Project Mag6D

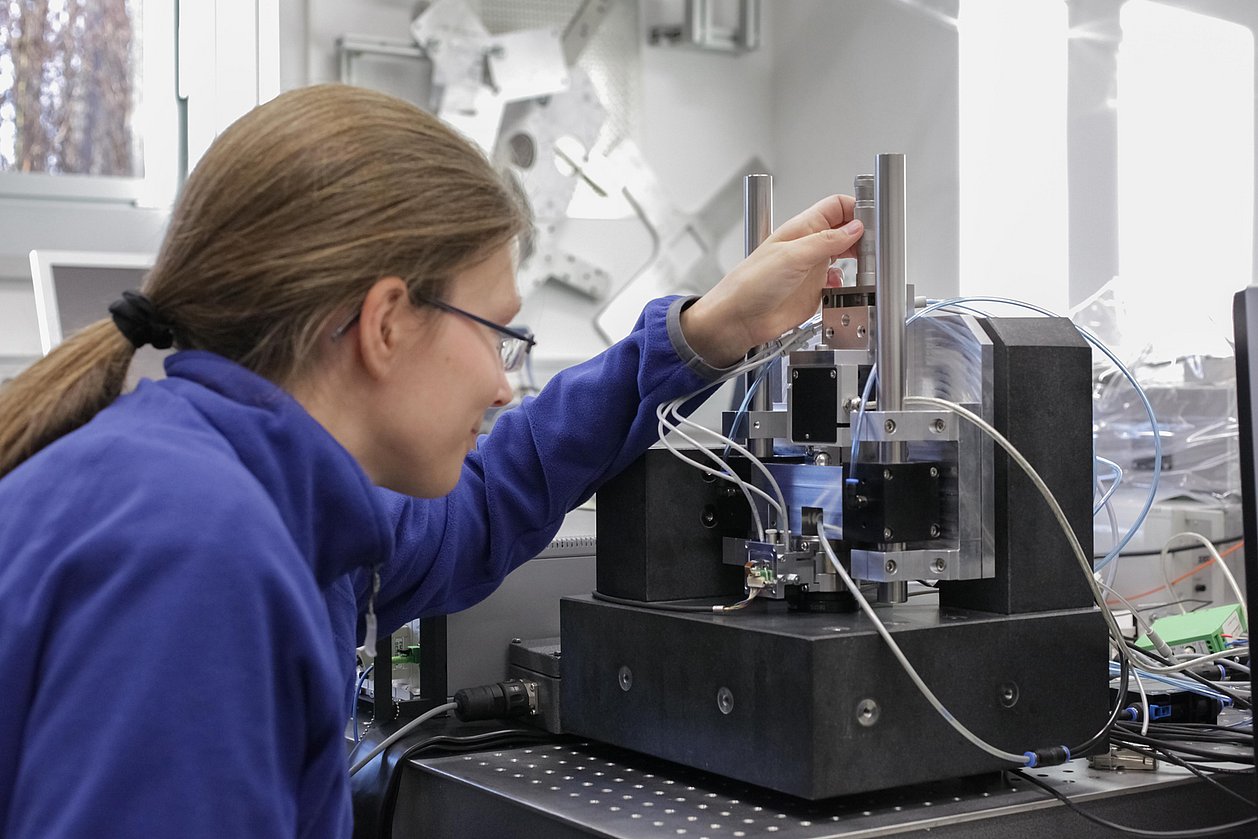

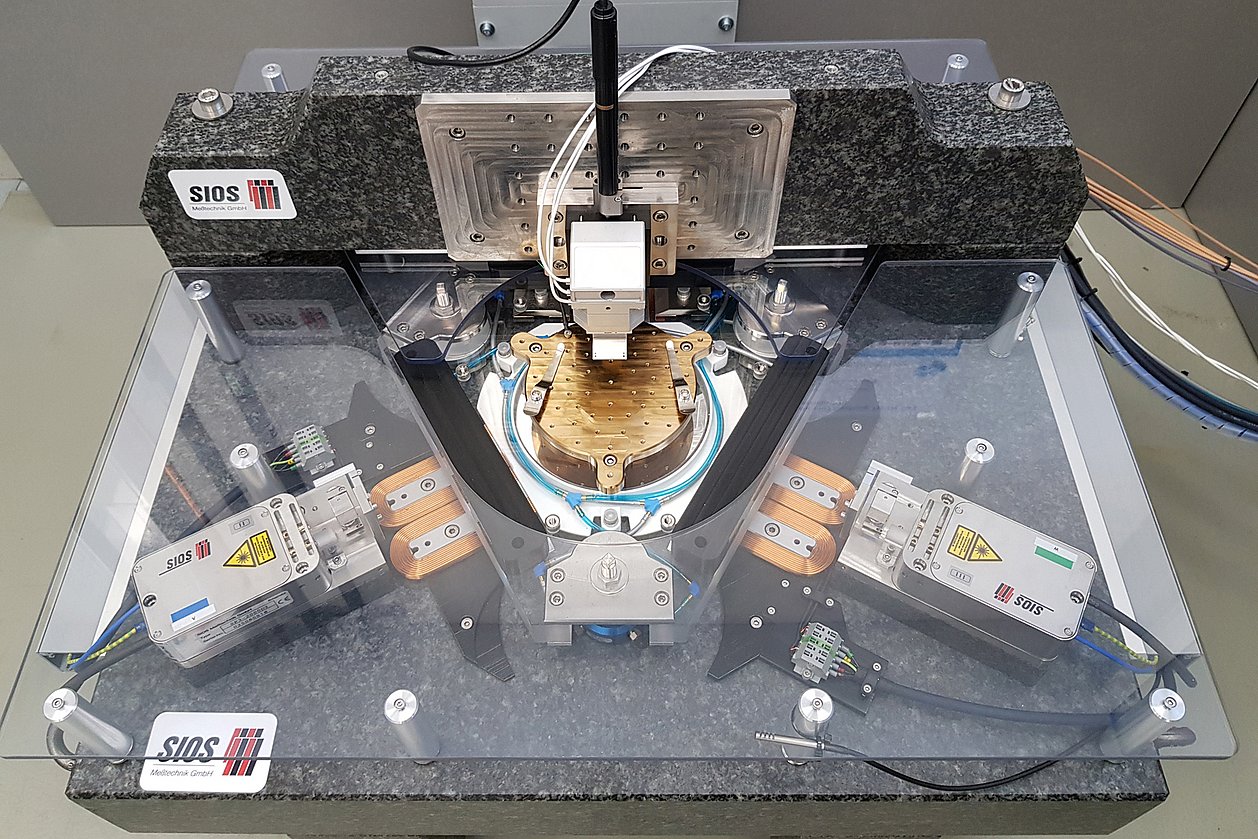

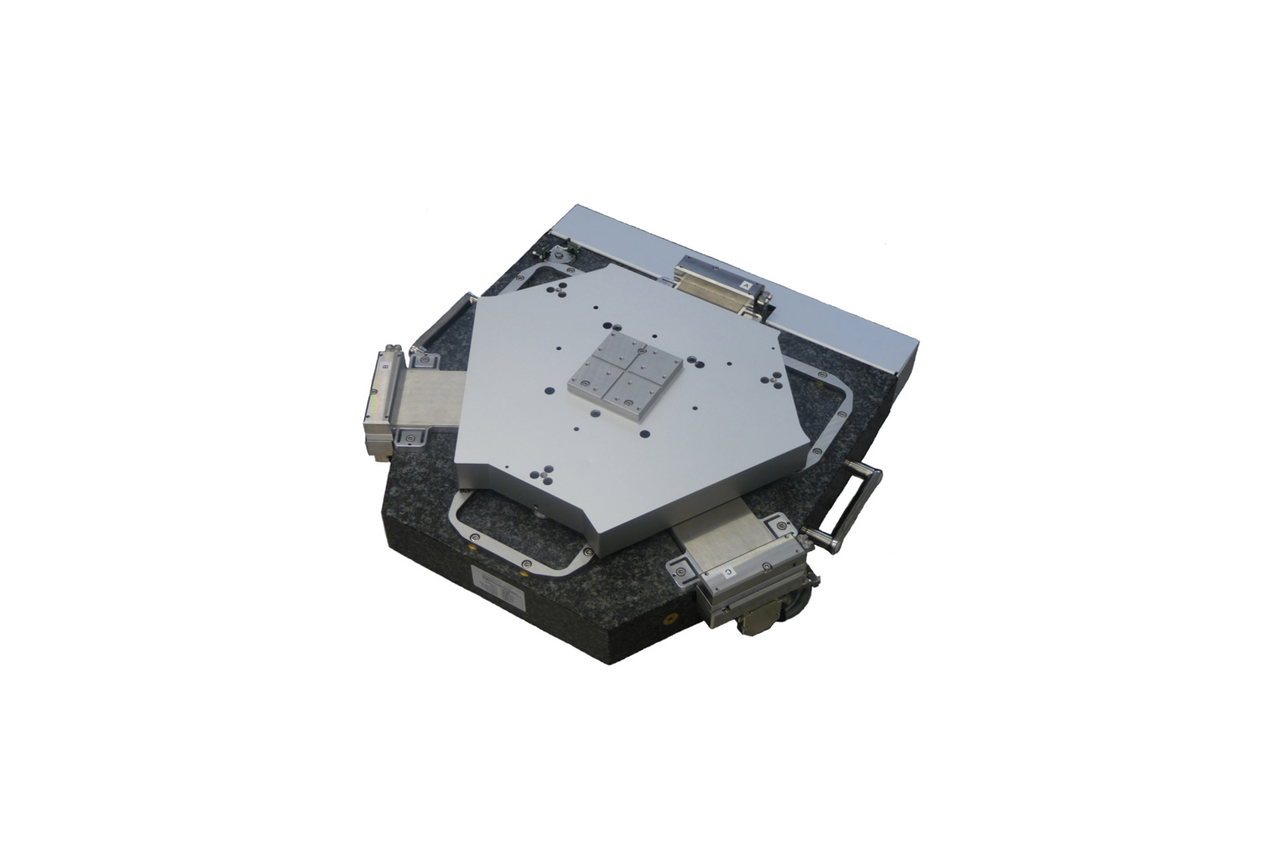

Within the project a novel planar drive system was developed which is magnetically guided and moves objects with nanometer precision.

Systems like the Mag6D will be necessary for a particle-free production of microchips or for certain processes in materials research, surface measurement technology, the life sciences and the biotech sector. This high-precise positioning system moves a load accurately through six coordinates – the three spatial axes and the rotation around each of them. The stage levitates, supported only by a magnetic field which serves as drive and guidance for all the axes. The stage is entirely cable-free and functions without any form of contact, with the consequence that it will work in absolutely clean environments almost without generating any contaminant particles at all.

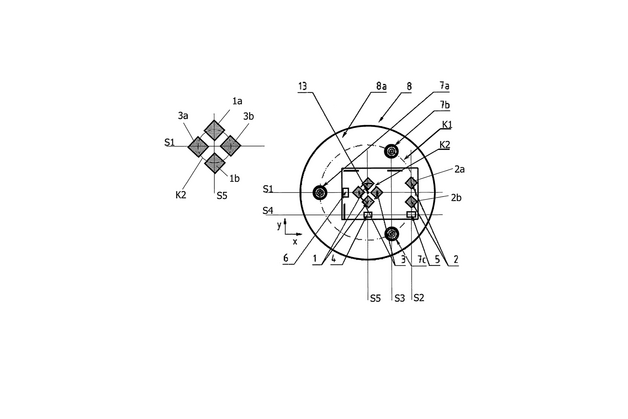

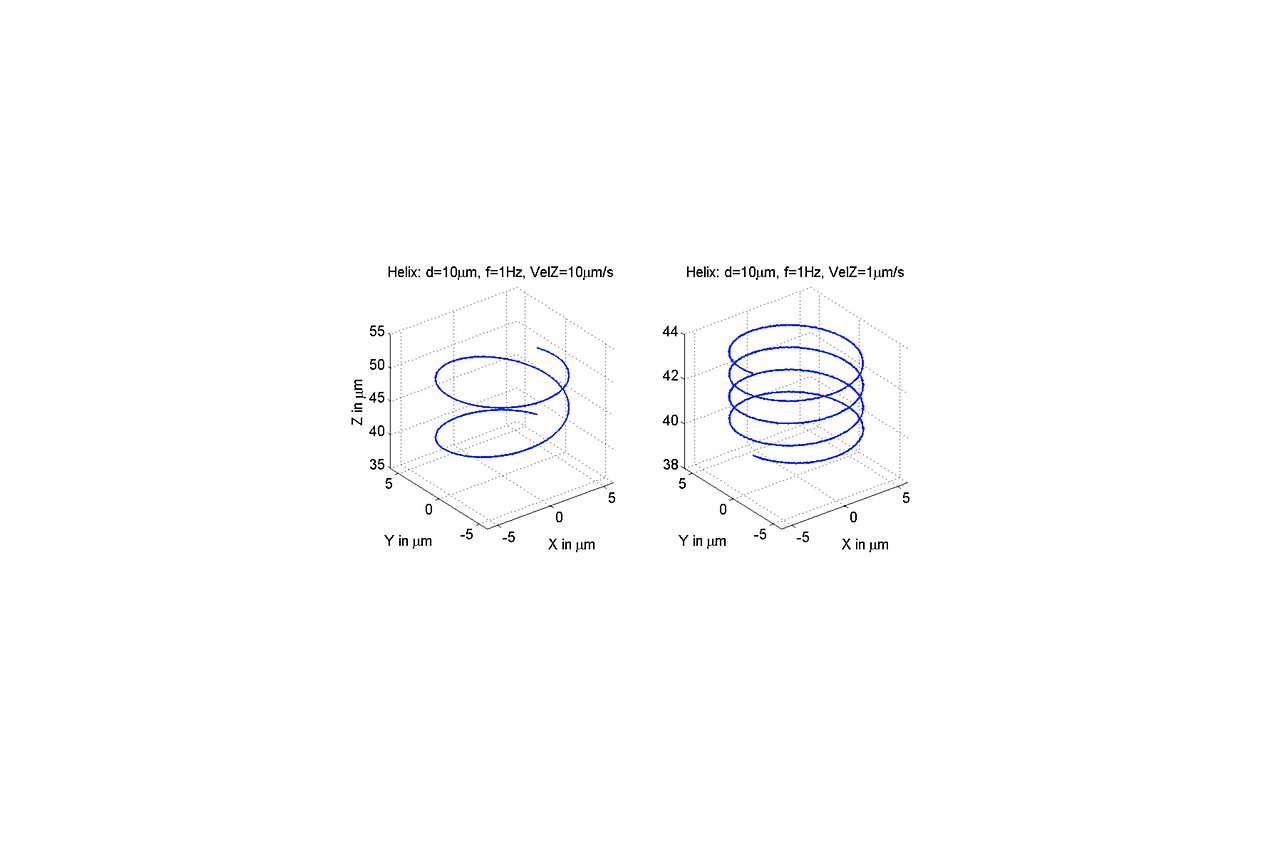

The positioning of the stage within the six degrees of freedom is modified by an optical incremental measurement system with a new type of sensor head made up of optical and capacitive sensors. The drive achieves highly precise movement: deviation from the ideal is never more than ten nanometers.

For the prototype system, the IMMS has developed a planar magnetic drive system. In addition, the Institute has created a compensation method which automatically covers the manufacturing and material tolerances of assemblies. With the aid of correction matrices in the control loop it allows a nanometer-precise movement in six dimensions.

The partner PI offers the system under the name PIMag®6D.

Acronym / Name:

Mag6D / Development of a technologically new, magnetically guided 6D-positioner for high-precision scanning applications in the field of surface profiling and biotechnology.Duration:2010 – 2011

Application:

Research institutions and ultra-precision mechanical engineering| 6D-positioning of objects even in vacuum| high-precision-drive-technology| biotechnologyResearch field:Magnetic 6D-direct drives with nanometre precision

Related content

Reference

Steffen Arnold, Physik Instrumente

”Our scientists have moved forward in the company of their IMMS colleagues into magnetic drive territory where there are prospects of hitherto unattainable accuracy of positioning, whether on a plane or in 6 dimensions.”

6D planar magnetic levitation system - PIMag 6D

Christoph Schäffel1. Michael Katzschmann1. Hans-Ulrich Mohr1. Rainer Glöss2. Christian Rudolf2. Carolin Walenda2.JSME Mechanical Engineering Journal, Vol. 3 (2016) No. 1 p. 15-00111, The Japan Society of Mechanical Engineers, DOI: doi.org/10.1299/mej.15-00111

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, D-98693 Ilmenau, Germany. 2Physik Instrumente (PI) GmbH & Co. KG, Karlsruhe, Germany.6D Planar Magnetic Levitation System – Mag6D

Christoph Schäffel1. Michael Katzschmann1. Hans-Ulrich Mohr1. Rainer Gloess2. Christian Rudolf2. Christopher Mock2. Carolin Walenda2.14th International Symposium on Magnetic Bearings, Linz, Austria, www.magneticbearings.org/publications/

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, D-98693 Ilmenau, Germany. 2Physik Instrumente (PI) GmbH & Co. KG, D-76228 Karlsruhe, Germany.Planar Magnetic 6D Levitating system with Compact Sensor

Christoph Schäffel1. Michael Katzschmann1. Hans-Ulrich Mohr1. Rainer Glöß2. Christian Rudolf2. Christopher Mock2. Carolin Walenda2. R. Liang2.27th Annual Meeting of the American Society for Precision Engineering (ASPE), 2012, in Proceedings, ISBN 978-1-887706-61-2, p. 99-102

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau. 2Physik Instrumente (PI) GmbH & Co. KG, Karlsruhe, Germany.Article6D Magnetic Levitation Positioning System with Compact Integrated 6D Sensor

C. Rudolf1. C. Mock1. C. Walenda1. R. Glöss1. R. Liang1. C. Schäffel2. M. Katzschmann2. H.-U. Mohr2.12th EUSPEN International Conference, 2012, in Proceedings P7.04 Vol II, ISBN 978-0-9566790-0-0

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau. 2Physik instrumente Karlsruhe Germany.Article

Patent

DE 10 2010 014 663

Device for determining the position of a rotor element in a planar drive and similar motion system

Press release,

IMMS für den Innovationspreis Thüringen 2012 nominiert

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Funding

The Mag6D project was funded by the ZIM programme “Central Innovation Programme SME” promoted by the German Federal Ministry of Economic Affairs and Technology (BMWi), grant number KF2534501BN9.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)