Dr.-Ing. Stephan Gorges

“For me, there is no satisfaction in designing the hundredth exhaust elbow so that it can be manufactured for a few cents less. I rather set my sights on raising the functionality to the highest technically possible level, so I concern myself with vertical movement systems in nanometre positioning and measuring machines. Why did I choose to come to IMMS? Here, I am a member of a team like a family group in which we all level with each other.“

”In many areas of industry, production development has reached ”saturation point“. Because of the expense of functional improvements, maufacturers can only attempt to pare down their costs. For me, however, there is no professional satisfaction in designing the hundredth exhaust elbow so that it can be manufactured for a few cents less. I would rather set my sights on raising the functionality to the highest technically possible level of quality.

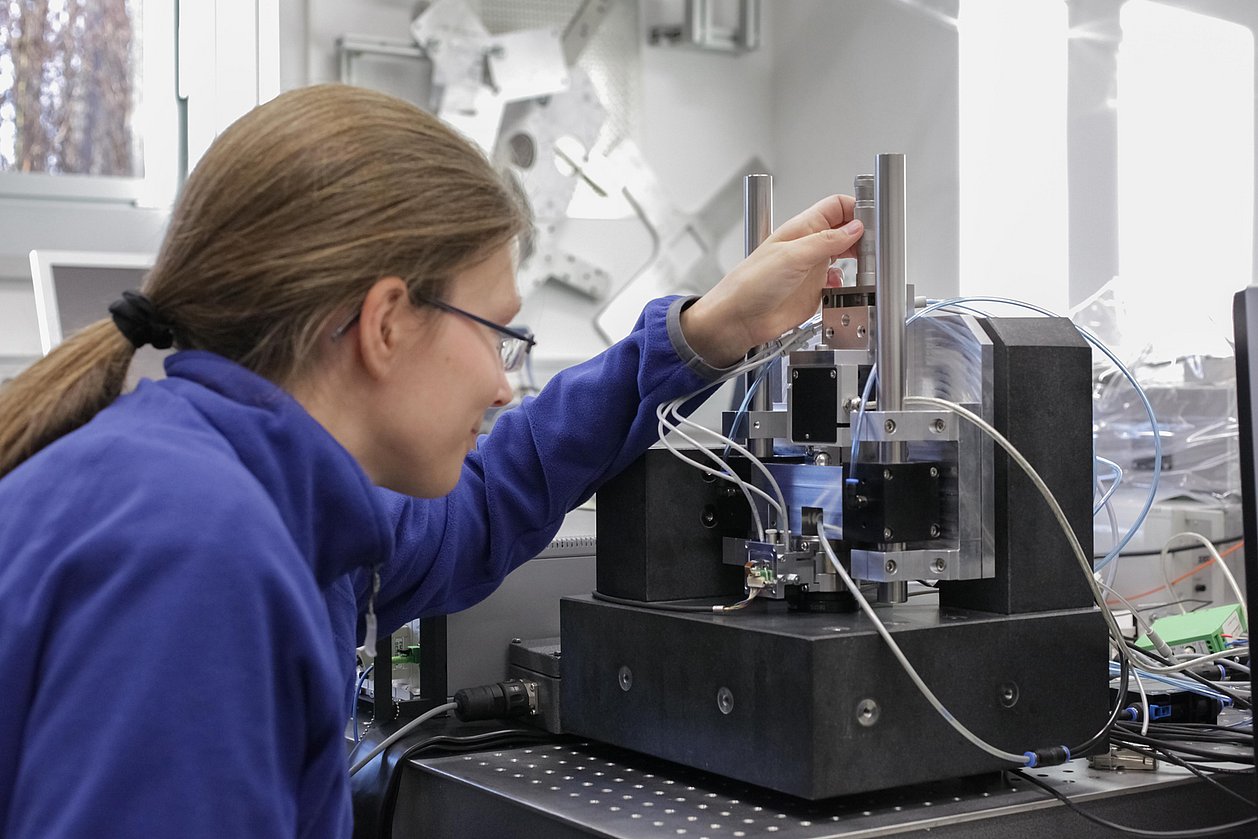

Also, when one is carrying out R&D for small and medium-sized companies, one has the chance to be fully involved from the initial idea through to construction and commissioning of a prototype. Understanding systems is a core competence at IMMS: working there, I have to grasp how all the systems function – drives, transmission, movement, measurement and control systems – so that they all work together in harmony. It is our philosophy not to lose sight of the whole and not to be too compartmentalised in our thinking. I have to apply all the knowledge I have acquired and, by extending and deepening it, meet new challenges.

As my degree subject was mechatronics, it is these interdisciplinary demands which attract me. In the mechatronics section at IMMS, we deal not only with mechanical-electrical microsystems but also with precision drives. In these highly technical fields there is a need for new thinking to enable macroscopic objects to be moved with precision on the nanometre scale. Ilmenau TU started up the NanoFab graduate college to help improve these extremely accurate machines and to research new processing possibilities in the area of nanoscale product fabrication. The role that IMMS plays in the graduate college enables me to concern myself with the particular demands of vertical movement systems in nanometre positioning and measuring machines.

Why did I choose to come to IMMS? Easy! Having spent an internship at IMMS while studying for the BSc and written my dissertation there, I had already had the experience and pleasure of working here with these colleagues. So it was not a difficult decision to apply for a job with them when I had graduated. The decisive factor was the working atmosphere. Here, I am a member of a team like a family group in which we all level with each other, giving help as needed and learning a lot from each other. Besides, the offices and labs are modern in their equipment and furnishings, so that working conditions are very pleasant. But even outside work, there are frequent activities to share with colleagues, such as barbecues, cycle rides or toboggan races.“

Related content

Project

K4PNP+Z

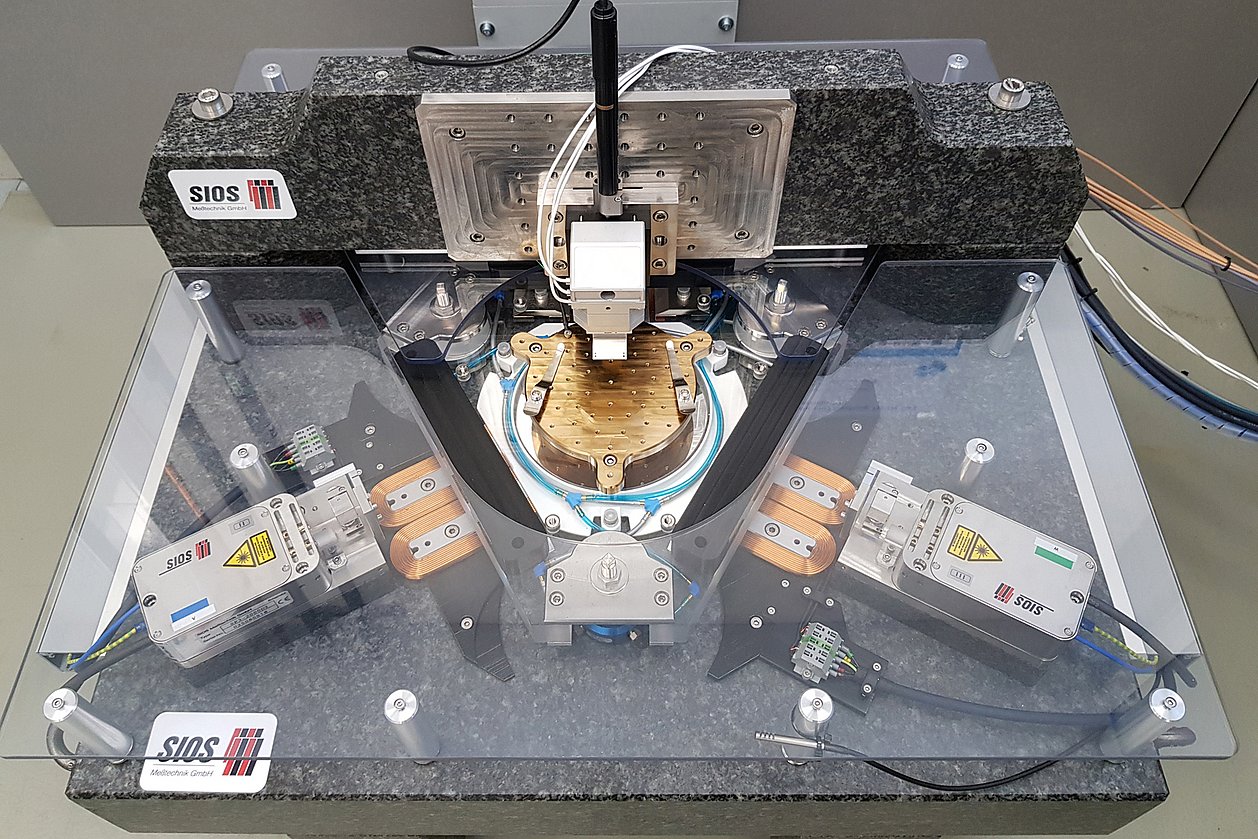

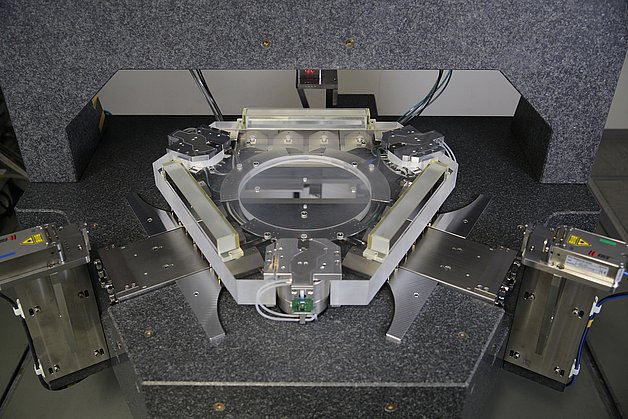

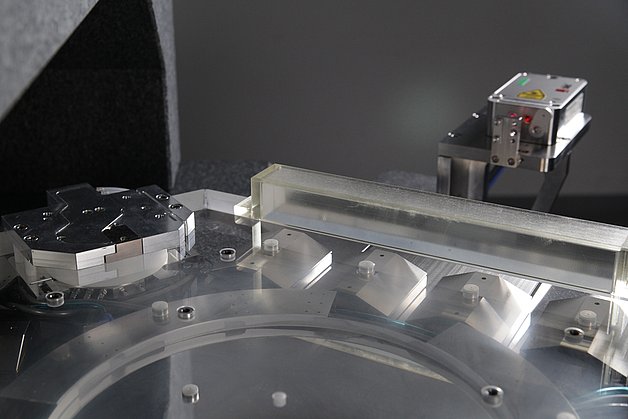

IMMS developed actuators to position objects in planes with diameters up to 200 mm and a vertical stroke of 25 mm with nanometre precision.

Project

NanoFab

IMMS has been working on solutions for a highly dynamic drive system for multi-axis manufacturing and processing of objects with nanometre precision in the Research Training Group 2182 ”NanoFab“.

Vertikale Nanopositionierung mit bis zu 25 mm Verfahrweg – Hubmodule für die hochgenaue Positionierung im Raum

Stephan Gorges1. Steffen Hesse1. Ludwig Herzog1.Konstruktion (2023), 07-08, Sonderteil Antriebstechnik, Seite 28 - 31, VDI Fachmedien, ISSN 0720-5953, e-paper.vdi-fachmedien.de/konstruktion/2023

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.Operation and performance evaluation of vertical nanopositioners for 10 mm stroke in a 3D lift and tilt test setup

Steffen Hesse1. Michael Katzschmann1. Alex S. Huaman1. Stephan Gorges1. Eberhard Manske2.euspen – Special Interest Group Meeting: Precision Motion Systems & Control, 15th – 16th November 2022, s-Hertogenbosch, The Netherlands, NL

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 2Institut für Prozessmess- und Sensortechnik, Technische Universität Ilmenau, Ilmenau, Germany.Investigations on the Tracking Control and Performance of a Long Stroke Vertical Nanopositioning Drive

Alex S. Huaman1. Stephan Gorges1. Michael Katzschmann1. Steffen Hesse1. Thomas Fröhlich2. Eberhard Manske2.Euspen (European Society for Precision Engineering and Nanotechnology) – 22nd International Conference & Exhibition, 30 May – 3 June 2022, Geneva, Switzerland

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 2Institute of Process Measurement and Sensor Technology, Technische Universität Ilmenau, 98693 Ilmenau, Germany.Nanometergenaue Hubmodule für die Präzisionsantriebstechnik

Stephan Gorges1.Konstruktion (2021) Nr. 11-12, Sonderteil Antriebstechnik, Seite 36 - 40, www.ingenieur.de/fachmedien/konstruktion/antriebstechnik/hubmodule-fuer-die-praezisionsantriebstechnik/

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.

Patent

DE 10 2021 103 220

Positioning system for the three-dimensional positioning of an object and method for its operation

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)