Press releases

RoMulus research project: Intelligent sensor systems for Industry 4.0

Reducing development and manufacturing costs

- “Robust multi-sensor technology for status monitoring in Industry 4.0 applications” (RoMulus) research project

- Eleven partners researching new development methods for intelligent multi-sensor systems

- Cost-effective manufacturing, even in small quantities

- German Federal Ministry of Education and Research (BMBF) is sponsoring the project

Stuttgart, Germany – Multi-sensor systems form a crucial basis for the success of Industry 4.0 applications. They record, process, and transmit a number of measurement parameters, such as pressure, acceleration, and temperature, all in a highly compact space. Machines are not the only ones to receive such sensors; workpieces are also increasingly being fitted with the intelligent sensor systems so that each product can provide its blueprint and report its manufacturing status. Based on this information, production is largely able to organize and monitor itself.

Eleven research partners now aim to simplify and accelerate the development of intelligent multi-sensor systems. As part of the RoMulus project, they want to standardize and refine the steps leading up to the finished product in such a way that it is possible to produce even small quantities in a cost-effective manner. As a result, they are improving the market position of small- and medium-sized enterprises (SME) in the sensor technology sector.

In the future, SMEs will be able to offer their industrial customers customized sensor systems with considerably less effort and expense. The German Federal Ministry of Education and Research (BMBF) is supporting the RoMulus project as part of the IKT 2020 incentive program to the tune of approximately 4.5 million euros, which covers some 70 percent of the total investment amount.

Challenging development

The development of multi-sensor systems for Industry 4.0 applications is challenging. The task is to combine two technologies in a highly compact space, namely microelectromechanical sensors (MEMS), which measure mechanical parameters, such as pressure and acceleration, and microelectronic sensor components, which determine temperature, light intensity, and chemical concentrations. The finished systems must process large amounts of data in the most energy-efficient manner possible. Furthermore, they need to be robust enough to function reliably in an industrial setting.

Collaboration with semiconductor manufacturers and service providers

The German sensor technology sector predominantly comprises small and medium-sized enterprises. As a general rule, they are unable to cover all of the services themselves that are necessary for the development and production of multi-sensor systems, which is why they rely on close collaboration with semiconductor manufacturers and service providers for research and development. “We want to disentangle and standardize this collaboration − and thereby the design and manufacturing processes,” says project coordinator Dr. Eckhard Hennig, professor at Reutlingen University. In the future, SMEs will be able to select and compile development services as well as electronic components as if from a large kit, depending on what solution the customer requires for their very specific industrial application.

“RoMulus makes it possible to systematically design and cost-effectively manufacture robust, energy-efficient multi-sensor systems, even in small quantities. As a result, German sensor technology manufacturers are leading the field in terms of creating an important technological basis for Industry 4.0 applications,” explains Dr. Reinhard Neul from Robert Bosch GmbH.

Eleven partners from research and industry

As part of the RoMulus project, eleven partners are pooling their expertise – from semiconductor manufacturers and development companies to SMEs. They are as follows: Zeiss, the Fraunhofer Institute IIS/EAS, Reutlingen University, Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, microsensys GmbH, Robert Bosch GmbH, the Technical University of Munich, TETRA Gesellschaft für Sensorik, Robotik und Automation mbH, the University of Bremen, the University of Freiburg, and X-FAB Semiconductor Foundries AG. The edacentrum in Hanover is responsible for project management. The abbreviation RoMulus stands for “robust multi-sensor technology for status monitoring in Industry 4.0 applications.” The project began in October 2015 and is scheduled to last three years.

Press photos: Image-No. Media-ID #1-RB-22296-e, Image No. Media-ID #1-RB-22296-d

Background information on the internet: Project website www.edacentrum.de/romulus

The research partners:

- Zeiss (business sector: Semiconductor Manufacturing Technology) SMT GmbH

- Fraunhofer Institute for Integrated Circuits IIS, Division Engineering of Adaptive Systems EAS

- Reutlingen University

- IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH

- microsensys GmbH

- Robert Bosch GmbH

- Technical University of Munich

- TETRA Gesellschaft für Sensorik, Robotik und Automation mbH

- University of Bremen

- University of Freiburg

- X-FAB Semiconductor Foundries AG

Project management: edacentrum GmbH

Text source: RoMulus project consortium

Funding

The RoMulus project has been supported within the Research Programme ICT 2020 by the German Federal Ministry of Education and Research (BMBF) under the reference 16ES0362.

Related content

Project

RoMulus

Systematic design and economical manufacture for intelligent multi-sensor systems in small quantities

Patent

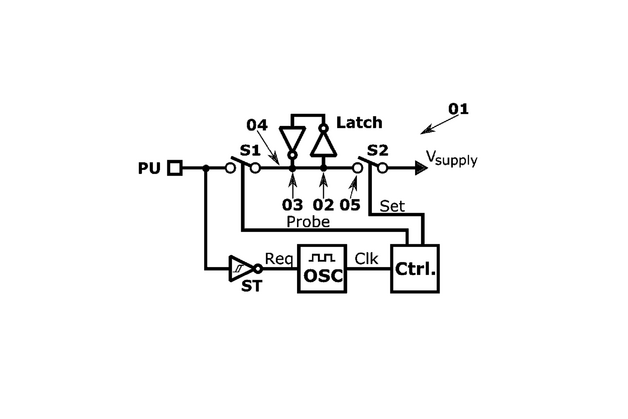

DE 10 2016 119 927

Circuit arrangement for providing the charging energy for a level change on a signal bus, calibration method and signal transmission system

Event,

CiS Workshop 2023

Workshop Simulation & Design 2023 at CiS Forschungsinstitut für Mikrosensorik

Event,

Analog 2020

Zwei Vorträge auf der 17. ITG/GMM-Fachtagung Analog 2020, Analoge Schaltungen: Schlüsselsysteme für Automotive, IoT und zukünftige drahtlose…

Event,

TuZ 2020

32. GI/GMM/ITG-Workshop Testmethoden und Zuverlässigkeit von Schaltungen und Systemen

Event,

elmug4future 2019

Two presentations at the Technology Conference on Condition, Health and Quality Monitoring – Sensors, Methods and Applications

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.