Project sUSe

To use compressed air for industrial processes in an energy-efficient way, IMMS has developed the electronics platform for an automatable sensor solution.

Compressed air leaks cause the most energy losses in industry. Up to 10% of electrical energy is used there just to generate compressed air. On average, 30 percent of this is lost due to leaks. This makes it all the more important to find leaks, evaluate losses and initiate maintenance measures as a result. The goal of the sUSe project was therefore to develop a solution for compressed air systems that can be permanently integrated or retrofitted, which simplifies repair and maintenance decisions and significantly increases energy efficiency.

Monitoring of compressed air systems with distributed ultrasonic and volume flow sensors

To achieve this, the partners have developed a holistic monitoring system consisting of several networked and permanently installable ultrasonic and volume flow sensors distributed throughout a compressed air system, which can be used to monitor and evaluate the energy efficiency of the compressed air systems.

On the one hand, the volume flow, i.e. the integral quantity of compressed air, is measured with corresponding sensors at various points in the system and related to the quantity that is fed into the compressed air system. On the other hand, leaks are acoustically located and evaluated by the ultrasonic sensors also distributed in the compressed air system and from their arrangement to each other. From the combined data of the total volume flow and identified leakage points, the proportions of the leakages in the compressed air loss can be precisely assigned.

IMMS contribution: Electronic platform, signal processing and communication

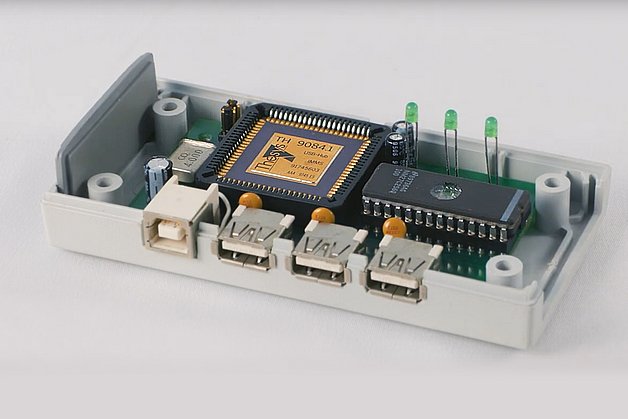

IMMS developed and implemented the digital processing of the sensor data on an electronic platform and developed a scalable and high-performance system for this purpose. This platform is used for each measuring point of the monitoring system.

To be able to adapt the sensors very flexibly for customer-specific tasks without having to make changes to the hardware, IMMS developed the components for signal processing with a model-based design technology and configured the application algorithms for integration into the electronic components (FPGA) on this basis.

To ensure that the platform is also compatible with future requirements and can be integrated into maintenance systems, IMMS implemented appropriate communication interfaces and protocols and established the corresponding communications capability of the wireless sensors.

Acronym / Name:

sUSe / Development of a scalable ultrasonic and volumetric flow sensor platform for optimising energy efficiency for maintenance 4.0Duration:2018 – 2020

Application:

Automation technology and Industry 4.0|Maintenance| energy efficiency| production| environmental technologyResearch field:Smart distributed measurement and test systems

Related content

Reference

Peter Otto, Postberg

“We are very satisfied with the result – the many years of IMMS experience in the design of embedded systems, with industrial projects and also the system understanding of IMMS from the previous product developments with SONOTEC have clearly contributed to the success.”

Lösungsvorstellung zur Detektion von Druckluftleckage und Optimierung von Druckluftanlagen

Peter Otto1. Peter Holstein2. Sebastian Uziel3.3. Industrieforum „Smarte Fertigung. Integration flexibler Fertigungstechnologien und intelligenter Prozessketten“, 21.01.2021, Online

1Postberg + Co. GmbH, 34121 Kassel. 2SONOTEC GmbH, 06112 Halle, Germany. 3IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.Überwachung von Druckluftanlagen zum Einsparen von Ressourcen

Sebastian Uziel1.Veranstaltungsreihe Ressourceneffizienz vor Ort – Digitalisierung & Ressourceneffizienz, 26. November 2019, Industrie- und Handelskammer Südthüringen, Suhl

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.Intelligente Instandhaltung und Optimierung der Energieeffizienz für Druckluftanlagen

Sebastian Uziel1.elmug4future, Technologiekonferenz, 24. - 25. September 2019, Erfurt

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.

Press release,

IMMS nominated for the 25th Innovation Award Thüringen 2022

Scalable ultrasound and volume flow sensor platform for optimising energy efficiency in industry

Press release,

From one of the world’s first USB hubs to AI

Video on 25 years of IMMS – transfers from basic research to industry

Event,

3. Industrieforum „Smarte Fertigung“

Integration flexibler Fertigungstechnologien und intelligenter Prozessketten

Event,

elmug4future 2019

Two presentations at the Technology Conference on Condition, Health and Quality Monitoring – Sensors, Methods and Applications

Contact

Contact

Dr.-Ing. Tino Hutschenreuther

Head of System Design

tino.hutschenreuther(at)imms.de+49 (0) 3677 874 93 40

Dr. Tino Hutschenreuther will answer your questions on our research in Smart distributed measurement and test systems and the related core topics Analysis of distributed IoT systems, Embedded AI and Real-time data processing and communications, on the lead applications Adaptive edge AI systems for industrial application and IoT systems for cooperative environmental monitoring as well as on the range of services for the development of embedded systems.

Funding

The sUSe project was funded by the Federal Ministry for Economic Affairs and Energy under the reference ZF4085709PO8 on the basis of a resolution of the German Bundestag.