Press releases

Annual Report 2024 online

Download under www.imms.de/annualreports

Dear reades,

In 2024, we completed our internal research groups “TIRELESS”, “AI” and “NextGenPos”. These research groups, which are funded by the German Land of Thüringen, are an important building block for the further development and realisation of IMMS’ strategic goals and for transfer projects with companies. These groups work on basic principles and initiate new research and development projects for the long-term strategic orientation of the institute. We present the results to you in this report. We are delighted that Thüringen will continue to support IMMS research from 2025 with “VirtuSen”, an internal research group. This will enable young researchers to focus on doctoral topics relating to the application of AI-based virtual sensor technology to effectively increase the precision of positioning systems.

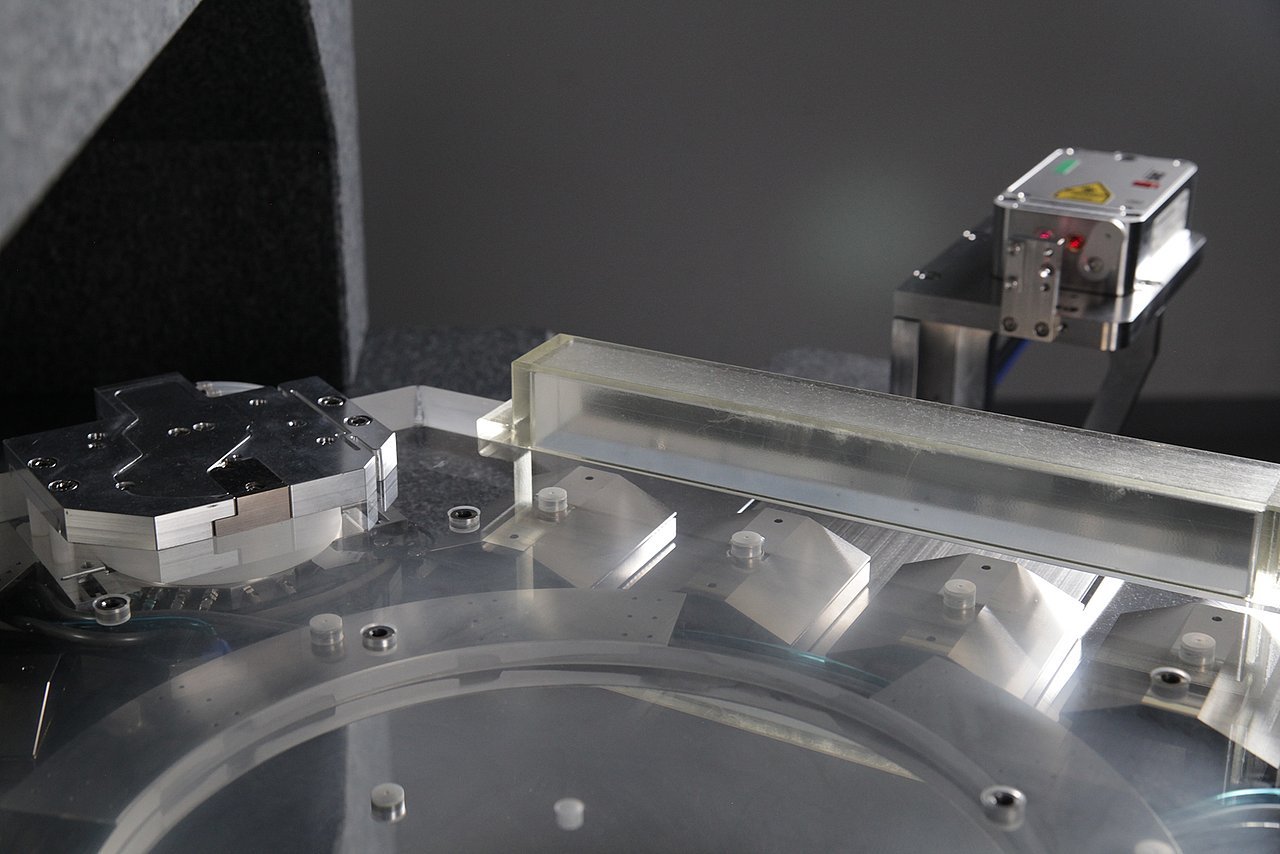

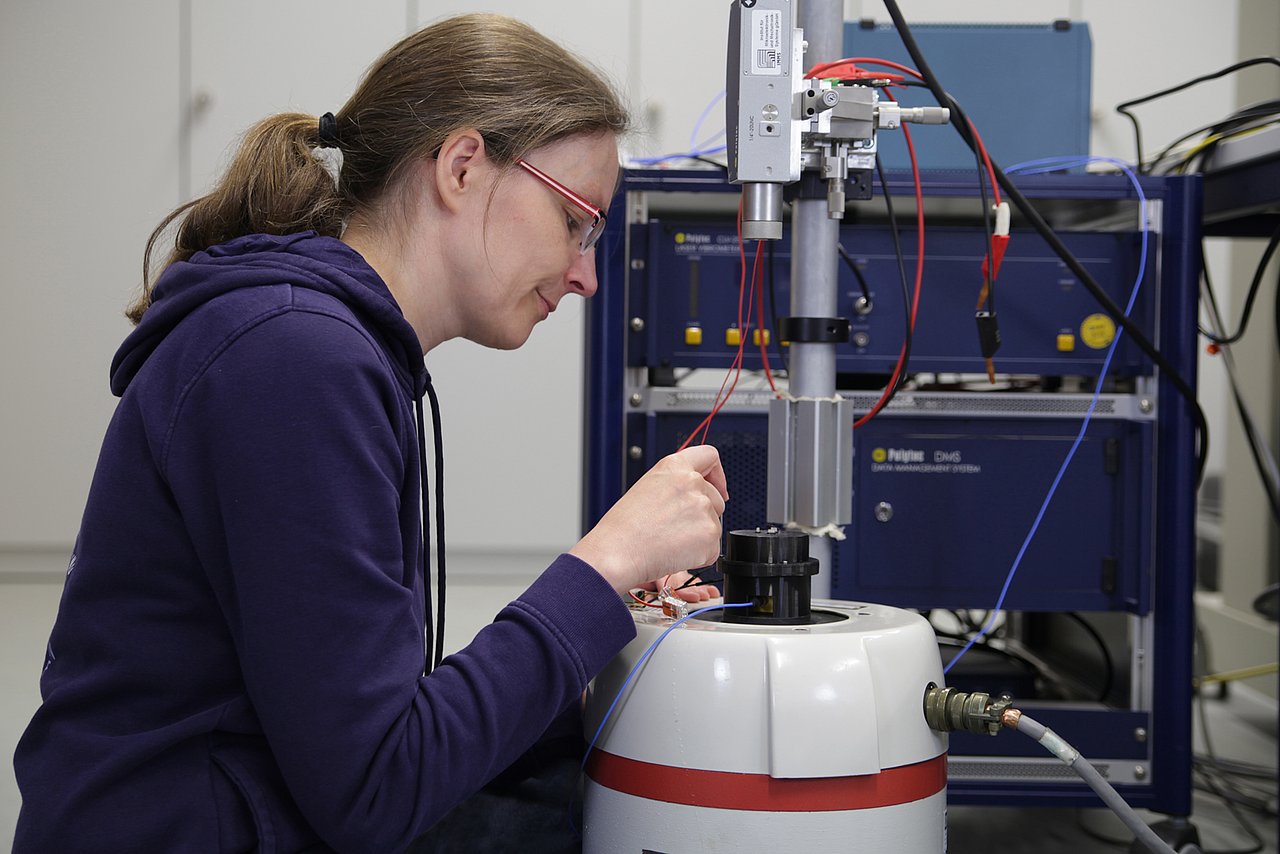

To our delight, one of our employees was not only awarded an iENA silver medal for his patent, he also successfully defended his dissertation on a new control concept for sub-nanometre-precise positioning developed in the NanoFab research training group.

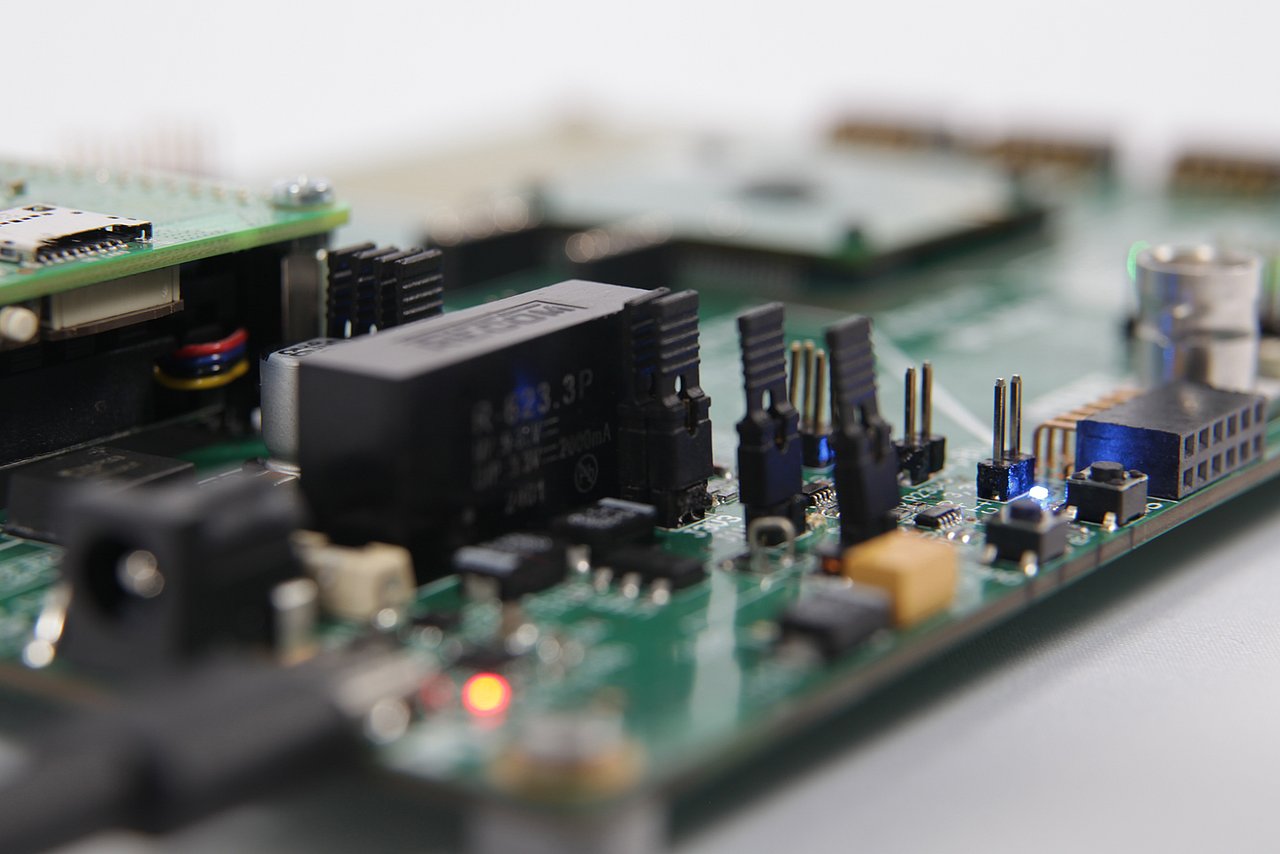

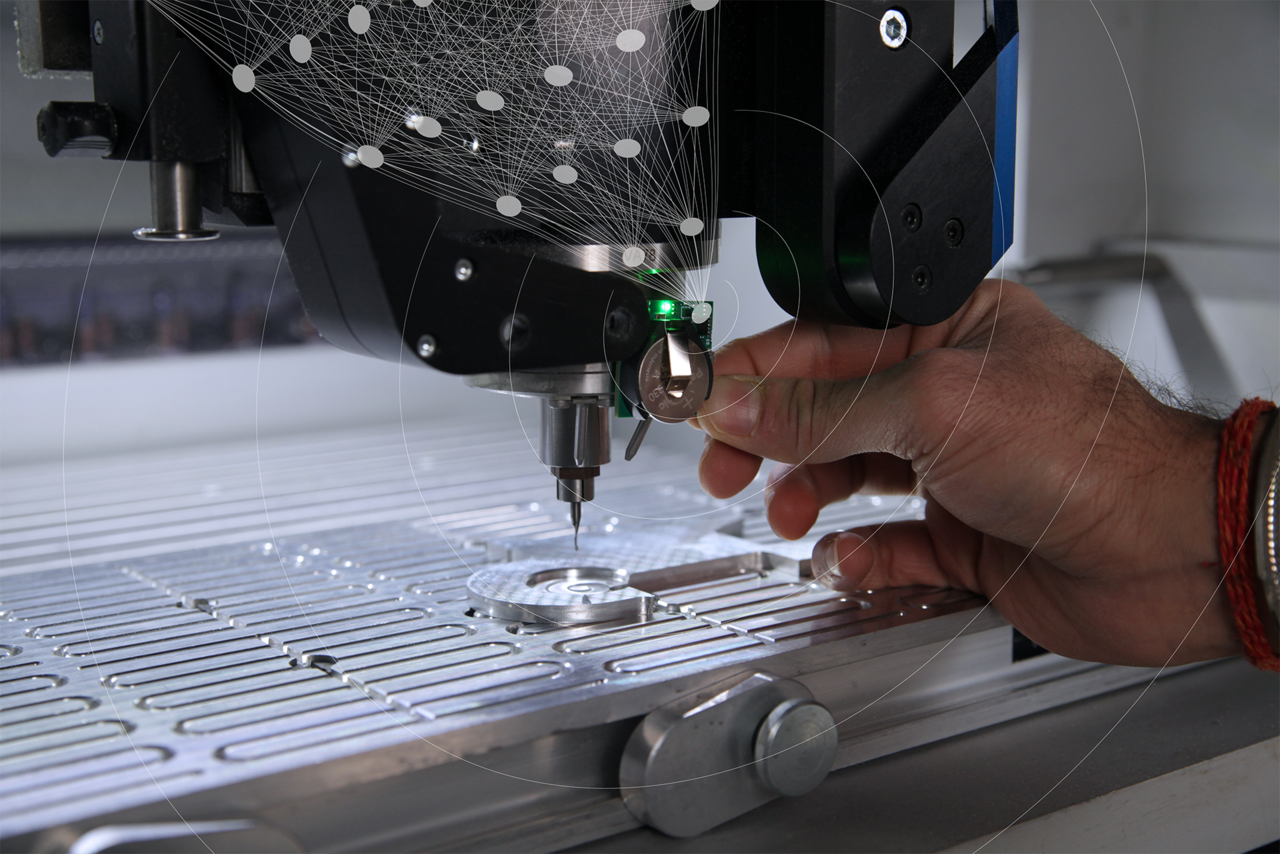

We used 2024 intensively to achieve important milestones in our research and thus refine the content of our three strategic research fields of “Integrated sensor systems”, “Smart distributed measurement and test systems” and “Magnetic 6D direct drives with nm precision”. This report highlights a selection of these. For example, we have implemented solutions for anomaly detection with edge AI and unsupervised learning for smart machine monitoring that reduce effort and increase benefits for users; we have developed methods for the design, architecture and modelling of trustworthy electronic systems; we have found ways to efficiently merge heterogeneous data for comprehensive analyses in agriculture and beyond; we have developed a direct drive system controlled in six dimensions for nanometre-precise positioning in a motion range of 200 mm diameter to 25 mm height and further advanced the modelling of electrodynamic energy harvesters.

These and other solutions are made possible by performance and funding. We would like to thank the German Land of Thüringen for its institutional funding, which makes our transfer work and cooperation with Thuringian SMEs possible in the first place. We would like to thank our committees for their support and advice in all matters. We would also like to thank all our research partners for their manifold impulses, which we transfer into application-orientated solutions. We would also like to thank our business partners and sponsors as well as all those who encourage us in our endeavours.

We would like to thank our employees for their commitment, their creative ideas and their performance; this leads to the innovative solutions that our partners value. You can find examples of this in our report. We wish you an exciting reading experience.

Ralf Sommer, Scientific Managing Director

Martin Eberhardt, Financial Managing Director

Related content

Project

MIRO

Future-proof regional fruit growing through systematic data collection (digital twin) and data exchange along the value chain

Project

HoLoDEC

IMMS researches ultra-low-power architectures (ULP) and circuit concepts as well as energy-efficient edge-AI systems with overall system energy…

Project

VE-VIDES

Against hacker attacks: Innovative chip architectures, modelling and verification methods for trustworthy electronics

Project

ECo-Harvester

In the project, the methodology for the co-design of mechanics and electronics of electrodynamic energy harvesters is being developed.

Event,

AI4PlantPhysio Workshop

Workshop in the AI4PlantPhysio project on plants and sensor technology at the University of Konstanz

Event,

SMACD 2025

International Conference on Synthesis, Modeling, Analysis and Simulation Methods, and Applications to Circuit Design

Event,

Bernburger Innovationstage

Wissenstransfer und Innovationen für die Landwirtschaft von morgen

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.