Project KI-EDA

IMMS developed smart models and tes methods for the design of sensor and control chips for I4.0 applications

The aim of KI-EDA was to harness the tools of artificial intelligence (AI) for the rapid and reliable design of customised encoder and sensor chips. Such microelectronic systems are needed for novel intelligent, autonomous production systems that can securely analyse data in a decentralised manner to predict and improve manufacturing scenarios.

Conventional design methods are usually not sufficient for complex and individual designs

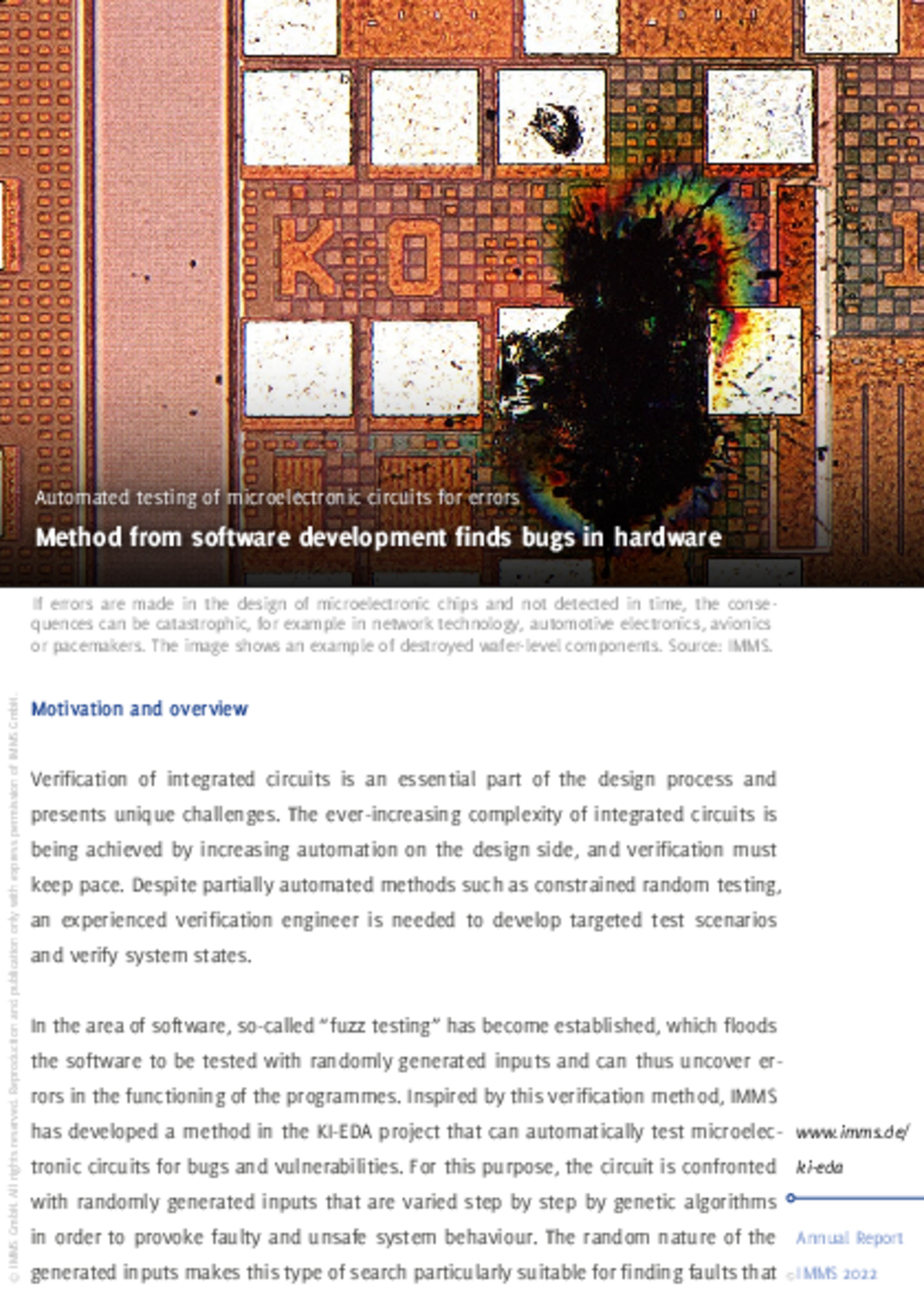

Encoder and sensor chips are used, for example, to detect rotary movements on machines and convert them into electronic signals for digital processing. These chips are customised for production machinery and processes and are becoming increasingly powerful and complex. The design and verification of the chips is reaching its limits with conventional electronic design automation (EDA) methods and is largely shaped by the experiential knowledge of design engineers.

New methods should reduce the development time of customised chips

This is why the KI-EDA project, which is being led by iC-Haus GmbH, has worked on AI-supported methods of design automation and on a modular system for chip design and test. Individual functions should be able to be selected, combined and simulated quickly and cost-effectively in the form of function blocks with short design times and a low error rate, and transferred into an encoder or sensor chip customised for the planned application. On this basis it will be possible to implement new functionalities such as AI-based predictive maintenance solutions flexibly and quickly. Errors in the design and thus time-consuming redesigns are to be reduced in this way.

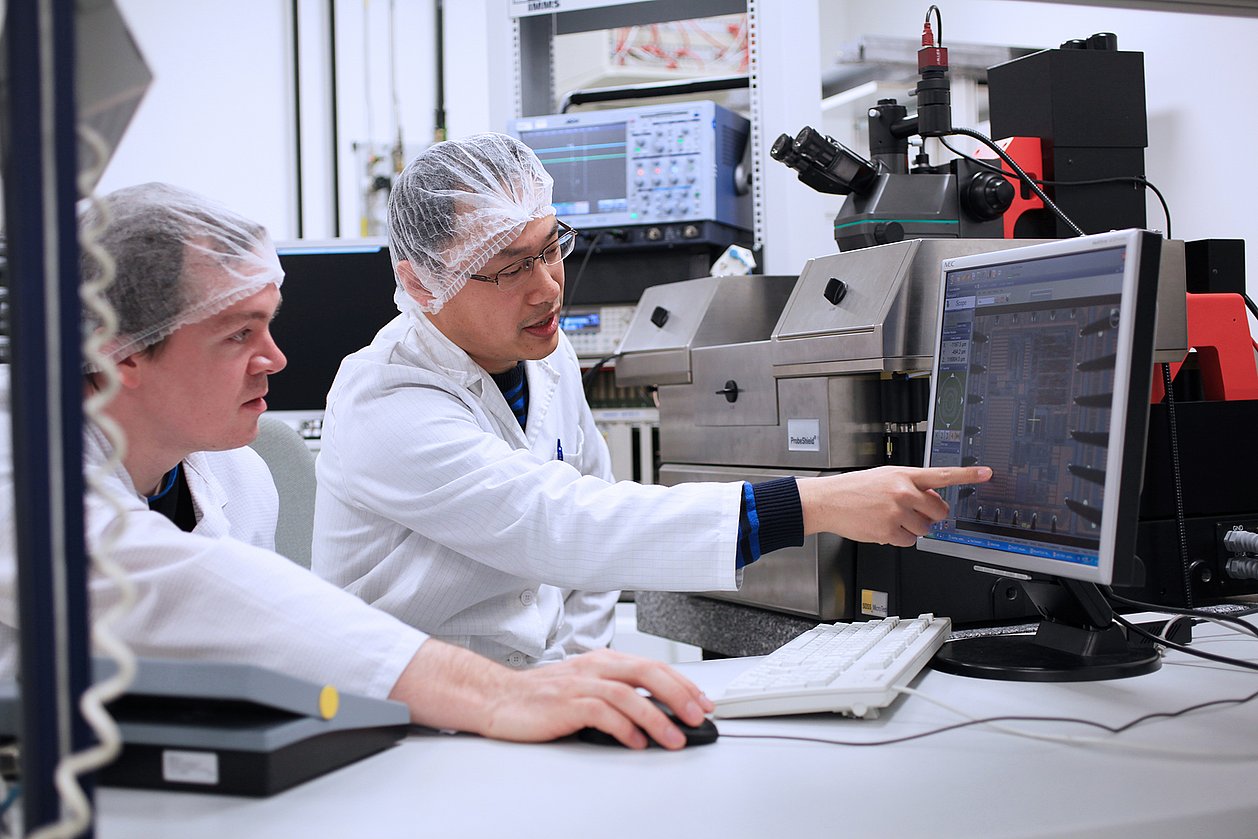

To this end, the partners iC-Haus and CENTITECH have researched and implemented intelligent functions and energy-autonomous solutions for the new microelectronic systems and characterised them in application-oriented demonstrators. This was intended to ensure the properties required for widespread and comprehensive use in I4.0 production environments. In addition, the partners ensure that the systems can be manufactured in high quantities.

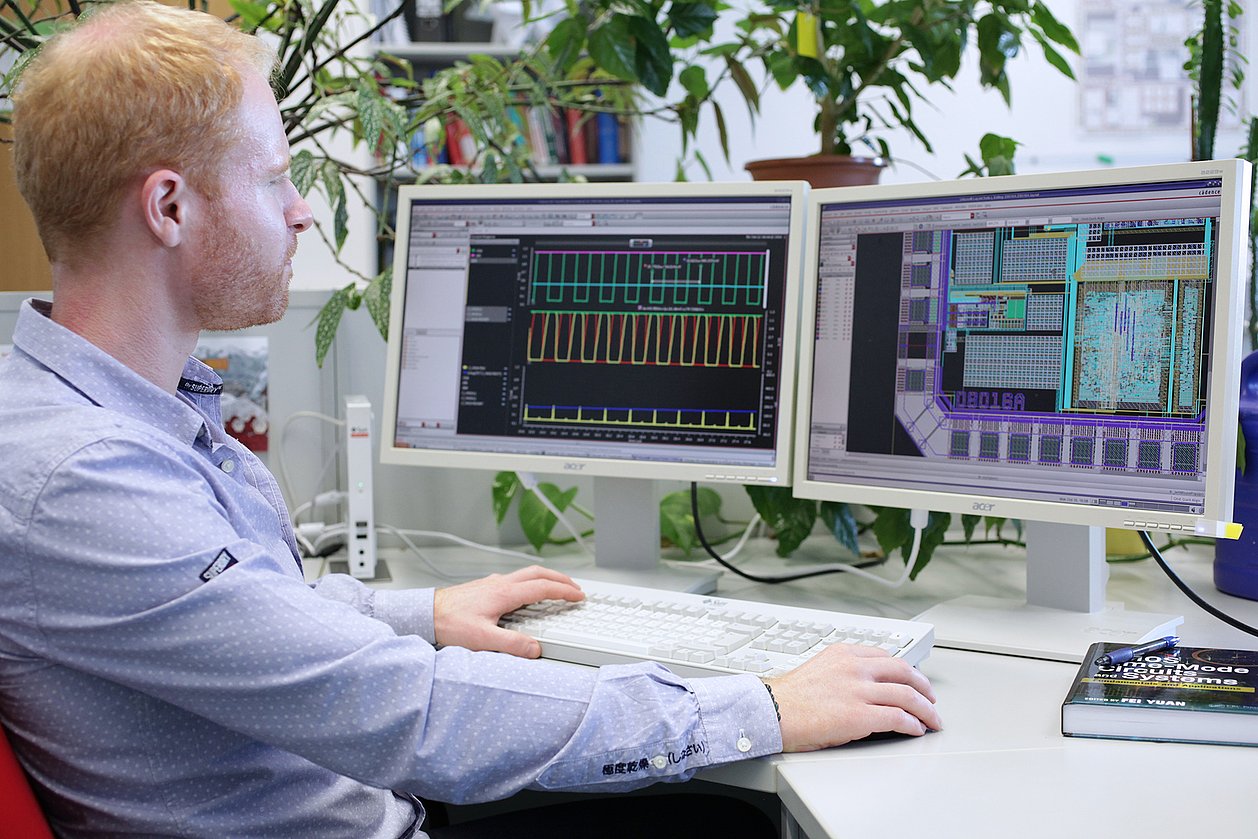

IMMS researched on ML algorithms and smart models for a modular system for fast and safe chip design

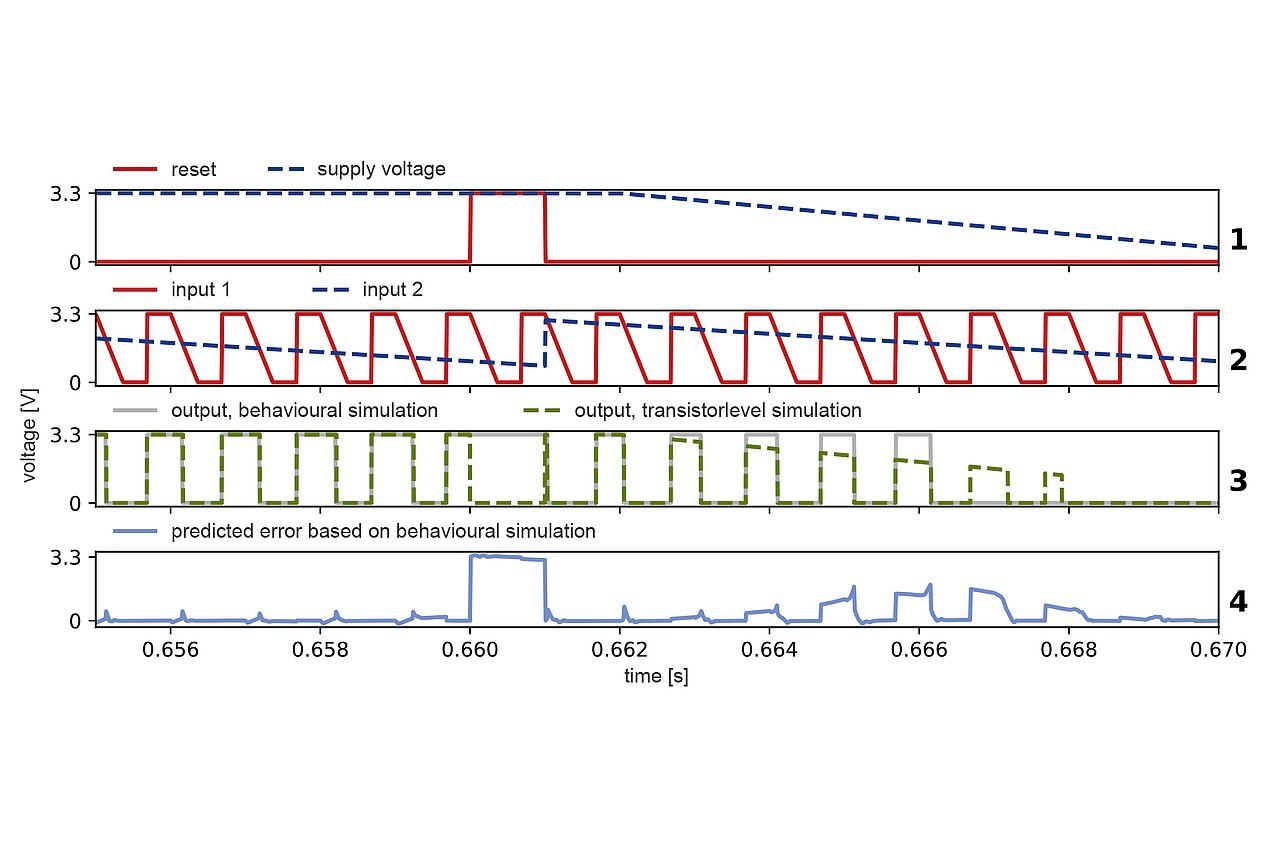

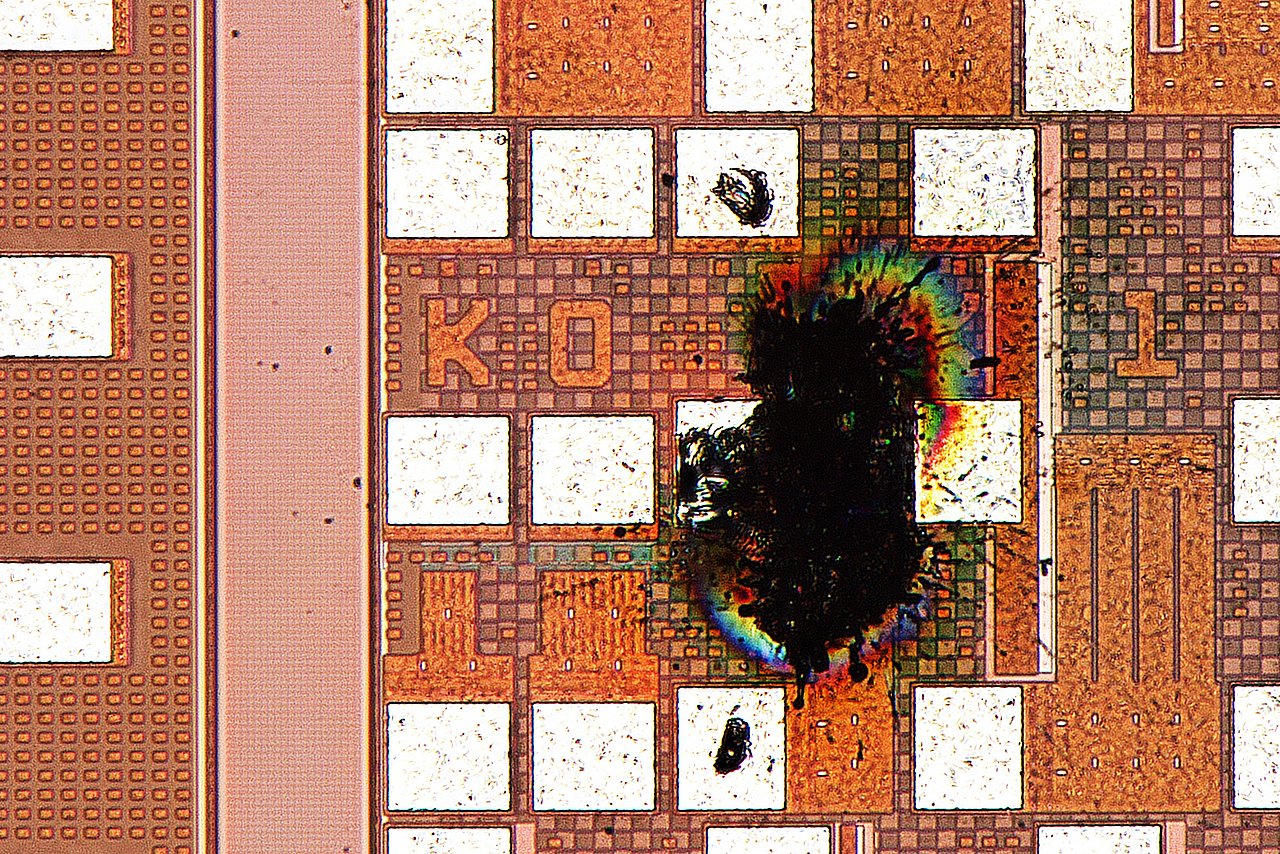

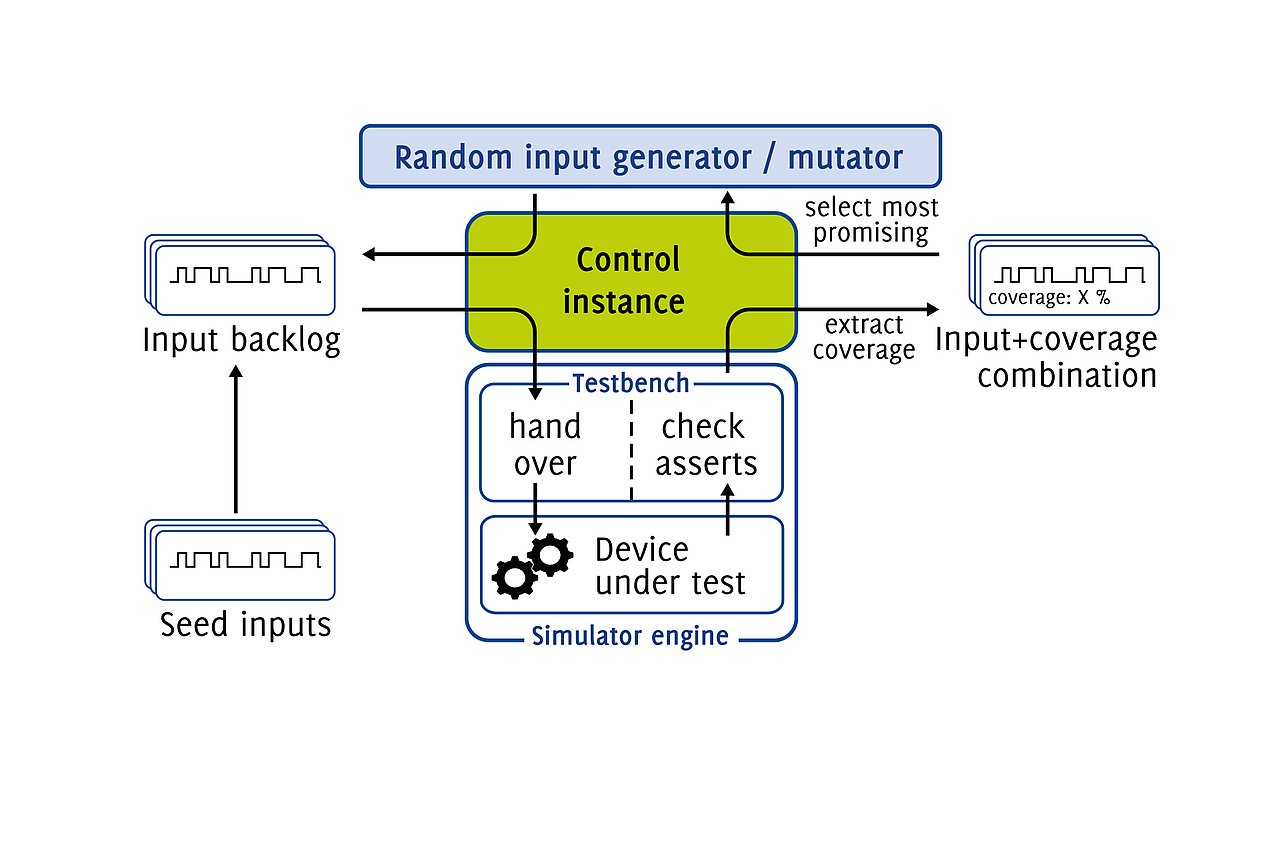

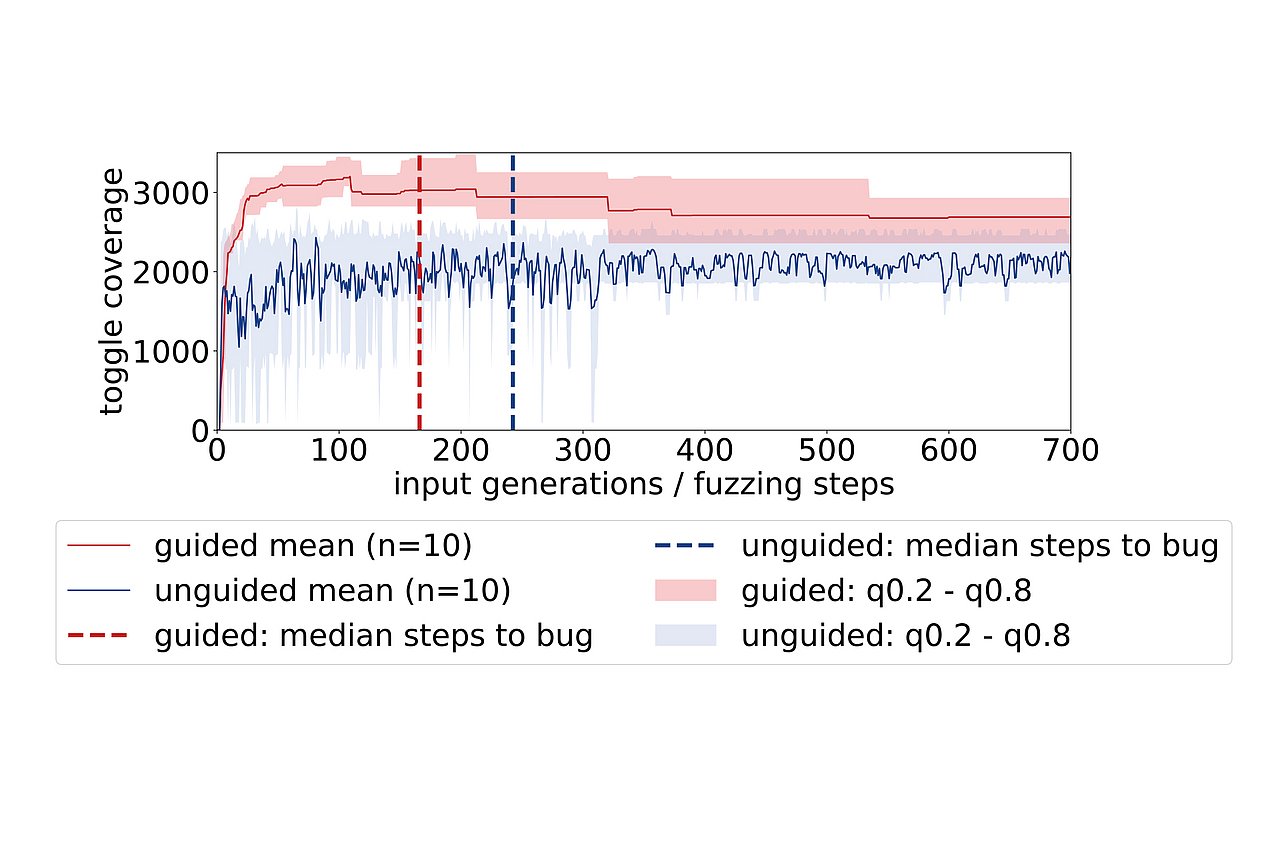

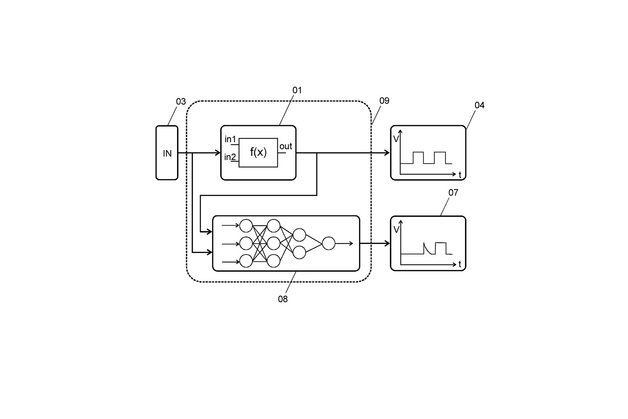

IMMS researched machine learning (ML) algorithms for their applicability in chip design (EDA) as a basis for transfer into a novel designer assistance system to make design processes more efficient and faster. The new ML methods researched will primarily serve a fast design validation and thus increase design security. They are aimed in particular at model-based debugging and should reduce the complexity of working with IP libraries, i.e. with collections of existing circuit components or electronic blocks. New chips can thus be assembled in a modular system. In addition, IMMS researched and implemented „smart models“. For the first time, new algorithms enabled models to computationally check their own range of validity and thus exclude false-positive verification results.

Acronym / Name:

KI-EDA / Modular system with artificial intelligence for the accelerated development of special chips for Industry 4.0Duration:2020 – 2023

Application:

Automation technology and Industry 4.0|EDA| Electronic Design Automation| Automation Chip Design| ASIC Design| VerificationResearch field:Integrated sensor systems

Related content

Reference

Dr. Heiner Flocke, iC-Haus GmbH

”By sharing expertise and resources, we were able to jointly develop a solution that met and even exceeded the requirements.“

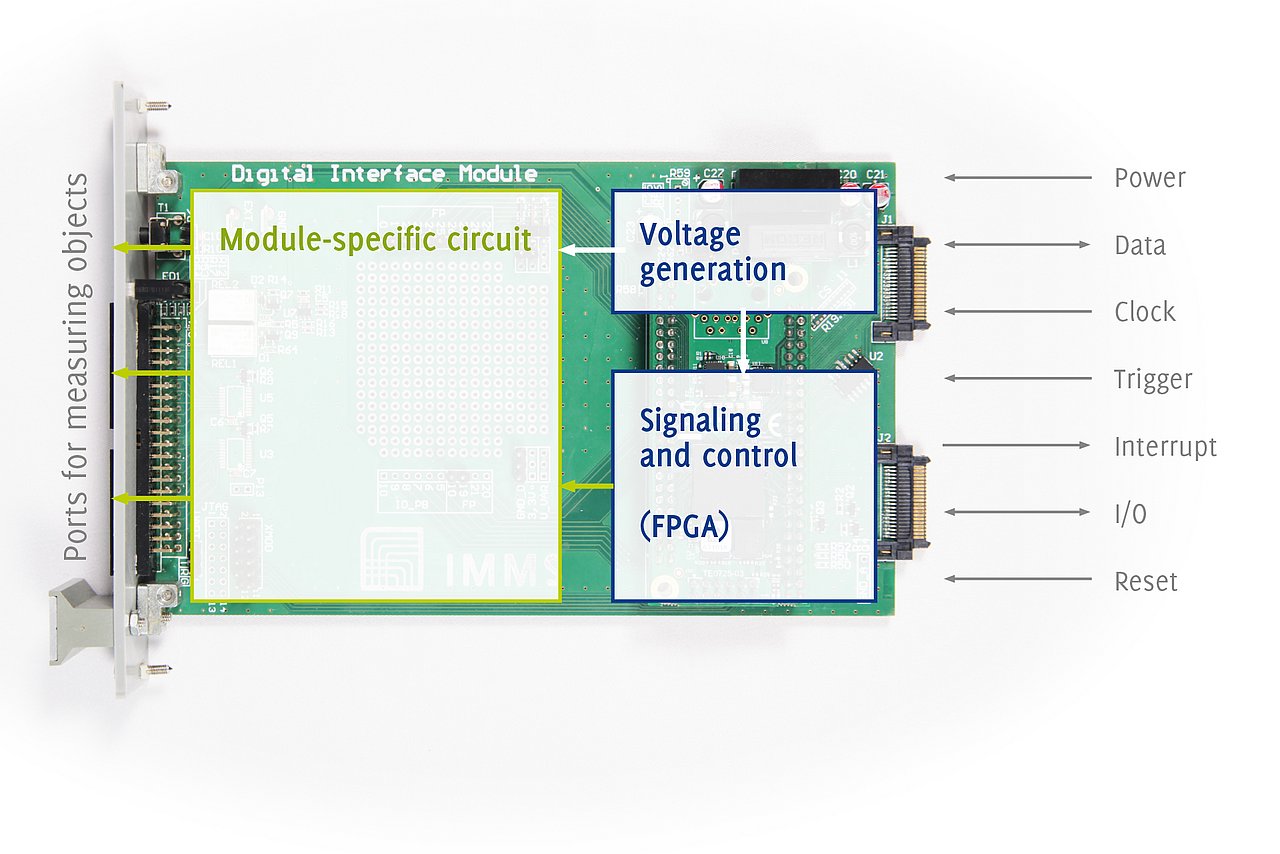

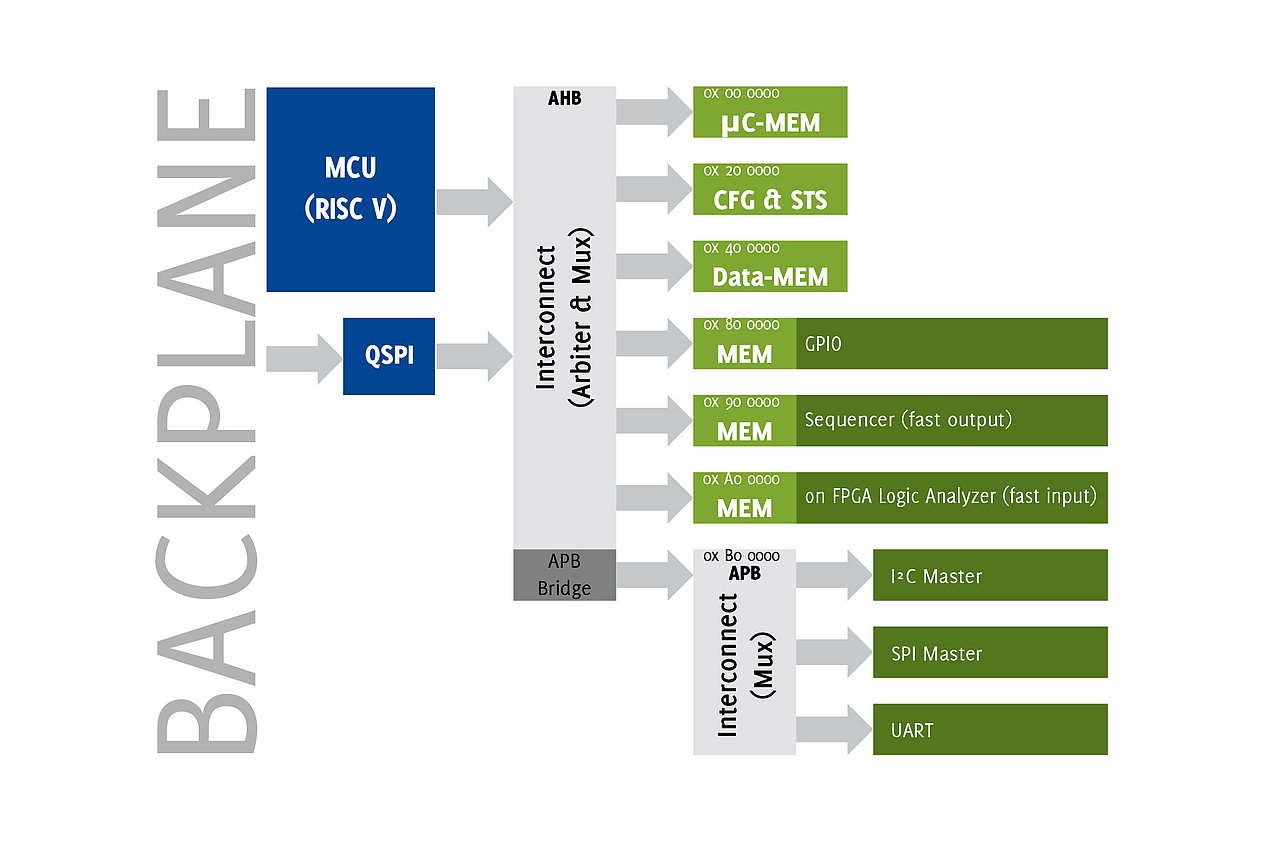

Testsystem für die Charakerisierung analoger und digitaler Strukturen – Mixed-Signal-Analyse wird mobiltauglich

Tom Reinhold1.Elektronik, 24.2024, 26. November 2024, Seite 70 - 73, ePaper: wfm-publish.blaetterkatalog.de/frontend/mvc/catalog/by-name/ELE

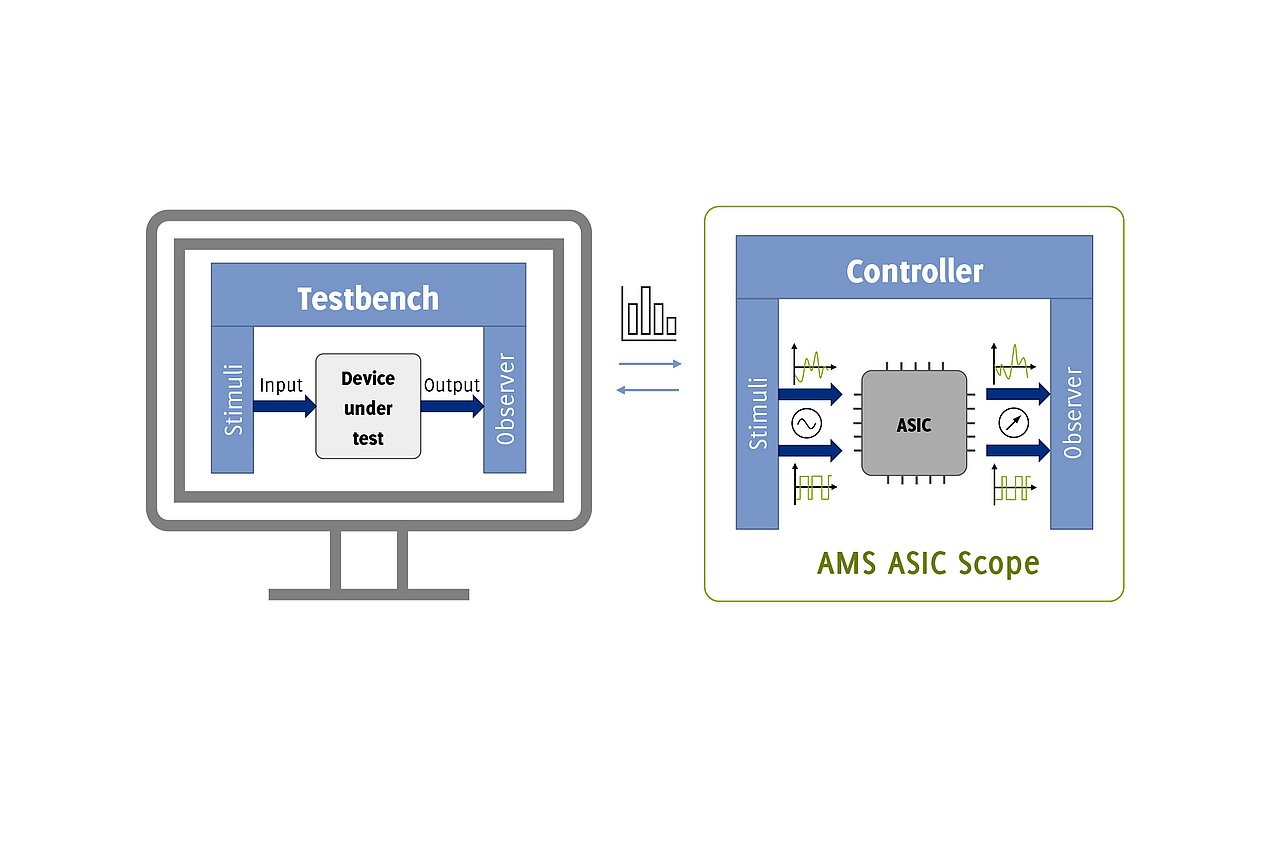

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.Validierung KI-basierter Simulationsmethoden im Chip-Entwurf, Testbench in Hardware

Tom Reinhold1.Elektronik, 25.2023, 29. November 2023, Seite 60 - 64, ePaper: wfm-publish.blaetterkatalog.de/frontend/mvc/catalog/by-name/ELE

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.Automatisiertes Testen mikroelektronischer Schaltungen – Fuzzing findet Bugs in Hardware

Henning Siemen1. Jonas Lienke1. Georg Gläser1.Elektronik, 21.2023, 18. Oktober 2023, Seite 64 - 67, ePaper: wfm-publish.blaetterkatalog.de/frontend/mvc/catalog/by-name/ELE

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.IC-Entwicklung: Effizientere Simulation mit KI-basierter Modellfehlerschätzung

Henning Siemen1. Martin Grabmann1. Eric Schäfer1. Georg Gläser1.Elektronik, 17-18/2023, 23. August 2023, Seite 66 - 69, ePaper: wfm-publish.blaetterkatalog.de/frontend/mvc/catalog/by-name/ELE

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.

Press release,

Reliable and faster chip designs through invasive and parametric simulation methods

Dissertation on new methods for automation in integrated circuit design

Press release,

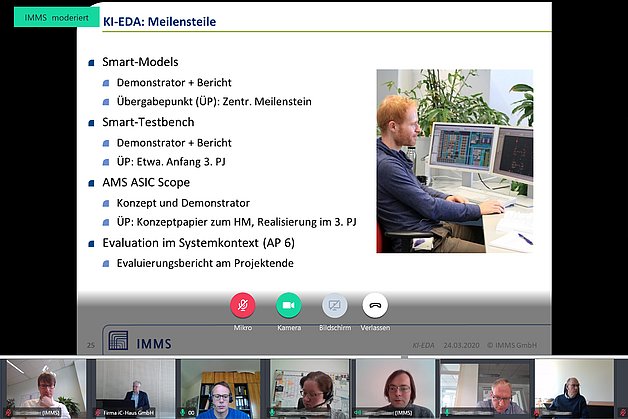

KI zum Entwurf von Antriebssteuerchips als Schlüsselprodukte für die Industrie 4.0

Virtuelles Kick-off-Meeting zum Projektstart von KI-EDA

Event,

SMACD 2023

International Conference on Synthesis, Modeling, Analysis and Simulation Methods, and Applications to Circuit Design

Event,

SMACD 2022

International Conference on Synthesis, Modeling, Analysis and Simulation Methods, and Applications to Circuit Design

Contact

Contact

Eric Schäfer, M. Sc.

Head of Microelectronics / Branch Office Erfurt

eric.schaefer(at)imms.de+49 (0) 361 663 25 35

Eric Schäfer and his team research Integrated sensor systems, especially CMOS-based biosensors, ULP sensor systems and AI-based design and test automation. The results are being incorporated into research on the lead applications Sensor systems for in-vitro diagnostics and RFID sensor technology. It will assist you with services for the development of Integrated circuits and with IC design methods.

Funding

The KI-EDA project was funded by the Federal Ministry of Education and Research within the framework of the programme ”Microelectronics for Industry 4.0 (ElektroniK I4.0)“ under the consortium number es2eli4001, IMMS under the reference 16ME0010.