Patent DE 10 2021 103 220

Positioning system for the three-dimensional positioning of an object and method for its operation

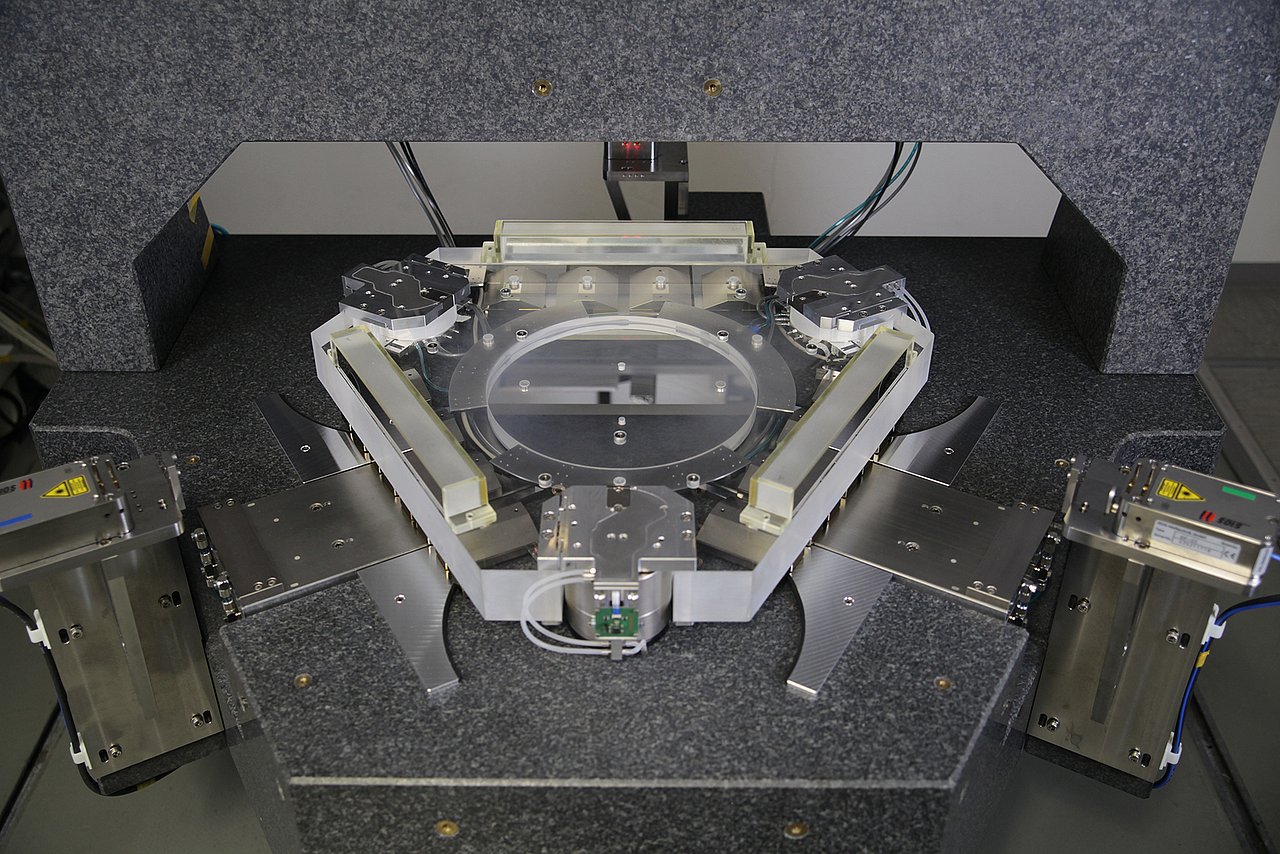

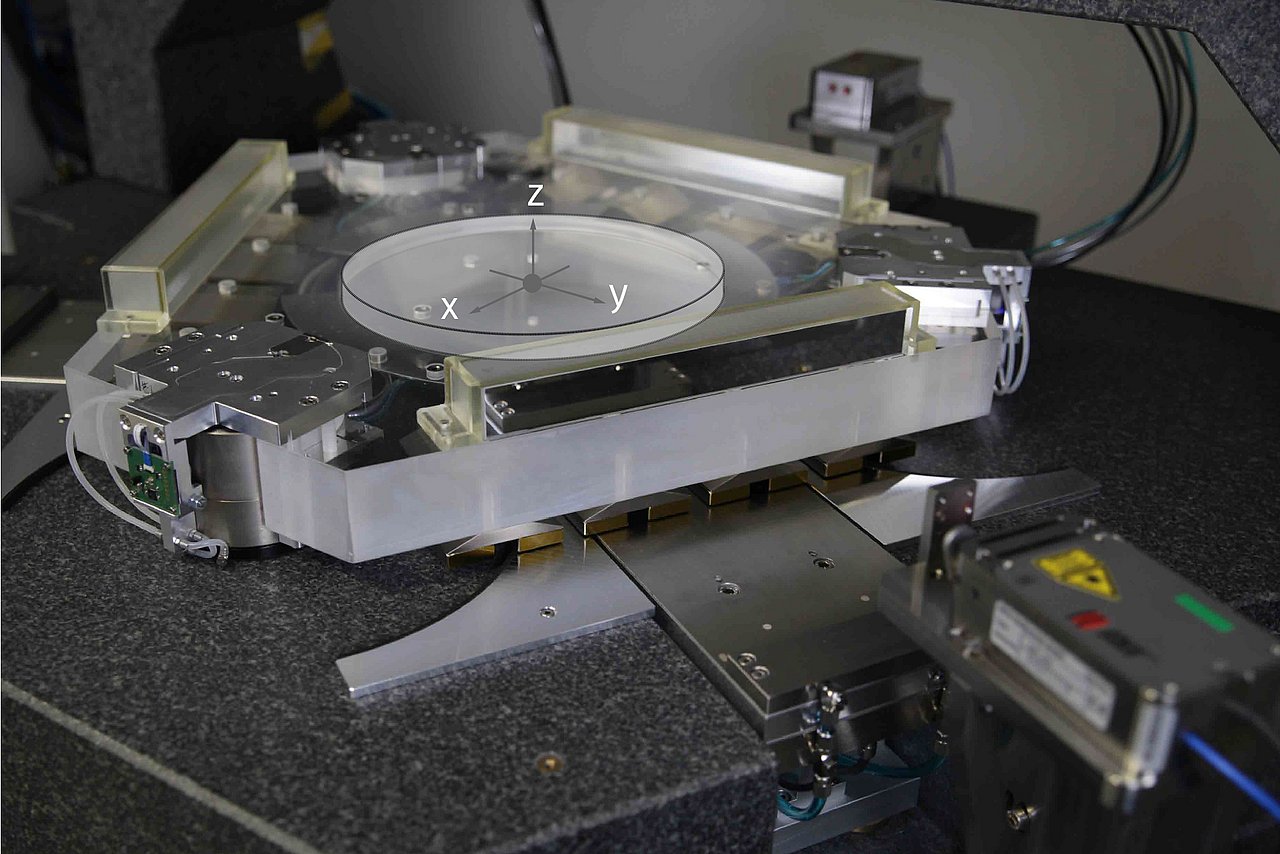

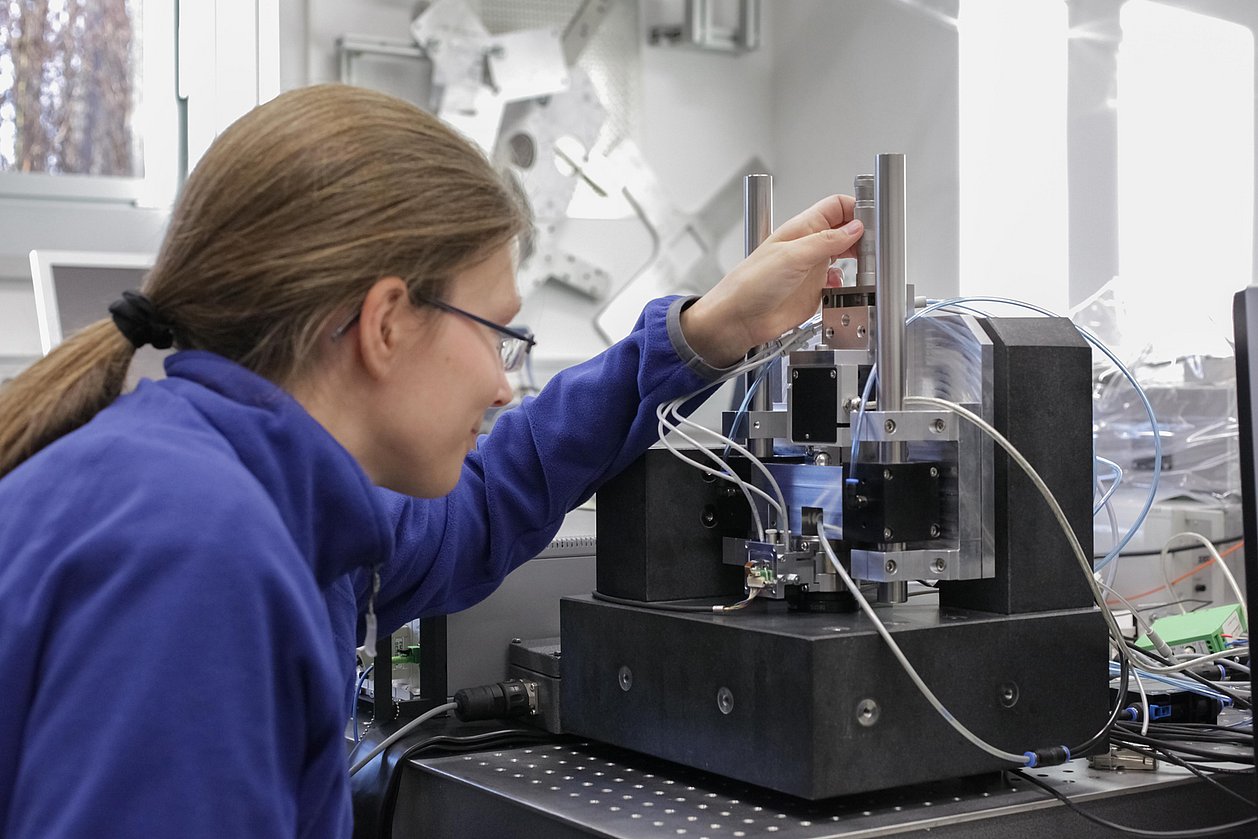

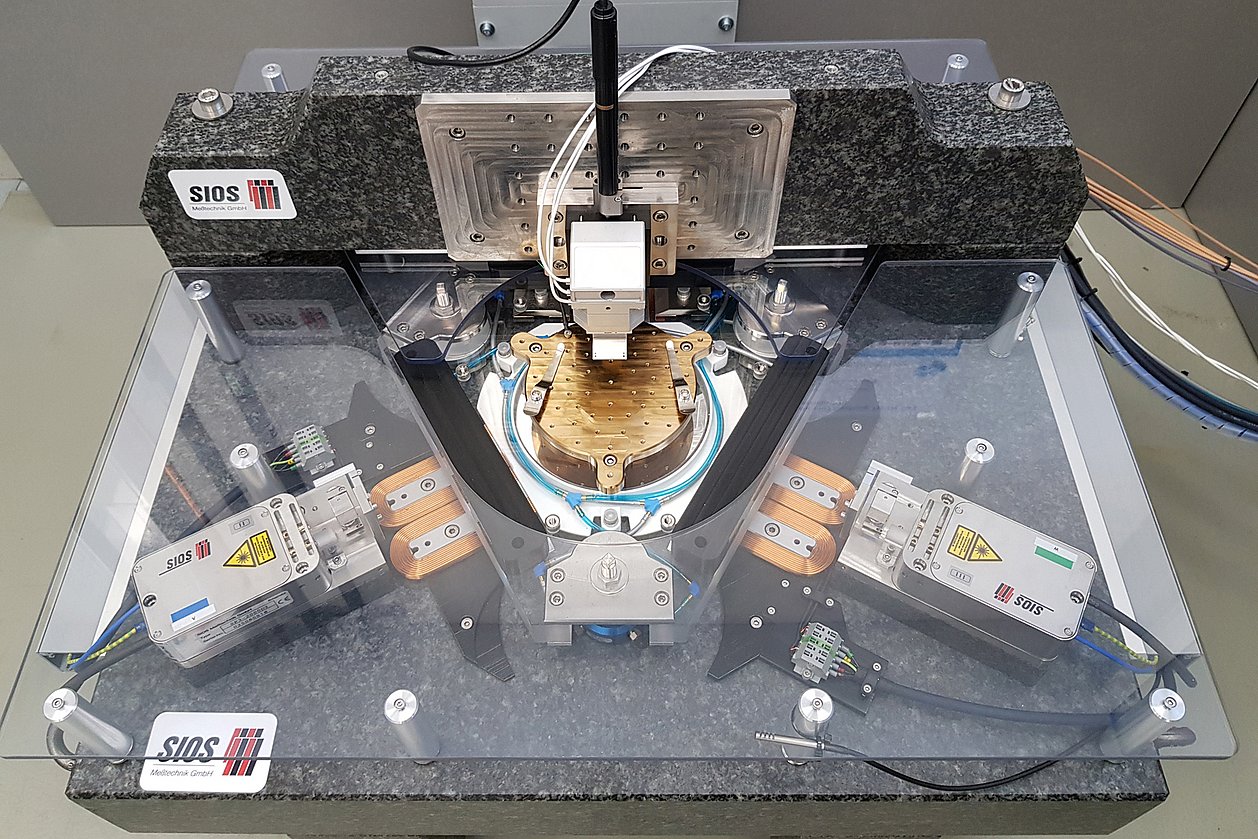

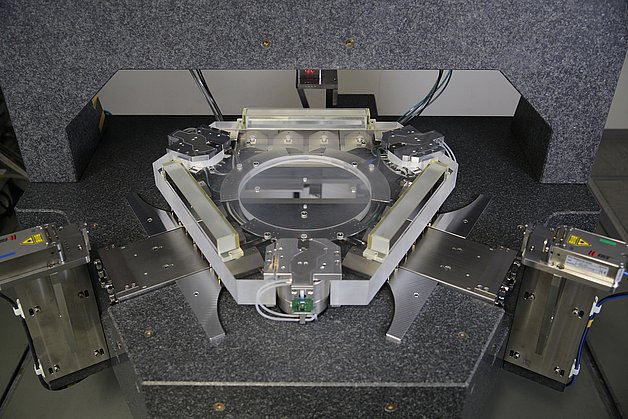

The invention relates to an extension of the function of a nanopositioning system developed at IMMS with a planar drive, aerostatic slider guidance and laser interferometric displacement and angle measurement. The (planar) slider is additionally equipped with aerostatically guided actuator systems that allow the slider to be lifted with virtually no ohmic power loss. The horizontal drive force is generated via frame-fixed flat coils and moving magnets.

The idea of the invention is to track the planar drive coils (flat coils) of the vertical slider movement by lifting them in order to maintain an almost constant distance between the coils and the slider. This allows the range in which nanometre-precise positioning in the vertical direction is possible to be increased from 10 to 25 mm.

The focus is on the measurement, calibration and manipulation/processing of objects such as

- Step height standards and periodic standards for calibration

- Micro components and optical filter elements

- flat optical components, curved mirrors, lenses, lens arrays, Fresnel lenses, spheres and aspheres etc.

- Wafers The invention enables the realisation of large vertical travel ranges of, for example, x, y, z: 200 x 200 x 25 mm3.

The positioning system comprises a stator arranged in an x-y plane, which indirectly carries electric magnetic coils (01). The positioning system also comprises a slider with permanent magnets arranged above the stator. By energizing the coils (01), forces can be generated on the permanent magnets in order to position the slider in a plane parallel to the x-y plane. The positioning system further comprises at least one positioning actuator located on the stator for positioning the slider in a z-direction perpendicular to the x-y plane and at least one coil actuator (11) located on the stator for positioning the coils (01) in the z-direction. The invention also relates to a method for operating the positioning system according to the invention.

Patent No.:DE 10 2021 103 220

Inventor:Steffen Hesse. Christoph Schäffel. Michael Katzschmann. Bianca Leistritz. Stephan Gorges. Jorge Amado Gonzalez Whittinham

Application:

nanometre-precise measurement| calibration and manipulation/processing of objectsResearch field:Magnetic 6D-direct drives with nanometre precision

published patent application

Application date:11 February 2021

Date of first publication:11 August 2022

Related content

Project

K4PNP+Z

IMMS developed actuators to position objects in planes with diameters up to 200 mm and a vertical stroke of 25 mm with nanometre precision.

NPS6D200 – A Long Range Nanopositioning Stage with 6D Closed Loop Control

Steffen Hesse1. Alex Huaman1. Michael Katzschmann1. Bianca Leistritz1. Ludwig Herzog1.Appl. Sci. 2024, 14, 6972. DOI: doi.org/10.3390/app14166972

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Vertikale Nanopositionierung mit bis zu 25 mm Verfahrweg – Hubmodule für die hochgenaue Positionierung im Raum

Stephan Gorges1. Steffen Hesse1. Ludwig Herzog1.Konstruktion (2023), 07-08, Sonderteil Antriebstechnik, Seite 28 - 31, VDI Fachmedien, ISSN 0720-5953, e-paper.vdi-fachmedien.de/konstruktion/2023

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.