Project VirtuSen

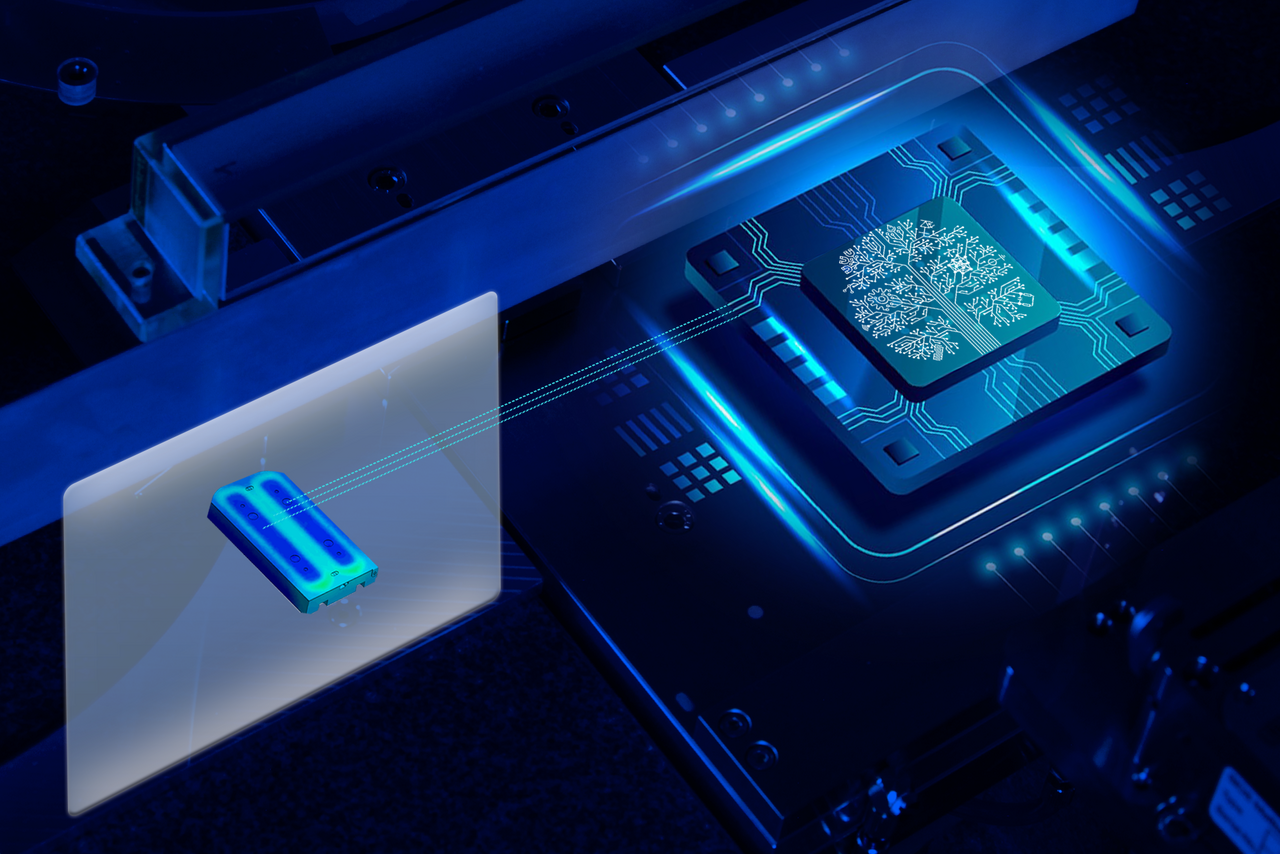

With the help of virtual sensor technology and AI, it is intended to detect and compensate for disturbing influences on complex mechatronic systems such as high-precision drives with spatial resolution

Monitoring sensors are often limited

When monitoring machines or other complex mechatronic systems, in addition to monitoring the actual status of the systems and topics such as preventive maintenance, the aim is always to be able to implement new system solutions with improved performance parameters based on the information collected. In addition to system parameters, disturbing influences such as temperature, humidity or mechanical stresses and their spatial distribution are also important. It is often not possible to place physical sensors at the measuring points required for a comprehensive assessment due to functional and spatial restrictions. In practice, the disturbance variables are therefore only recorded at a few points by a limited number of sensors. However, this also limits the use of suitable countermeasures.

AI-based virtual sensor technology extends solution space

In the VirtuSen research group, IMMS is working on significantly improving the monitoring of systems using AI-based virtual sensor technology. AI approaches can be used to map complex system behaviour based on just a few input variables. This is to be utilised in VirtuSen to be able to evaluate a spatial distribution with limited information from real sensors. The aim is to use additional AI-based virtual sensors for the disturbance variables to predict the behaviour of the overall system so that targeted countermeasures can then be determined and taken.

Application for effectively increasing the precision of positioning systems

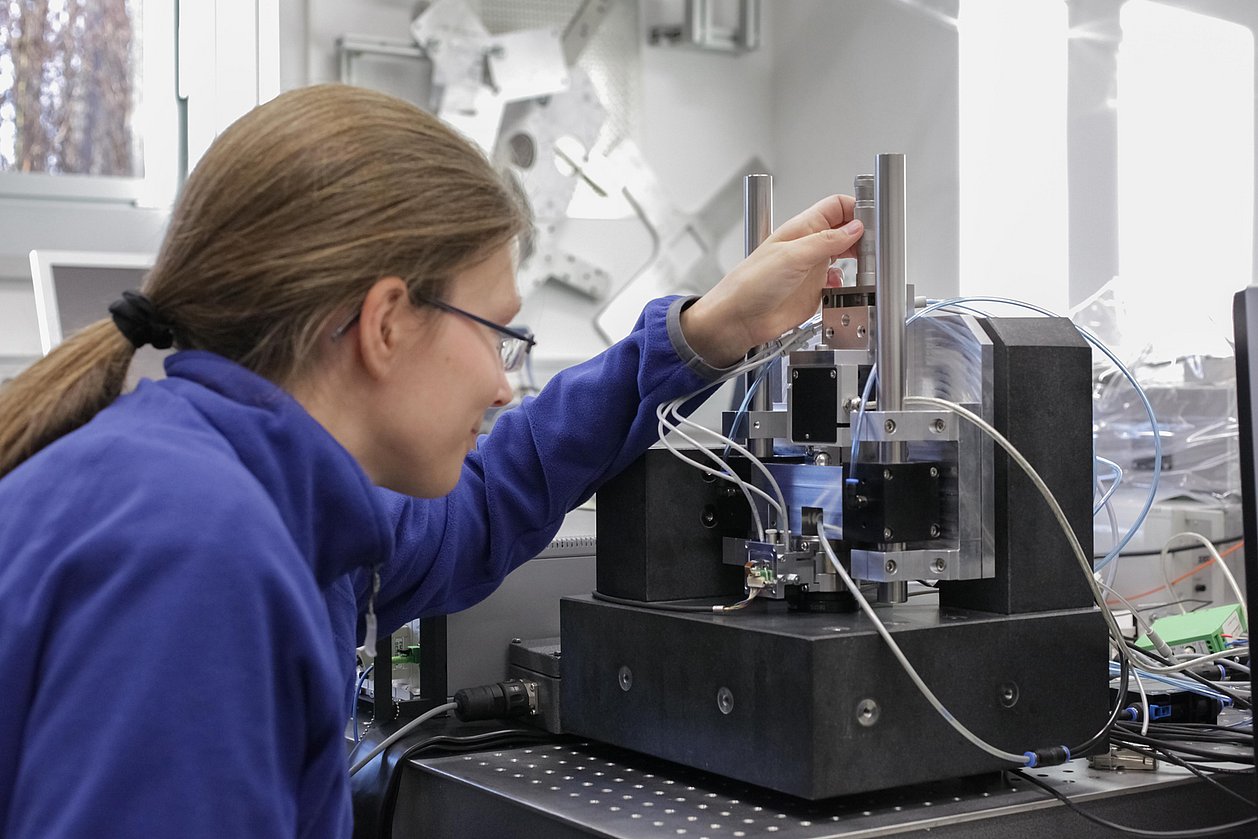

This is particularly relevant for high-precision positioning and measuring systems. The smallest environmental influences, such as temperature fluctuations and the associated material expansion, can significantly distort the accuracies to be achieved in the sub-nanometre range. For high-precision applications, it is particularly important to know the spatial distribution of disturbance variables. It is intended that environmental influences on such systems can be quantified more precisely using the results from VirtuSen to be able to reduce their effect on positioning accuracy in the future.

Outlook

IMMS is focussing on using the results from VirtuSen to increase the precision of the positioning systems researched at IMMS to meet future industrial requirements. On this basis, the long-term goal is to transfer the approaches to a wide range of machines, measurement technology, mechatronic systems, etc. and to significantly increase their performance and cost efficiency.

Acronym / Name:

VirtuSen / Application of virtual sensor technology provided by AI to effectively increase the precision of positioning systemsDuration:2025 – 2027

Application:

|Monitoring for high-precision drives| complex mechatronic systems| measurement technology| machinesResearch field:Smart distributed measurement and test systems|Magnetic 6D-direct drives with nanometre precision

Partner

Related content

Development and validation of a simplified coil model for CFD simulation of a nano-positioning planar drive system

Ina Naujokat1. Ludwig Herzog1. Steffen Hesse1. Parastoo Salimitari1.Euspen Special Interest Conference: Precision & Performance 2025, Proceedings: www.euspen.eu/euspen-knowledge-base/proceedings-search/, November 18-20, 2025, Cranfield University, United Kingdom

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Experimental characterization of thermal disturbances in a 6DOF nanopositioning system under varying operational conditions

Parastoo Salimitari1. Steffen Hesse1. Michael Katzschmann1. Ludwig Herzog1.Euspen Special Interest Conference: Precision & Performance 2025, Proceedings: www.euspen.eu/euspen-knowledge-base/proceedings-search/, November 18-20, 2025, Cranfield University, United Kingdom

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.

Event,

euspen SIC 2025

euspen Special Interest Conference: Precision & Performance 2025 (combining MATADOR, LAMDAMAP & Thermal Issues)

Event,

InnoCON 2025

Innovation policy flagship event of the German Land of Thüringen. Topic “Key technologies: Paving the way for the world of tomorrow“

Contact

Contact

Dr.-Ing. Tino Hutschenreuther

Head of System Design

tino.hutschenreuther(at)imms.de+49 (0) 3677 874 93 40

Dr. Tino Hutschenreuther will answer your questions on our research in Smart distributed measurement and test systems and the related core topics Analysis of distributed IoT systems, Embedded AI and Real-time data processing and communications, on the lead applications Adaptive edge AI systems for industrial application and IoT systems for cooperative environmental monitoring as well as on the range of services for the development of embedded systems.

Funding

The research group ‘Application of AI-based virtual sensor technology to effectively increase the precision of positioning systems – VirtuSen’ is funded by the German Land of Thüringen.