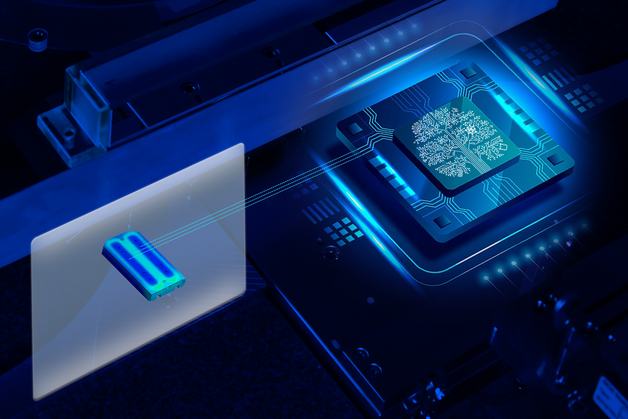

Lead application Adaptive edge AI systems for industrial application

Based on our research, it will be possible to integrate artificial intelligence directly into the sensor and thus derive decisions in real time without detouring via the cloud. The automated adaptation to new environmental conditions can open up versatile fields of application.

These solutions can be used to detect fault conditions or wear directly in the process or to implement measurement systems for maintenance that enable direct evaluation based on the sensor data. This makes an active contribution to the conservation of resources (computing time, communication overhead).

Contact

Contact

Dr.-Ing. Tino Hutschenreuther

Head of System Design

tino.hutschenreuther(at)imms.de+49 (0) 3677 874 93 40

Dr. Tino Hutschenreuther will answer your questions on our research in Smart distributed measurement and test systems and the related core topics Analysis of distributed IoT systems, Embedded AI and Real-time data processing and communications, on the lead applications Adaptive edge AI systems for industrial application and IoT systems for cooperative environmental monitoring as well as on the range of services for the development of embedded systems.

Related content

Project

VirtuSen

With the help of virtual sensor technology and AI, it is intended to detect and compensate for disturbing influences on complex mechatronic systems such as high-precision drives with spatial resolution

Project

HoLoDEC

IMMS researches ultra-low-power architectures (ULP) and circuit concepts as well as energy-efficient edge-AI systems with overall system energy modeling

Project

ProQuaOpt

IMMS is developing an AI-based control system for resource-efficient online optimisation of injection moulding

Project

Trib.US

Real-time capable platform and algorithms for mobile multi-sensor inspection device for the maintenance of roller bearings

Reference

Heinz-Wolfgang Lahmann, GFE – Gesellschaft für Fertigungstechnik und Entwicklung Schmalkalden e.V.

”In our collaboration with IMMS, we particularly appreciate the expertise in the field of sensor data acquisition and processing, the high application orientation of the solutions and the constructive contacts with its employees – not least when working together on site on machines and equipment.”

Reference

Peter Otto, Postberg

“We are very satisfied with the result – the many years of IMMS experience in the design of embedded systems, with industrial projects and also the system understanding of IMMS from the previous product developments with SONOTEC have clearly contributed to the success.”

Reference

Prof. Dr. Peter Holstein, SONOTEC GmbH

“IMMS has designed the digital components of the hardware to be used in our new digital ultrasonic testing device. The signal processing performance achieved is largely based on FPGA technology, a field in which IMMS has excellent references. Our joint work with IMMS went off perfectly.”

Real-Time Optimal Parameter Recommendation for Injection Molding Machines Using AI with Limited Dataset

Roy Bipasha1. Silvia Krug1,2. Tino Hutschenreuther1.AI 2026, 7, 49. doi.org/10.3390/ai7020049

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany. 2Department of Computer and Electrical Engineering, Mid Sweden University, Holmgatan 10, 85170 Sundsvall, Sweden.Case Study on Compression of Vibration Data for Distributed Wireless Condition Monitoring Systems.

Rick Pandey1. Felix Grimm2,3. Dominik Nille2. Christoph Böckenhoff2. Jonathan Gamez1. Sebastian Uziel1. Albert Dorneich2. Tino Hutschenreuther1. Silvia Krug1,4.Applied Sciences 2025, 15, 12346. DOI: doi.org/10.3390/app152212346

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany. 2Balluff GmbH, 73765 Neuhausen auf den Fildern, Germany. 3Institute of Smart Sensors (IIS), University of Stuttgart, 70569 Stuttgart, Germany. 4Department of Computer and Electrical Engineering, Mid Sweden University, Holmgatan 10, 851 70 Sundsvall, Sweden.Development and validation of a simplified coil model for CFD simulation of a nano-positioning planar drive system

Ina Naujokat1. Ludwig Herzog1. Steffen Hesse1. Parastoo Salimitari1.Euspen Special Interest Conference: Precision & Performance 2025, Proceedings: www.euspen.eu/euspen-knowledge-base/proceedings-search/, November 18-20, 2025, Cranfield University, United Kingdom

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Experimental characterization of thermal disturbances in a 6DOF nanopositioning system under varying operational conditions

Parastoo Salimitari1. Steffen Hesse1. Michael Katzschmann1. Ludwig Herzog1.Euspen Special Interest Conference: Precision & Performance 2025, Proceedings: www.euspen.eu/euspen-knowledge-base/proceedings-search/, November 18-20, 2025, Cranfield University, United Kingdom

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.