Prof. Dr. Martin Hoffmann, Ilmenau TU

”IMMS made a significant contribution to the project on the basis of its expertise in finite element modelling, which for the MEMS elements supported not only static and dynamic simulation but also mode analysis.“

”In the ’PRIMOS‘ project (Piezoelectric MEMS Resonators for integrated RF Reference Oscillator Applications) our Department of Micromechanical Systems worked jointly with IMMS and the TU’s RF and Microwave Research Laboratory. MEMS (microelectromechanical systems) unite sensors, actuators and, where necessary, electronic controls in a single component. It was the goal of ’PRIMOS‘ to develop silicon-based MEMS resonators for the frequency range above 200 MHz. It is the intention that they should in future replace quartz resonators such as those which create time signals in computers. Quartz resonators cannot be manufactured in combination with micro-processors but require subsequent integration. MEMS as clock generators can be manufactured in silicon together with the integrated circuits. They are, in addition, smaller, robuster and cheaper. The MEMS resonators which are so far commercially available are capacitively excited and are not suitable to high frequencies. Because those developed in the ’PRIMOS‘ project have piezo-electric coupling, they open up the possibilities of much higher frequency ranges.

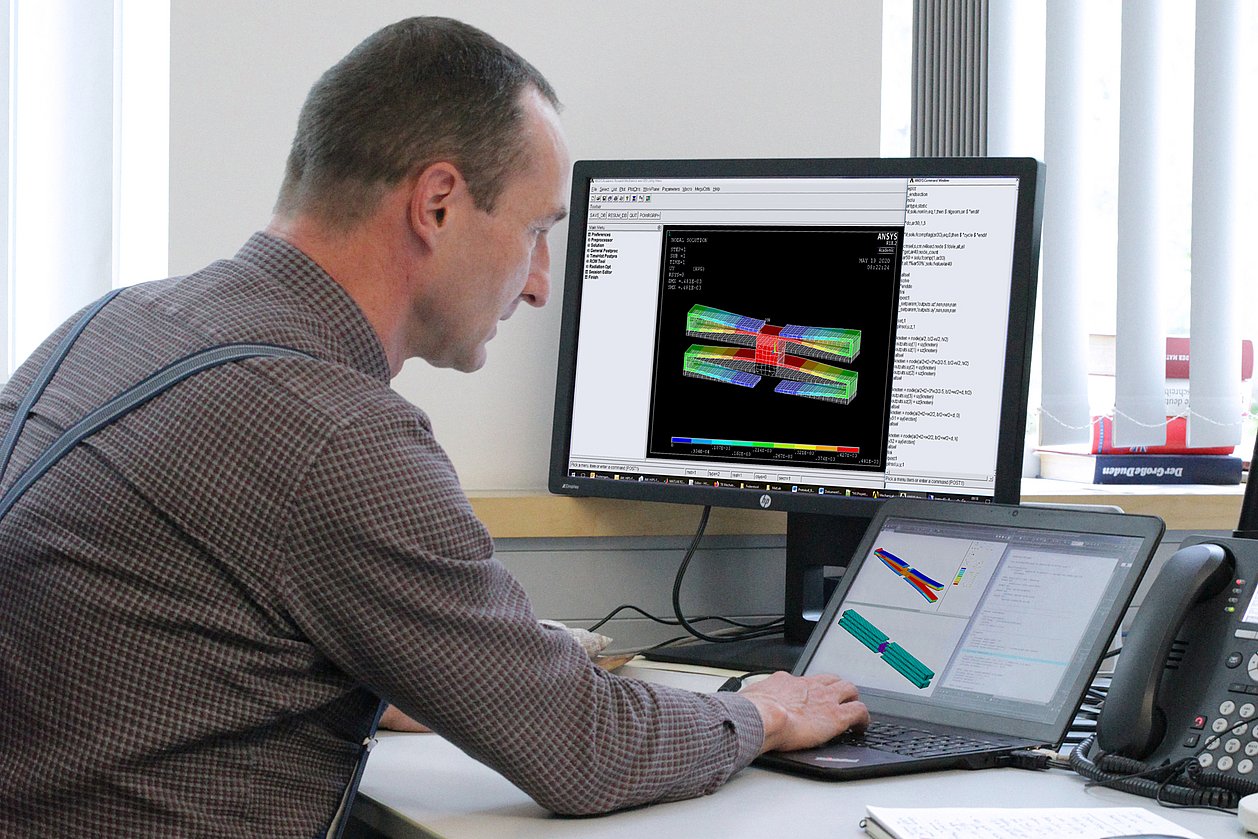

For the MEMS resonators, it was the task of our department to research and then implement the chip-compatible manufacturing process. We worked very closely with IMMS to optimise the basic structure of the test resonators and the means whereby they suppressed spurious modes. IMMS made a significant contribution to the project on the basis of its expertise in finite element modelling, which for the MEMS elements supported not only static and dynamic simulation but also mode analysis. The Institute incorporated the engineering design directives resulting from our research into its design activities. Using its measurement instruments, it also established the nature of the mechanical motion or the resonators.

The staff at IMMS brought to our project not only comprehensive know-how for the various applications but also perfect teamwork to support our joint achievement of the project’s extremely ambitious aims. Since August 2012, the ’PRIMOS‘ outcomes have been serving as the basis for the research endeavour known as ’MUSIK‘, to the success of which IMMS is further contributing.“

The reference is related to:

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.