Project SMARTIEHS

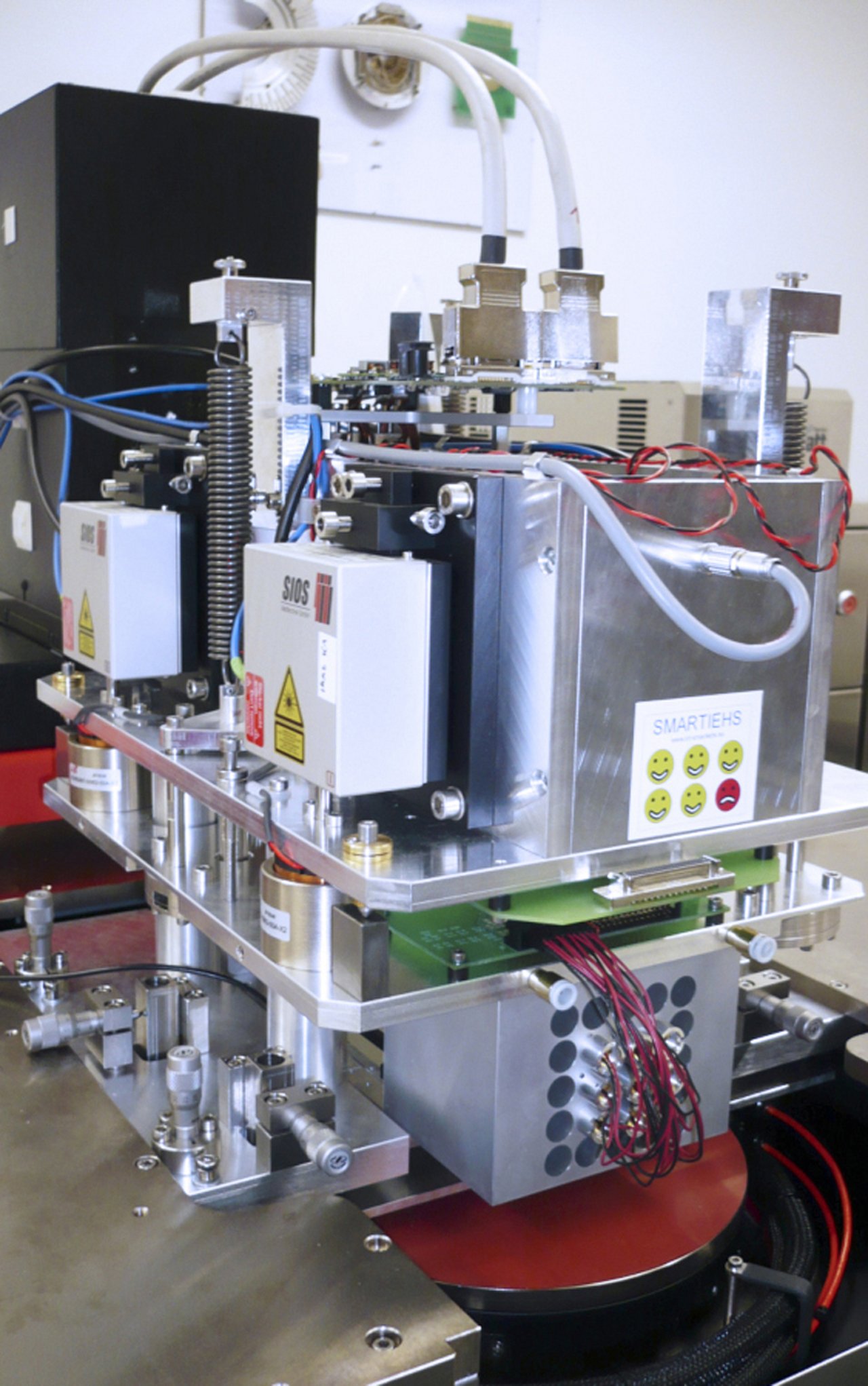

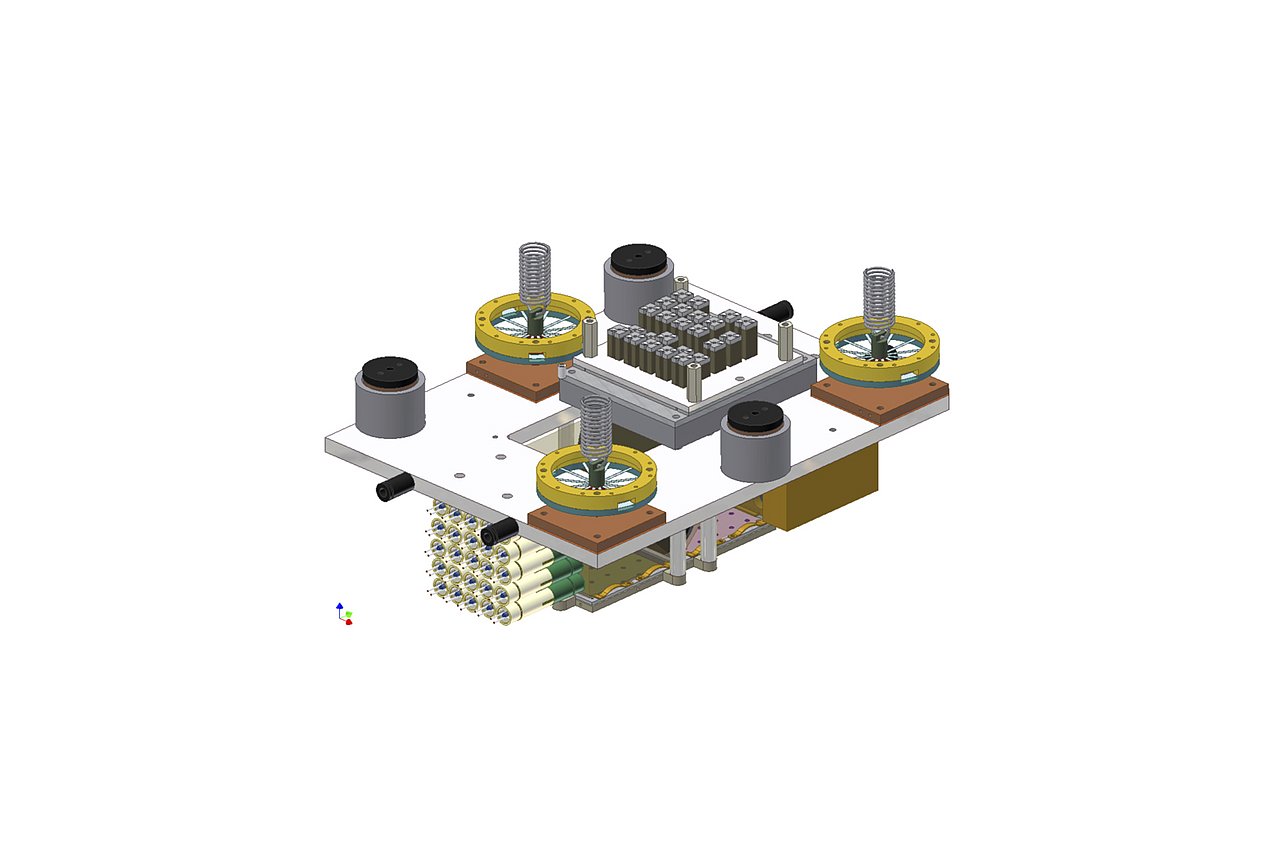

The newly developed measurement system can simultaneously inspect MEMS structures on wafer level to significantly reduce test effort.

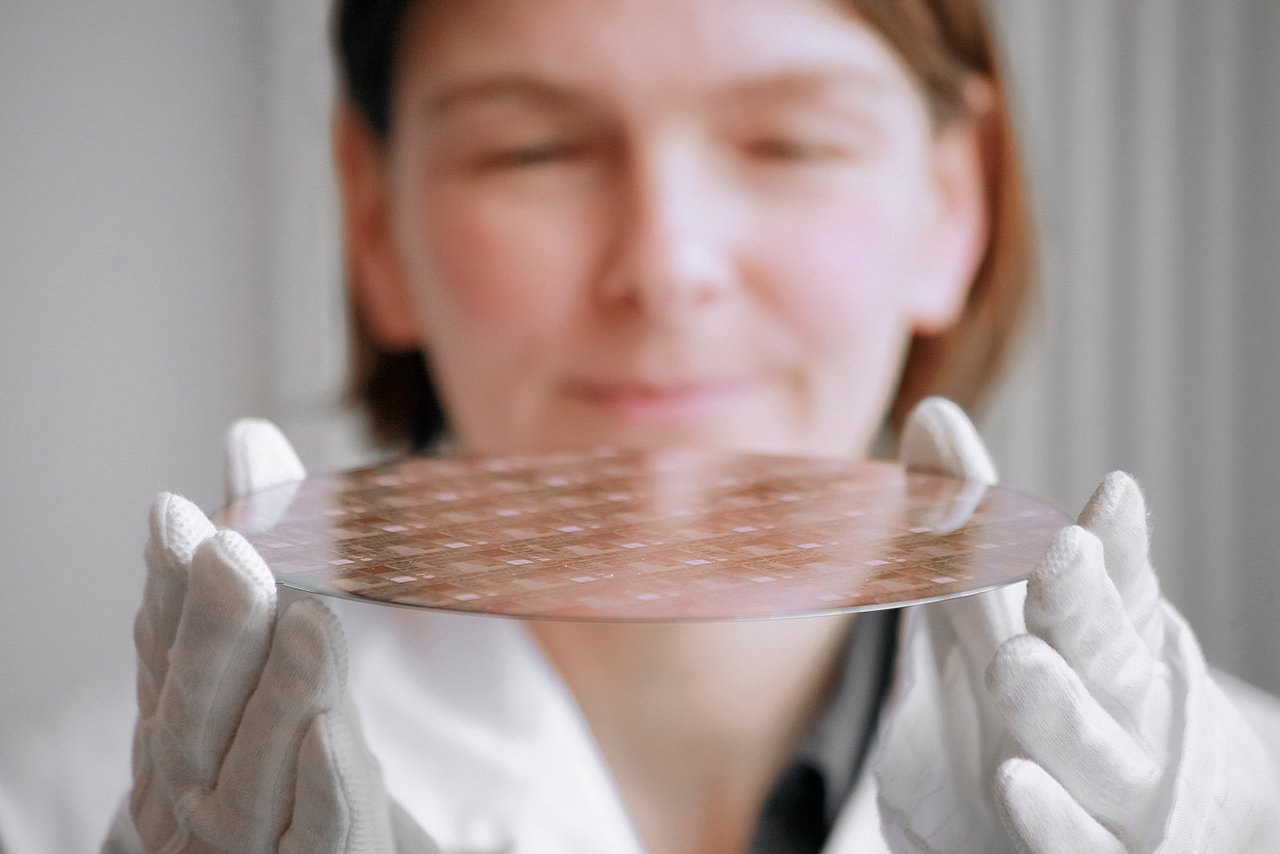

In the semiconductor industry the trend towards larger wafer diameters and smaller elements leads to a higher number of units that have to be tested per wafer. In addition, the rising quality standards demand a 100% test of all elements. All these requirements cannot be efficiently met with the currently applied test methods, since by now single elements are sequentially measured. On 8-inch wafers, for example, an average of 10,000 structures is placed. In order to test these structures faster, a scalable parallel measurement system was developed in the project. It is able to simultaneously test 25 MEMS structures on wafer level. An extension to up to 100 test units is possible.

IMMS was leading the implementation of the whole inspection system and the test methods. The system platform constructed at the institute united all developed mechanical and optical assemblies of all project partners in a full working demonstrator.

Furthermore, IMMS developed hardware and software components to process the data of the smart pixel cameras of the test system and created precise drive and control solutions of the scanning unit.

Acronym / Name:

SMARTIEHS / SMART InspEction system for High Speed and multifunctional testing of MEMS and MOEMSDuration:2008 – 2011

Application:

|high-precision positioning and motion of objectsResearch field:Integrated sensor systems

Related content

Das Parallelisieren von Motor- und Regelungsentwurf reduziert Entwicklungszeit und -kosten

Dr. Ch. Schäffel1. M. Katzschmann1.Erschienen in MSR-Magazin, Automatisierungstechnik für Fertigung und Prozess, 03/2010

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau.ArticleOptical, mechanical and electro-optical design of an interferometric test station for massive parallel inspection of MEMS and MOEMS

K.Gastinger1. K.H.Haugholt1. M. Kujawinska2. M.Jozwik2. C. Schäffel3. S. Beer4.Paper 7389-56, SPIE Europe Optical Metrology, 14.- 18. Juni 2009, München

1SINTEF, Norway. 2Warsaw Univ. of Technology, Poland. 3IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau. 4Ctr. Suisse d'Electronique et de Microtechnique SA, Switzerland.Article

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Funding

The project was funded by the European Union via the FP7-ICT-2007-2 program, grant number 223935 GA.