Press releases

IMMS nominated for the 25th Innovation Award Thüringen 2022

Scalable ultrasound and volume flow sensor platform for optimising energy efficiency in industry

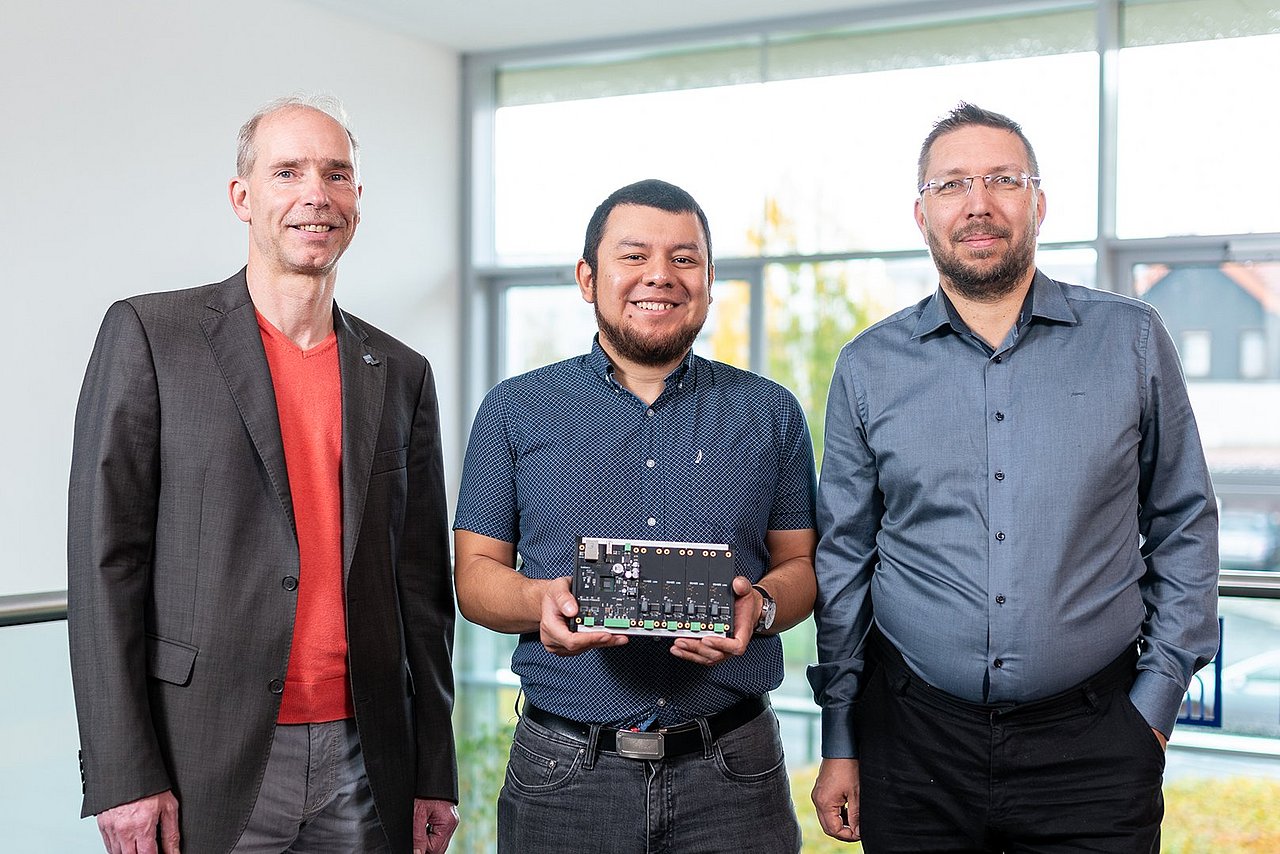

On 30 November 2022 in Weimar, IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH (IMMS GmbH) has been nominated in the category “Industry and Material” for the scalable ultrasonic and volume flow sensor platform “sUSe” for the Innovation Award “XXV. Innovationspreis Thüringen 2022”. The platform is intended for the optimisation of energy efficiency in industry. The system will be prepared for market launch with the development partner SONOTEC GmbH from spring 2023.

Platform helps save energy for compressed air in industry

“Even before the energy crisis, industry was combating leaks in compressed air lines, as they cause the most energy losses and thus also unnecessary costs. In view of the current price development, it is even more important for companies to find such leaks, evaluate losses and initiate maintenance measures,” explains Dr. Tino Hutschenreuther, Head of System Design at IMMS.

Up to 10% of electrical energy is used in a wide variety of industries to generate compressed air alone, for example to drive machines and cylinders, transport materials or small parts, cool molded or cast parts, flush gas tanks or operate exhaust, ventilation and drying systems. On average, 30% of this compressed air is lost due to leakage.

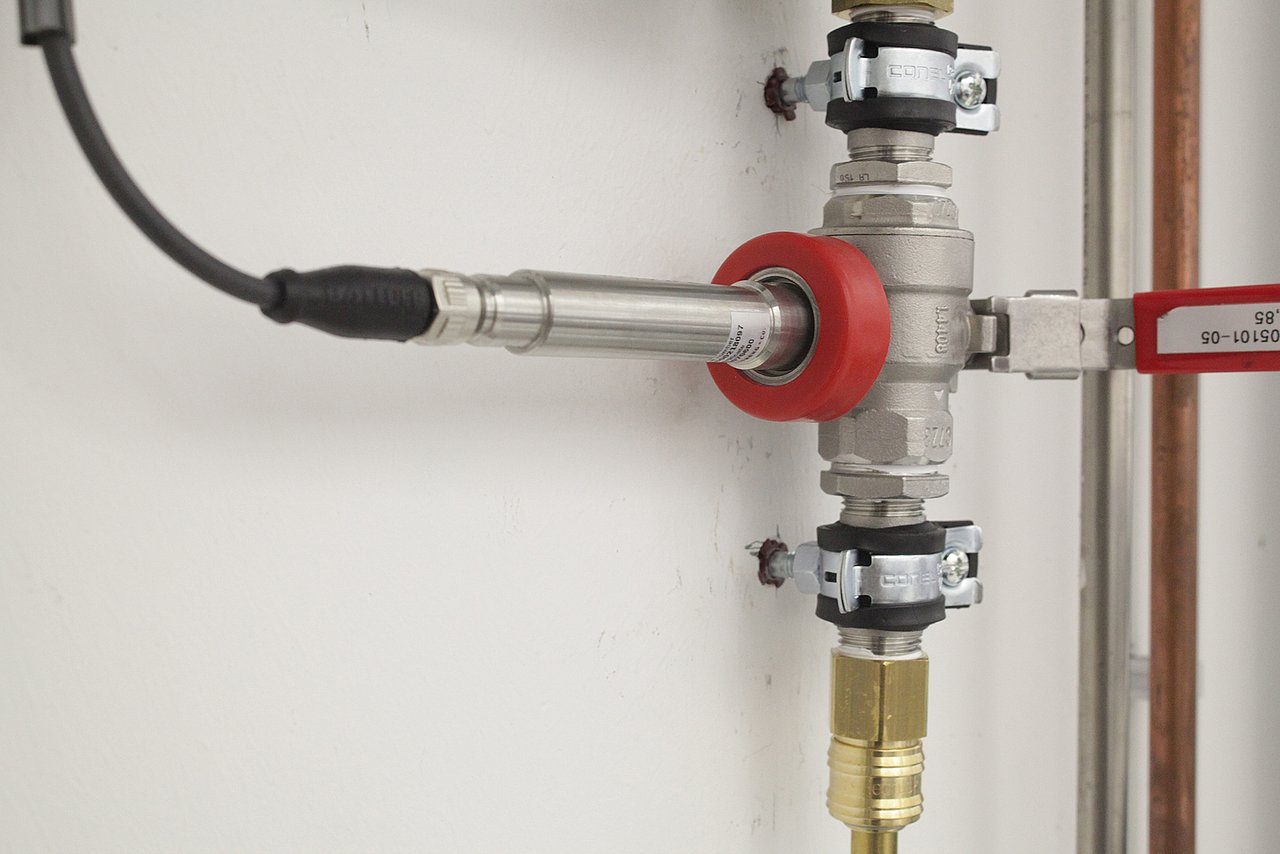

To significantly reduce such losses, IMMS has developed the sUSe electronics platform for an automatable solution for the sensors of the cooperation partners SONOTEC GmbH and Postberg+Co. GmbH. The sUSe system consisting of platform and sensors can be retrofitted in industrial compressed air systems to permanently monitor them, improve energy efficiency and save CO2 emissions.

For the first time worldwide, the system combines hybrid sensor technology and data fusion in one device which allows for a holistic and continuous monitoring

Until now, leaks in compressed air systems have been measured, analysed, located and documented in reports by service technicians, usually commissioned externally, using individual sensors or various devices. Continuous monitoring usually does not take place and the data can neither be networked nor connected to ERP systems.

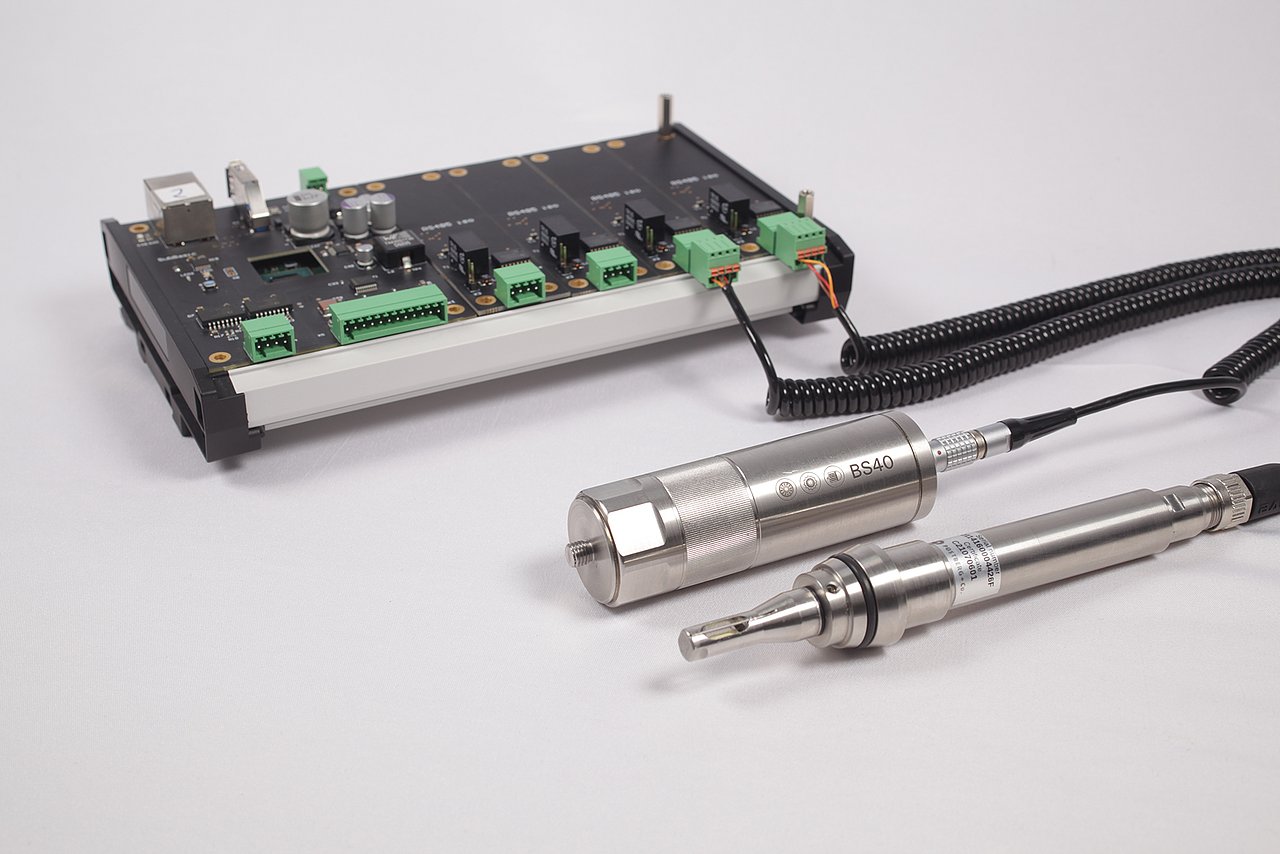

The sUSe platform developed at IMMS forms the basis of a worldwide novel, holistic monitoring system for compressed air systems. It consists of the platform and several ultrasonic and volume flow sensors that are distributed over a compressed air system, networked and permanently installed.

On the one hand, volume flow sensors from the partner Postberg measure the amount of compressed air flowing through at various points in the system. This is related to the quantity fed into the compressed air system. On the other hand, ultrasonic sensors from SONOTEC GmbH, which are also integrated in the system, acoustically locate leaks and evaluate their loss.

With the sUSe platform, all data from a wide variety of sensors are merged and digitally processed. This data fusion enables a comprehensive evaluation, because now leakage points and total volume flow are considered together. As a result, the share of losses in the total consumption of compressed air can be precisely allocated.

“With this completely new concept of evaluating compressed air losses holistically, companies can concentrate on the major construction sites with sound data,” Hutschenreuther continues.

“After all, about 70 percent of compressed air losses can be attributed on average to about 10 percent of leaks, which you can now target and eliminate first with maintenance measures.”

Electronics platform, AI-based signal processing, communications solution, performance features

Since compressed air is supplied in varying quantities at changing points for many applications, such as for various actions of an industrial robot, the sUSe platform and all associated sensors must operate synchronously in terms of time. Therefore, IMMS has taken a modular approach to the design of the hardware components. The sensors acquire data simultaneously via a synchronisation mechanism to ensure the real-time capability of the system. The algorithms implemented by IMMS are used to evaluate the different channels within the system and provide an assessment. AI accelerators can be retrofitted via an expansion slot to significantly increase processing power.

This edge AI platform for decentralised data processing is used for each measuring point of the monitoring system. To be able to adapt the system very flexibly for different applications without having to make changes to the hardware, IMMS developed the signal processing components using a model-based design technology and configured the application algorithms for FPGA integration on this basis. Suitable communications interfaces and protocols were implemented for integration into maintenance systems and the corresponding communications capability of the platform was established.

In detail, the platform offers a completely digital data structure, sampling rates up to 400 kHz for synchronous and phase-accurate sampling for analogue and digital sensors, broadband measurements, exchangeable algorithms, scalable computing power, sensor data fusion, calibration function, cloud integration and networking via various techniques and protocols, and connectivity to ERP systems.

Market launch in 2023 and potential for further applications

“In view of the current dynamics on the subject of energy saving, the market launch planned for 2023 comes at the right time,” says Michael Münch, Managing Director of SONOTEC GmbH. Beyond the monitoring of compressed air systems, he also sees versatile application potential in predictive maintenance, process monitoring and quality assurance. He adds that the modular platform architecture has been developed in such a way that very specific market requests can be effectively handled with different sensor combinations. “We assume that completely new market segments can be opened up with the technology,” Münch concludes.

Funding

The sUSe project was funded by the Federal Ministry for Economic Affairs and Energy under the reference ZF4085709PO8 on the basis of a resolution of the German Bundestag.

This might also be interesting for you

Related content

Project

sUSe

To use compressed air for industrial processes in an energy-efficient way, IMMS has developed the electronics platform for an automatable sensor…

Event,

3. Industrieforum „Smarte Fertigung“

Integration flexibler Fertigungstechnologien und intelligenter Prozessketten

Event,

elmug4future 2019

Two presentations at the Technology Conference on Condition, Health and Quality Monitoring – Sensors, Methods and Applications

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.