Lead application nm measurement and structuring of objects

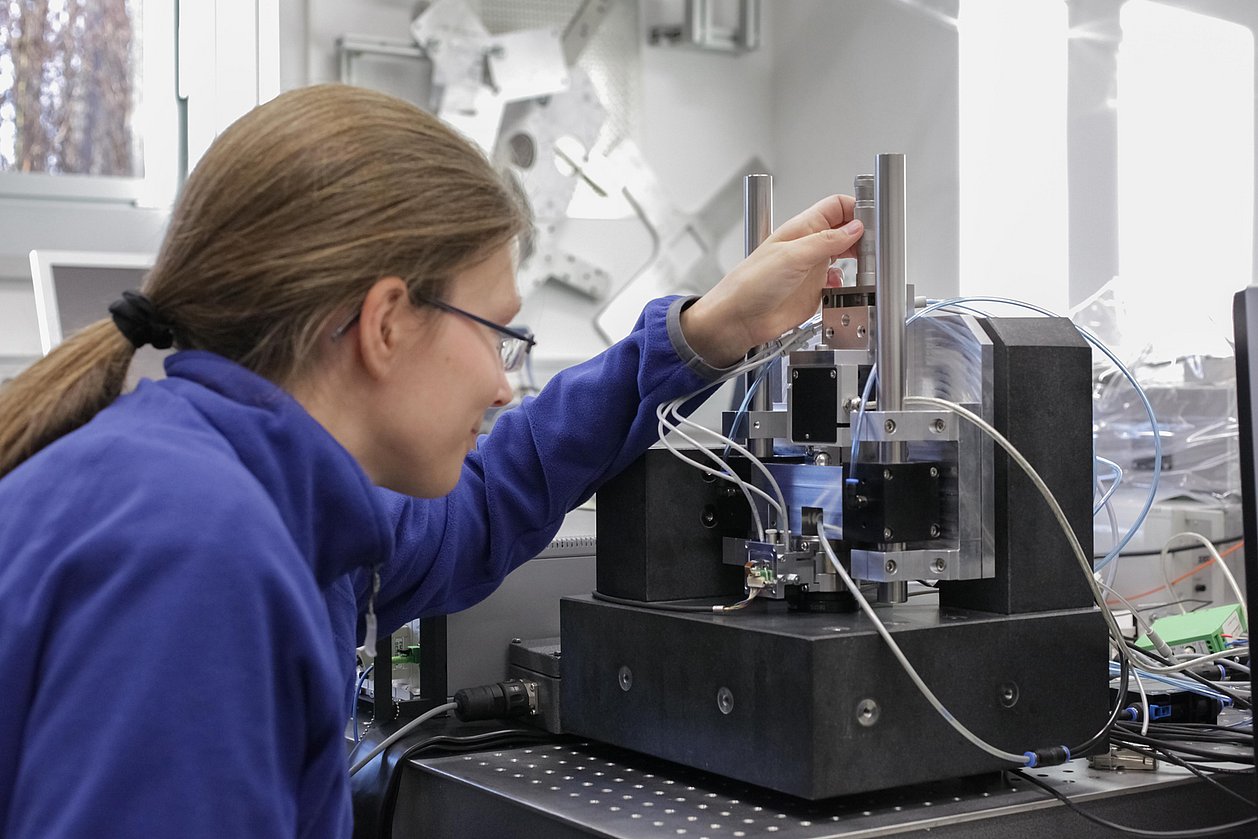

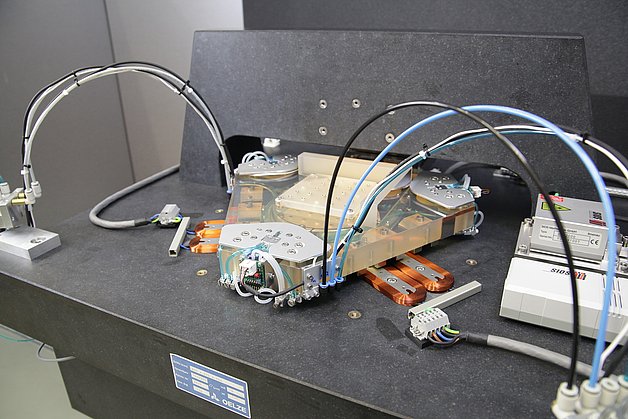

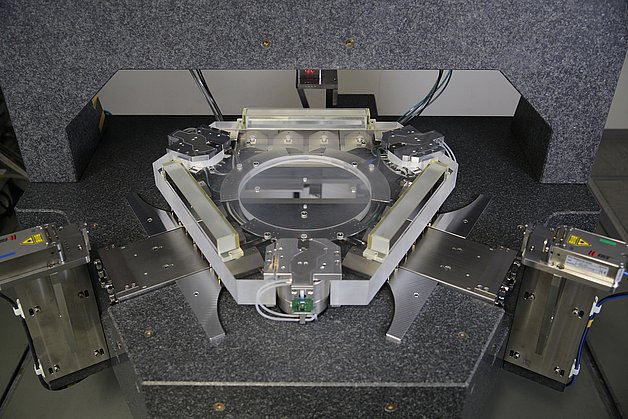

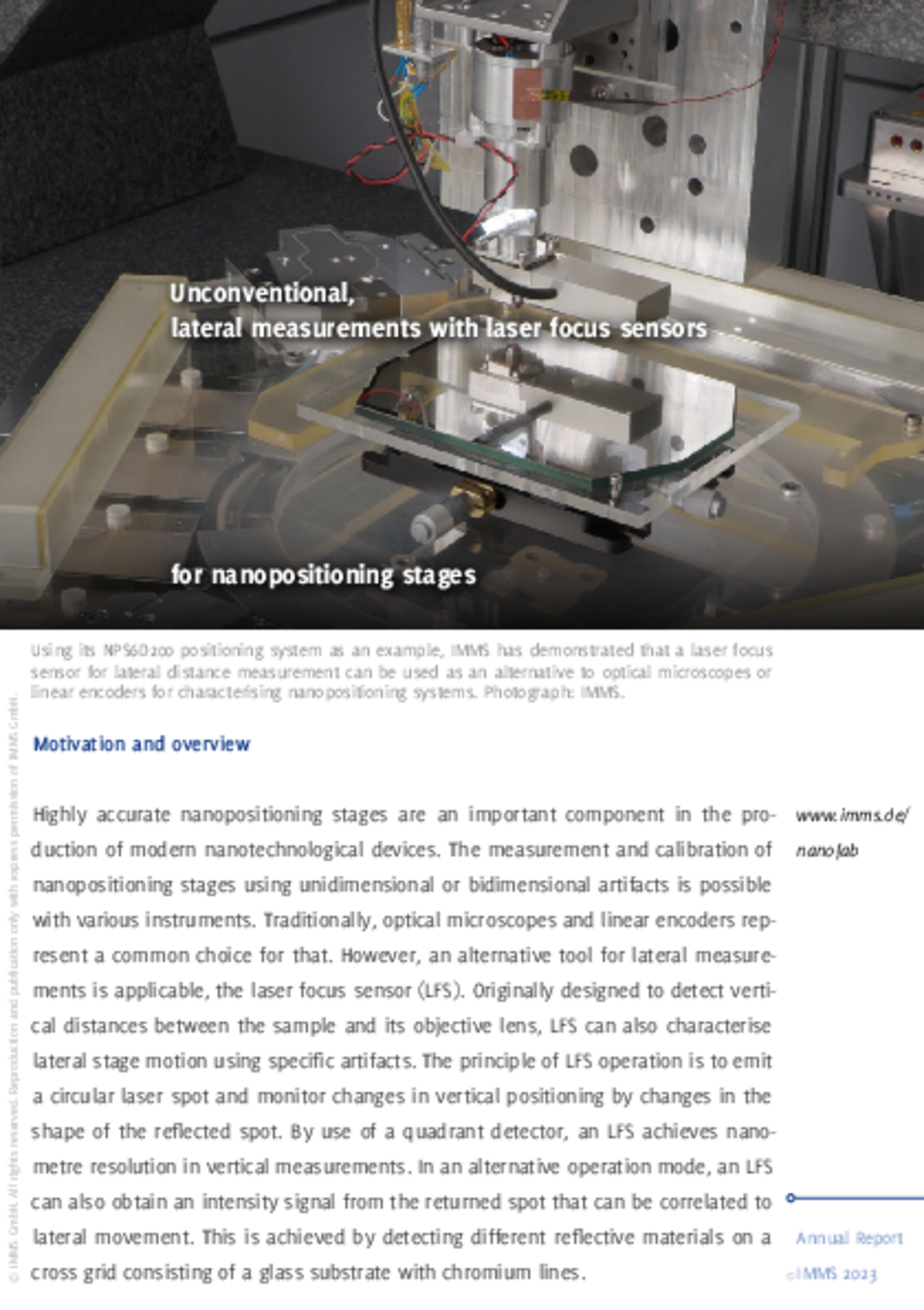

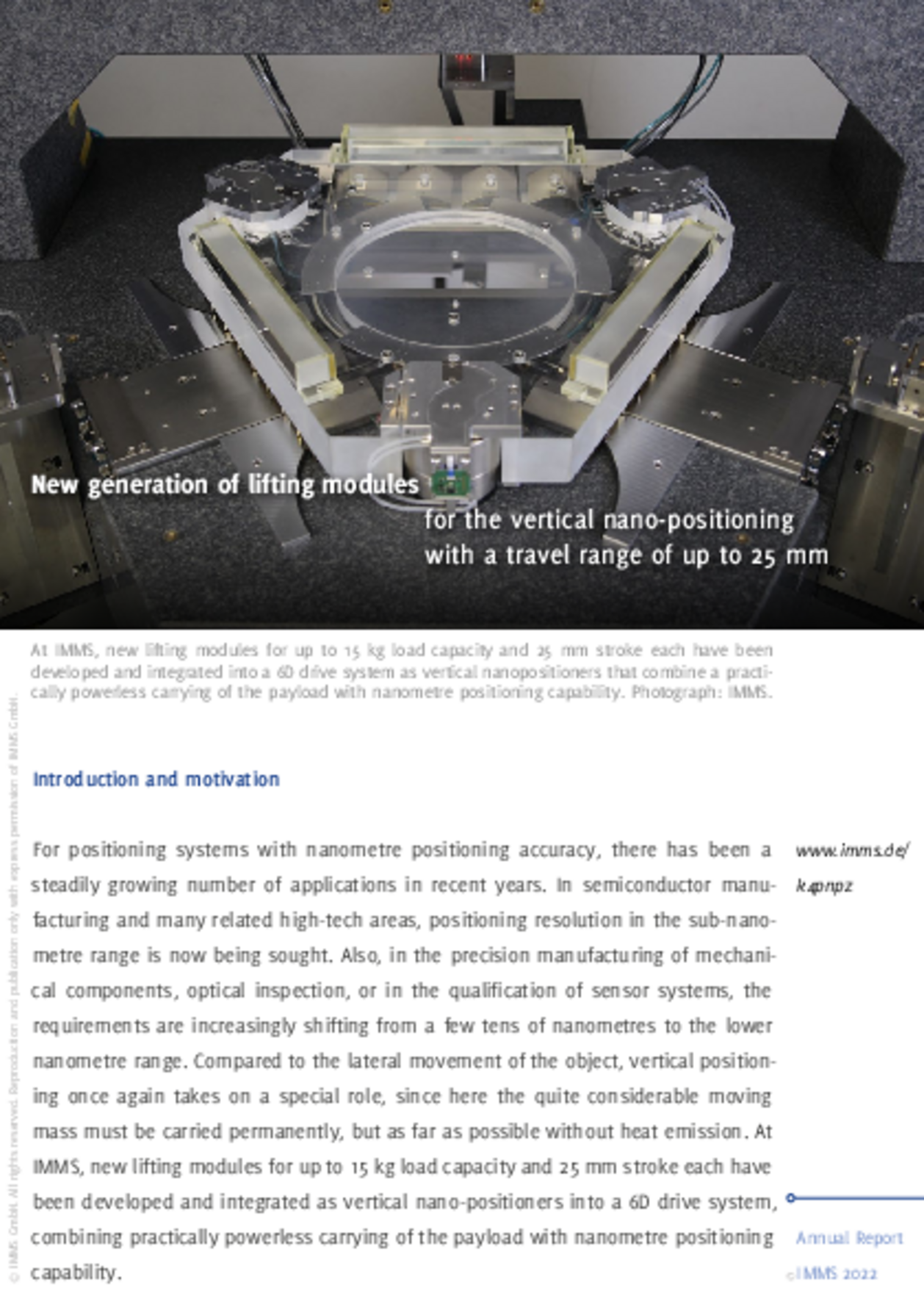

Our goal is to create the basis for the measurement and manufacturing technology of the future with high-precision drive systems. From today’s planar (2.5D) motion accuracies in the sub-µm range, we are on the way to spatial (6D) positioning accuracies in the single-digit nm range. On the basis of our research, we are developing actuators that make it possible to position an object on a surface with a diameter of 100 mm and a vertical stroke of 10 mm with nanometre precision. In perspective, the diameter will be extended to 200 mm and the z-stroke to 25 mm. Such systems are used, for example, in precision metrology and for the production of semiconductor wafers and exposure masks in microelectronics manufacturing.

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Related content

Project

MC_NPS

Combination of a high-precision drive from research with industrial control for nanometre-precise positioning in high-tech applications

Project

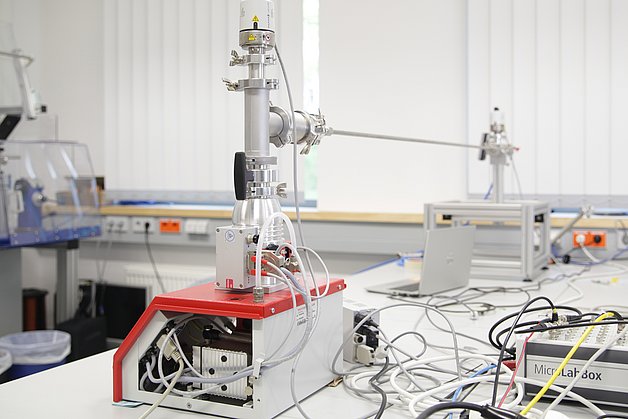

OptoMed vacuum air bearings

Air bearings in high-precision vacuum applications? Together with our partners, we are exploring the technical feasibility of this (apparent) contradiction.

Project

NFM-100

For fundamental research on nanometrology and nanofabrication at Ilmenau TU, the nanofabrication machine NFM-100 was realised as a system which enables the scanning of surfaces (AFM) as well as the processing by field emission scanning probe lithography for the first time in an xy-travel range of Ø100 mm.

Project

K4PNP+Z

IMMS developed actuators to position objects in planes with diameters up to 200 mm and a vertical stroke of 25 mm with nanometre precision.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/1/csm_Aerolas_Logo_ohne-Claim_434x112_a80595ae78.png)

Reference

Michael Muth, AeroLas

“We have for many years been appreciative of our cooperation with IMMS. The results from this project will be the basis of product design to the specification of future AeroLas customers. IMMS will likewise be an important partner for us in future developments because of its outstanding expertise in the field of magnetic drives.“

Reference

Peter Chall, ALSI

”The achieved extreme precision, reproducibility and productivity of the laser dicing technology are at the forefront of international excellence. The close cooperation with IMMS leads to innovative developments, which is a basis that we can count on to expand our position as a leading technology provider.“

Sensor for Picometer-Scale Positioning in Vacuum – Demonstration of an IDS3010-Based Ultra-Precise Closed-loop Linear Drive System

Markus Øverland1. Gregor Schindler1. Alex S. Huaman2. Ludwig Herzog2.Technical Note: Motion & Sensing 15, attocube systems GmbH. V10/25. PDF: marketing.attocube.com/acton/attachment/4434/f-ed569c35-99d8-435b-b87f-8f6a30a97ca2/1/-/-/-/-/TechNote_MAS-15_Sensor%20for%20Picometer-Scale%20Positioning%20in%20Vacuum.pdf

1attocube systems GmbH, Eglfinger Weg 2, 85540 Haar, Germany. 2IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.NPS6D200: Long-Range-6D-Nanopositionierung mit interferometrischem Feedback für das Closed-Loop-Regelungssystem

Steffen Hesse1.Experten-Tag für Präzisionsmesstechnik, 28. - 29. Oktober 2025, bei SIOS Meßtechnik GmbH, Ilmenau, Germany

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Nanometer-Positionierung mit 6D-Regelung

Steffen Hesse1.Mikroproduktion, Fachmagazin, Ausgabe 03/2025, Seite 44 - 48

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Herausforderungen und Lösungsansätze bei der Entwicklung kraftgekoppelter Hochpräzisions-Vertikalantriebe

Ludwig Herzog1.18. Jahrestagung „Feinwerktechnische Konstruktion“, 25. - 26. September 2025, Dresden, Germany

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)