Research field Smart distributed measurement and test systems

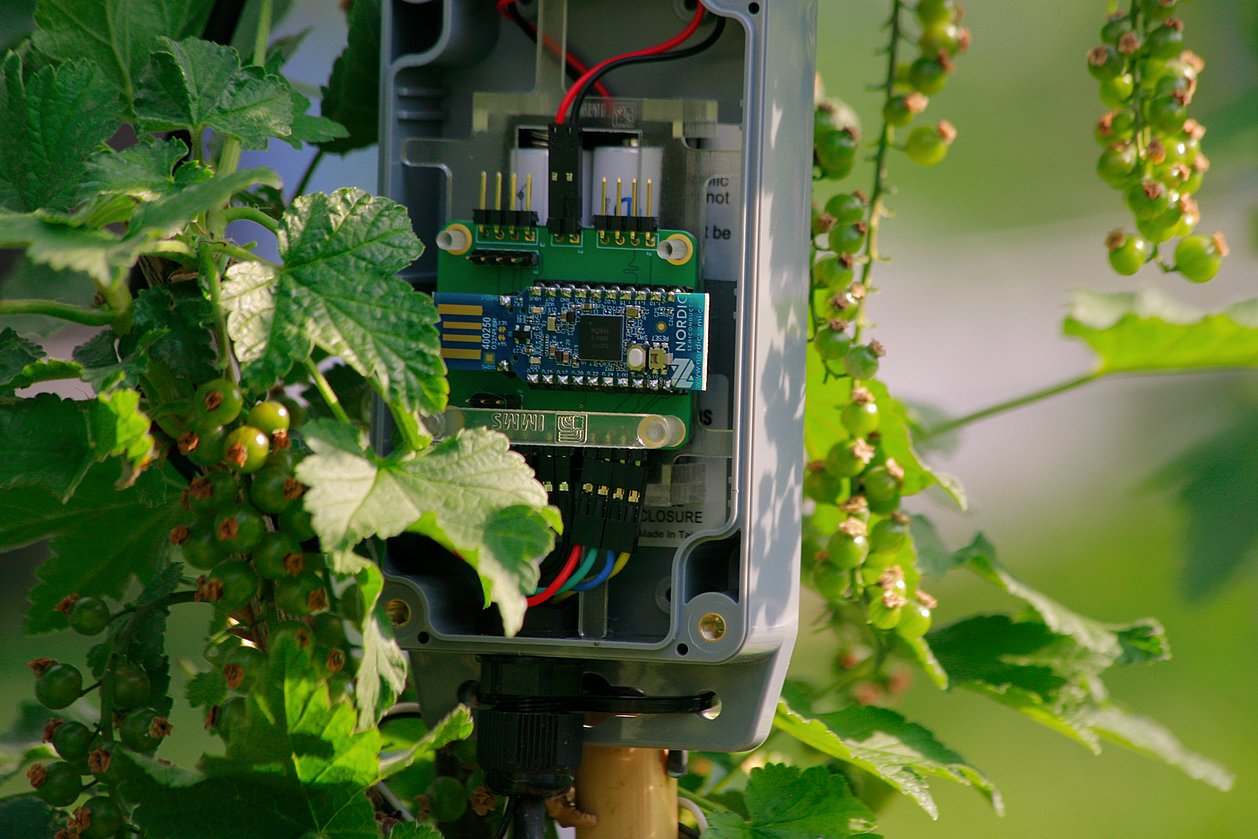

Integrated sensor ICs represent the heart of sensor and measurement systems. These can be wireless sensors, handheld diagnostic devices or high-performance stationary device solutions for machine monitoring, for example.

Challenges of increasingly performant sensors

Increasingly performant sensors and their rapidly expanding number lead to immense amounts of data, which are ever more pushing previous technologies to their limits when it comes to transmitting, processing and using them. Therefore, it will be necessary to design systems for sensing, measuring and testing in such a way that they can validate, process and evaluate data automatically in the future. We intend to achieve this by directly incorporating intelligence into the devices. Interconnecting these systems creates the possibility of distributing the tasks in the network. However, new challenges arise in the form of dynamic aspects due to network protocols and changing tasks over time.

In this research field, we therefore focus on three questions

- How can sensor data be automatically processed into usable information as close as possible to the point of origin in a fast, cost-effective and energy-efficient way?

- What additional information can be obtained with the help of distributed sensor systems?

- How can such a system be modelled based on different subsystems in order to evaluate energy requirements, the optimal distribution of functionalities in the network and the influence of topology decisions?

Contact

Contact

Dr.-Ing. Tino Hutschenreuther

Head of System Design

tino.hutschenreuther(at)imms.de+49 (0) 3677 874 93 40

Dr. Tino Hutschenreuther will answer your questions on our research in Smart distributed measurement and test systems and the related core topics Analysis of distributed IoT systems, Embedded AI and Real-time data processing and communications, on the lead applications Adaptive edge AI systems for industrial application and IoT systems for cooperative environmental monitoring as well as on the range of services for the development of embedded systems.

Related content

Project

RGBS

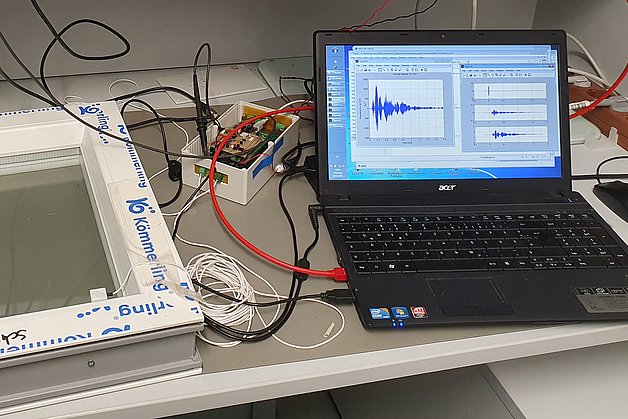

Development of a new retrofittable glass break sensor based on ultrasound technology with greater precision and robustness

Project

Multi-Interact

For health research, a highly parallelised multiplex system is being developed to precisely and kinetically determine binding energies between biomolecules.

Project

VirtuSen

With the help of virtual sensor technology and AI, it is intended to detect and compensate for disturbing influences on complex mechatronic systems such as high-precision drives with spatial resolution

Reference

Dr. Alexander Maier, Fraunhofer IOSB-INA

“We very much appreciate not only the sound, practical engineering knowledge of the IMMS staff concerning Industry 4.0-compatible protocols and systems but also the personal contact and the constructive manner of IMMS’ collaboration. And so we shall be delighted if we can tackle upcoming subjects together.”

Reference

Friedrich Becker, TURCK Electronics GmbH

“With its experience in the spheres of signal processing and integrating communications and systems for industry, IMMS contributed significantly to the execution of the science which the partners in Chemnitz and Offenburg derived from theoretical principles in cable diagnostics and communications interfaces.”

Reference

Dirk-Hendrik John, Software-Service John GmbH

“From our point of view, the design IMMS came up with for the architecture was in itself convincing. Further, we were impressed by its support in integrating our application with the MQTT standard. Both during the ongoing joint field test in Jena and during the entire project period, IMMS staff were always readily available with prompt support if questions or problems arose.”

Evaluierung und Test der Empfangsleistung von Funksystemen

Björn Bieske1. Michael Schenk2.38. ITG / GMM / GI -Workshop Testmethoden und Zuverlässigkeit von Schaltungen und Systemen (TuZ 2026), 22. - 24. Februar 2026, Potsdam, Germany

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany. 2Adolf Würth GmbH & Co. KG.Digitale Lösungen für den Obstbau: Assistenzsystem Obstverarbeitung – Digitaler Obstsorten-Zwilling

Lukas Oehm1. Marco Götze2.Obstbautag Mecklenburg-Vorpommern 2026, 24. Februar 2026, Güstrow, Mecklenburg-Vorpommern, Germany

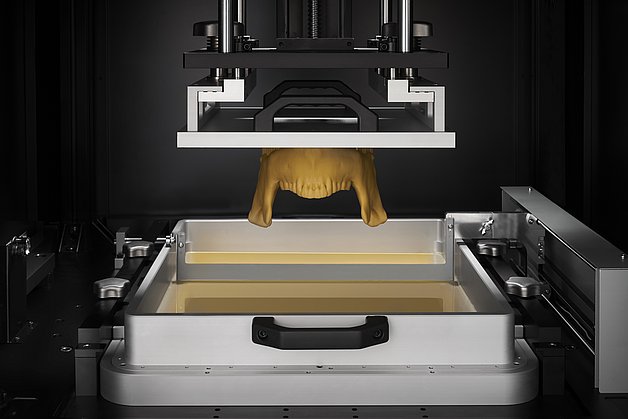

1Fraunhofer-Institut für Verfahrenstechnik und Verpackung IVV, Dresden. 2IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Real-Time Optimal Parameter Recommendation for Injection Molding Machines Using AI with Limited Dataset

Roy Bipasha1. Silvia Krug1,2. Tino Hutschenreuther1.AI 2026, 7, 49. doi.org/10.3390/ai7020049

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany. 2Department of Computer and Electrical Engineering, Mid Sweden University, Holmgatan 10, 85170 Sundsvall, Sweden.Case Study on Compression of Vibration Data for Distributed Wireless Condition Monitoring Systems.

Rick Pandey1. Felix Grimm2,3. Dominik Nille2. Christoph Böckenhoff2. Jonathan Gamez1. Sebastian Uziel1. Albert Dorneich2. Tino Hutschenreuther1. Silvia Krug1,4.Applied Sciences 2025, 15, 12346. DOI: doi.org/10.3390/app152212346

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany. 2Balluff GmbH, 73765 Neuhausen auf den Fildern, Germany. 3Institute of Smart Sensors (IIS), University of Stuttgart, 70569 Stuttgart, Germany. 4Department of Computer and Electrical Engineering, Mid Sweden University, Holmgatan 10, 851 70 Sundsvall, Sweden.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/7/csm_20130223_dcSen_ProberEF_MM_MG_3325_1920x1280_588e478d86.jpg)