Project INPOS

Novel 6DOF integrated direct drive moving large objects with small vertical dimensions through nanometre spaces

Direct drives incapable of raising objects with nanometre-accuracy above large areas

Direct drives can position objects with high speed and precision, backlash-free and without any intervening gears or coupling. One of their uses is in semiconductor manufacture, for instance the manouevring of reticles. A positioning stage is usually part of the equipment for measuring and structuring substrates, wafers, reticles and the like. The slider of this stage moves objects with extreme accuracy on one plane. In production, this already happens with an accuracy of less than 10 nanometres.

But the manufacturing is carried out on different levels. Here an example is the structuring of wafer layers. Such layers are often as thin as a few nanometres; an entire wafer may be between 0.7 and 0.9 mm thick. Presently available systems of wafer measurement only achieve the extremely low level of measurement uncertainty over a mere few square millimetres. Across their full area, for whole wafers with diameter 150 to 300 mm the typical measurement uncertainty is only in the ± 0.5 to ± 1 micrometre range.

Solution to the problem: an integrated 6DoF direct drive with pneumatic gravity compensators for the lifting

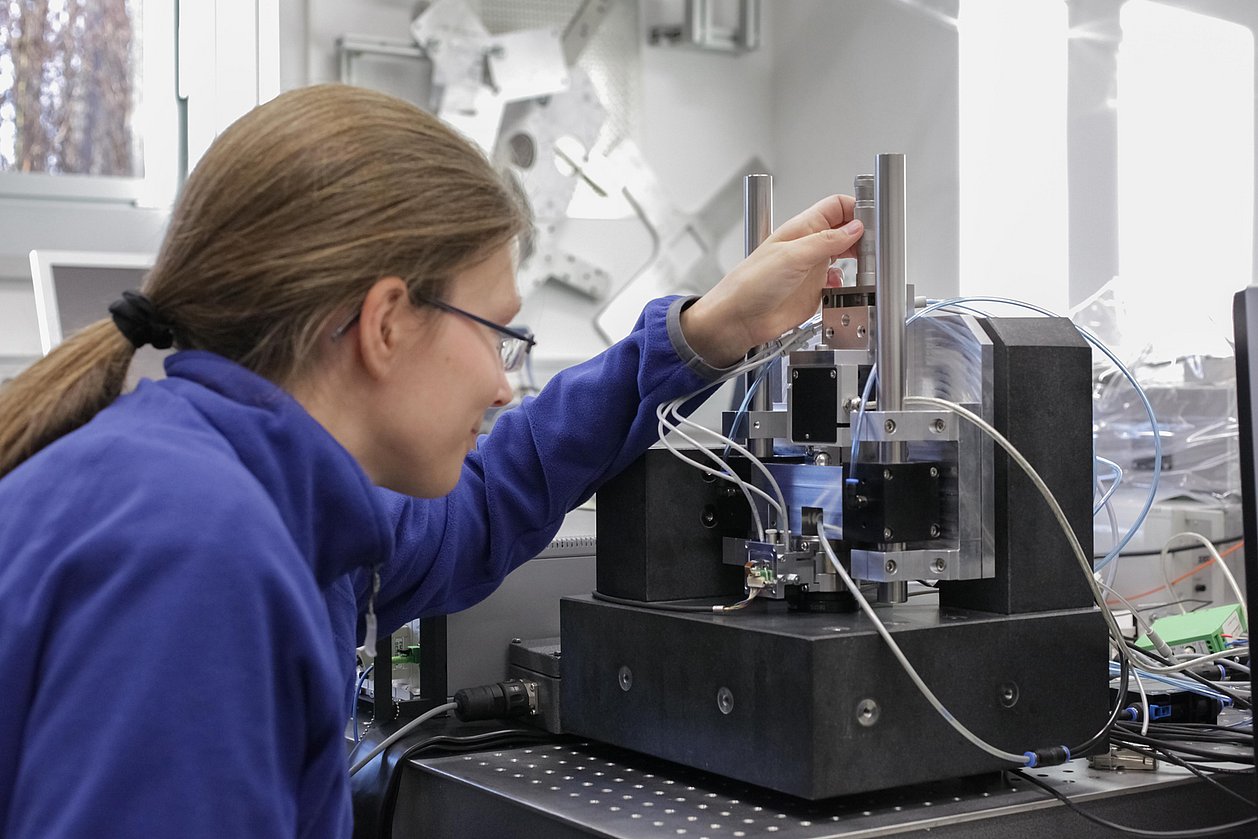

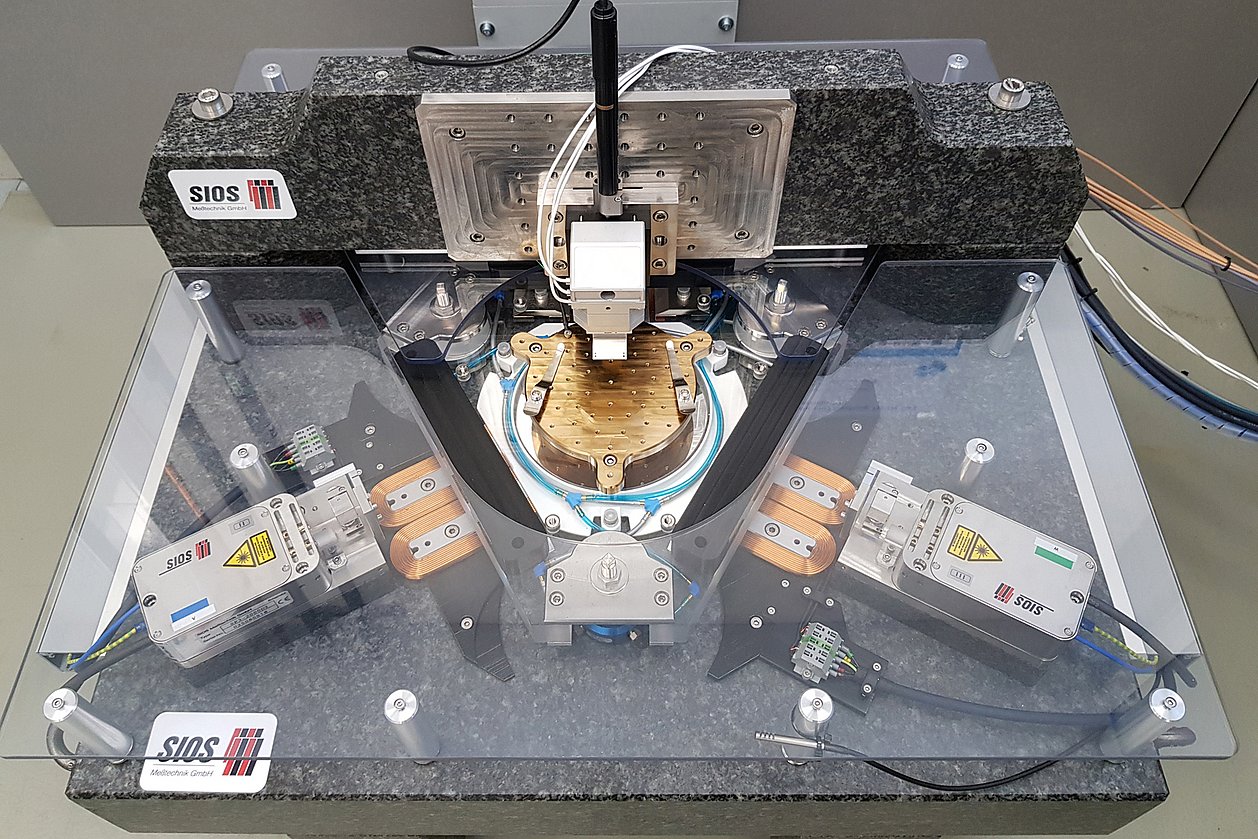

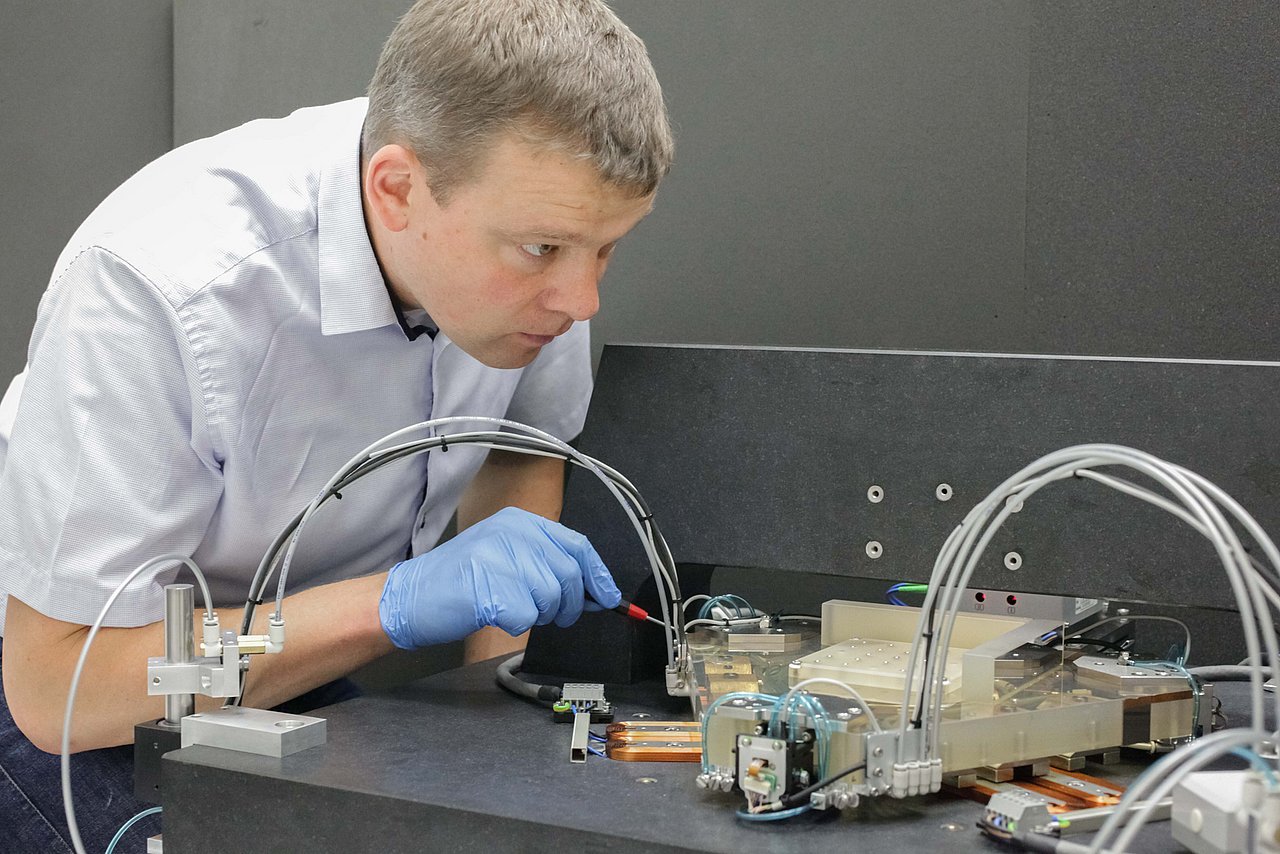

In joint work with SIOS Meßtechnik GmbH and Ilmenau University of Technology, IMMS has developed a 6-dimensional direct drive with air bearing which can move objects along three spatial axes and freely in space around these axes in an area of travel appropriate to the application: planar diameter of 100 mm, ascent or descent range of 10 mm under active control with nanometre-accuracy. Pneumatic gravity compensation assists the raising and lowering by constantly approximating to zero the power to be supplied by the vertical electromagnetic actuators. As a result there is next to no current flowing in the actuator coils, which means there is no unwanted source of heat in the measuring space to interfere with the necessary precision of measurement.

The principle behind this drive is absolutely new in the field of six-dimensional direct drives and has been applied in no known drive system to date. Investigations have already been carried out into its scalability for other applications with a planar field diameter of 200 mm.

Acronym / Name:

INPOS / Integrated planar 6DOF positioning and measurement systemDuration:2017 – 2019

Application:

Research institutions and ultra-precision mechanical engineering|Structuring of surfaces| high-precision mechatronic drives| precision drive technology| biotechnologyResearch field:Magnetic 6D-direct drives with nanometre precision

Related content

Reference

Dr. Denis Dontsov, SIOS Meßtechnik GmbH

“The positioning results achieved clearly have high potential for resolving detailed enquiries from future customers and for new types of SIOS nanopositioning systems offering a significantly extended field of measurement.”

Hochpräzise positionieren – Integrierter 6-DOF-Direktantrieb bewegt Objekte nanometergenau im Raum

Christoph Schäffel1.Konstruktion, Sonderteil Antriebstechnik, www.ingenieur.de/fachmedien/konstruktion/antriebstechnik/hochpraezise-positionieren/, 13. Oktober 2020

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.Integrated Planar 6-DOF Nanopositioning System

Stephan Gorges1. Steffen Hesse1. Christoph Schäffel1. I. Ortlepp2. E. Manske2. E. Langlotz2. D. Dontsov3.2019 11th IFAC Symposium on Nonlinear Control Systems (NOLCOS 2019), 4 - 6 September 2019, Vienna, Austria , IFAC-PapersOnLine, Volume 52, Issue 15, 2019, Pages 313-318, ISSN 2405-8963, DOI: doi.org/10.1016/j.ifacol.2019.11.693

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 2Technische Universität Ilmenau, 98693 Ilmenau, Germany. 3SIOS Meßtechnik GmbH, 98693 Ilmenau, Germany.Design and Modeling Approach for a Lifting and Actuating Unit for the Application in Nano-Precision Machines

Stephan Gorges1. Steffen Hesse1.33rd Annual Meeting of the American Society for Precision Engineering (ASPE), 2018, 4-9 November 2018, Las Vegas, Nevada, USA

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.Development of an Integrated Guiding and Actuation Element for High Dynamic Nanopositioning Systems

Stephan Gorges1. Bianca Leistritz1. Steffen Hesse1. I. Ortlepp2. G. Slotta3. Christoph Schäffel1.Ilmenau Scientific Colloquium 2017, Session 1.1 – Precision Measurement Technology, 11-15 September 2017, Ilmenau

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 2Institut für Prozessmess- und Sensortechnik, TU Ilmenau. 3AeroLas GmbH.

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Funding

The INPOS project has been funded by the Federal Ministry for Economic Affairs and Energy (BMWi) in response to a decision of the German Federal Parliament under the reference ZF408707LT7.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)