Project SME Digital

Under the name ”Smart Sensor Systems Model Factory“ we are supporting enterprises in their gradual adoption of Industry 4.0 technology.

Objectives

Since October 2016, IMMS has had a support role in the gradual introduction of Industry 4.0 technology to industrial companies in the region. To meet the growing demand for customer-specific products and services and so to remain competitive, small and medium-sized enterprises (SMEs) are having to optimise their processes and join forces. For this reason, the Ilmenau Mittelstand 4.0 centre of excellence has been set up to support to SMEs as they begin to apply the digitisation and other technologies needed in Industry 4.0. The electronic solutions are to be the means of bringing flexibility and optimum methodology into every process in the added-value chain and every stage of business through from the drawing board to manufacture in commercially-linked networks.

The Ilmenau SME Digital Centre Ilmenau

The German federal ministry for industry (BMWi) has funded the digital centre with Technische Universität Ilmenau at its head so that four partners, called Fabs, can offer relevant information and innovative approaches which are then put to the test. The Fabs, or ”Modellfabriken (model factories)“ bridge a number of fields, which include the networking of machines and production processes, virtualisation, 3D printing and individualised production, the generating of process data and data transfer, and smart sensor systems.

The IMMS contribution as the ”Smart Sensor Systems Model Factory“

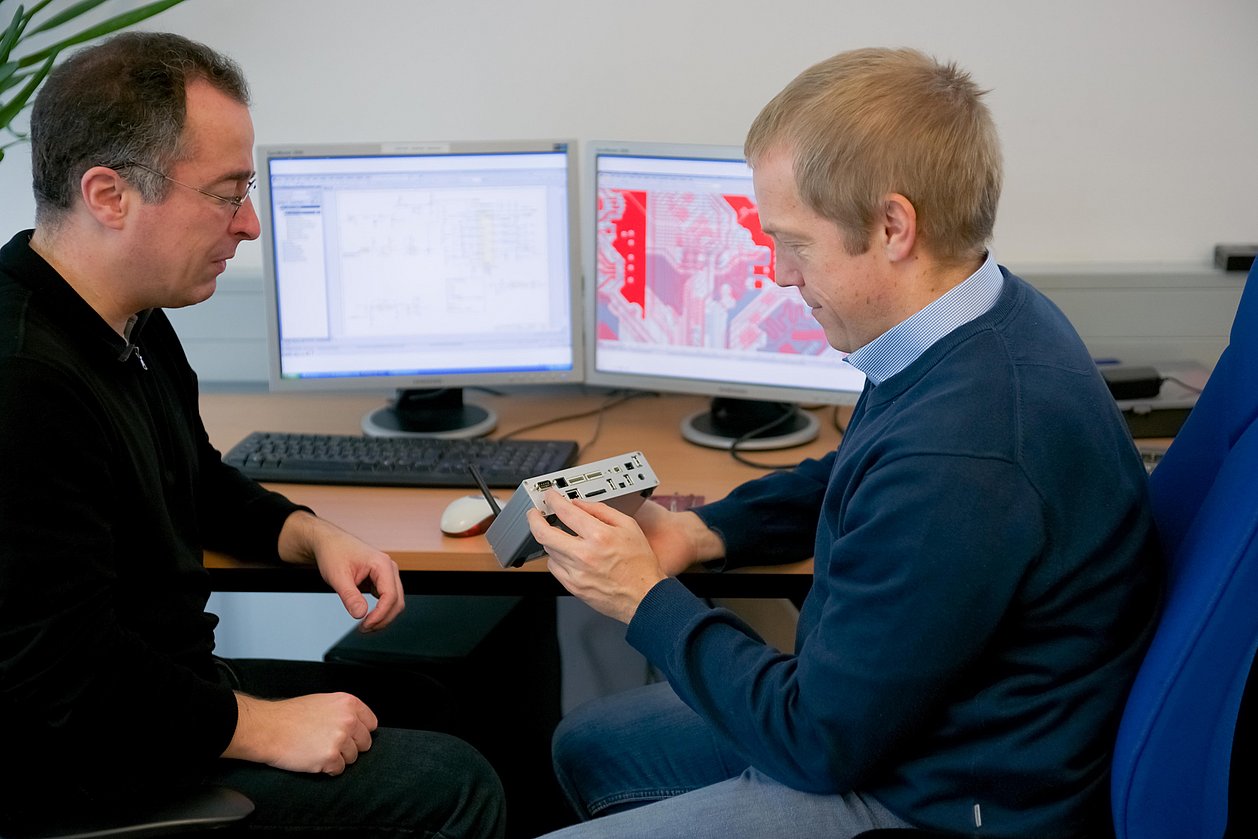

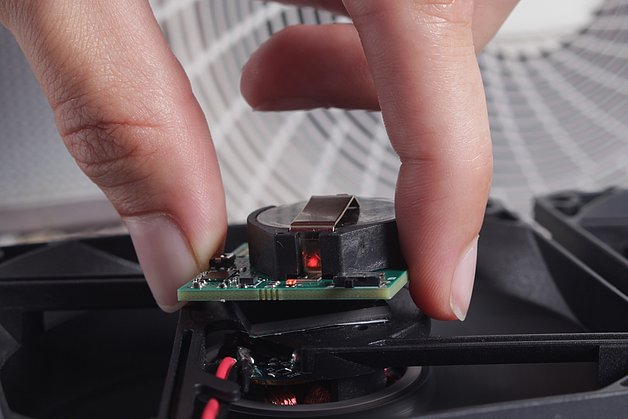

IMMS, now also known as the ”Smart Sensor Systems Model Factory“, is supporting other enterprises in their gradual adoption of the technology applicable in Industry 4.0. An example of what this means is refitting machinery and equipment with wireless and networked sensors so that data can be obtained and processed to underpin new diagnostic, maintenance and service plans. Using universal electronics platforms for components that are Industry 4.0 compatible, together with open-source software, is an effective means of achieving rapid, reasonably priced, real-time innovation.

All SME Digital events of IMMS

AI trainer at IMMS

Since May 2020, AI trainers from SME Digital have been supporting the planning and design of concrete AI implementation measures and strategies, imparting knowledge on methods of artificial intelligence and machine learning in digitisation and helping with their introduction, implementation and expansion. AI trainer Wolfram Kattanek of the ”Smart Sensor Systems Model Factory“ at IMMS offers support in the following areas:

- intelligent sensor and measurement systems

- sensor-based AI-based signal processing

- Machine condition monitoring and predictive maintenance

- Knowledge transfer from research to SMEs

- practical demonstration and implementation projects with AI

Acronym / Name:

SME Digital / ”Smart Sensor Systems Model Factory“ in the Ilmenau SME Digital Centre IlmenauDuration:2016 – 2026

Project website:„Mittelstand-Digital Zentrum Ilmenau“ (in German)

Application:

Automation technology and Industry 4.0|Automotive| Energy and energy storage| Mechanical engineering| Plastics| Ceramics| Optics/optoelectronics| Micro-/nanotechnologyResearch field:Smart distributed measurement and test systems

Related content

Wie wird mein Unternehmen KI-ready? Bedarfsgerechte Analyse- und Unterstützungspotenziale für KMU durch eine institutionsübergreifende Zusammenarbeit

Sebastian Gerth1, 4. Martin Folz2, 4. Wolfram Kattanek3, 4.Mittelstand-Digital Magazin „Wissenschaft trifft Praxis“, Ausgabe 22, „KI-Readiness“

1Mittelstand-Digital Zentrum Ilmenau (TU Ilmenau). 2Mittelstand-Digital Zentrum Chemnitz (TU Chemnitz). 3Mittelstand-Digital Zentrum Ilmenau (IMMS GmbH). 4KI-Hub Sachsen-Thüringen.Mit smarten Sensorsystemen und KI zu nachhaltigerer Produktion

Wolfram Kattanek1.Digital-Gipfel 2023, 20. November 2023, Jena

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.A Case Study on Suitability of Machine Learning for Predictive Drill Bit Sharpness Estimation

Umut Onus1. Stefan Marr2. Sebastian Uziel1. Silvia Krug1.2021 IEEE International Workshop on Metrology for Industry 4.0 and IoT, DOI: doi.org/10.1109/MetroInd4.0IoT51437.2021.9488429, 7-9 June 2021, Rome, Italy, online

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 2GFE Gesellschaft für Fertigungstechnik und Entwicklung Schmalkalden e.V..Kontinuierliches Monitoring von Ethernet-Kabeln

Sebastian Uziel1.Online-Stammtisch Sensorik 4.0, Diagnoselösungen in der industriellen Anwendung, 20. Mai 2021, online

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.

Press release,

Gemeinsam durch die Krise: Thüringer Netzwerke starten branchenübergreifende Initiative

Informationen, Förder- und Unterstützungsmöglichkeiten für KMU in Thüringen

Press release,

Reinhard Bütikofer zu Besuch im „Mittelstand 4.0-Kompetenzzentrum Ilmenau“

Lösungen zur Vernetzung und zu Energie- und Ressourceneffizienz an TU Ilmenau und IMMS vorgestellt

Press release,

Ramelow besucht „Mittelstand 4.0-Kompetenzzentrum Ilmenau“ am IMMS alias „Modellfabrik Migration“

Sommertour durch Digitalisierungsthemen – dritte Woche #ZukunftThüringen startet am IMMS

Press release,

Bundestagsabgeordneter Tankred Schipanski zu Besuch am IMMS

Am 12. Juli 2018 besuchte der für den Landkreis Gotha und den Ilm-Kreis gewählte Bundestagsabgeordnete Tankred Schipanski das IMMS. Zur Pressemitteilung auf www.tankred-schipanski.de.

Event,

Thuringian Mechanical Engineering Day 2025

Production of the future: automated, networked and collaborative

Event,

InnoCON 2025

Innovation policy flagship event of the German Land of Thüringen. Topic “Key technologies: Paving the way for the world of tomorrow“

Event,

KI-Tag für den Mittelstand

Veranstaltung des Mittelstand BVMW e.V. Thüringen im Rahmen der Thüringen Ausstellung in Zusammenarbeit mit dem ITnet Thüringen e.V.

Contact

Contact

Dr.-Ing. Frank Spiller

Head of Business Development and Central Projects

frank.spiller(at)imms.de+49 (0) 3677 874 93 61

As Head of Business Development and Central Projects Dr. Frank Spiller is your contact person for SME Digital topics as well as for the research and development of application-specific automation systems for industry:

- Retrofittable sensors for innovative diagnostics, maintenance and service concepts

- Universal electronic platforms for Industry-4.0-compliant components

- Open source software and AI-based data processing for industrial applications

Implementation projects

Indoor swimming pool

Remote readout technology for an automated water disinfection system with UV sensors

KSS

IMMS contributes to automated monitoring of cooling lubricants: Sensor installation as proof of concept for determining coolant-relevant data.

KIQ

IMMS has developed an AI-based, retrofittable and cost-effective solution for quality assurance of machining tools.

The work of IMMS as ”Smart Sensor Systems Model Factory“ was funded by the German Federal Ministry for Economic Affairs and Energy in the ”SME Digital Centre Ilmenau“ under the reference 01MF21008C.