Project Trib.US

Real-time capable platform and algorithms for mobile multi-sensor inspection device for the maintenance of roller bearings

Roller bearings are indispensable in any industrial sector. As ball or tapered roller bearings, they guide rotating or pivotally moving machine components such as shafts, axles, or wheels and transfer loads between components. They are used in engines and transmissions, or on pumps and shafts, among others, in consumer goods, wind turbines, industrial robots, or in conveyor belt transport rollers.

If a roller bearing is defective, it can lead to a complete system failure. Detecting wear on roller bearings and its causes in a timely manner is important to avoid downtime costs and consequential damage to equipment. The problem, however, is that roller bearings are often installed in a way that makes them difficult or very labour-intensive to inspect and maintain.

In the Trib.US project, IMMS and SONOTEC GmbH have therefore developed an integrated mobile solution to assist in maintenance decisions for roller bearings during inspections. The result is a smartphone-like device with three sensor channels. This allows defects to be pinpointed more accurately and their causes to be determined more quickly, reducing or preventing production downtime.

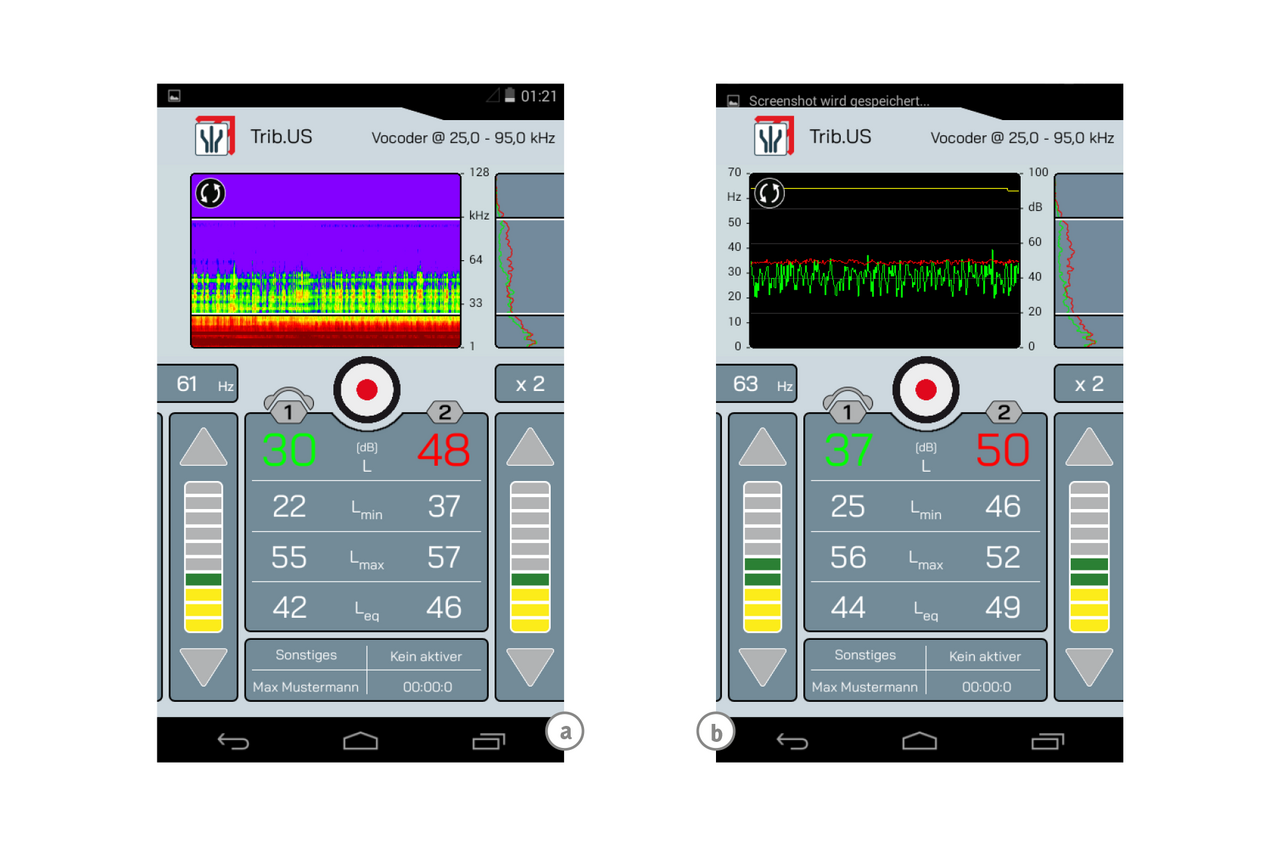

The device uses ultrasound, acceleration, rotational speed, and temperature sensors to detect deviations in signals that distinguish faulty roller bearings from those operating normally. Through correlation and sensor data fusion, conclusions can be drawn about defects, and this information is displayed directly in real-time on the device. This allows for on-the-fly assessment of which bearings are defective during machine operation. It enables a planned proactive replacement, preventing costly unplanned downtime and repairs.

For this purpose, IMMS has developed and implemented a real-time capable platform as well as algorithms for signal evaluation and correlation. The partner SONOTEC GmbH has provided the ultrasonic sensor technology, the user interface, and the associated maintenance management software. SONOTEC is preparing the prototype for mass production, expected to commence around mid/late 2024.

Acronym / Name:

Trib.US / Multi-channel ultrasonic testing device for maintenanceDuration:2021 – 2023

Application:

Automation technology and Industry 4.0|Predictive Maintenance| Production| MiningResearch field:Smart distributed measurement and test systems

Partner

Related content

Press release,

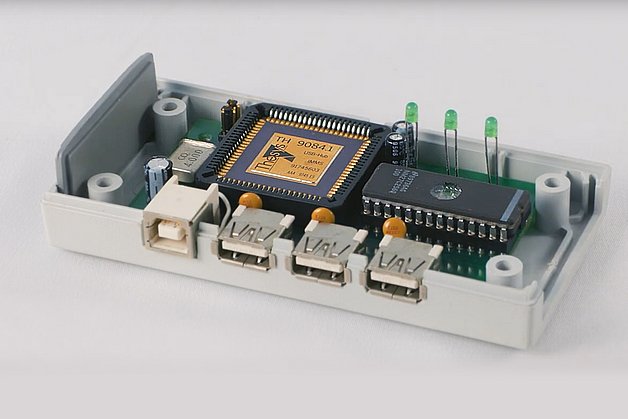

From one of the world’s first USB hubs to AI

Video on 25 years of IMMS – transfers from basic research to industry

Contact

Contact

Dr.-Ing. Tino Hutschenreuther

Head of System Design

tino.hutschenreuther(at)imms.de+49 (0) 3677 874 93 40

Dr. Tino Hutschenreuther will answer your questions on our research in Smart distributed measurement and test systems and the related core topics Analysis of distributed IoT systems, Embedded AI and Real-time data processing and communications, on the lead applications Adaptive edge AI systems for industrial application and IoT systems for cooperative environmental monitoring as well as on the range of services for the development of embedded systems.

Funding

The Trib.US project was funded by the German Federal Ministry for Economic Affairs and Energy (BMWi) / Federal Ministry for Economic Affairs and Climate Action (BMWK) on the basis of a resolution of the German Bundestag under the reference KK5048102AT0.