Project HoTSens

Integrated sensors and microelectronics operate at 300°C, enabling more efficient processes

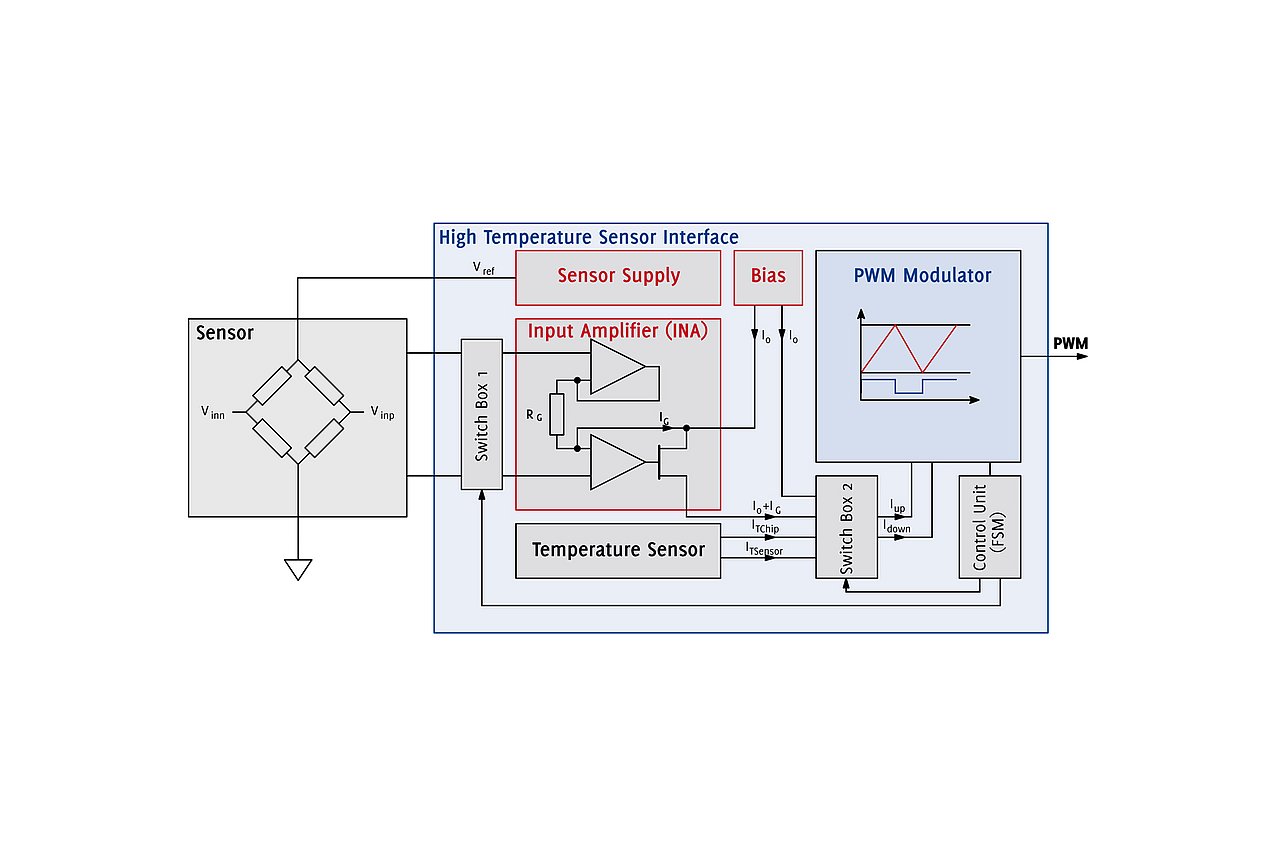

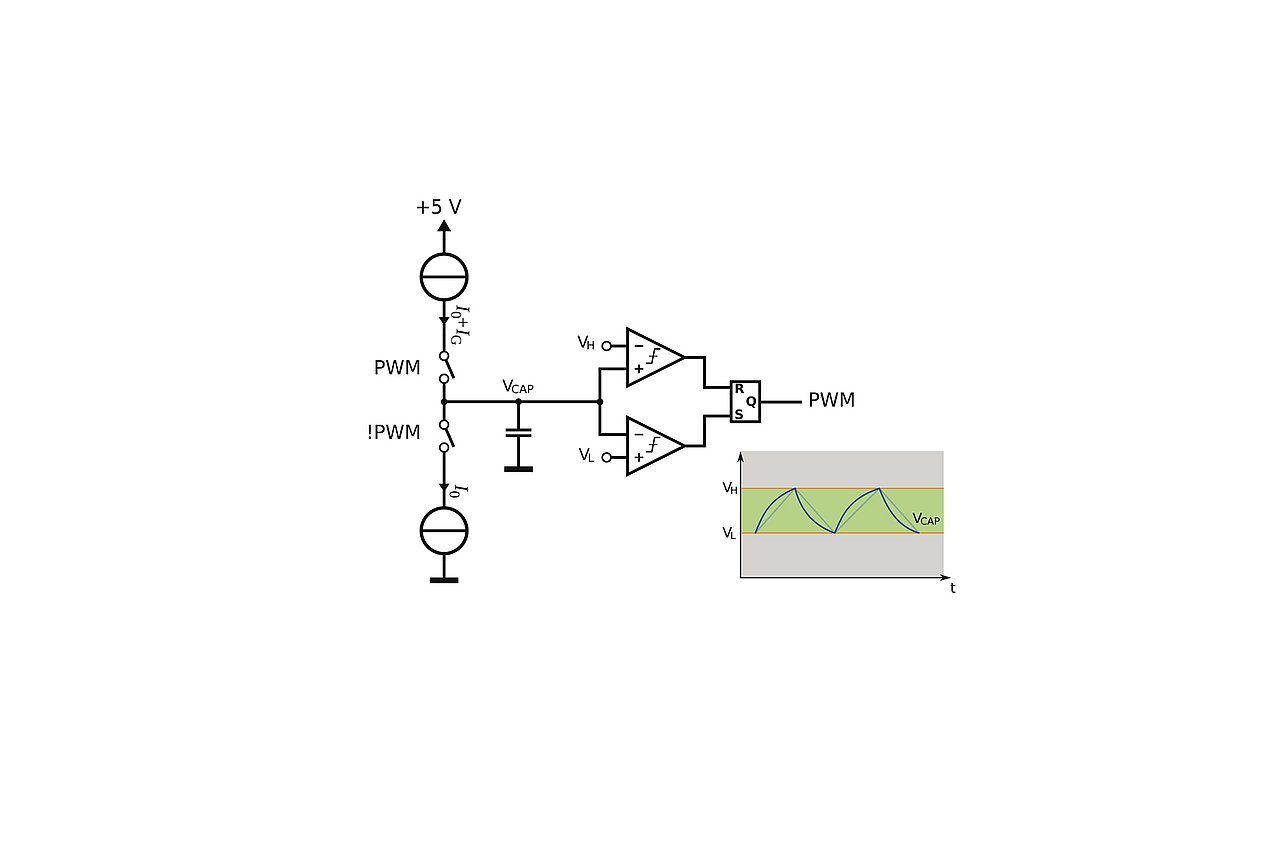

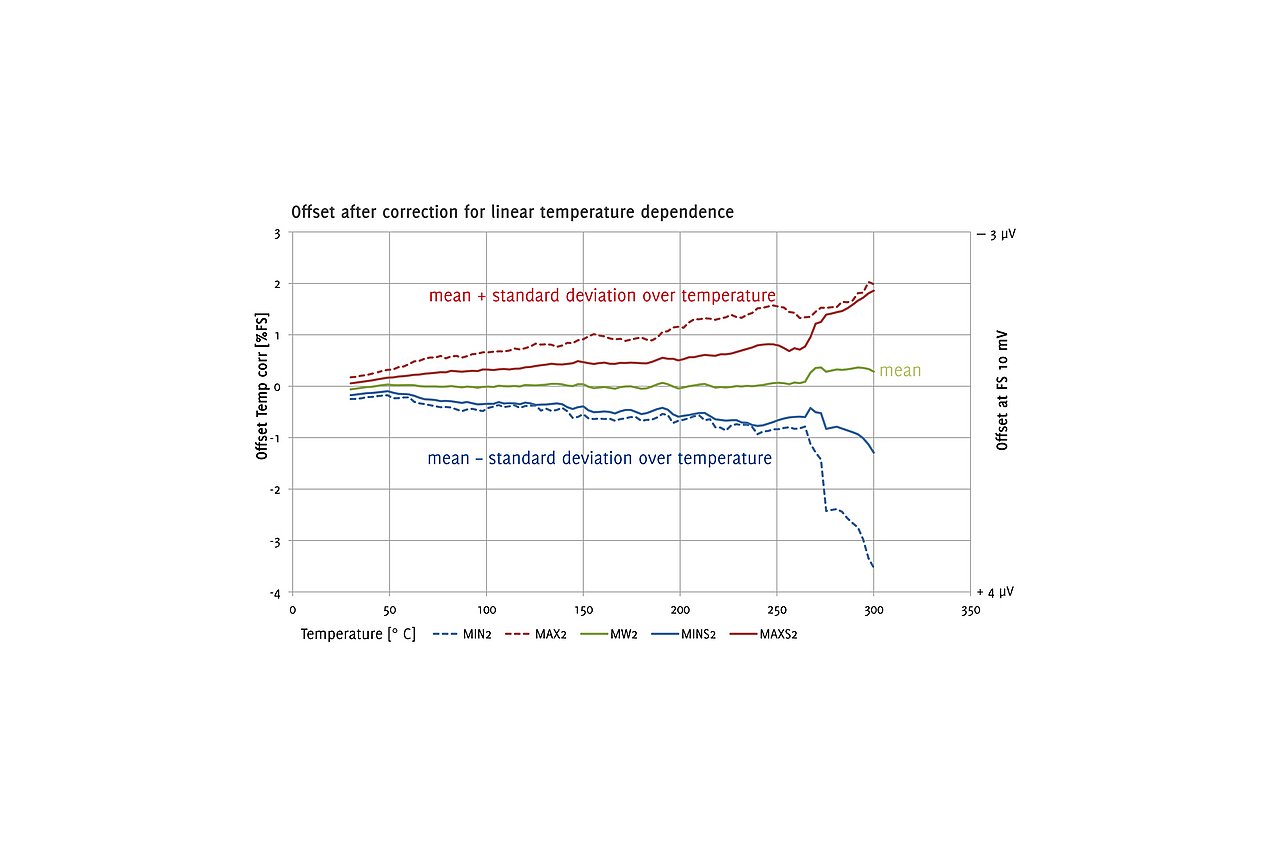

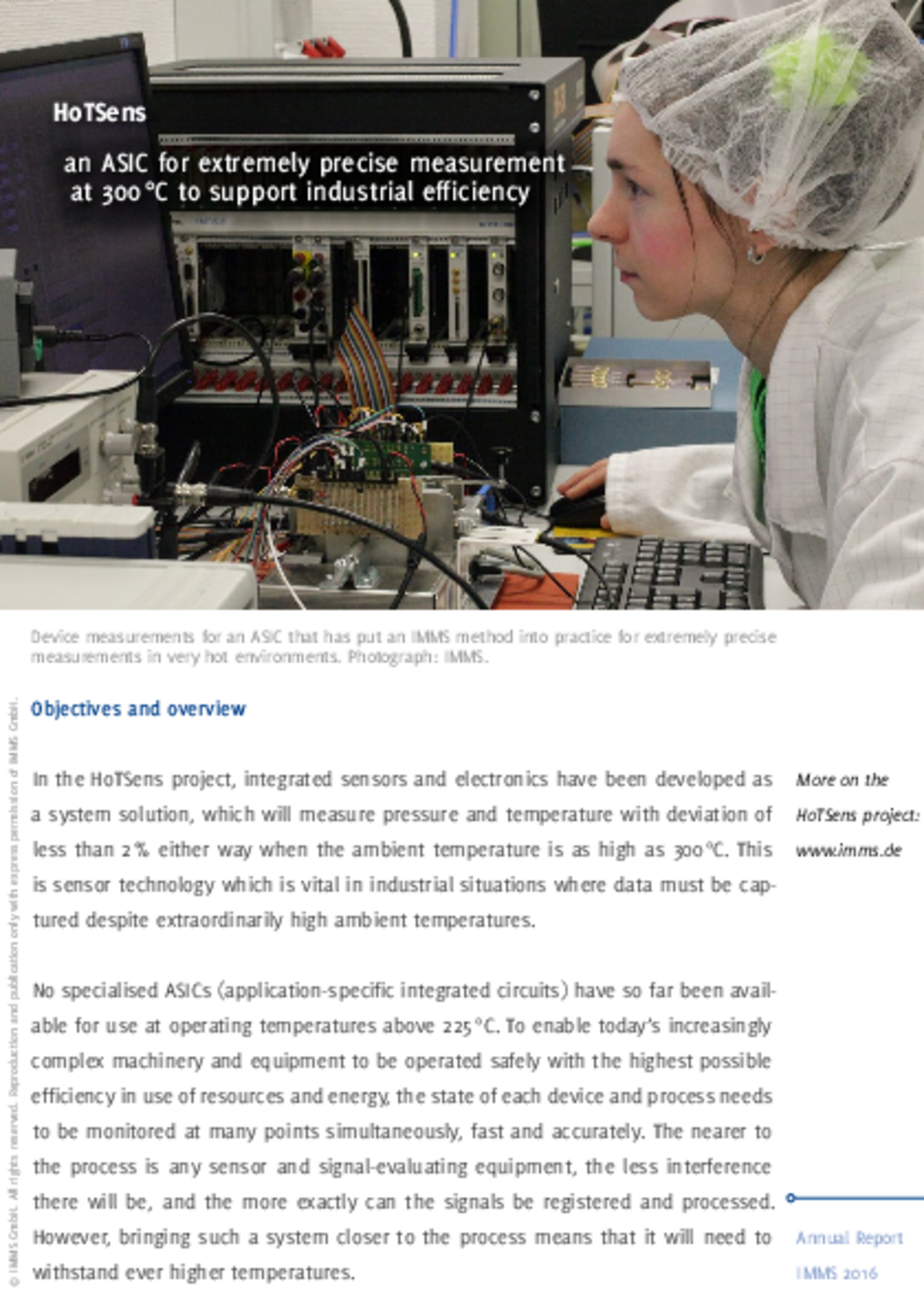

In the HoTSens project, integrated sensors and electronics have been developed as a system solution, which will measure pressure and temperature with deviation of less than 2% either way when the ambient temperature is as high as 300°C.

This is sensor technology which is vital in industrial situations where data must be captured despite extraordinarily high ambient temperatures.

No specialised ASICs (application-specific integrated circuits) have so far been available for use at operating temperatures above 225°C. To enable today’s increasingly complex machinery and equipment to be operated safely with the highest possible efficiency in use of resources and energy, the state of each device and process needs to be monitored at many points simultaneously, fast and accurately. The nearer to the process is any sensor and signal-evaluating equipment, the less interference there will be, and the more exactly can the signals be registered and processed. However, bringing such a system closer to the process means that it will need to withstand ever higher temperatures.

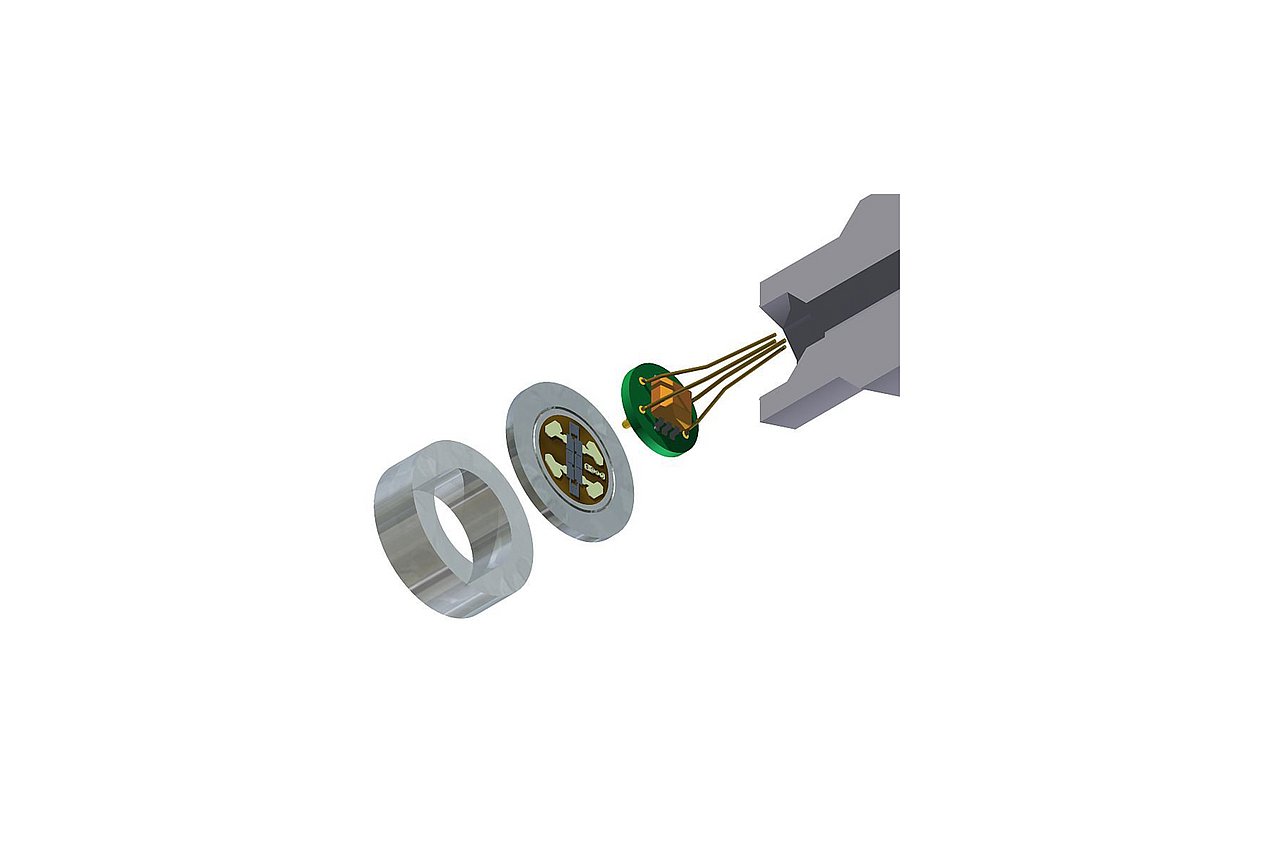

The new module has high-temperature electronics integrated into it. The resulting sensor system will amplify and calibrate the primary signals from a combined pressure and temperature sensor in such a way that any potential errors in the pressure signal are ironed out.

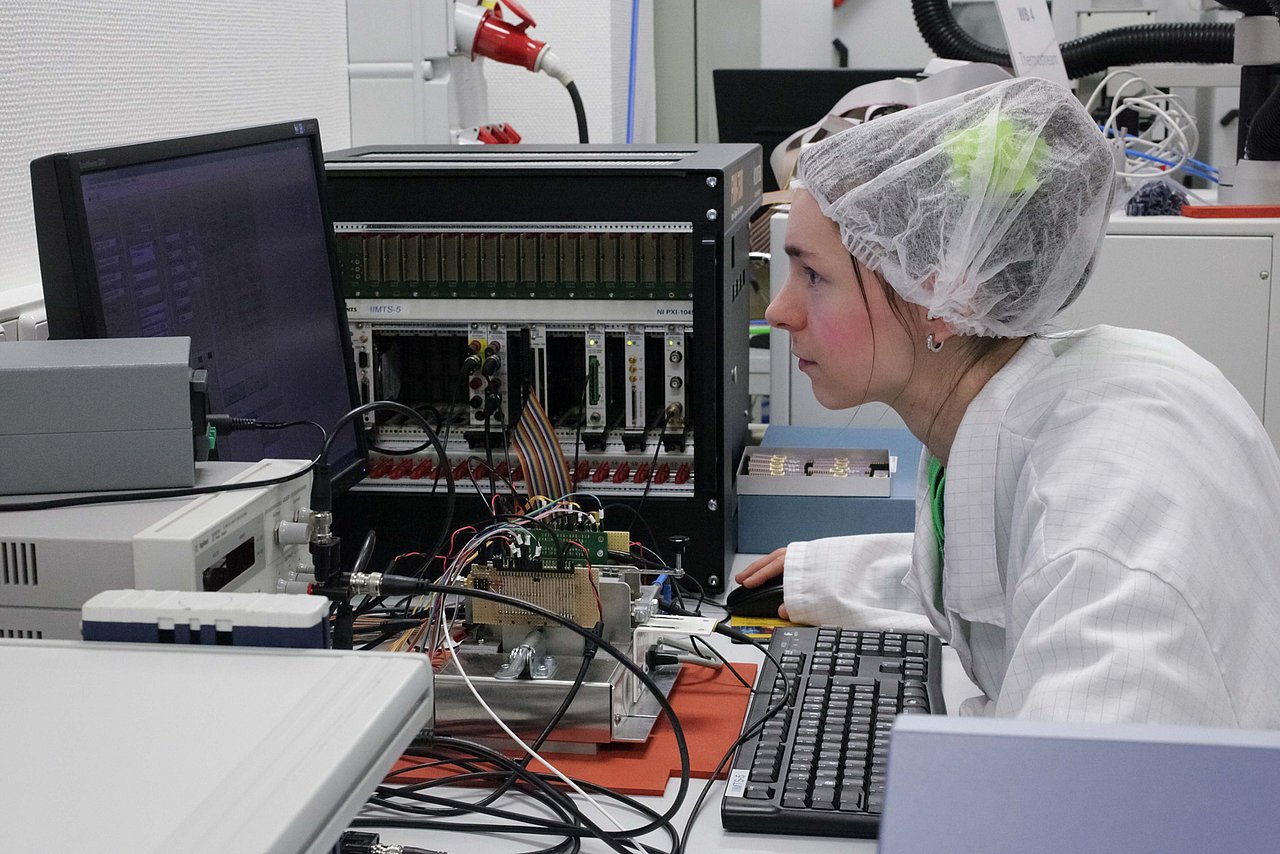

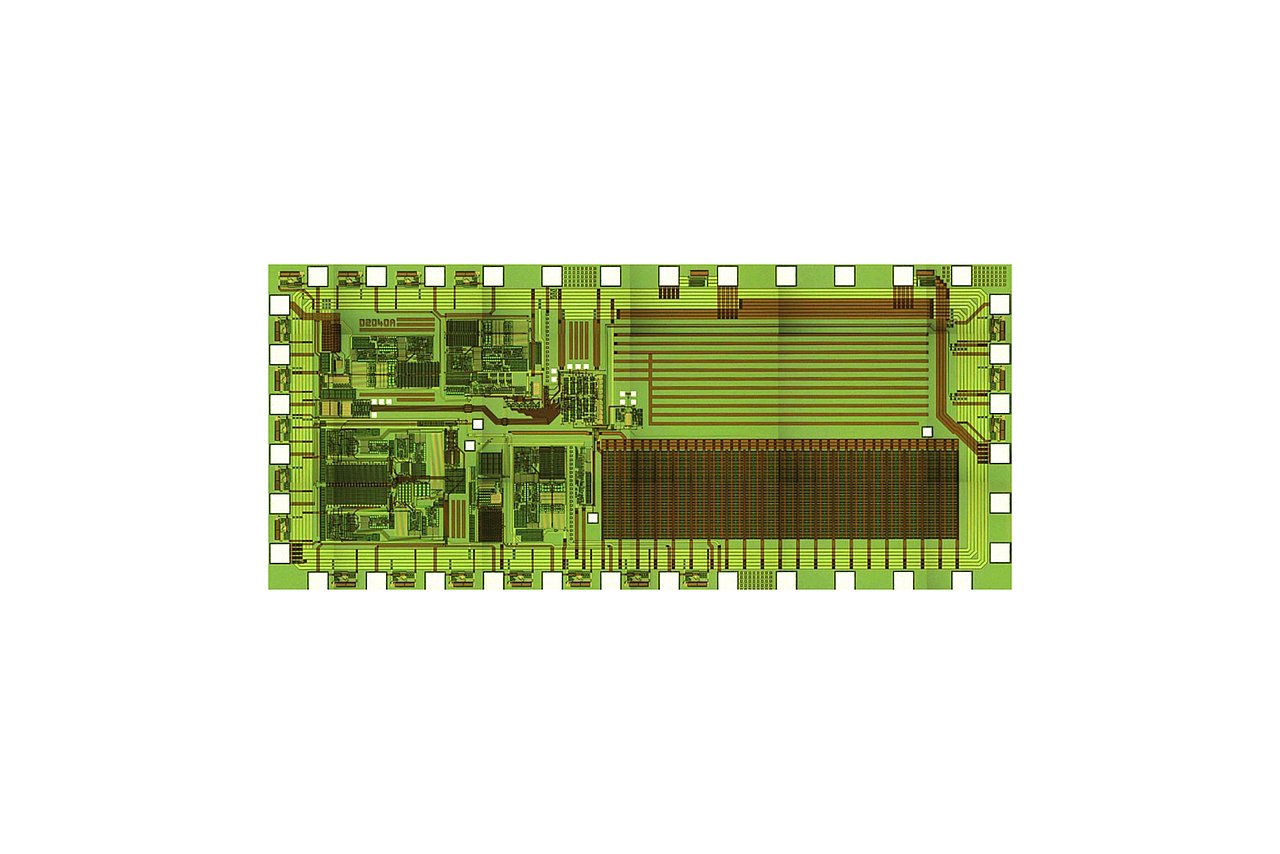

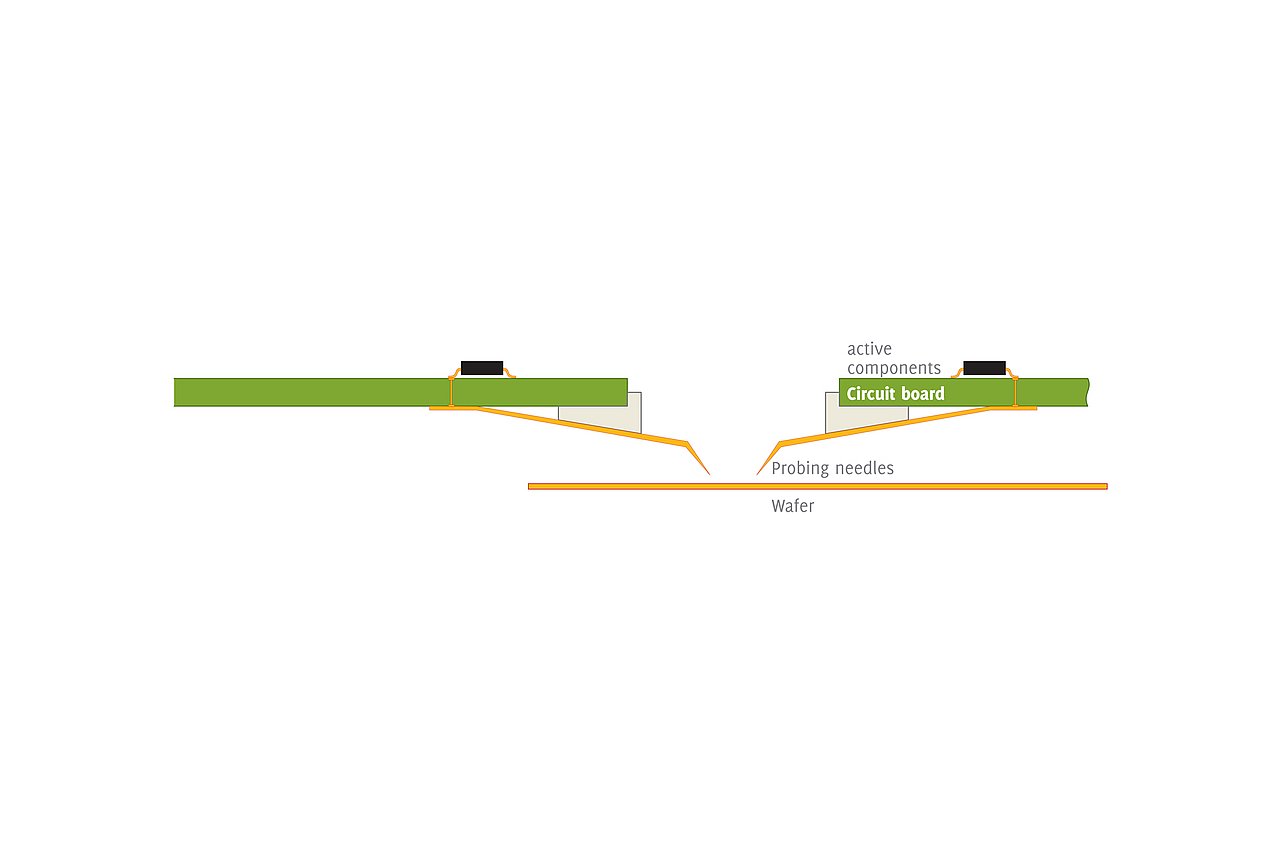

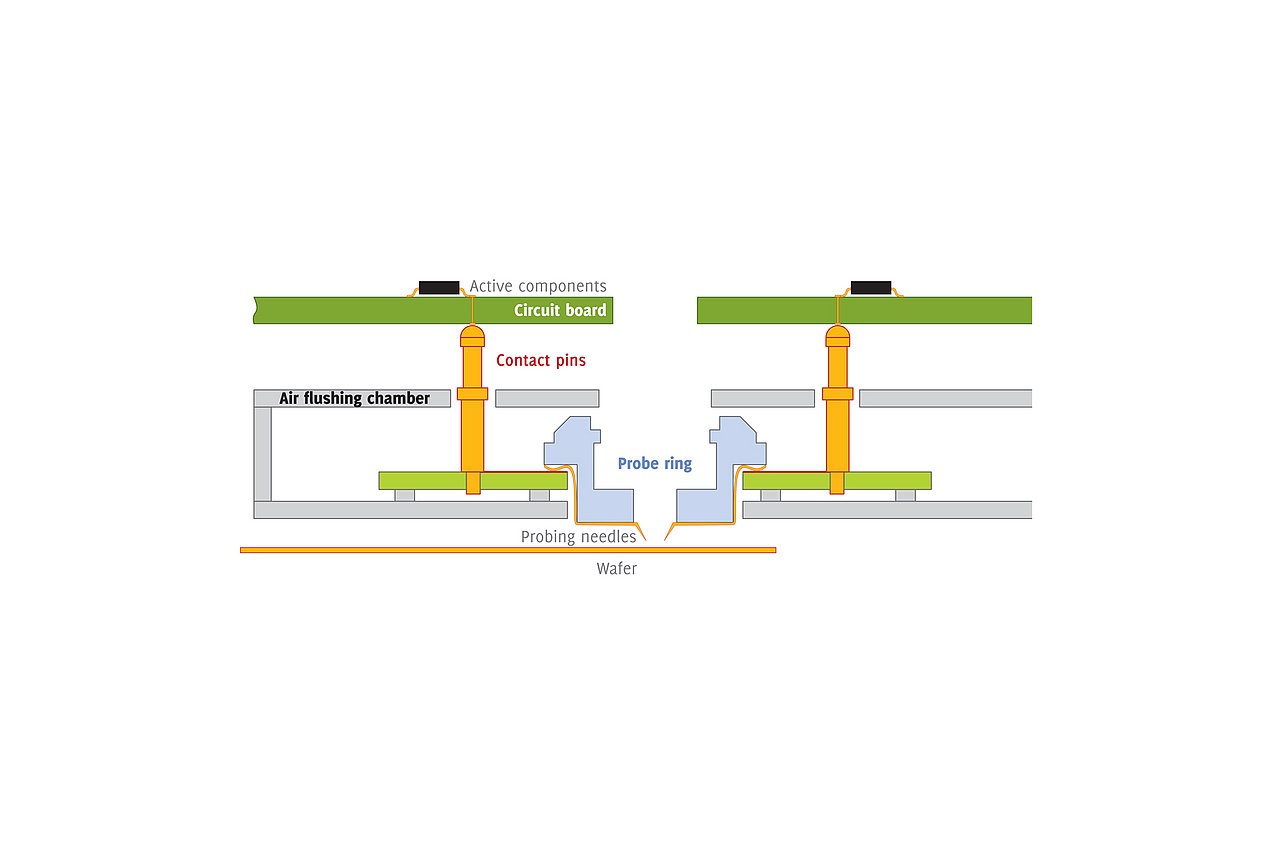

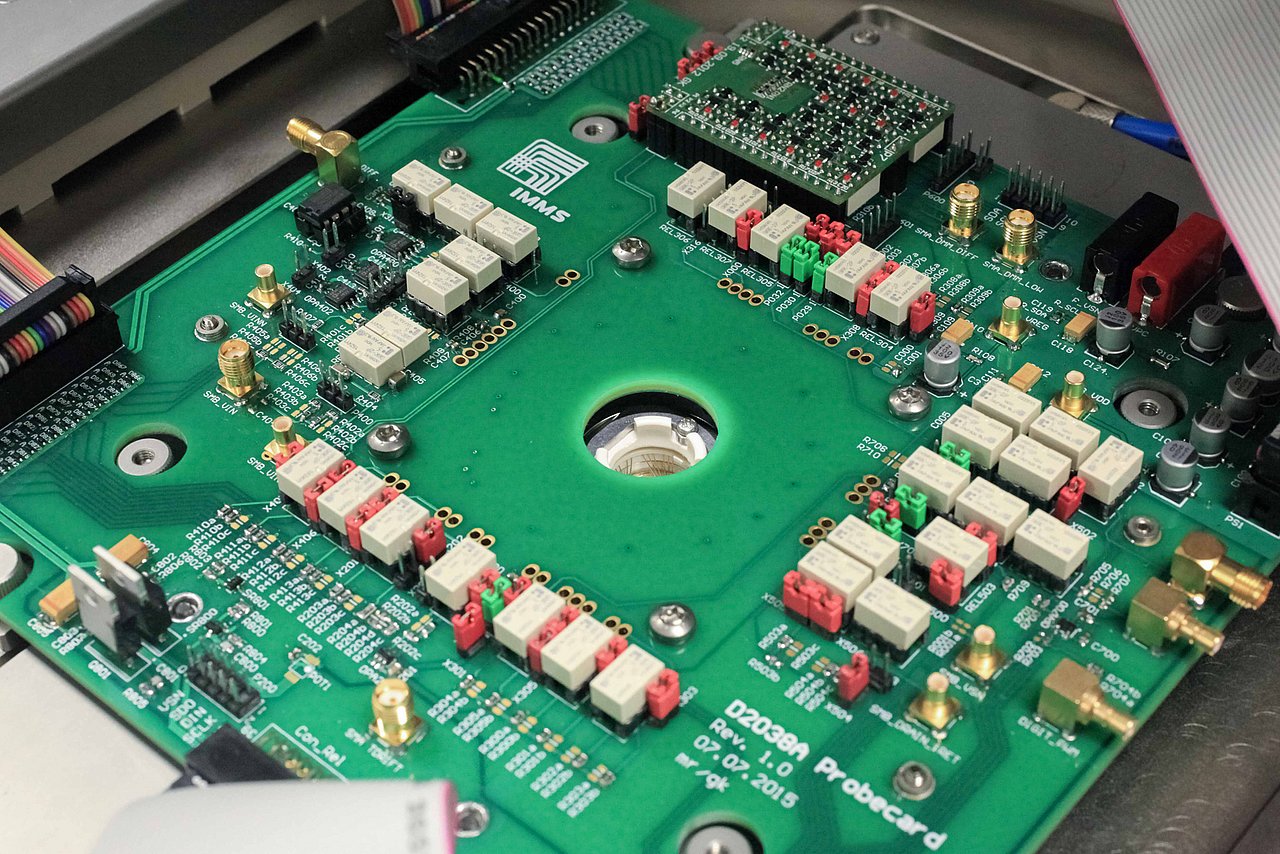

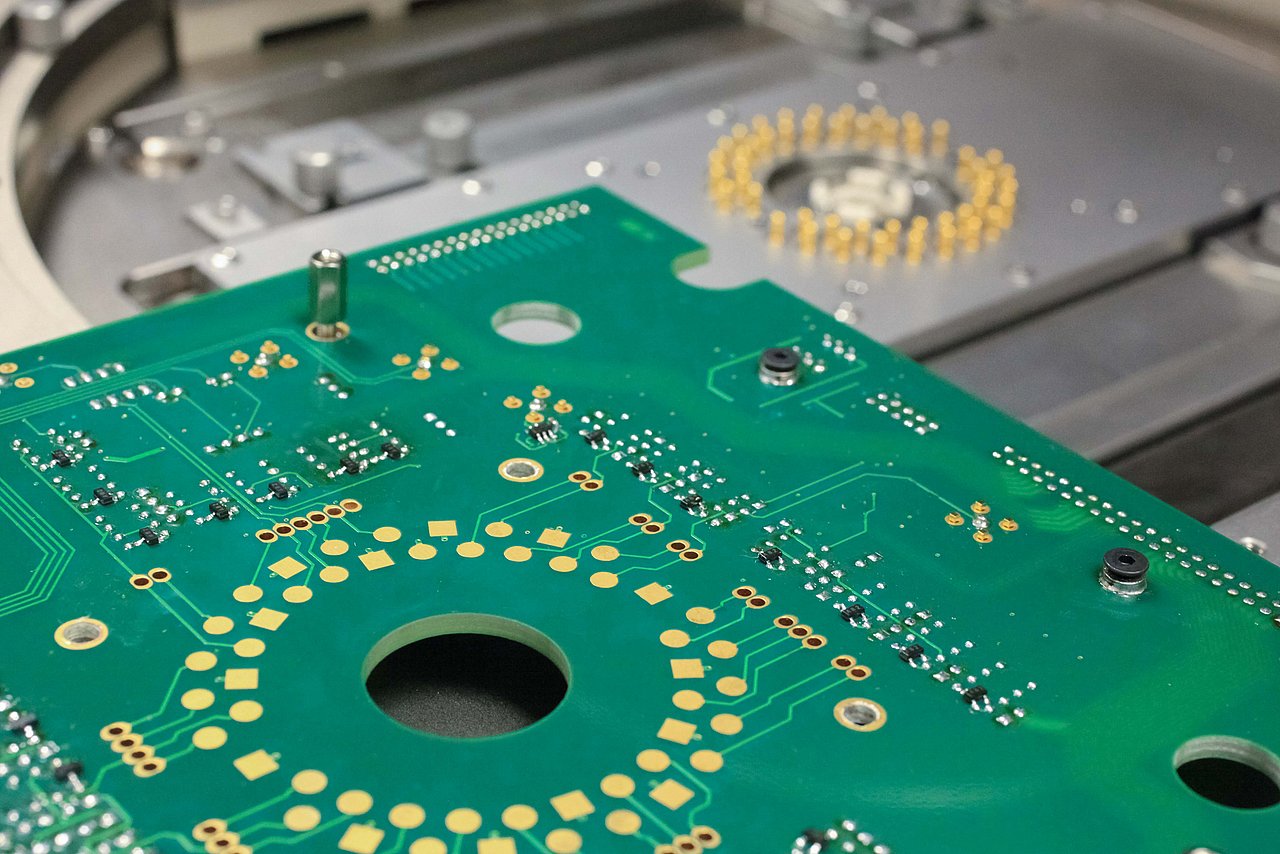

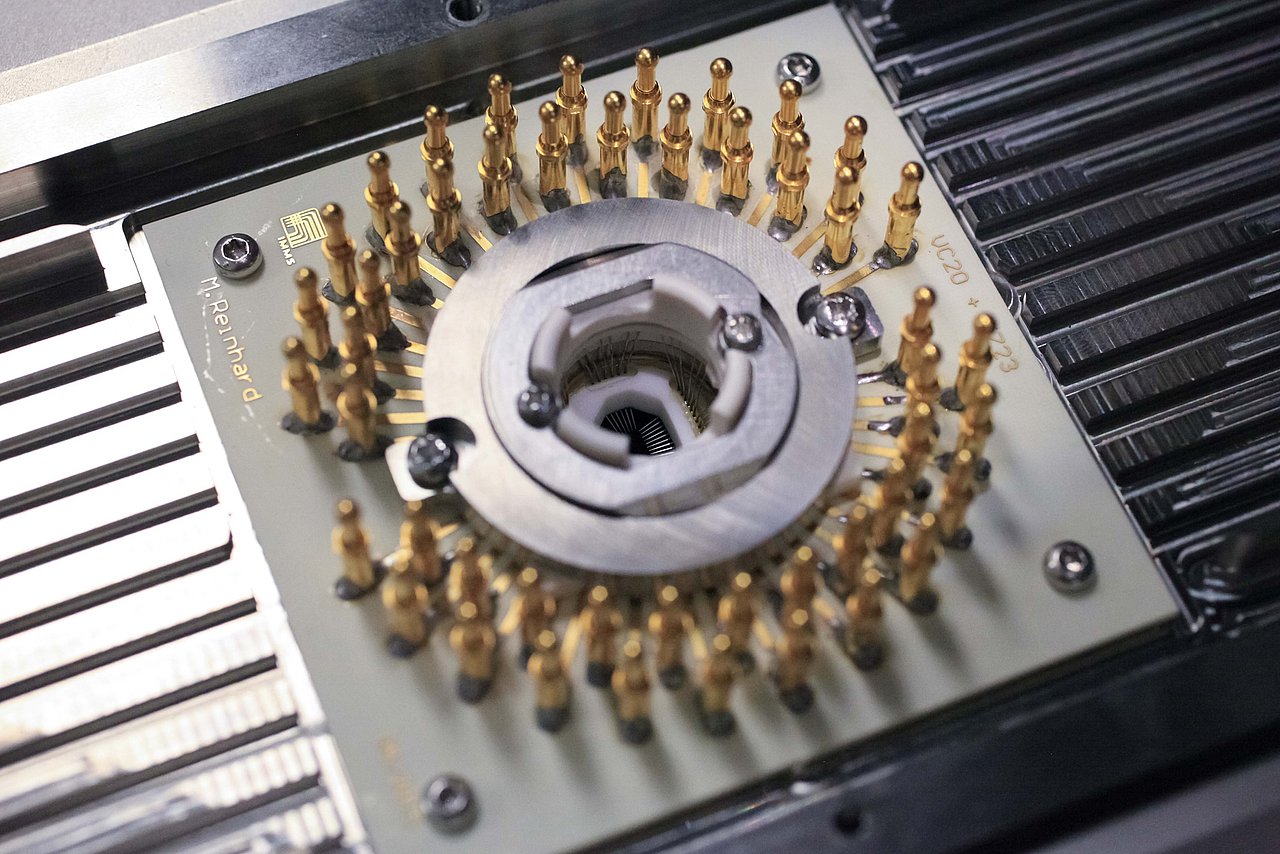

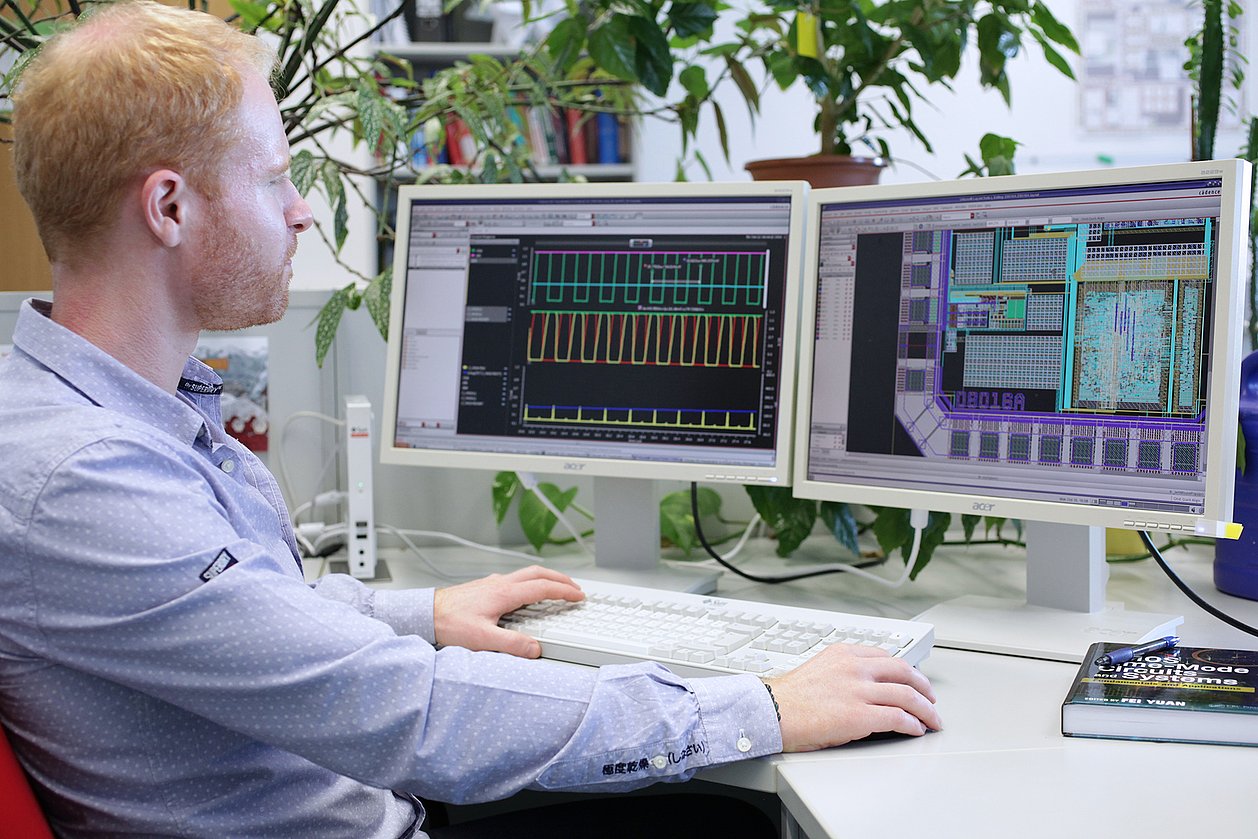

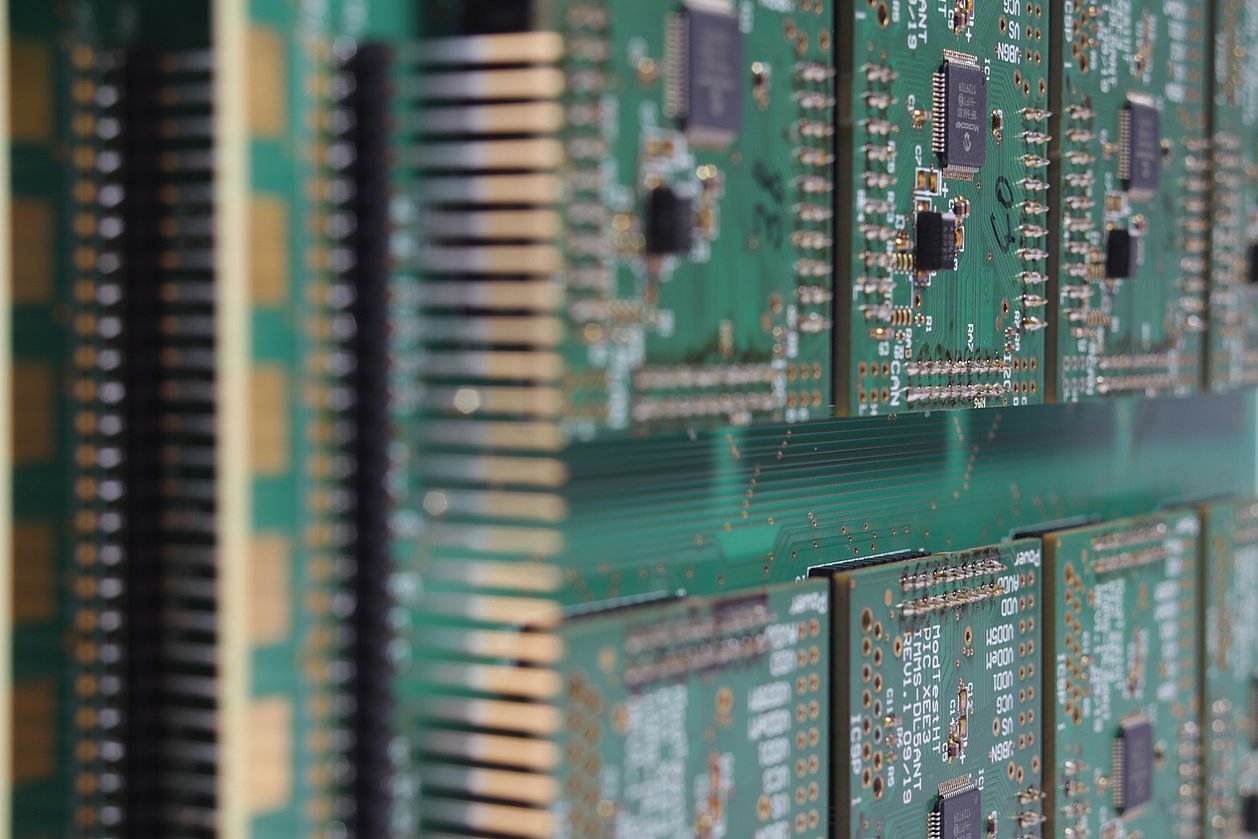

IMMS has developed high-temperature ASICs with time-coded signals and adjustment algorithms for precise measurements and has tested and characterised them. For the purpose, a new test setup was first designed and made, then successfully tested. It has an integrated cooling system to enable full semi-automatic wafer testing up to 300°C. Second, a high-precision substitute bridge circuit has been designed, then constructed and successfully used for the characterisation.

Acronym / Name:

HoTSens / Development, test and characterisation of a high-temperature ASIC for pressure sensor structures for an extended temperature range to 300°CDuration:2013 – 2016

Application:

|precise process control for plastics extrusion| optimally efficient combustion for large diesel engines| aviation industry| on-shore and off-shore drillingResearch field:Integrated sensor systems

Related content

Modulare Hochtemperatur-Testplattform bis 300 °C

Bjoern Bieske1. Tom Reinhold1. Marco Reinhard1.30. GI/GMM/ITG-Workshop, Testmethoden und Zuverlässigkeit von Schaltungen und Systemen (TuZ 2018), 4.-6. März 2018, Freiburg im Breisgau, Germany

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany.High-Precision Mixed-Signal Sensor Interface for a Wide Temperature Range [0° – 300°C]

Georg Gläser1. Dagmar Kirsten2. André Richter1. Marco Reinhard1. Gerrit Kropp1. Dirk M. Nuernbergk3.Journal of Microelectronics and Electronic Packaging, January 2018, Vol. 15, No. 1, pp. 1-8, DOI: doi.org/10.4071/imaps.523847

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau. 2X-FAB Semiconductor Foundries AG, Erfurt, Germany. 3Melexis GmbH, Germany.High-Precision Mixed-Signal Sensor Interface for a Wide Temperature - Range [0°-300°C]

Georg Gläser1. Dirk M. Nuernbergk2. Dagmar Kirsten3. André Richter1. Marco Reinhard1. Gerrit Kropp1.International Conference and Exhibition on High Temperature Electronics Network, HiTen 2017, 10-12 July 2017, Queens College, Cambridge, UK

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 2Melexis GmbH, Erfurt. 3X-FAB Semiconductor Foundries AG, Germany, Erfurt.Design and characterization of a high-temperature pressure measurement system

Georg Gläser1.Workshop on High Temperature Electronics, 29.11.2016 - 30.11.2016, Duisburg

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ehrenbergstraße 27, 98693 Ilmenau, Germany.

Patent

DE 10 2016 113 283

Method for determining a resistive deflection of a Wheatstone bridge in a high temperature environment

Event,

TuZ 2018

Event,

Long Night of the Sciences

Discover interactive demonstrators, lectures on chip design and test setups.

Event,

HiTEN 2017

Lecture

High-Precision Mixed-Signal Sensor Interface for a Wide Temperature - Range [0°-300°C]

Georg Gläser1, Dirk M. Nuernbergk2, Dagmar Kirsten3, André Richter1, Marco Reinhard1, Gerrit Kropp1

1IMMS Institut für Mikroelekronik- und Mechatronik-Systeme gemeinnützige GmbH

2Melexis GmbH, Erfurt

3X-FAB Semiconductor Foundries AG, Germany, Erfurt

Event,

TuZ 2016

Two presentations at the 28th GMM/GI/ITG Workshop on test methods and reliability of circuits

Contact

Contact

Eric Schäfer, M. Sc.

Head of Microelectronics / Branch Office Erfurt

eric.schaefer(at)imms.de+49 (0) 361 663 25 35

Eric Schäfer and his team research Integrated sensor systems, especially CMOS-based biosensors, ULP sensor systems and AI-based design and test automation. The results are being incorporated into research on the lead applications Sensor systems for in-vitro diagnostics and RFID sensor technology. It will assist you with services for the development of Integrated circuits and with IC design methods.

Funding

The HoTSens project was funded by the German Federal Ministry of Education and Research in the IKT 2020 programme under the reference 16ES0008.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/7/csm_20130223_dcSen_ProberEF_MM_MG_3325_1920x1280_588e478d86.jpg)