elmug4future 2019

Description:

RFID-Sensortransponder für Industrieanwendungen, Eric Schäfer

Intelligente Instandhaltung und Optimierung der Energieeffizienz für Druckluftanlagen, Sebastian Uziel

Related content

Patent

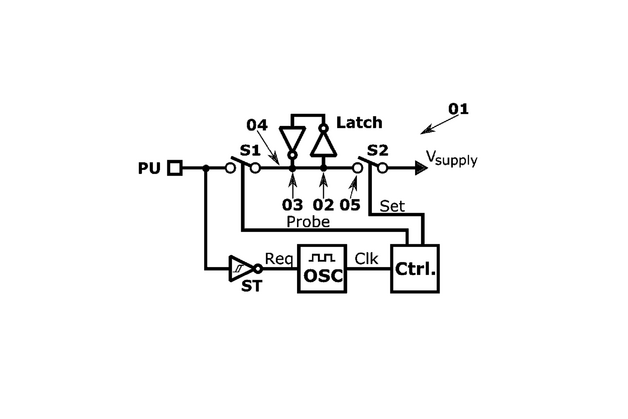

DE 10 2016 119 927

Circuit arrangement for providing the charging energy for a level change on a signal bus, calibration method and signal transmission system

Press release,

Energieeffizienz für serielle Inter-Chip-Kommunikation mit kommerziellen drahtlosen Sensoren

iENA-Silbermedaille für Latch-basierten aktiven Ultra-Low-Power-Pull-Up-Emulator

Press release,

IMMS nominated for the 25th Innovation Award Thüringen 2022

Scalable ultrasound and volume flow sensor platform for optimising energy efficiency in industry

Press release,

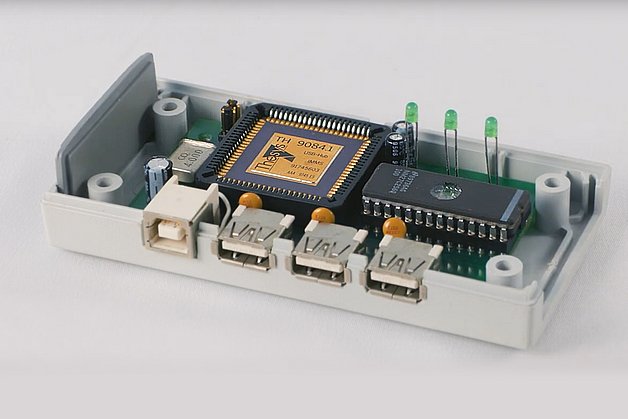

From one of the world’s first USB hubs to AI

Video on 25 years of IMMS – transfers from basic research to industry

Press release,

Highly accurate and battery-free measurement via RFID

IMMS PhD candidate defends dissertation on precise passive RFID sensor technology

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.