Project Multi-Interact

For health research, a highly parallelised multiplex system is being developed to precisely and kinetically determine binding energies between biomolecules.

In health research, it is necessary to determine various biomarkers of the biomolecules to be analysed using multiplexing technologies for effective development processes in the fields of diagnostics and pharmaceutics. To this end, interaction processes between the molecule groups are to be analysed using parallel measurements.

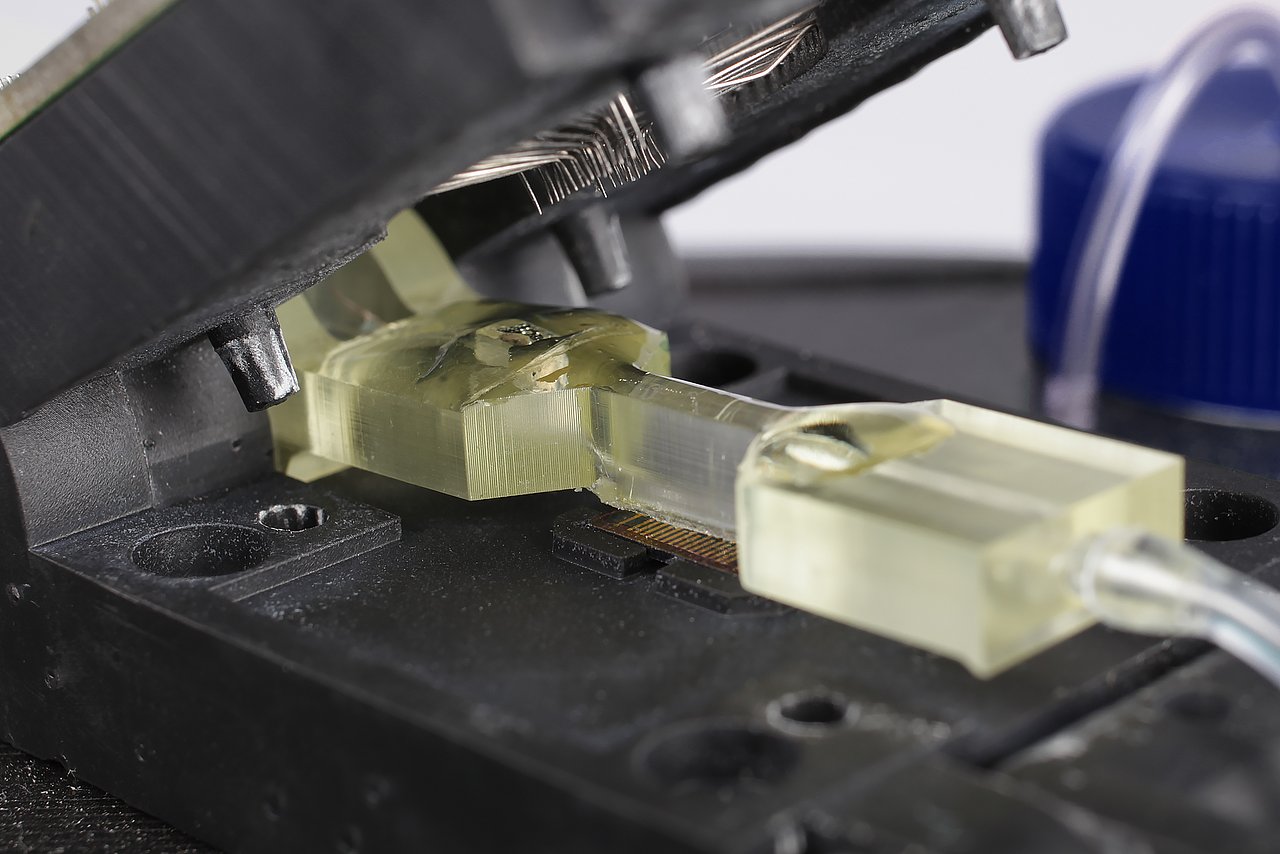

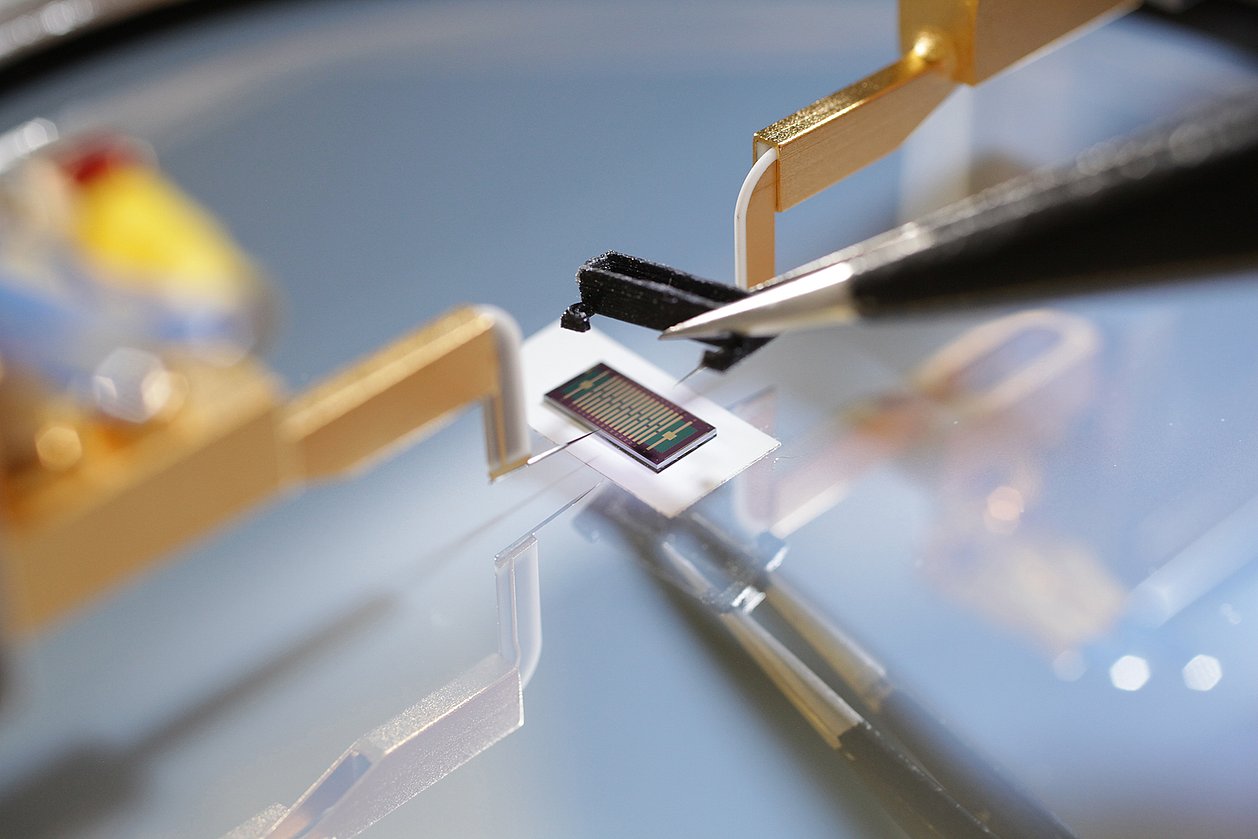

With the help of functionalised carbon nanomembranes on graphene field effect transistors (GraFET) and an electronic circuit for measurement and evaluation, it is possible to determine these biological interactions. If these GraFETs are multiplied with different functionalisation layers, the kinetic binding energies of different biomarkers can be determined in parallel by multiplexing. The measurement is thus scalable and can later enable a low-cost device design.

Research tasks of the project partners

IPHT Jena will develop miniaturised sensor arrays for the multiplex system and FSU Jena will develop highly sensitive graphene with carbon nanomembranes. IMMS will develop the electronic, highly parallelised readout methods and electronics and the FZMB will research the possibilities for detecting the label-free binding of active ingredients and substances in complex biological matrices.

IMMS measurement electronics

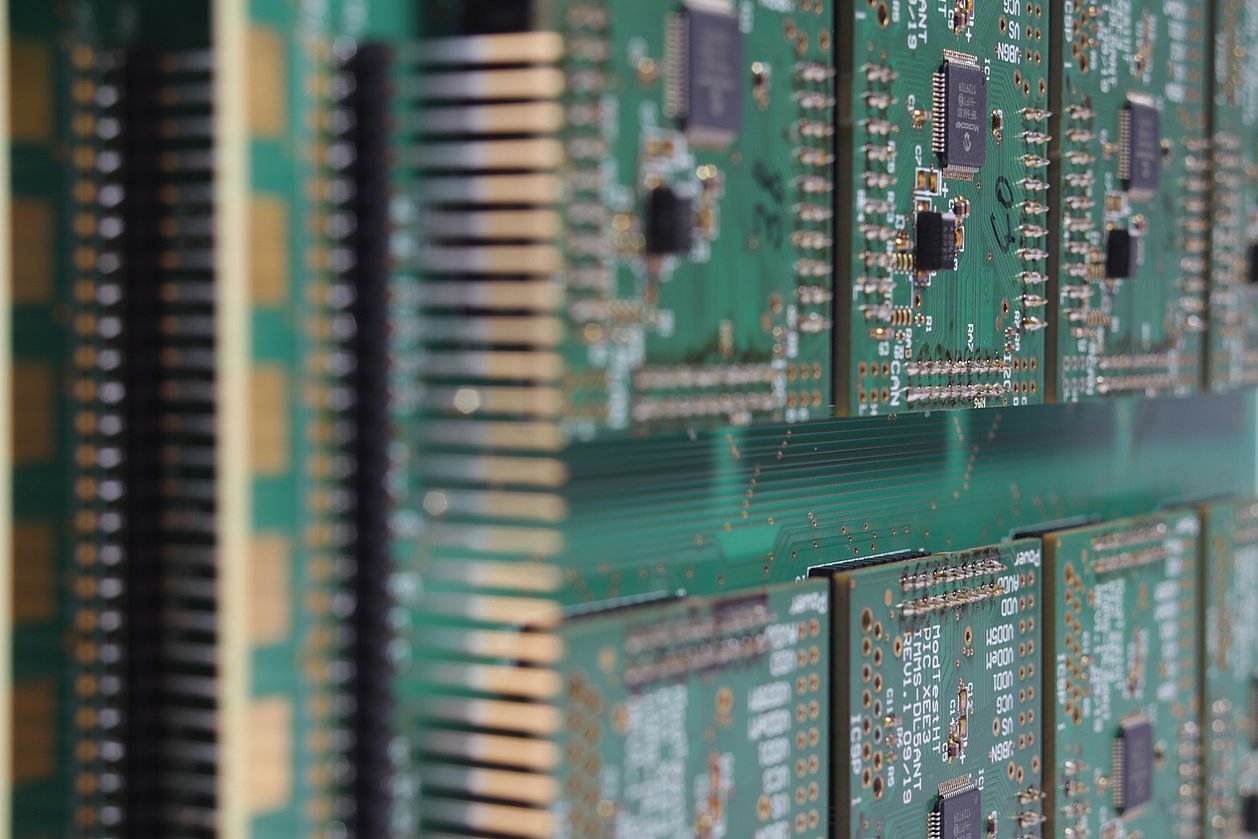

The binding of biomarkers on the surface of the GraFET causes charge carriers to accumulate there. This variation correlates with the change in the charge neutrality point (CNP) of the GraFET. To this end, IMMS will develop, construct and characterise measurement electronics that determine the CNP of several GraFETs in parallel.

An automated test setup will then be used to visualise the readout of an up to 100-fold GraFET array in real time on a PC.

Acronym / Name:

Multi-Interact / Biointeraction technology based on 2D sensor materials for time-resolved multiparameter analysis in the pharmaceutical and diagnostics sectorDuration:2025 – 2027

Application:

Life Sciences|Bioanalytics| characterisation of biomarkers| kinetic determination of binding energyResearch field:Smart distributed measurement and test systems

Contact

Contact

Dipl.-Ing. Michael Meister

Head of Industrial Electronics and Measurement Technology

michael.meister(at)imms.de+49 (0) 3677 874 93 20

Michael Meister is your contact for testing services, the development of test methodologies, and long-term measurements. He answers your questions on Modular and mobile test systems that we develop in our research in Smart distributed measurement and test systems as well as about testing and characterisation of integrated sensor systems. He is responsible for the test equipment at IMMS and will support you in the validation of ASIC and MEMS developments.

Funding

The Multi-Interact research group is funded by the German Land of Thüringen and the European Social Fund Plus (ESF+) under the reference 2024 FGR 0070.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/7/csm_20130223_dcSen_ProberEF_MM_MG_3325_1920x1280_588e478d86.jpg)