Patent DE 10 2010 014 663

Device for determining the position of a rotor element in a planar drive and similar motion system

Device for determining the position of a rotor element in a planar drive and similar movement system,

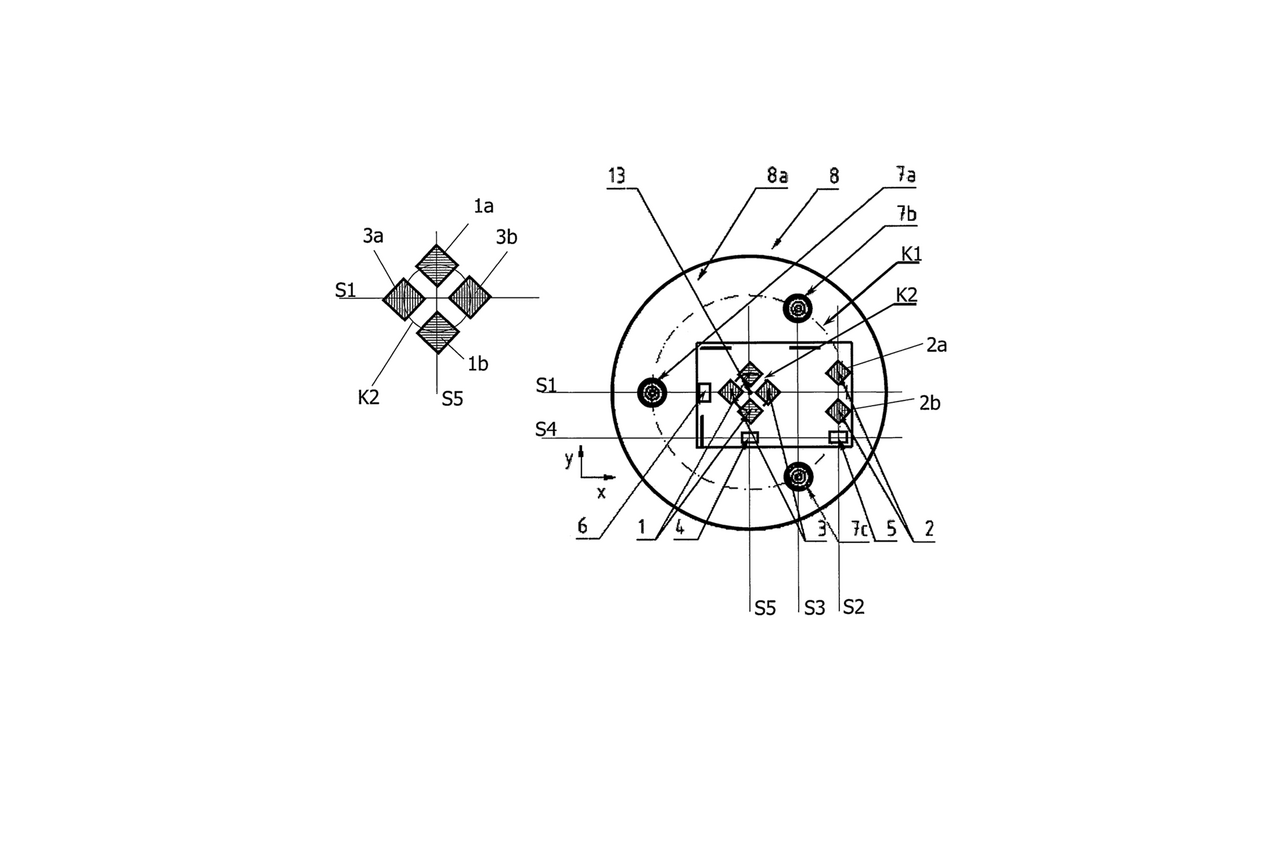

- comprising a compact sensor measuring head (8) with sensor elements (1, 2, 3, 4, 5, 6, 7) arranged on a sensor carrier (8a) for detecting movements of the slider element in three translational degrees of freedom (x, y, z) and three rotational degrees of freedom (rx, ry, rz) as well as

- an incremental surface scale (9) moved relative to the sensor measuring head, scanned by the sensor elements and arranged opposite the sensor elements,

characterised in that a first sensor element (1), a second sensor element (2) and a third sensor element (3) are in the form of a first pair of elements (1a, 1b), a second pair of elements (2a, 2b) and a third pair of elements (3a, 3b), a seventh sensor element (7) is in the form of a multiple element (7a, 7b, 7c), wherein the multiple element (7a, 7b, 7c) is evenly distributed on a first scanning circuit (K1), the first pairs of elements (1a, 1b) and third pairs of elements (3a, 3b) are arranged evenly on a second scanning circuit (K2) in the form of individual elements located opposite one another in each case, and the first scanning circuit (K1) and the second scanning circuit (K2) have a common scanning centre (13).

Features, advantages:

- direct, non-contact 6D position determination of the moving part of a high-precision positioning system

- all sensor elements are spatially close to each other and measure the displacement of one and the same monolithic object, e.g. a cross grid with coating, thus short metrological loops and minimisation of interferences on the position determination

- No sensor-related supply lines to the moving part required

- Higher accuracy of position detection compared to a serially stacked measuring arrangement

These advantages come into play with

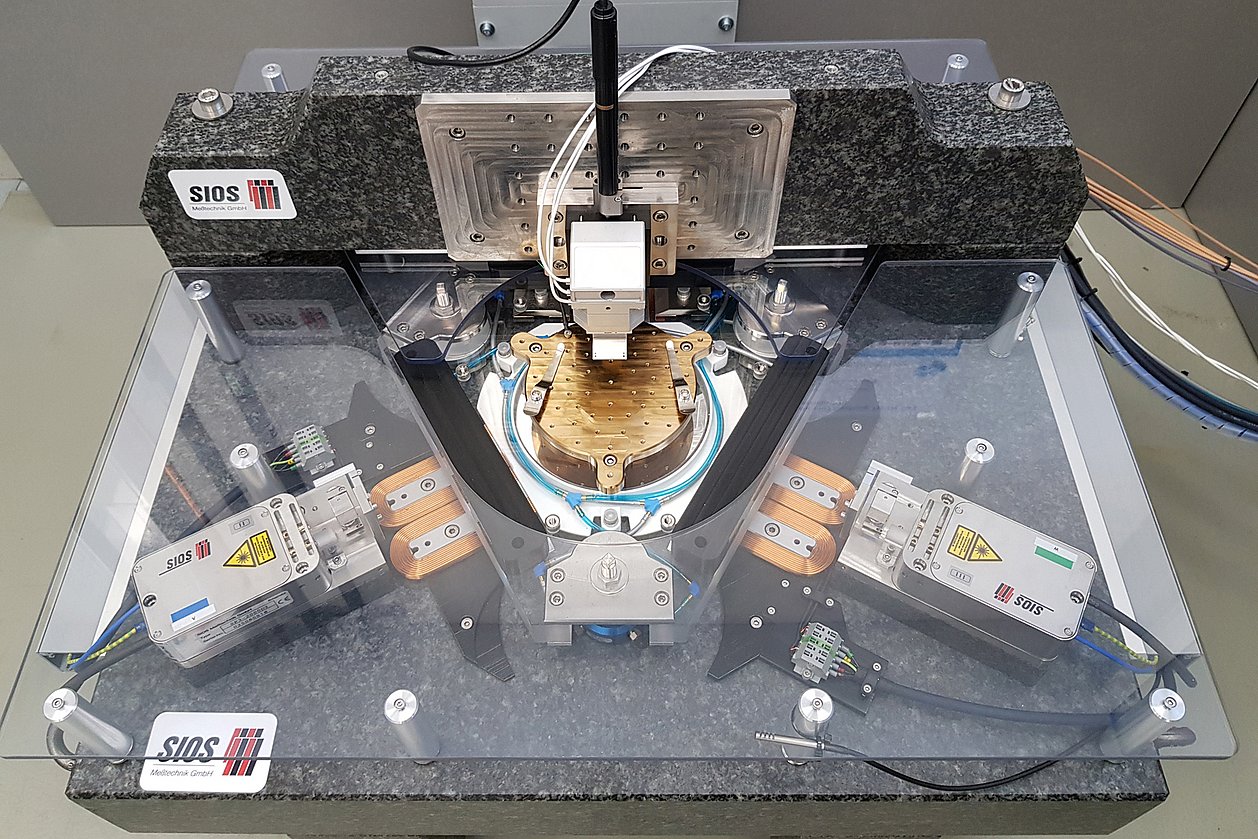

- 6D controlled nanopositioning systems with a large planar working range and an additional vertical adjustment of the moving slider

- Magnetic 6D direct drives with nm precision and nm measurement and structuring of objects

Patent No.:DE 10 2010 014 663

Inventor:Christoph Schäffel. Hans-Ulrich Mohr. Dominik Karolewski. Steffen Hesse. Michael Katzschmann

Application:

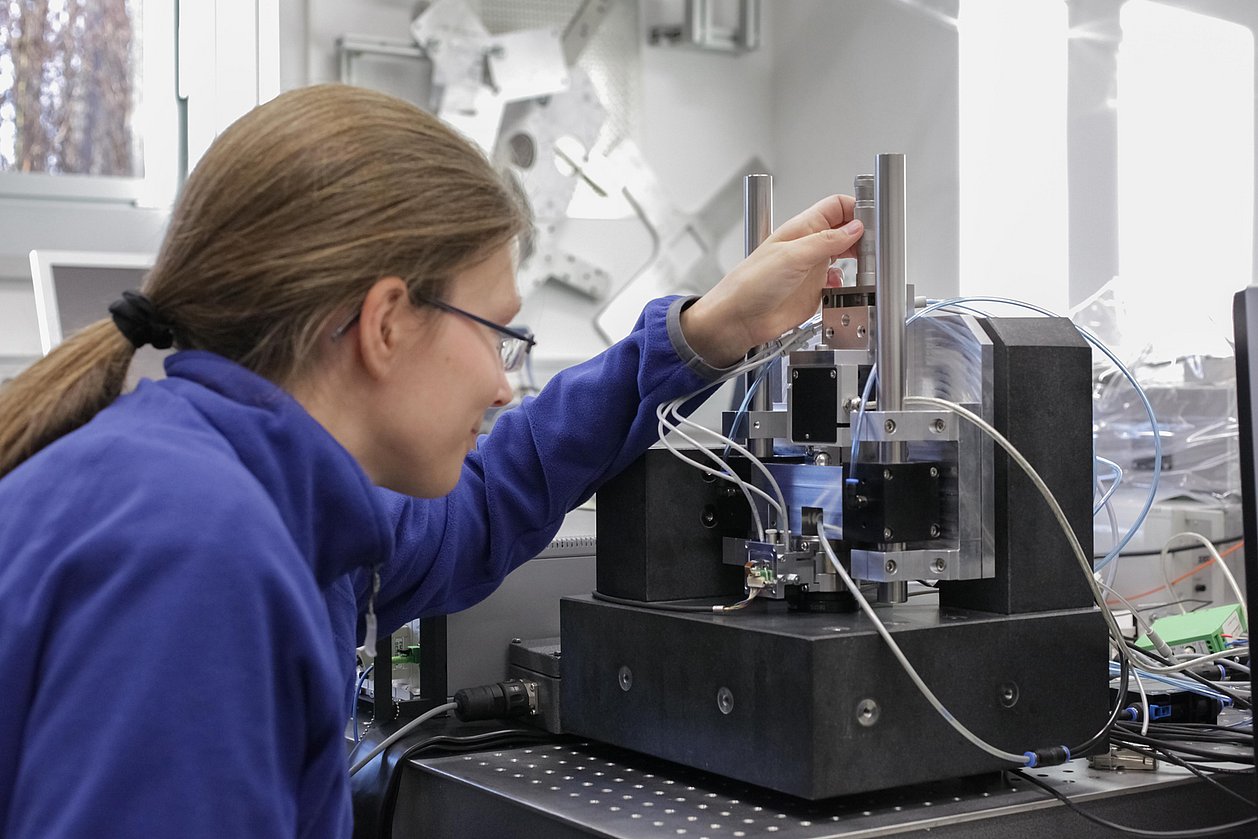

High-precision nanopositioning| nm measurement and structuring of objects| application or production of high-precision measurement and production technology systems (e.g. semiconductor/microelectronics production)Research field:Magnetic 6D-direct drives with nanometre precision

granted patent

Application date:12 April 2010

Date of first publication:21 July 2011

Date of publication of grant:30 April 2015

Related content

Project

Mag6D

Within the project a novel planar drive system was developed which is magnetically guided and moves objects with nanometer precision.

Press release,

IMMS für den Innovationspreis Thüringen 2012 nominiert

6D planar magnetic levitation system - PIMag 6D

Christoph Schäffel1. Michael Katzschmann1. Hans-Ulrich Mohr1. Rainer Glöss2. Christian Rudolf2. Carolin Walenda2.JSME Mechanical Engineering Journal, Vol. 3 (2016) No. 1 p. 15-00111, The Japan Society of Mechanical Engineers, DOI: doi.org/10.1299/mej.15-00111

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, D-98693 Ilmenau, Germany. 2Physik Instrumente (PI) GmbH & Co. KG, Karlsruhe, Germany.6D Planar Magnetic Levitation System – Mag6D

Christoph Schäffel1. Michael Katzschmann1. Hans-Ulrich Mohr1. Rainer Gloess2. Christian Rudolf2. Christopher Mock2. Carolin Walenda2.14th International Symposium on Magnetic Bearings, Linz, Austria, www.magneticbearings.org/publications/

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, D-98693 Ilmenau, Germany. 2Physik Instrumente (PI) GmbH & Co. KG, D-76228 Karlsruhe, Germany.Planar Magnetic 6D Levitating system with Compact Sensor

Christoph Schäffel1. Michael Katzschmann1. Hans-Ulrich Mohr1. Rainer Glöß2. Christian Rudolf2. Christopher Mock2. Carolin Walenda2. R. Liang2.27th Annual Meeting of the American Society for Precision Engineering (ASPE), 2012, in Proceedings, ISBN 978-1-887706-61-2, p. 99-102

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau. 2Physik Instrumente (PI) GmbH & Co. KG, Karlsruhe, Germany.Article6D Magnetic Levitation Positioning System with Compact Integrated 6D Sensor

C. Rudolf1. C. Mock1. C. Walenda1. R. Glöss1. R. Liang1. C. Schäffel2. M. Katzschmann2. H.-U. Mohr2.12th EUSPEN International Conference, 2012, in Proceedings P7.04 Vol II, ISBN 978-0-9566790-0-0

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau. 2Physik instrumente Karlsruhe Germany.Article

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.