MEMS – simulation, design and test

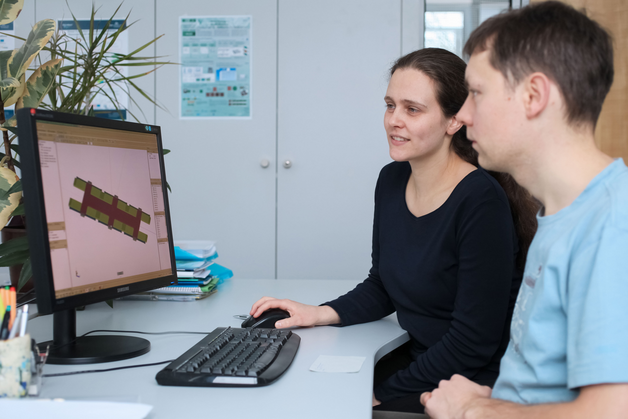

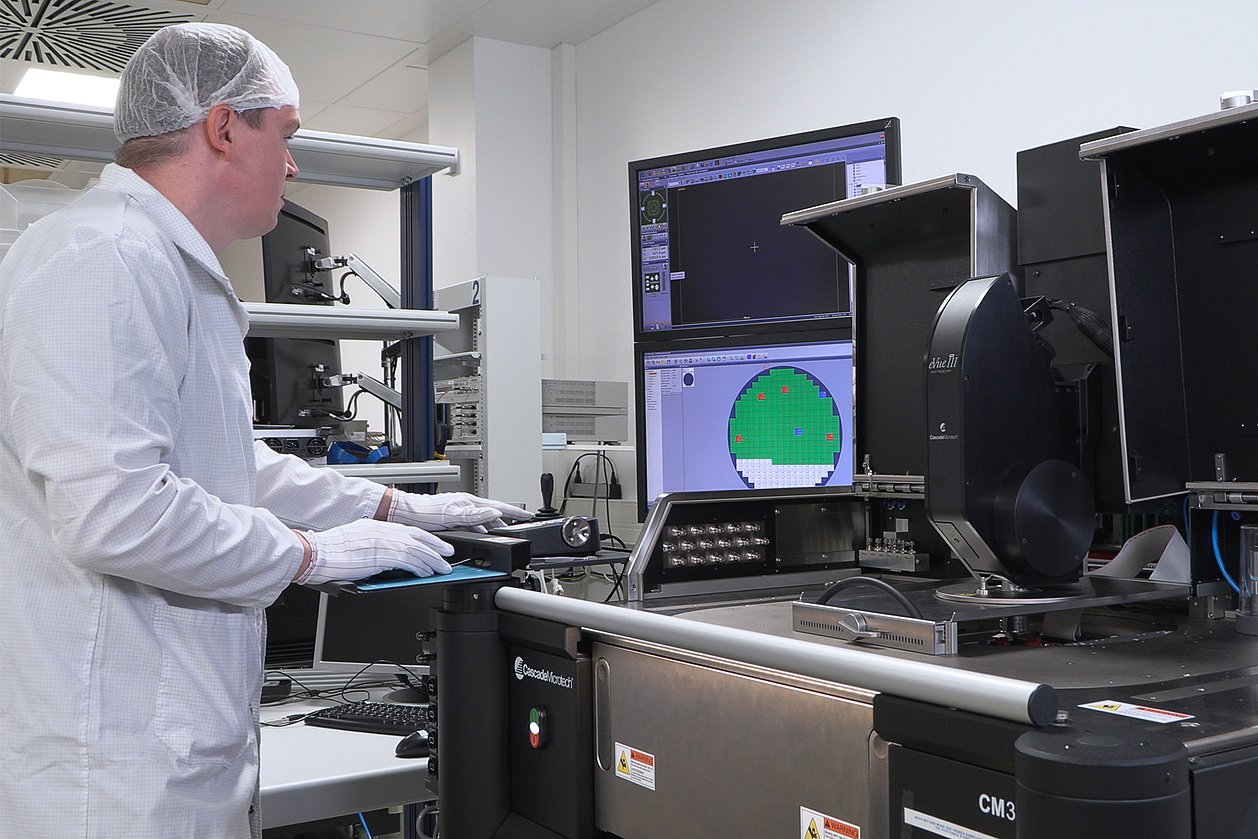

As a design house for the open technology platform XMB-10 from X-FAB, we develop acceleration sensors according to your specification in a semi-automated design process. For the testing of MEMS, we focus on the vibrometric investigation of sensors. This includes functional tests, e.g. of resonators up to 1.2 GHz, as well as indirect parameter identification. From vibrometric measurement data and FE parameter calculations, material stresses of beam- and membrane-based sensors can be determined.

We have been supporting research institutes in the field of MEMS for a long time. In recent years, we have already been able to successfully transfer some of the research results into products of our industrial partners.

Based on experience from numerous research and customer projects we offer the following services.

Service offering

- design, layout and test of acceleration sensors in XMB10 technology from X-FAB

- development of customised 1D, 2D or 3D accelerometers based on customer specifications

- execution of electrical tests

- shock tests in cooperation with partners

- FE simulation of cantilever-, beam- and membrane-based sensor structures with different operating principles

- piezoresistive

- piezoelectric

- magnetostrictive

- optimisation of sensor structures with respect to sensor parameters, such as sensitivity and non-linearity, taking into account technologically determined process tolerances

- vibrometric investigations of MEMS

- functional test, e.g. of resonators

- indirect determination of material properties, e.g. material stresses

- monitoring of material stress of membrane-based sensors over the entire manufacturing process from wafer level to packaging

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Related content

Vibrometry in the Field of MEMS – Application Examples from Stress to Quality Factor Identification

Steffen Michael1.CiS-Workshop "Simulation und Design", 26. September 2023, Erfurt, Germany

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.Characterizing Dynamics of MEMS Devices on Wafer Level Using Optical Measurement Techniques

Sebastian Giessmann1. Steffen Michael2. Eric Lawrence3. Dr. Heinrich Steger4.Commercial Micro Manufacturing International Magazine (CMM Magazine), 08-2023, VOL 16 NO. 3, pp. 30-39

1MPI Corporation. 2IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 3Polytec, Inc.. 4Polytec GmbH.Entwurf, Evaluierung und Optimierung von HF- und UHF-RFID-Sensorsystemen

Björn Bieske1. Tom Reinhold1. Jun Tan1.Analog 2020, 17. ITG/GMM-Fachtagung, Analoge Schaltungen: Schlüsselsysteme für Automotive, IoT und zukünftige drahtlose Technologien, 28-30 September 2020, online

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.Flexible PXI-Plattform für Evaluierung und Test von HF- und UHF-RFID-Sensorsystemen

Björn Bieske1. Tom Reinhold1. Jun Tan1.32. GI/GMM/ITG-Workshop Testmethoden und Zuverlässigkeit von Schaltungen und Systemen (TuZ 2020), 16. - 18. Februar 2020, Ludwigsburg, Germany

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.

This might also be interesting for you

Service for R&D

Finite Element Modeling

We support you in the concept and development phase of new products with calculations and simulations to shorten development times and improve product parameters such as weight & material savings or minimisation of natural vibrations.

About us

Technical equipment

We use state-of-the-art technology for our R&D work. Among other things, we are permanently expanding our technical laboratory and equipment infrastructure to remain competitive in the international scientific environment.