Research field Magnetic 6D direct drives with nanometre precision

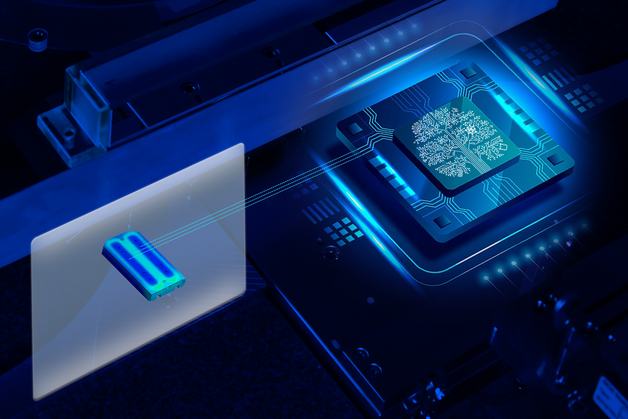

The continuous reduction in the size of the structural elements of technical products in many different sectors increases the demand for precision machinery with which tiniest structures and objects can be measured and manufactured with high accuracy. There are many such objects having spatial extents from millimetres to centimetres, while surface characteristics and functional elements are just a few microns or nanometres in size and have to be positioned with a precision less than one nanometre in the production process.

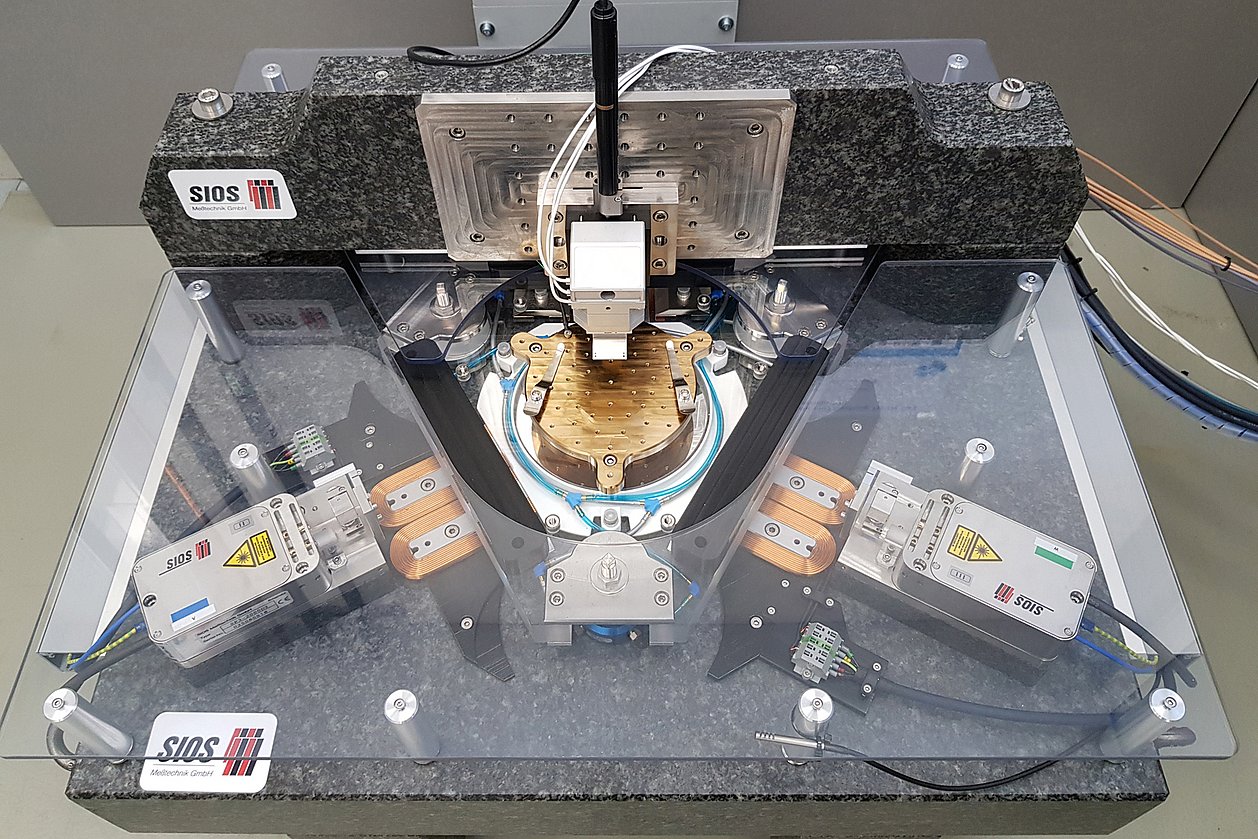

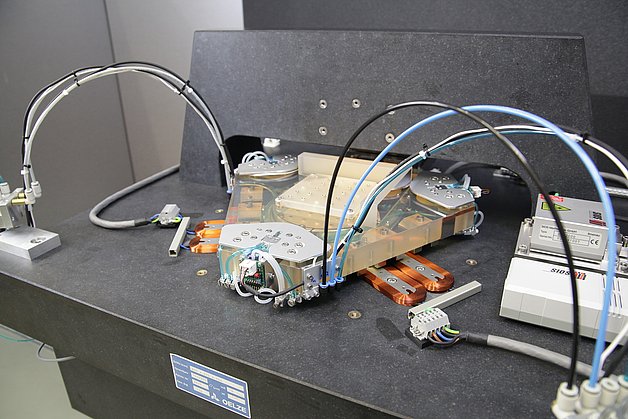

To blaze the trail for the manufacturing of components from the macro-world with the precision that is associated with the micro- and nano-world, we conduct research on the scientific fundamentals and technical solutions to implement nanopositioning systems acting over long distances of travel. Our highly dynamic integrated multi-coordinate drives move objects with the same accuracy over distances of several hundred millimetres within the shortest time. Our solutions are intended for use under vacuum, in cleanrooms and sites with particular requirements for thermal insulation and elimination of vibrations.

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Related content

Project

MC_NPS

Combination of a high-precision drive from research with industrial control for nanometre-precise positioning in high-tech applications

Project

OptoMed vacuum air bearings

Air bearings in high-precision vacuum applications? Together with our partners, we are exploring the technical feasibility of this (apparent) contradiction.

Project

VirtuSen

With the help of virtual sensor technology and AI, it is intended to detect and compensate for disturbing influences on complex mechatronic systems such as high-precision drives with spatial resolution

Project

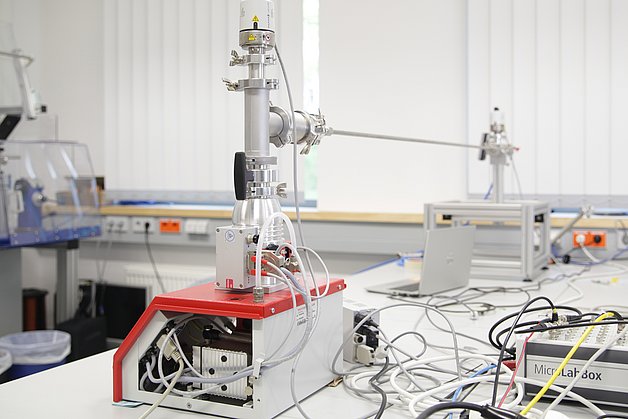

NFM-100

For fundamental research on nanometrology and nanofabrication at Ilmenau TU, the nanofabrication machine NFM-100 was realised as a system which enables the scanning of surfaces (AFM) as well as the processing by field emission scanning probe lithography for the first time in an xy-travel range of Ø100 mm.

Reference

Prof. Dr. Thomas Arnold, Leibniz IOM

“We are extremely pleased with the resulting demonstration device. Besides proven competence in drive design and experience of product development in the service of research institutes, IMMS also brought to the task a highly professional, purposeful and constructive approach.”

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/1/csm_Aerolas_Logo_ohne-Claim_434x112_a80595ae78.png)

Reference

Michael Muth, AeroLas

“We have for many years been appreciative of our cooperation with IMMS. The results from this project will be the basis of product design to the specification of future AeroLas customers. IMMS will likewise be an important partner for us in future developments because of its outstanding expertise in the field of magnetic drives.“

Development and validation of a simplified coil model for CFD simulation of a nano-positioning planar drive system

Ina Naujokat1. Ludwig Herzog1. Steffen Hesse1. Parastoo Salimitari1.Euspen Special Interest Conference: Precision & Performance 2025, Proceedings: www.euspen.eu/euspen-knowledge-base/proceedings-search/, November 18-20, 2025, Cranfield University, United Kingdom

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Experimental characterization of thermal disturbances in a 6DOF nanopositioning system under varying operational conditions

Parastoo Salimitari1. Steffen Hesse1. Michael Katzschmann1. Ludwig Herzog1.Euspen Special Interest Conference: Precision & Performance 2025, Proceedings: www.euspen.eu/euspen-knowledge-base/proceedings-search/, November 18-20, 2025, Cranfield University, United Kingdom

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Sensor for Picometer-Scale Positioning in Vacuum – Demonstration of an IDS3010-Based Ultra-Precise Closed-loop Linear Drive System

Markus Øverland1. Gregor Schindler1. Alex S. Huaman2. Ludwig Herzog2.Technical Note: Motion & Sensing 15, attocube systems GmbH. V10/25. PDF: marketing.attocube.com/acton/attachment/4434/f-ed569c35-99d8-435b-b87f-8f6a30a97ca2/1/-/-/-/-/TechNote_MAS-15_Sensor%20for%20Picometer-Scale%20Positioning%20in%20Vacuum.pdf

1attocube systems GmbH, Eglfinger Weg 2, 85540 Haar, Germany. 2IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.NPS6D200: Long-Range-6D-Nanopositionierung mit interferometrischem Feedback für das Closed-Loop-Regelungssystem

Steffen Hesse1.Experten-Tag für Präzisionsmesstechnik, 28. - 29. Oktober 2025, bei SIOS Meßtechnik GmbH, Ilmenau, Germany

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)