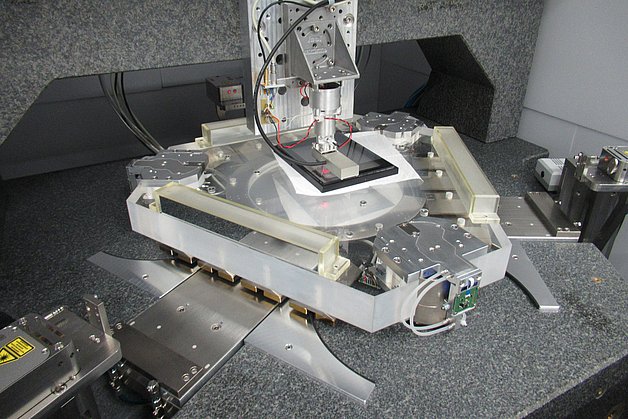

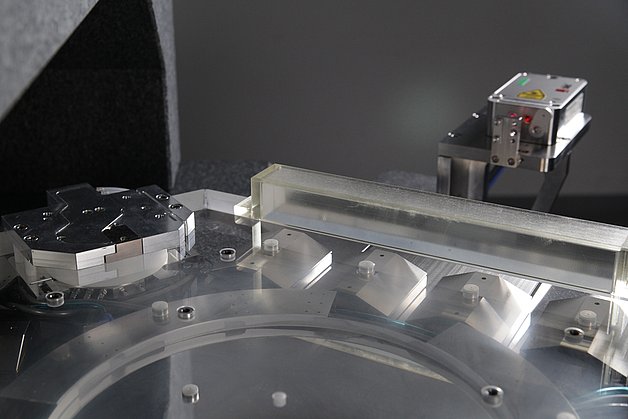

NFM-100

For fundamental research on nanometrology and nanofabrication at Ilmenau TU, the nanofabrication machine NFM-100 was realised as a system which enables the scanning of surfaces (AFM) as well as the processing by field emission scanning probe lithography for the first time in an xy-travel range of Ø100 mm.

Project

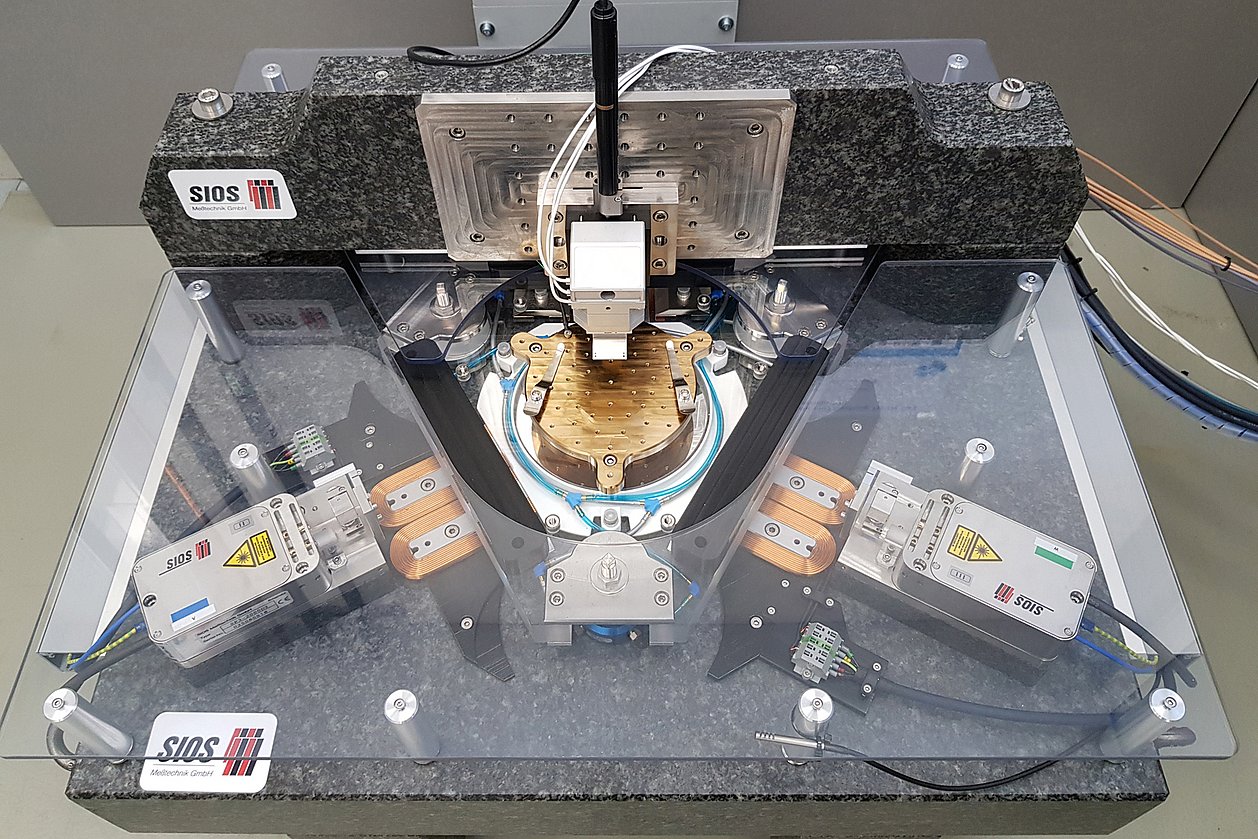

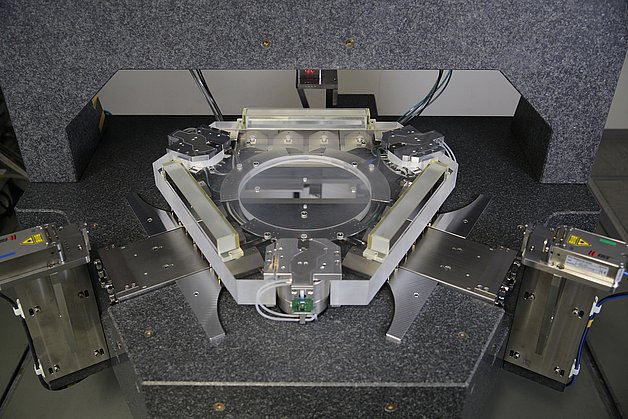

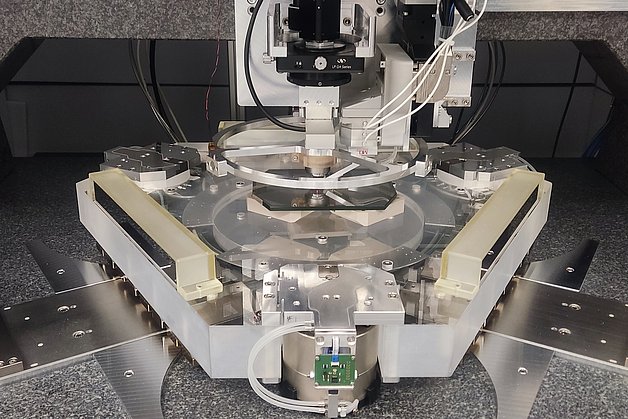

K4PNP+Z

IMMS developed actuators to position objects in planes with diameters up to 200 mm and a vertical stroke of 25 mm with nanometre precision.

Press release,

iENA-Silbermedaille für Beobachter der Atome

Neues Regelungskonzept zur sub-nanometergenauen Positionierung

Press release,

Hochempfindliche Beschleunigungsmessung mit kleinem MEMS-Sensor

IMMS erhält iENA-Bronzemedaille für mikroelektromechanischen Beschleunigungssensor

Press release,

High-precision drives released from vacuum

PTB and IMMS receive iENA bronze medal for new seal configuration for more precise displacement measurement in high-tech applications

Das Parallelisieren von Motor- und Regelungsentwurf reduziert Entwicklungszeit und -kosten

Dr. Ch. Schäffel1. M. Katzschmann1.Erschienen in MSR-Magazin, Automatisierungstechnik für Fertigung und Prozess, 03/2010

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau.ArticleOptical, mechanical and electro-optical design of an interferometric test station for massive parallel inspection of MEMS and MOEMS

K.Gastinger1. K.H.Haugholt1. M. Kujawinska2. M.Jozwik2. C. Schäffel3. S. Beer4.Paper 7389-56, SPIE Europe Optical Metrology, 14.- 18. Juni 2009, München

1SINTEF, Norway. 2Warsaw Univ. of Technology, Poland. 3IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau. 4Ctr. Suisse d'Electronique et de Microtechnique SA, Switzerland.Article

Event,

euspen SIG: Micro/Nano Manufacturing 2023

euspen Special Interest Group Meeting: Micro/Nano Manufacturing 2023

Contact

Contact

Eric Schäfer, M. Sc.

Head of Microelectronics / Branch Office Erfurt

eric.schaefer(at)imms.de+49 (0) 361 663 25 35

Eric Schäfer and his team research Integrated sensor systems, especially CMOS-based biosensors, ULP sensor systems and AI-based design and test automation. The results are being incorporated into research on the lead applications Sensor systems for in-vitro diagnostics and RFID sensor technology. It will assist you with services for the development of Integrated circuits and with IC design methods.

Contact

Dipl.-Ing. Michael Meister

Head of Industrial Electronics and Measurement Technology

michael.meister(at)imms.de+49 (0) 3677 874 93 20

Michael Meister is your contact for testing services, the development of test methodologies, and long-term measurements. He answers your questions on Modular and mobile test systems that we develop in our research in Smart distributed measurement and test systems as well as about testing and characterisation of integrated sensor systems. He is responsible for the test equipment at IMMS and will support you in the validation of ASIC and MEMS developments.

Mechatronics department

Our mechatronics team is interdisciplinary to ensure success in research and development for application-specific mechatronic systems for research and industrial customers, and takes care of the

- design of electro-magnetic actuators,

- modelling and simulation of the static, dynamic and thermal behaviour of mechatronic systems,

- development of suitable control algorithms and their programming, as well as the

- practical implementation in the form of prototypes.

Most of our scientific staff have academic degrees in mechatronics and control engineering as well as in related fields of study such as mathematics or electrical engineering.

We supervise four to six students per year in internships, bachelor's and master's theses at our location in Ilmenau. In addition, we provide staff for the SME Digital Team at IMMS.

We support you with research and development in the following areas

Back

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)