Dr. Katja Nicolai, IL Metronic

“From my point of view, the numerous outcomes, many of them already validated by demonstrators, speak for themselves. These wireless solutions with their energy self-sufficiency are blazing the trail for quick, cheap and easy retrofitting. I envisage their use not only in manufacturing processes but in other areas such as transport and logistics.”

”At IL Metronic, we develop, manufacture and distribute glass-to-metal feedthroughs for specific customer needs; also, sensors, sensor modules and electronic equipment for fields where sensors are combined with UV or wet locations. Additionally, we are in constant cooperation with universities and scientific institutes on various R&D matters. In my role as head of the industrial advisory council to the Green-ISAS research group in Thüringen, I have accompanied IMMS in developing basic technologies to underpin sensor-actuator systems which can be applied autonomously in Industry 4.0 settings. This work is of great interest not only to us at IL Metronic but also to many other companies around us.

Companies need production to be networked, automated and flexible in order to provide high quality in an efficient way. To achieve this, there are many points at which measurements and control data need to be captured, processed and transmitted. Machinery in these companies is rarely laid out in ways that suit such data capture and neither is it easy to equip with the necessary sensors. A universal upgrade of the sensor systems is not a simple matter. In many cases, sensors will have to work independently on a single machine. On that machine the sensor(s) are increasingly being required to carry out complex tasks, yet consume a minimum of energy. This balancing act is still no easy, automatic task. The technology is often at its limits and there remains a need for considerable research, which is, however, beyond the scope of SMEs as individual companies.

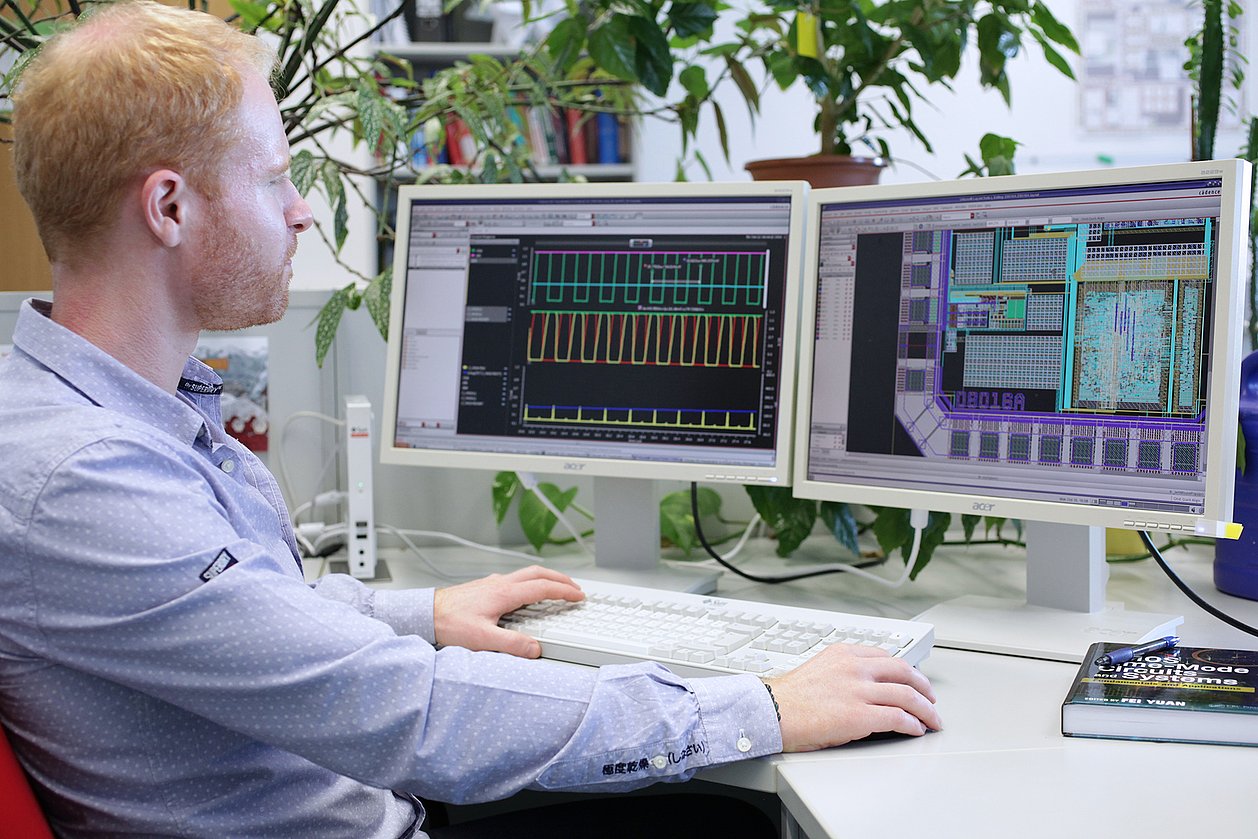

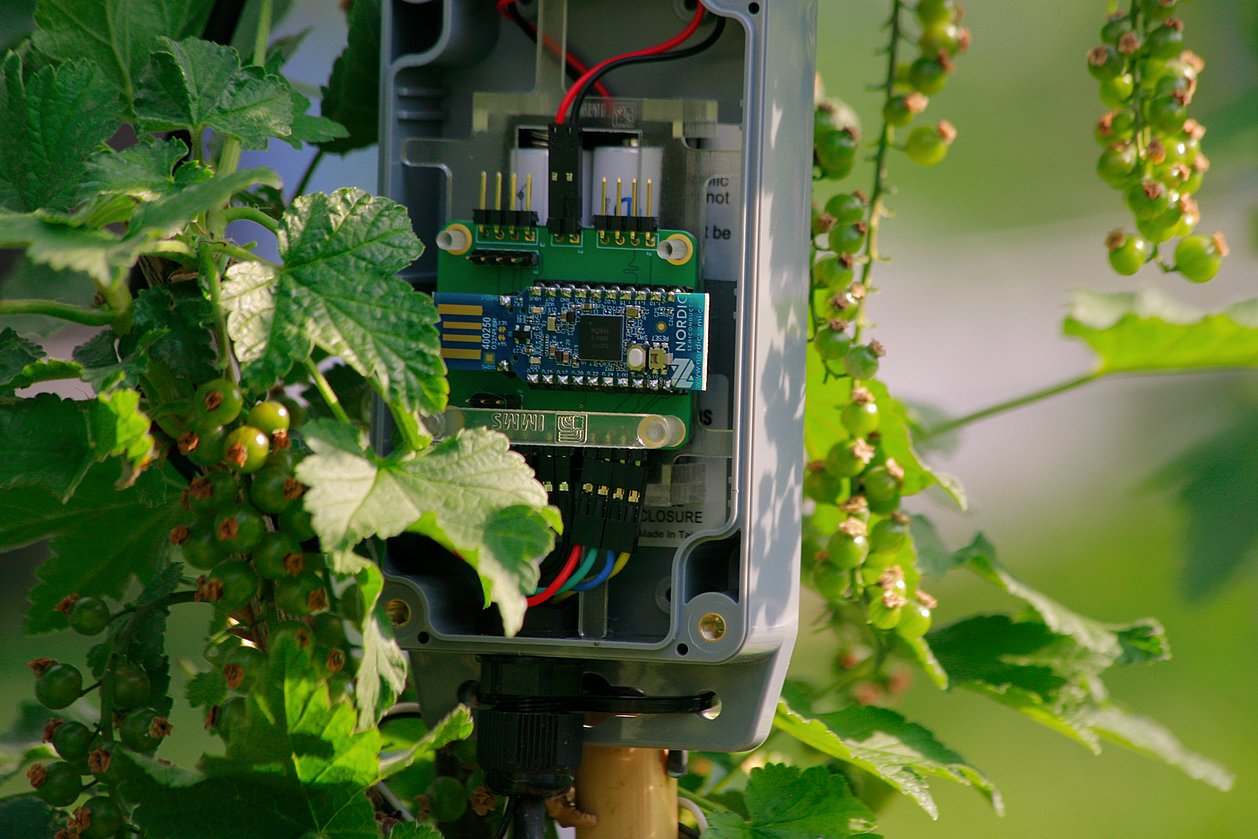

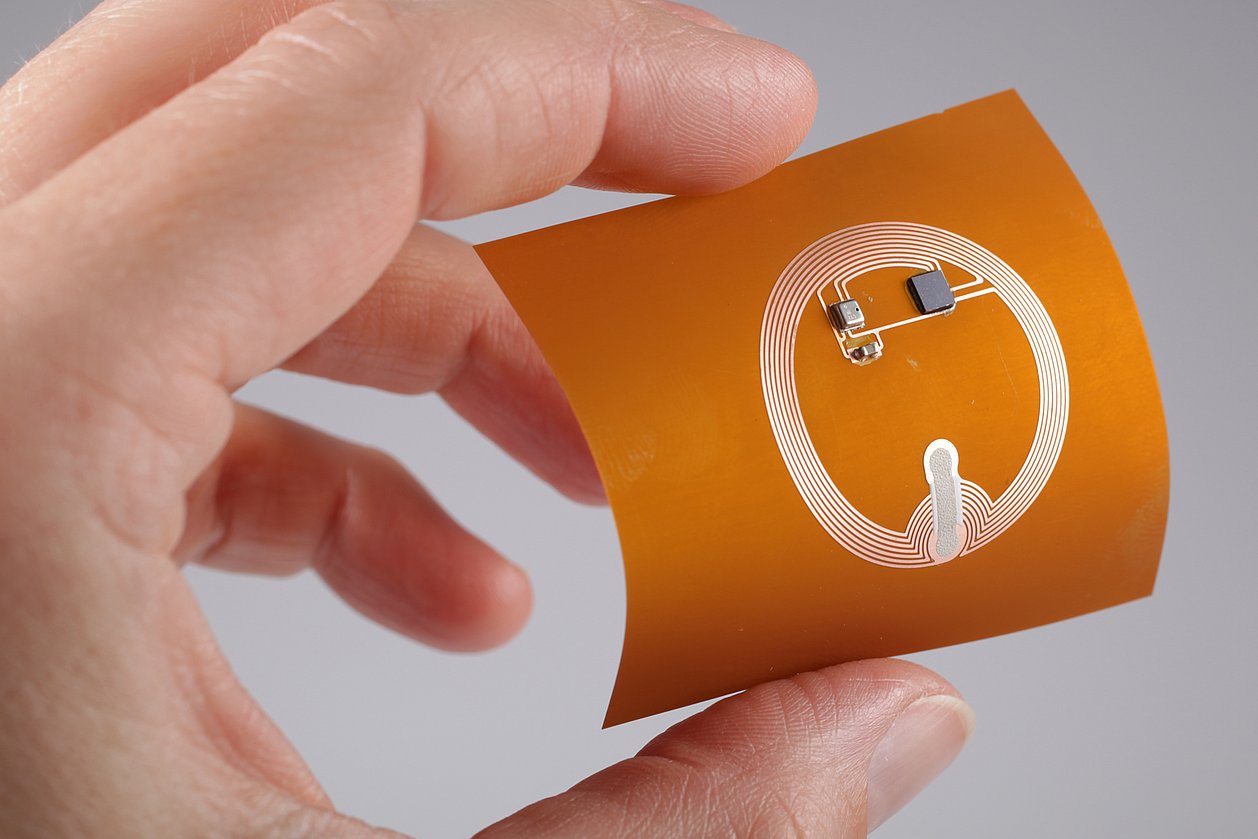

The IMMS scientists have been open from the first in presenting us, the advisory council, with their work and concepts. In early conversations and then regular workshops they have updated us on how they are approaching the demands in this area. In a mere two years, they have researched and developed a variety of solutions which, by means of new ideas on system architecture and smart energy management, result in more energy-efficient sensors, provide the sensor systems with a better energy supply and optimise the use of resources. Developments include two chips with minimum energy consumption together with their dedicated measurement technology, smart self-powering and energy-managing sensor systems and a design tool for application-specific energy harvesters. These harvesters exploit fine vibrations to supply the energy for independent smart sensors capable of monitoring machinery and plant.

From my point of view, the numerous outcomes, many of them already validated by demonstrators, speak for themselves. These wireless solutions with their energy self-sufficiency are blazing the trail for quick, cheap and easy retrofitting. I envisage their use not only in manufacturing processes but in other areas such as transport and logistics.

We are looking forward to addressing more questions with IMMS and carrying out the joint project for which a funding application has already been made.“

The reference is related to:

Contact

Contact

Dr.-Ing. Tino Hutschenreuther

Head of System Design

tino.hutschenreuther(at)imms.de+49 (0) 3677 874 93 40

Dr. Tino Hutschenreuther will answer your questions on our research in Smart distributed measurement and test systems and the related core topics Analysis of distributed IoT systems, Embedded AI and Real-time data processing and communications, on the lead applications Adaptive edge AI systems for industrial application and IoT systems for cooperative environmental monitoring as well as on the range of services for the development of embedded systems.