Project K4PNP+Z

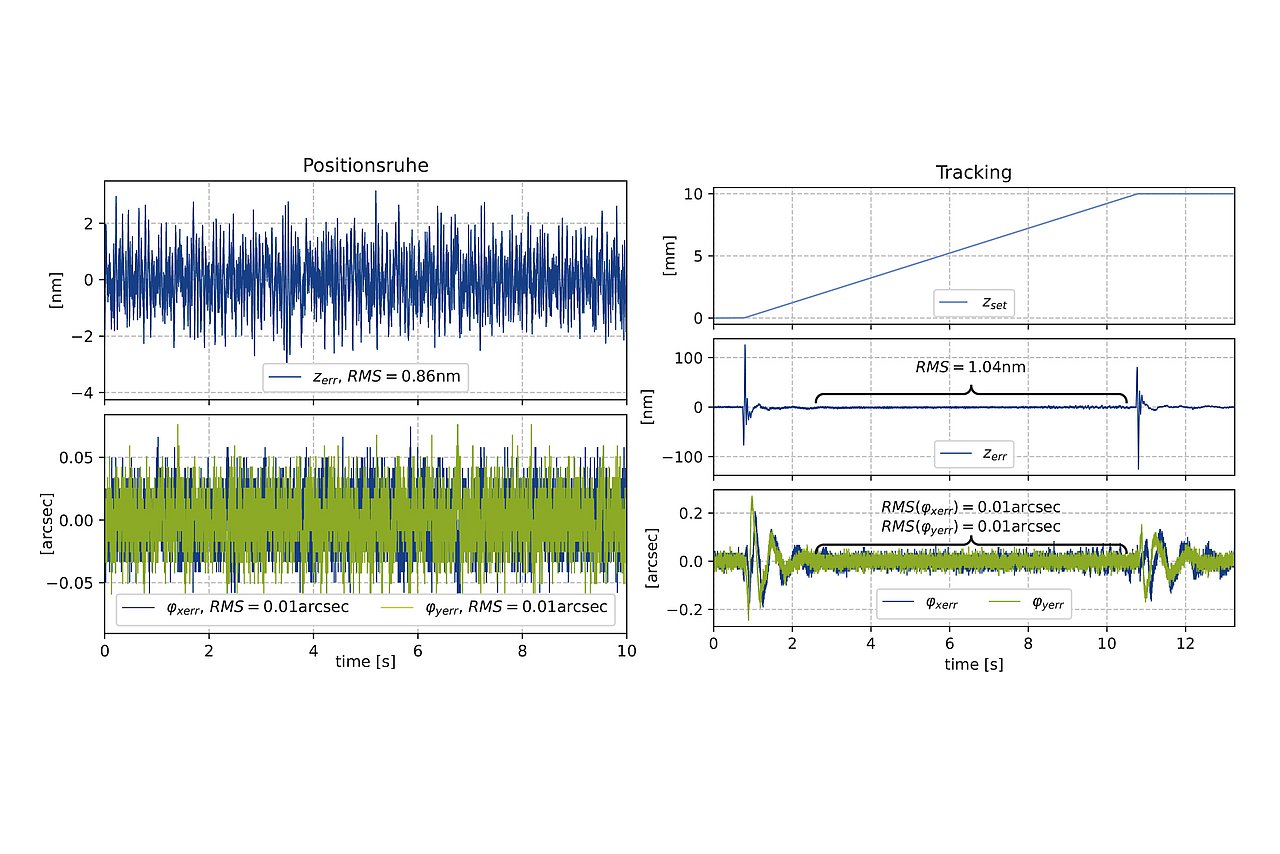

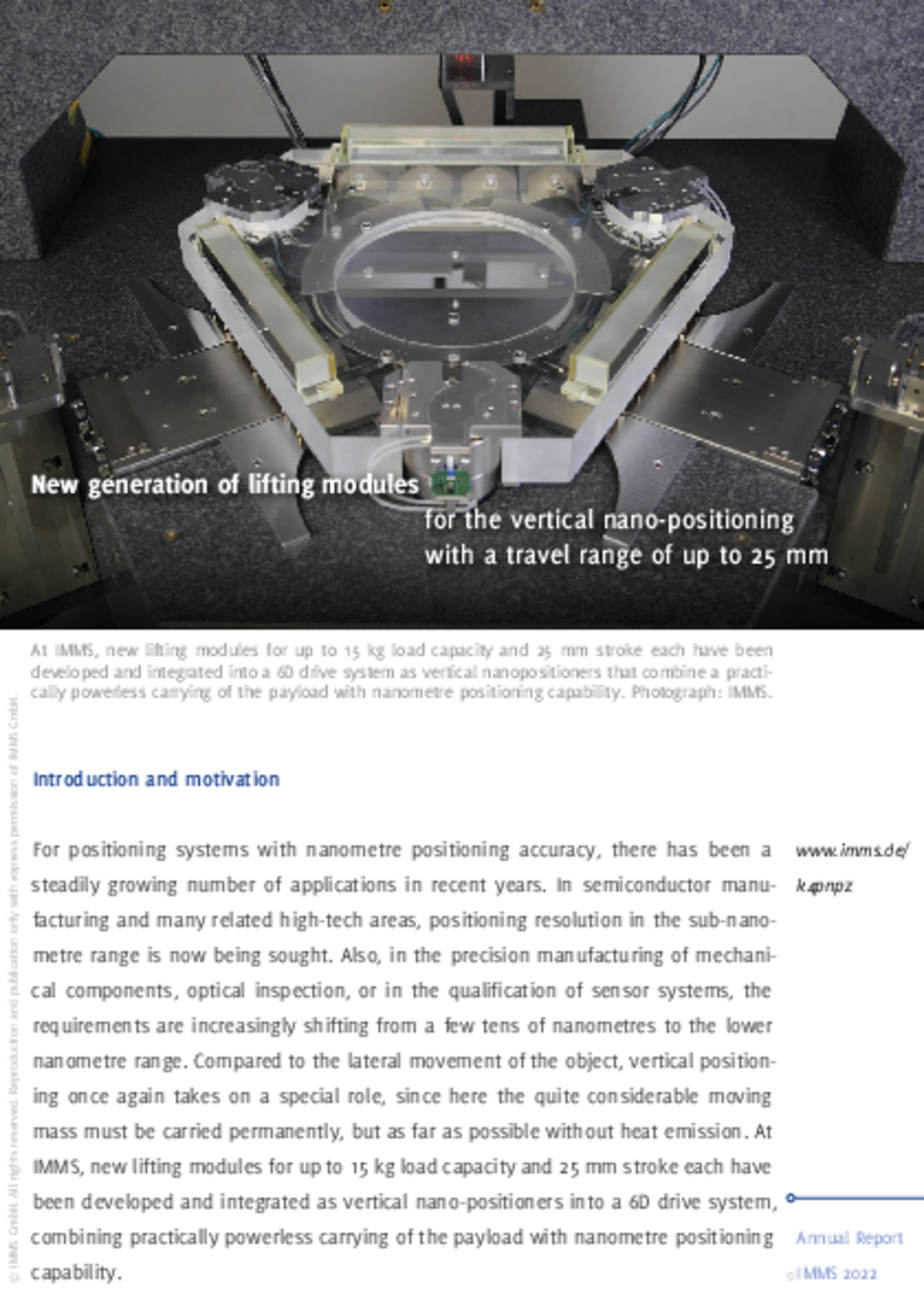

IMMS developed actuators to position objects in planes with diameters up to 200 mm and a vertical stroke of 25 mm with nanometre precision.

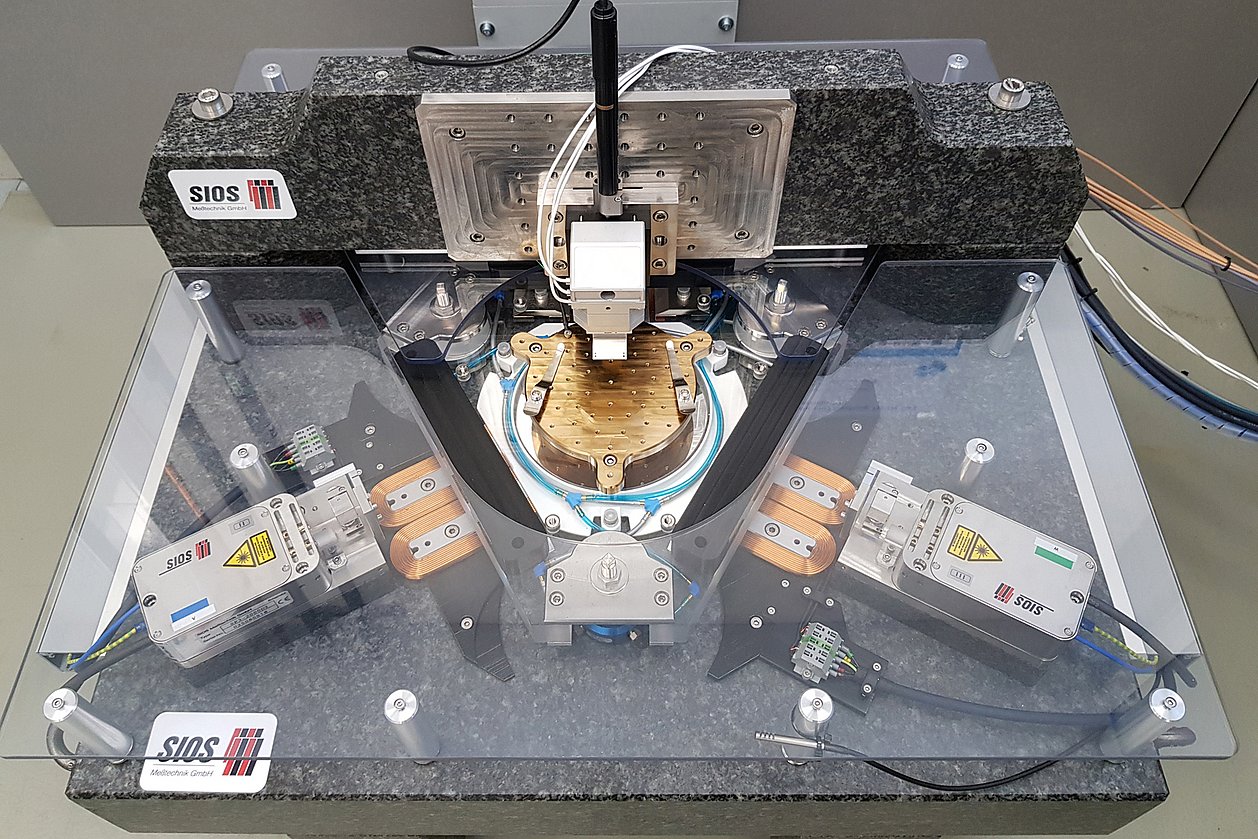

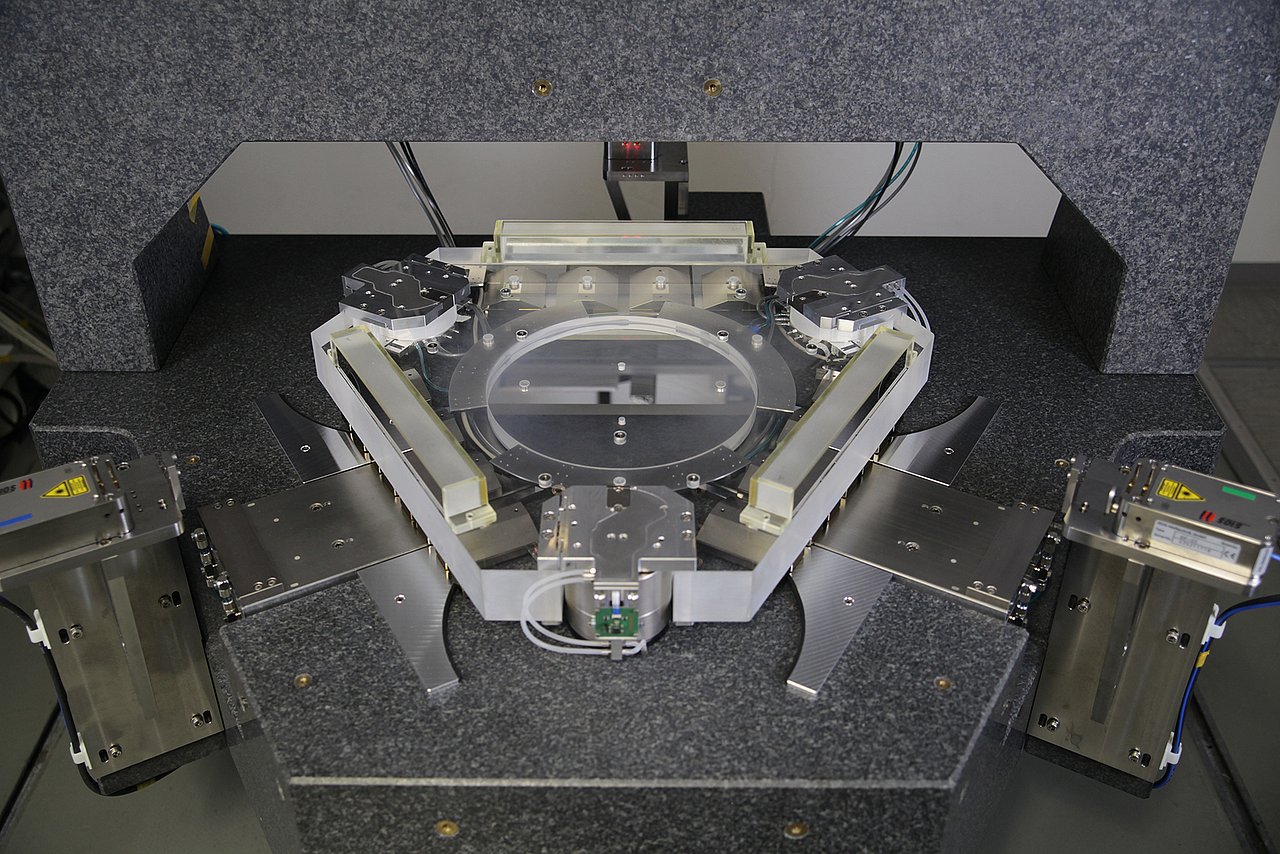

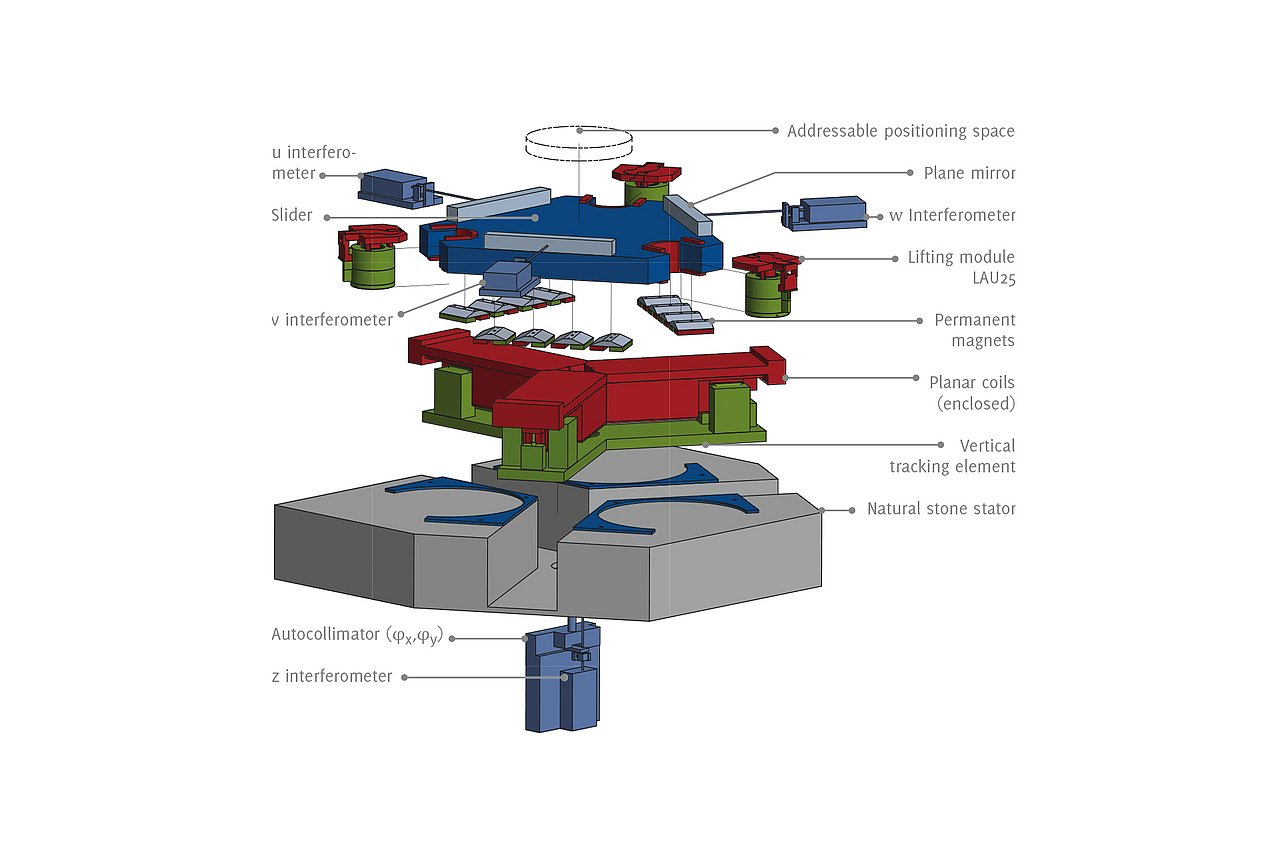

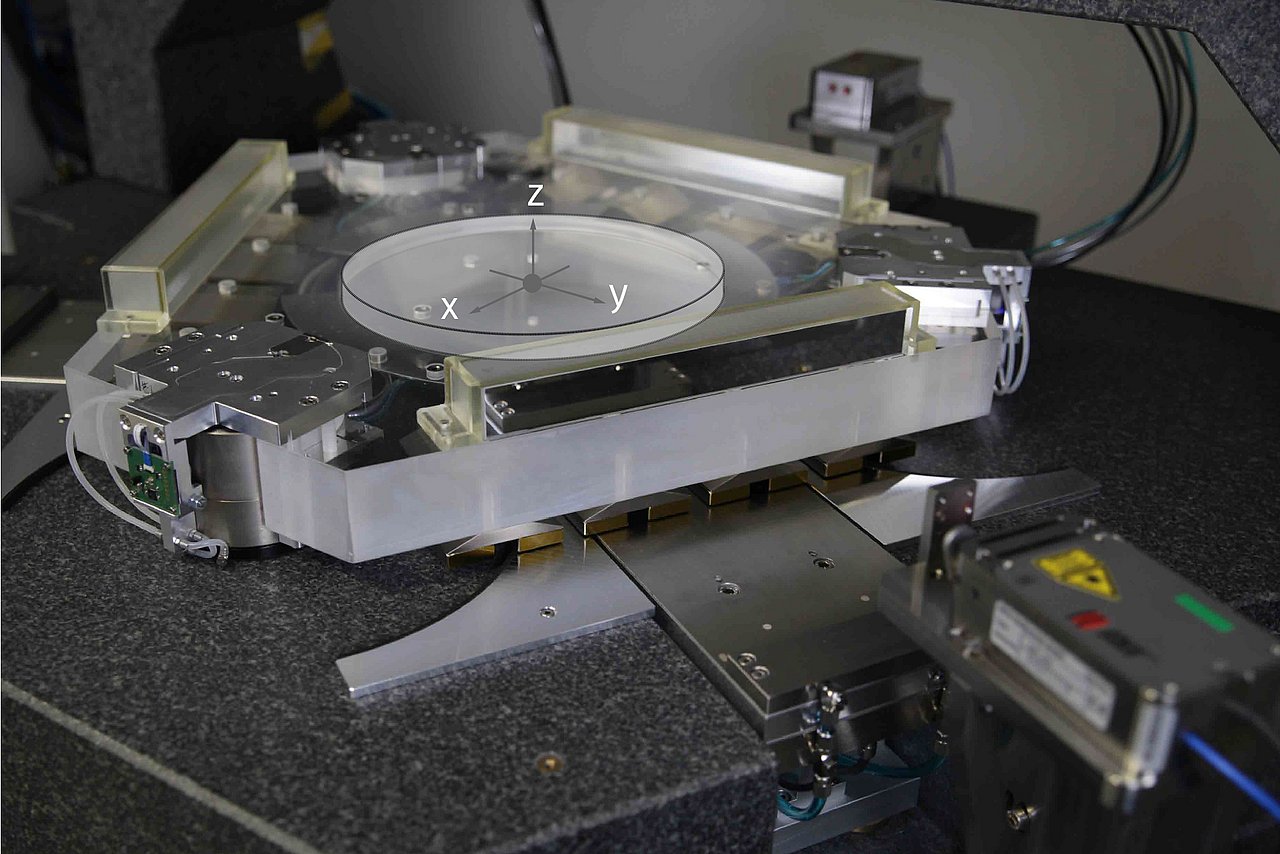

Direct drives position wafers and exposure masks in semiconductor production with high precision within one plane. To enable objects to be lifted with nanometer precision over an area of more than only a few square millimeters, IMMS had already developed a 6D direct drive with partners. This can raise and lower objects through 10 mm under active control with nanometre precision in a travel range of 100 mm diameter in the plane.

Larger vertical movements limit precision and movement dynamics up to now

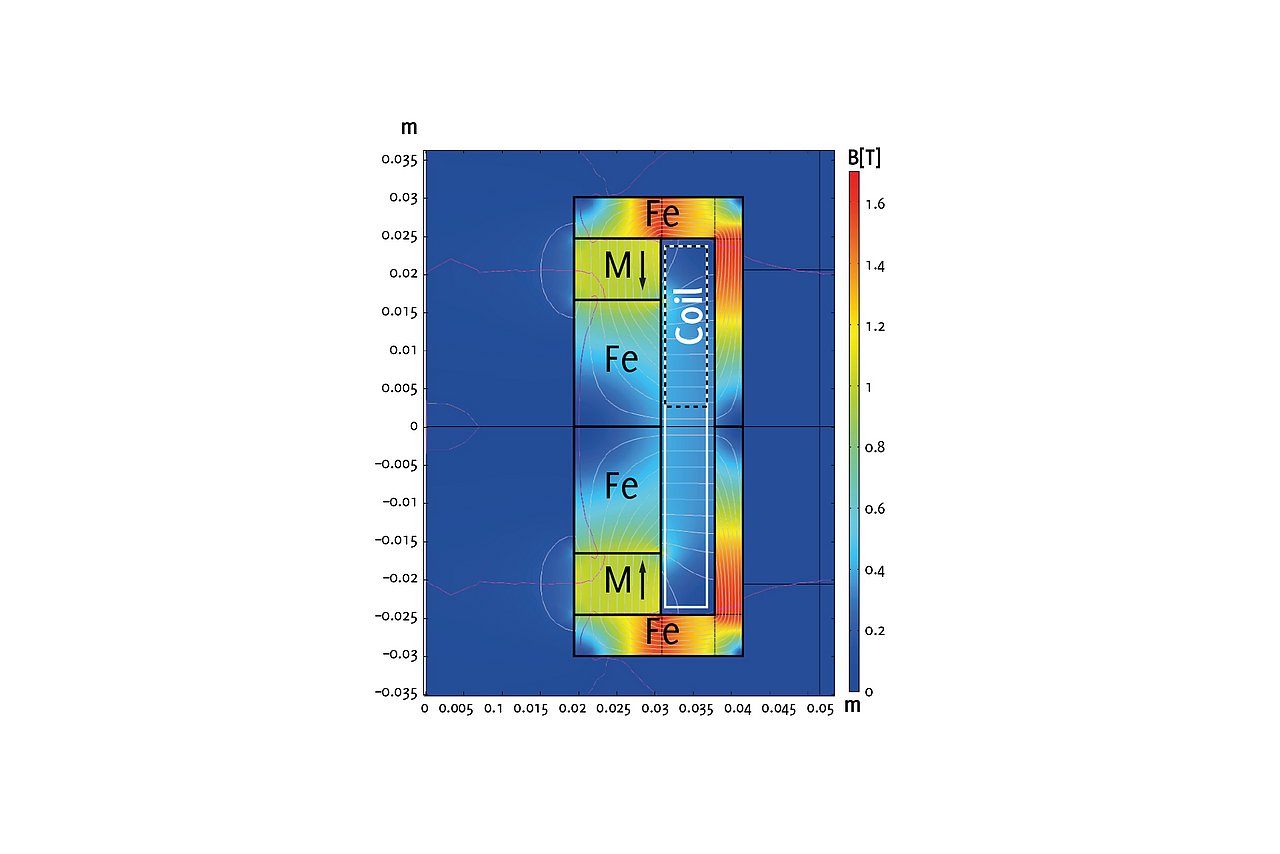

The requirements from industry do not only concern horizontal movements (x,y), in order to be able to structure and position surfaces and structures of millimetre or centimetre sized products with nanometre precision. Increasingly large vertical movements are to be carried out at the same time. The 6D direct drive works with electromagnetic vertical drives (z). The higher objects are lifted with it, the greater the distance between the x-y drive coils, which are fixed to the frame, and the magnetic coils in the slider, which are required for the horizontal precision movements. Even a small amount of lifting drastically reduces the efficiency of the x-y drive system, multiplying power losses and thereby limiting the achievable motion dynamics due to thermal effects.

New vertical tracking elements increase stroke distance

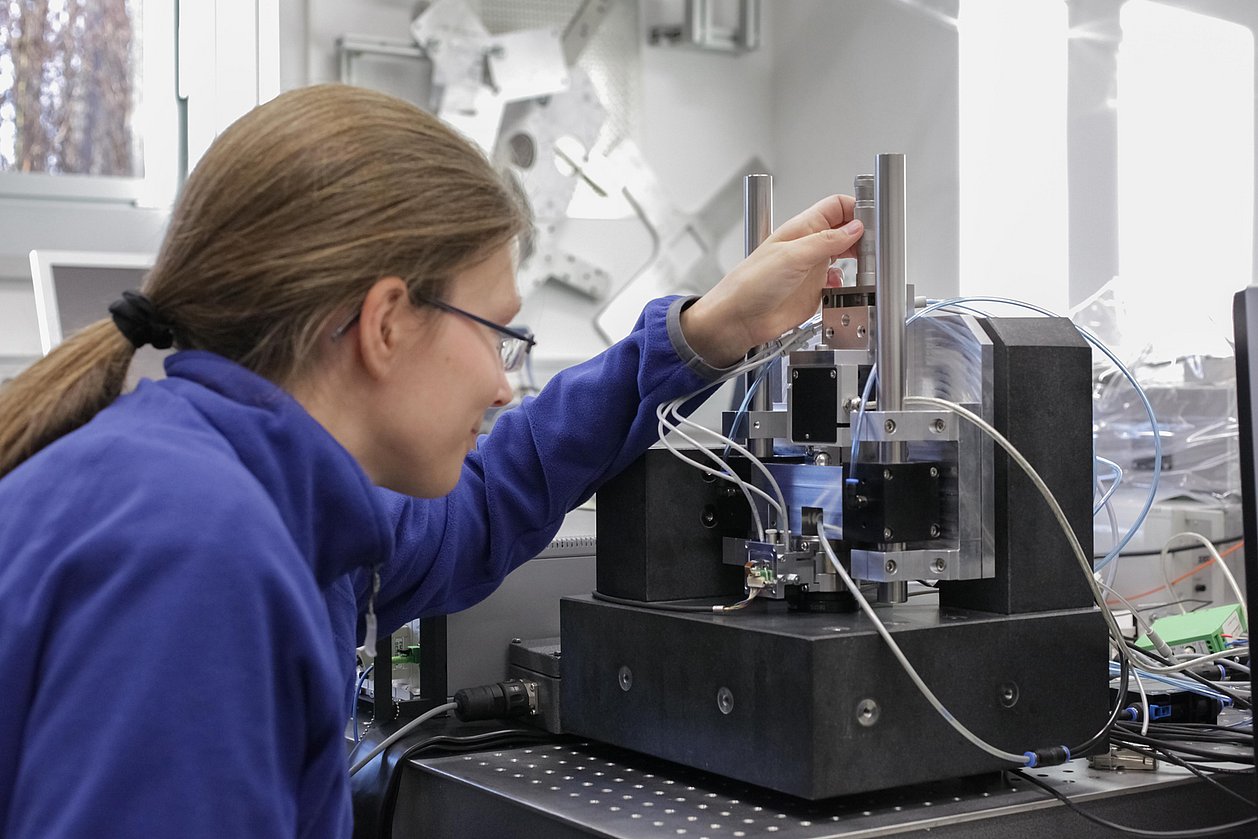

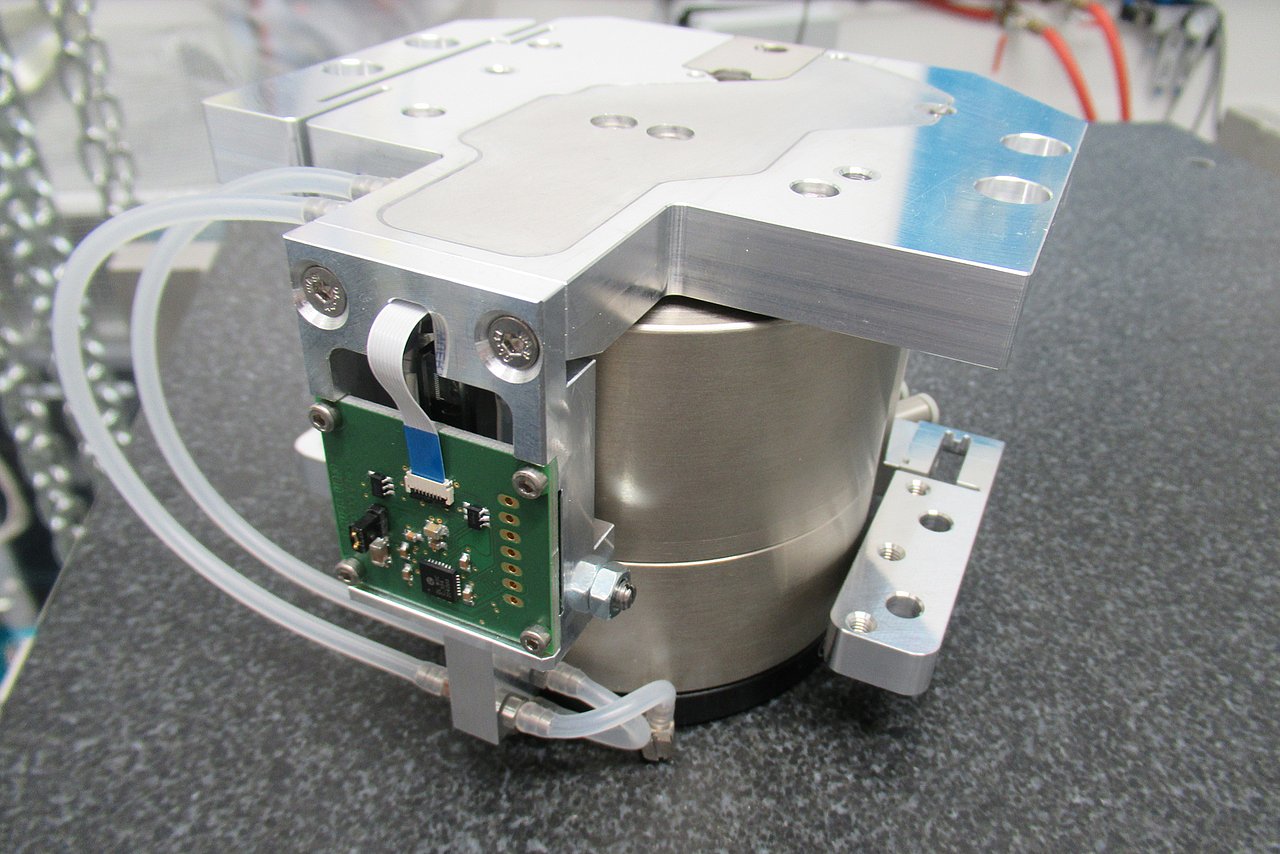

To overcome these hurdles, IMMS worked on concepts for new components in the K4PNP+Z project, with which the x-y drive coils, which have been fixed to the frame up to now, are now can be vertically tracked for a larger stroke and thus kept close to the magnets in the slider. These vertical tracking elements were built, integrated into the overall system and experimentally investigated. Likewise, the vertical drive units for the higher travel distances and for higher payloads were designed and tested. With this solution, z-strokes up to 25 mm with lateral travel ranges (x-y) over diameters of 200 mm can be reached.

Acronym / Name:

K4PNP+Z / Components for planar nanopositioning systems with extended z-measurement rangeDuration:2020 – 2022

Application:

Research institutions and ultra-precision mechanical engineeringResearch field:Magnetic 6D-direct drives with nanometre precision

Partner

Related content

NPS6D200 – A Long Range Nanopositioning Stage with 6D Closed Loop Control

Steffen Hesse1. Alex Huaman1. Michael Katzschmann1. Bianca Leistritz1. Ludwig Herzog1.Appl. Sci. 2024, 14, 6972. DOI: doi.org/10.3390/app14166972

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Vertikale Nanopositionierung mit bis zu 25 mm Verfahrweg – Hubmodule für die hochgenaue Positionierung im Raum

Stephan Gorges1. Steffen Hesse1. Ludwig Herzog1.Konstruktion (2023), 07-08, Sonderteil Antriebstechnik, Seite 28 - 31, VDI Fachmedien, ISSN 0720-5953, e-paper.vdi-fachmedien.de/konstruktion/2023

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.

Patent

DE 10 2021 103 220

Positioning system for the three-dimensional positioning of an object and method for its operation

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Funding

The K4PNP+Z project is funded by the German Federal Ministry for Economic Affairs and Energy (BMWi) / Federal Ministry for Economic Affairs and Climate Action (BMWK) as part of the “Central Innovation Programme for SMEs (ZIM)”programme under the reference ZF4085714JO9.

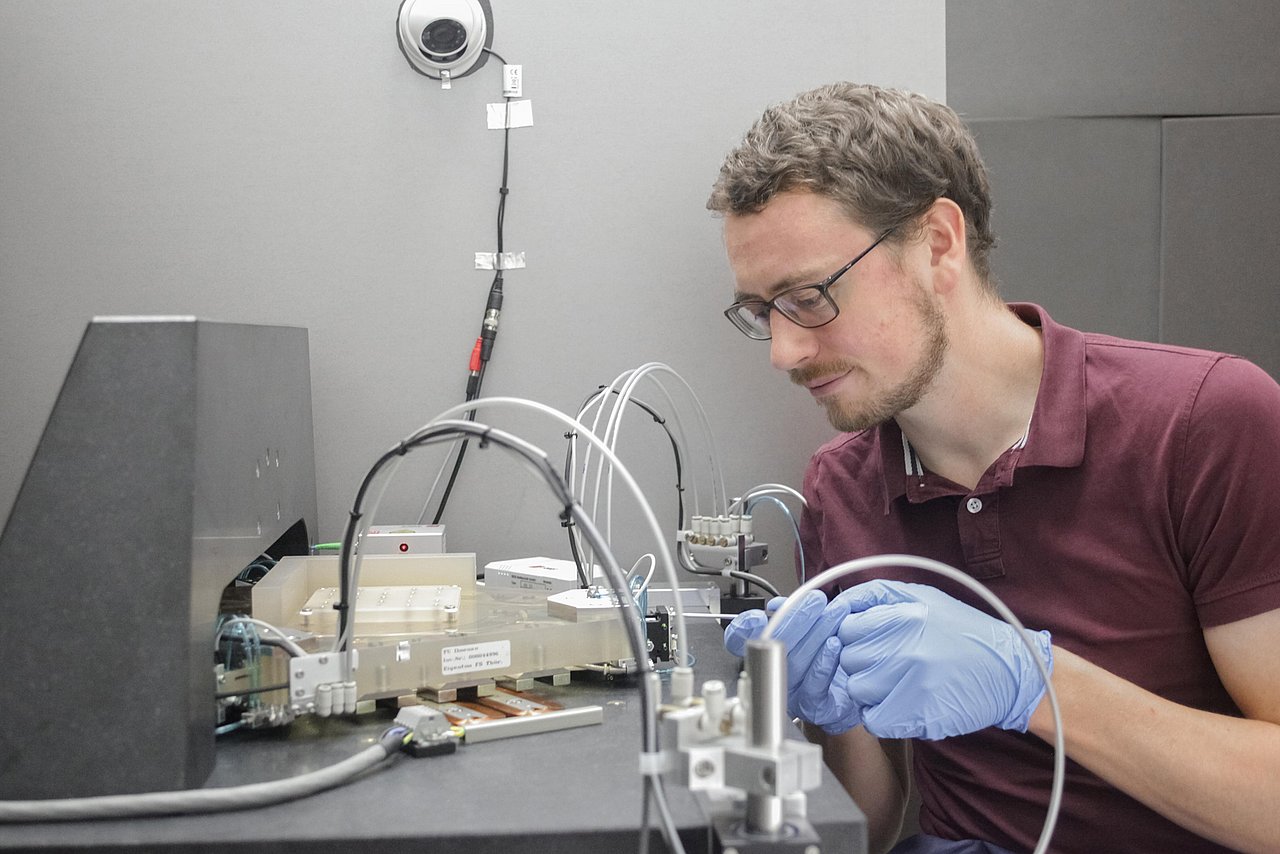

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)