Project OptoMed vacuum air bearings

Air bearings in high-precision vacuum applications? Together with our partners, we are exploring the technical feasibility of this (apparent) contradiction.

With ever smaller structure sizes on microelectronic chips, the demands on manufacturing accuracy in the semiconductor industry are growing.

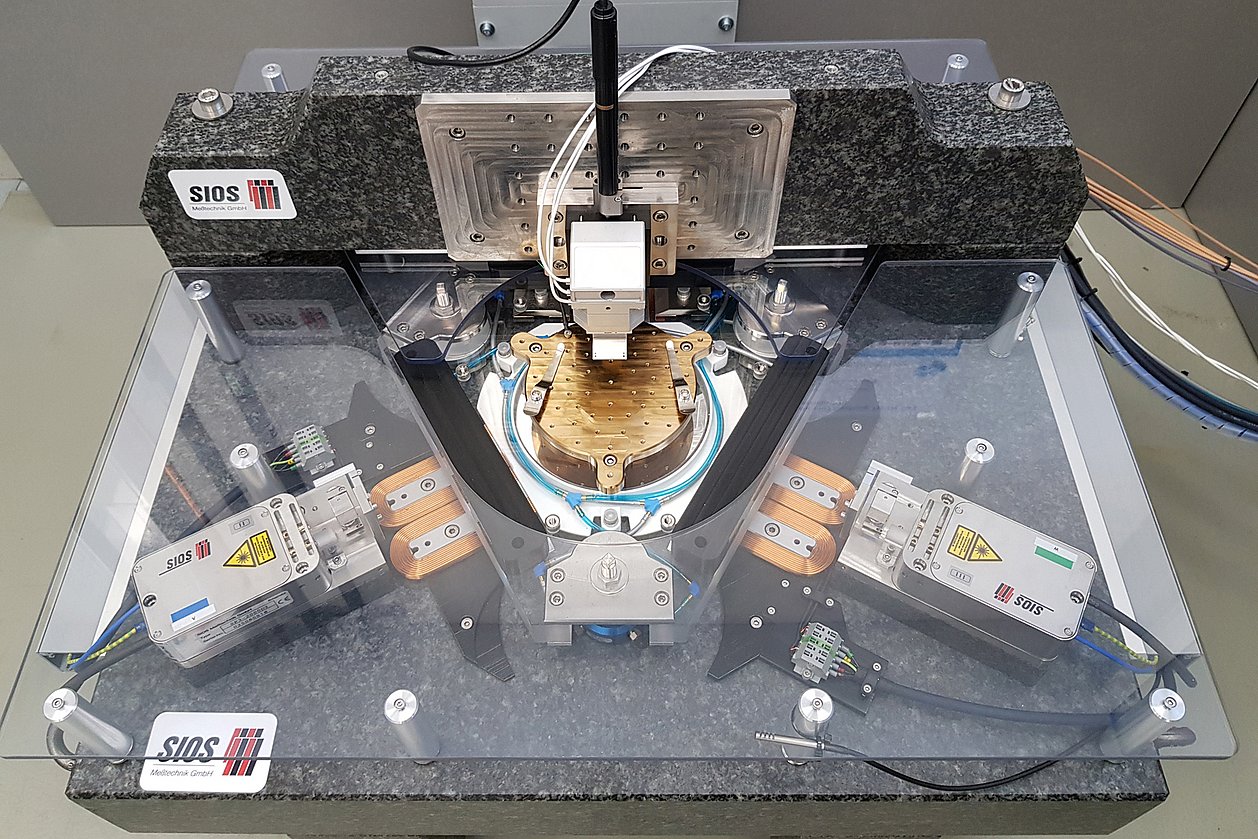

Positioning systems that have the highest precision over large motion ranges according to the current state of the art are air-bearing direct drive systems. Their moving part floats on a thin cushion of air. The stationary and sliding parts of the drive therefore do not touch each other, resulting in virtually friction-free movement. This enables positioning accuracies in the single-digit nanometre range, i.e. down to millionths of a millimetre.

At the same time, maximum particle-free purity is required in semiconductor production. This is why large parts of manufacturing are transferred to a vacuum. However, not all vacuums are the same. In the targeted high vacuum, the proportion of residual gas particles is less than a billionth of that under atmosphere.

So how can a system that relies on a continuous air supply function in such an airless environment? The answer seems simple. The air must be continuously extracted before it reaches the surrounding vacuum. This is made possible by suction grooves that surround the air bearing element and are connected to vacuum pumps.

The challenge is to find suction pipes (see illustration) that are large enough to remove enough air and at the same time generate so few disruptive forces that the advantages of air bearings are not eliminated. In addition, many materials cannot be used in a high vacuum due to their material composition and the associated outgassing.

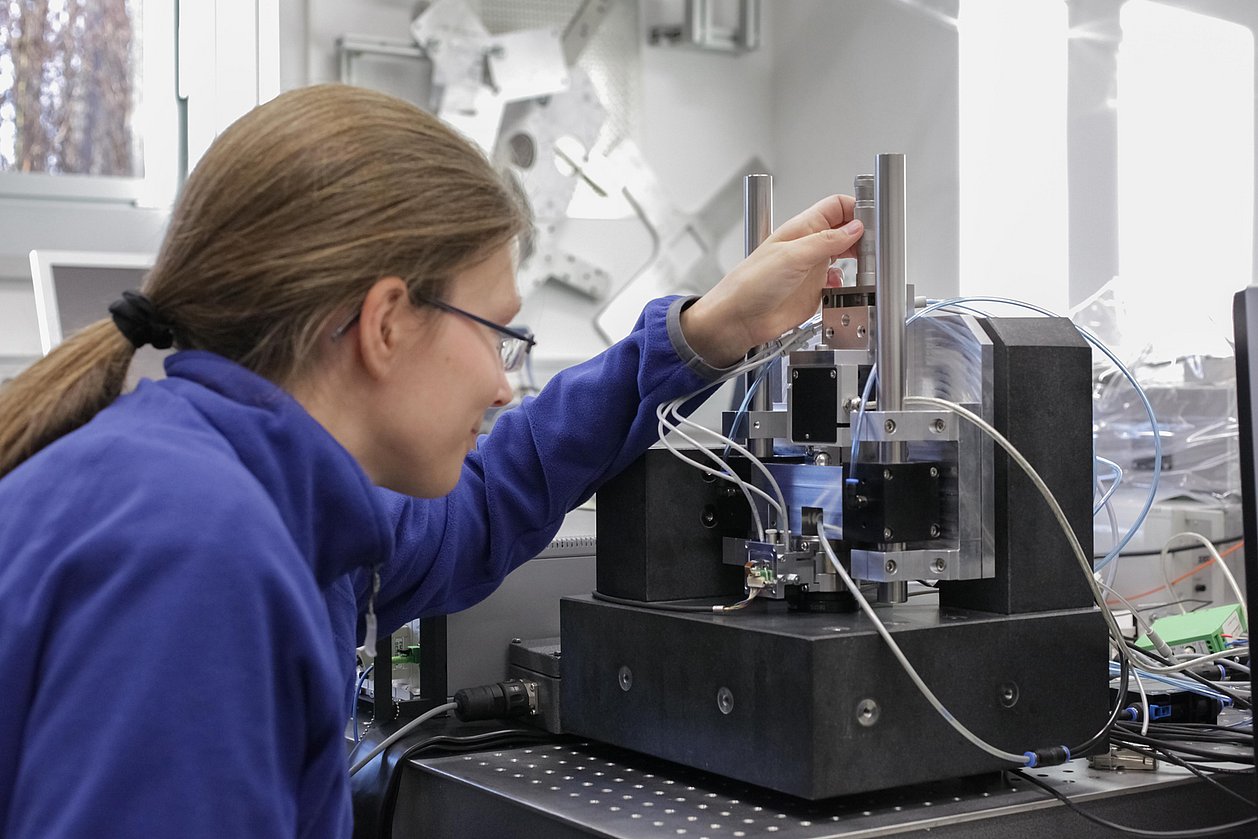

The project is therefore developing solutions for vacuum-compatible air bearings and demonstrating their function using a prototype drive system.

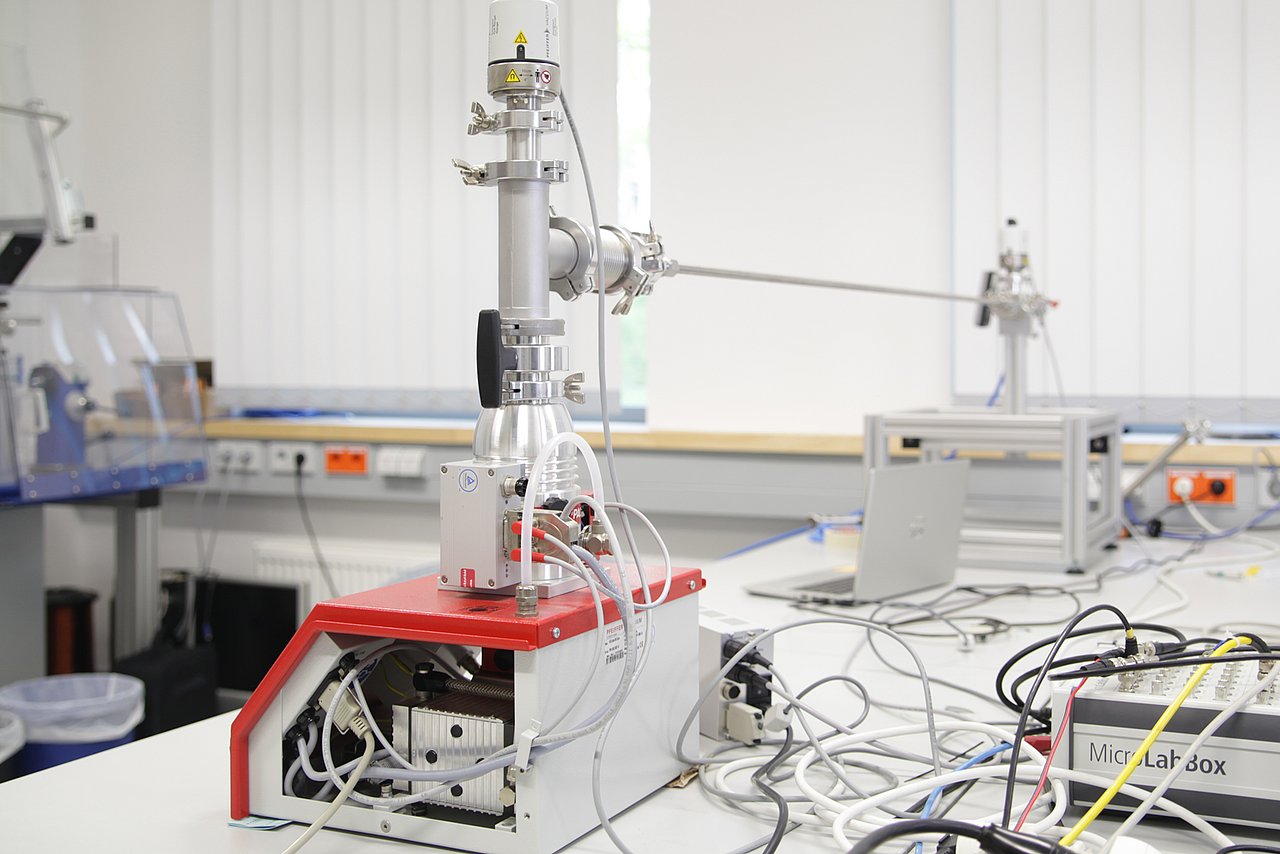

One of the first steps was to set up a test setup with which suction power losses can be determined, particularly in the molecular flow range, depending on the pipe geometry. This is necessary for reliable dimensioning of the bearing system and helps in the selection of suitable suction lines. The test bench offers the possibility of allowing the smallest quantities of gas flow of up to around 3x10–5 mbar l/s to flow into a pipe system in a defined manner and to determine the pressure difference between the beginning and end of the pipe using measurement technology.

Acronym / Name:

OptoMed vacuum air bearings / Development of a nanometre-precise drive system with low-noise air guidance for high-vacuum applications in semiconductor technologyDuration:2024 – 2026

Application:

Research institutions and ultra-precision mechanical engineering|Semiconductor manufacturing| optics| precision engineeringResearch field:Magnetic 6D-direct drives with nanometre precision

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Funding

The OptoMed vacuum air bearing project was funded by the German Federal Ministry for Economic Affairs and Energy (BMWE) based on a resolution of the German Bundestag under the reference 16KN118229.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)