Patent DE 10 2023 118 056

Positioning system with a controller and method for its configuration

The ongoing miniaturisation of technical products is leading to a growing demand in many industrial sectors for precision machines that can measure and process the smallest structures and objects with high accuracy. A new control concept for the compensation of interference forces makes a major contribution to increasing the precision of the drive systems required for this.

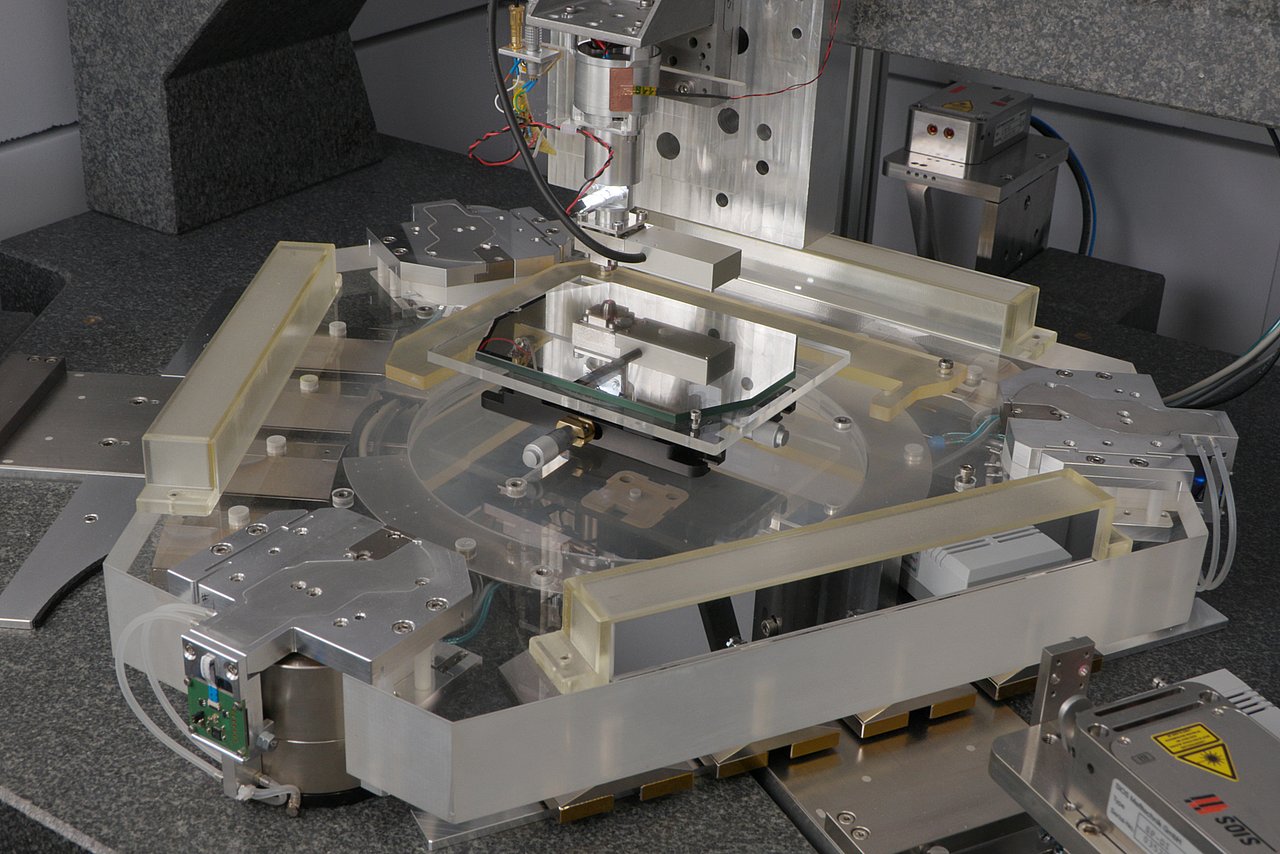

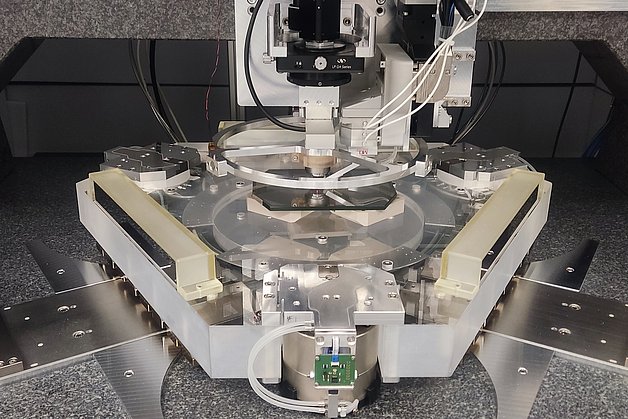

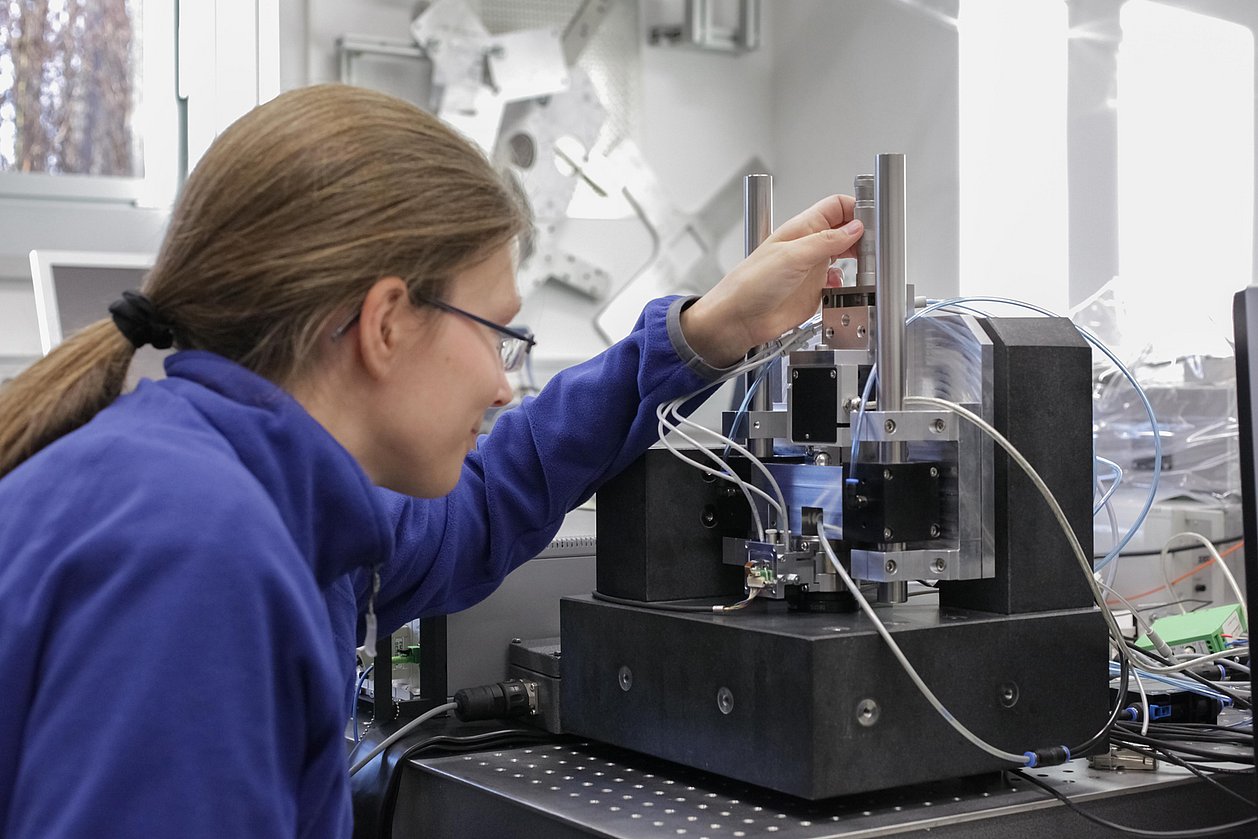

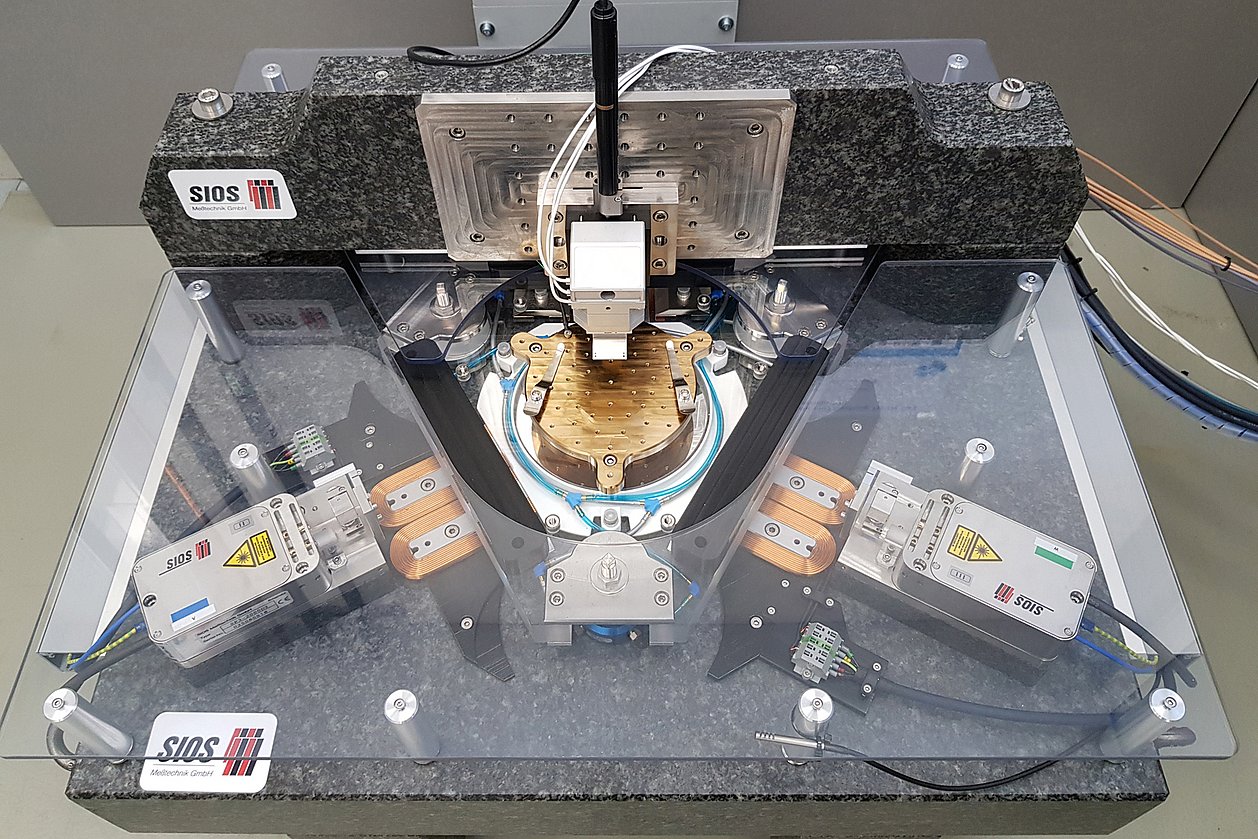

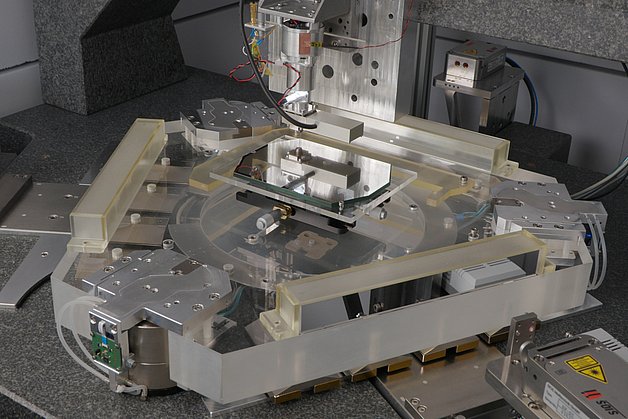

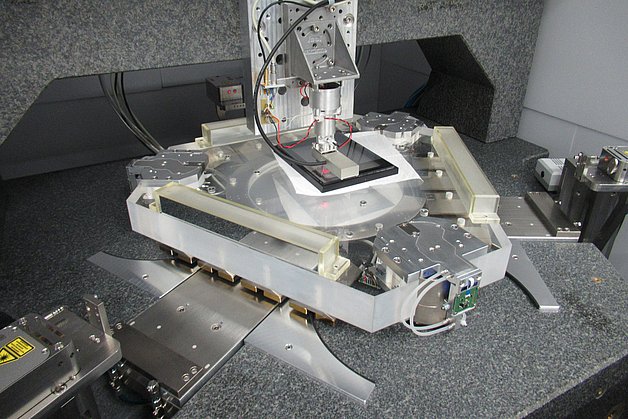

Highly dynamic multi-coordinate direct drive systems, such as those developed at IMMS, allow objects to be positioned in working ranges of several hundred millimetres in the shortest possible time with nanometre precision. Operation takes place in a closed control loop, i.e. a complex control algorithm calculates new target values for the drives from measurement data on the actual state of the positioning carriage. The newly developed control concept with an extended dynamic observer enables very effective compensation of disturbance variables and thus results in a significant increase in drive precision in dynamic operation.

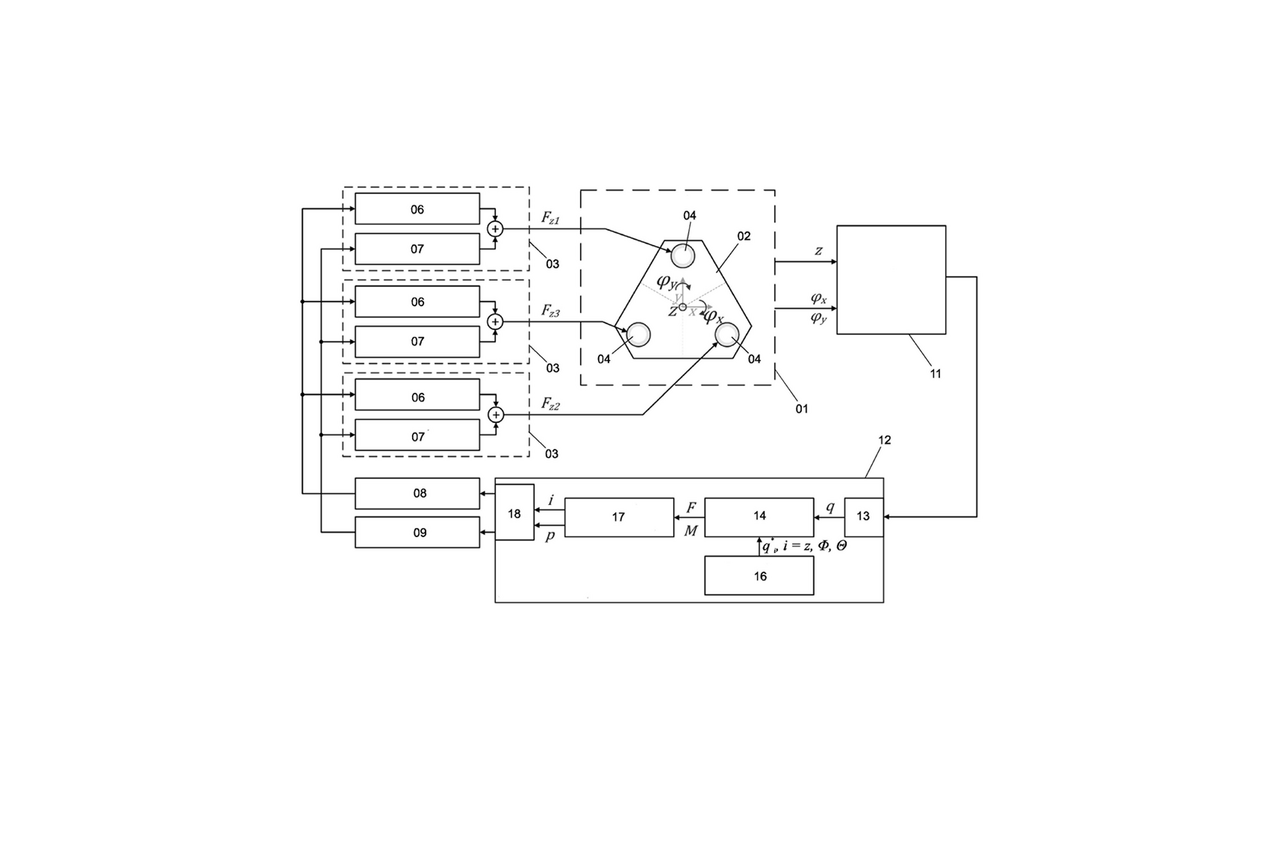

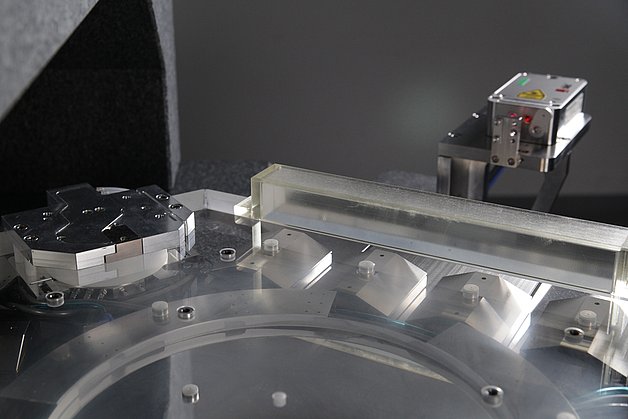

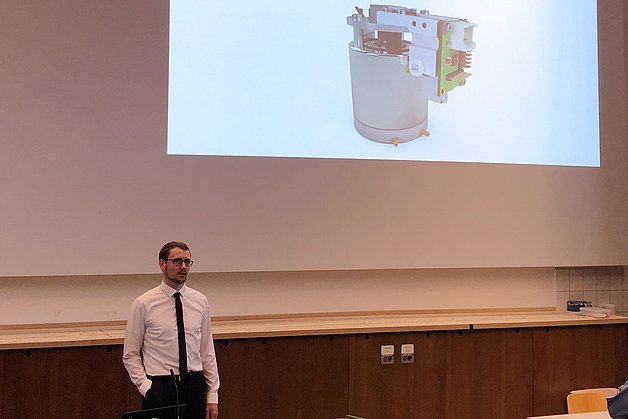

The idea behind the invention is a novel control concept for a nanometre-precise drive system with three lifting and actuating units (LAUs), which generate vertical movements and tilts around horizontal axes. In addition to the aerostatic guide, a single LAU contains two parallel-acting actuators for generating and transmitting a vertical force to the moving part. Precise vertical and tilting movement of the slider is only possible through the joint controlled operation of the three LAUs. The innovation in the control concept presented is the realisation of the decoupling with the aid of a disturbance estimator, which acts as an extended dynamic observer and predicts the acting disturbance forces. These estimated disturbances are used in the controller to compensate for actual disturbance forces and to counteract crosstalk between the axes as well as errors or environmental influences that can be modelled as disturbances.

Advantages of the invention

- Compensation of interference forces without their precise measurement

- Adaptive adjustment to long-term changes in interference

- Multi-axis coupled positioning systems can be controlled with the aid of single-axis controllers

- Increased precision of the multi-axis drive in dynamic operation

Patent No.:DE 10 2023 118 056

Inventor:Alex S. Huaman

Application:

High-precision nanopositioning| application or production of high-precision measurement and production technology systems (e.g. semiconductor/microelectronics production)Research field:Magnetic 6D-direct drives with nanometre precision

granted patent

Application date:07 July 2023

Date of first publication:02 October 2024

Date of publication of grant:02 October 2024

Related content

Project

NanoFab

IMMS has been working on solutions for a highly dynamic drive system for multi-axis manufacturing and processing of objects with nanometre precision in the Research Training Group 2182 ”NanoFab“.

Press release,

iENA-Silbermedaille für Beobachter der Atome

Neues Regelungskonzept zur sub-nanometergenauen Positionierung

Press release,

Ready for Take-off – Vertikalantrieb für die 3D-Nanofertigung vorgestellt

IMMS-Doktorand verteidigt Promotion im DFG-Graduiertenkolleg NanoFab

NPS6D200: Long-Range-6D-Nanopositionierung mit interferometrischem Feedback für das Closed-Loop-Regelungssystem

Steffen Hesse1.Experten-Tag für Präzisionsmesstechnik, 28. - 29. Oktober 2025, bei SIOS Meßtechnik GmbH, Ilmenau, Germany

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Nanometer-Positionierung mit 6D-Regelung

Steffen Hesse1.Mikroproduktion, Fachmagazin, Ausgabe 03/2025, Seite 44 - 48

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Herausforderungen und Lösungsansätze bei der Entwicklung kraftgekoppelter Hochpräzisions-Vertikalantriebe

Ludwig Herzog1.18. Jahrestagung „Feinwerktechnische Konstruktion“, 25. - 26. September 2025, Dresden, Germany

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.A virtual metrology frame test setup using fiber interferometric sensors

Davi Anders Brasil1. Steffen Hesse1. Ludwig Herzog1. Thomas Fröhlich2. Thomas Kissinger2.22nd International Metrology Congress (CIM 2025), Lyon, France, March 11-14, 2025

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany. 2Institute of Process Measurement and Sensor Technology, Technische Universität Ilmenau.

Event,

euspen SIG: Micro/Nano Manufacturing 2023

euspen Special Interest Group Meeting: Micro/Nano Manufacturing 2023

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.