Project GreenSense

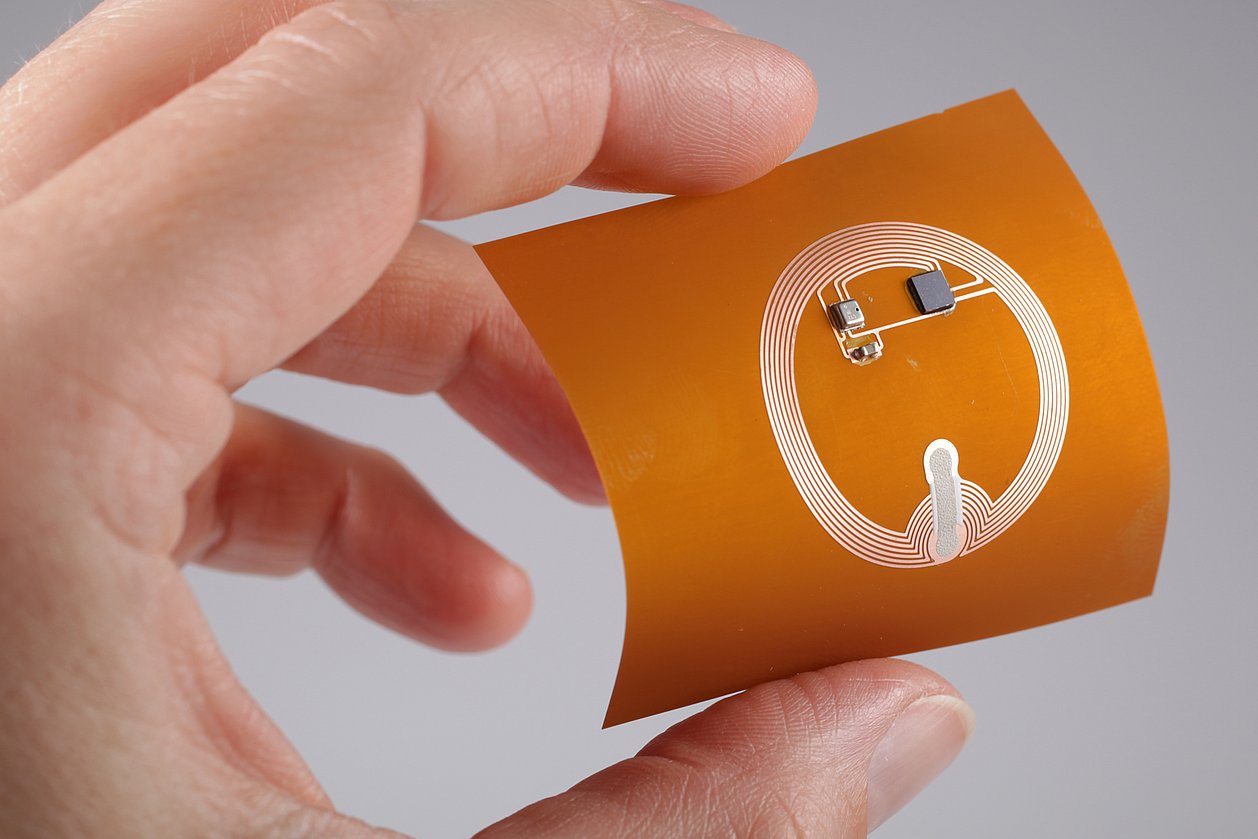

For bio-analysis IMMS developed energy-efficient multi-parametric RFID microsensors and energy harvesting modules for operating autonomous sensors.

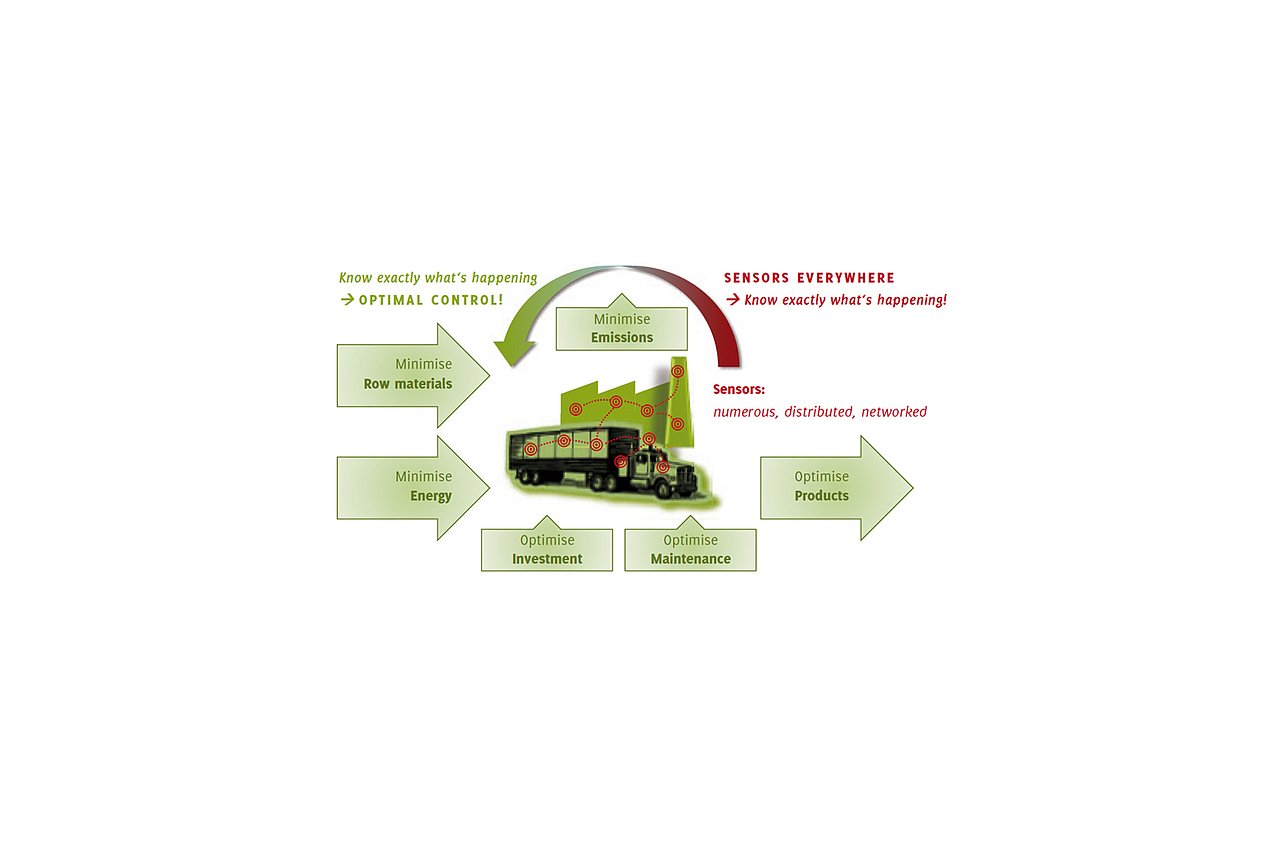

The aim of the project was to research and develop a modular technology platform for energy-autonomous smart sensor networks. The sensor networks are intended for use in a wide range of future scenarios, particularly in the monitoring and control of industrial production, transport and operational processes, so that those processes become more energy-efficient and less resource-intensive. The researchers developed hardware solutions for equipment that senses multiple parameters with embedded electronic signal processing, all at low cost and a high level of energy efficiency. Where access is difficult and the cost of the application must be kept to a minimum, energy harvesting solutions have been designed for operating energy-autonomous wireless sensors.

Cost- and energy-efficient hardware solutions for multi-parametric RFID microsensors

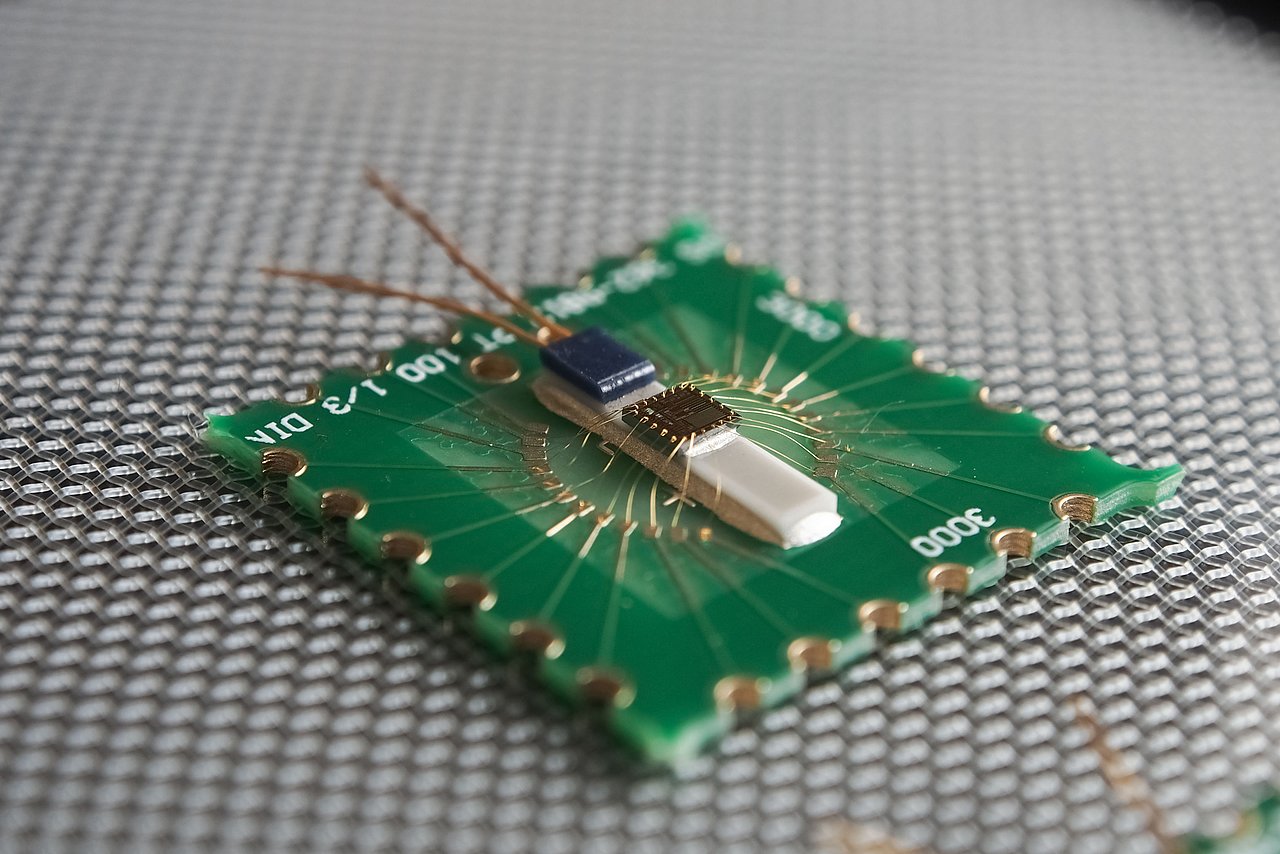

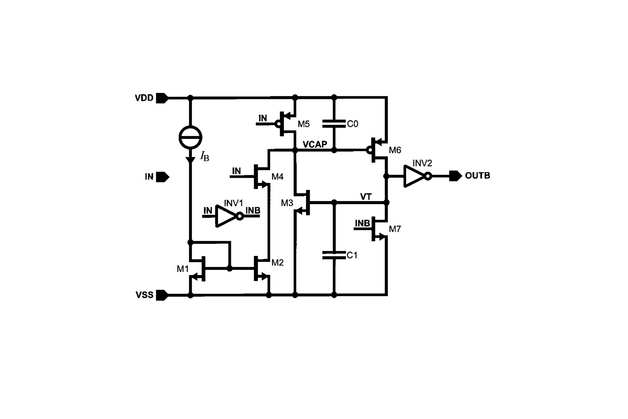

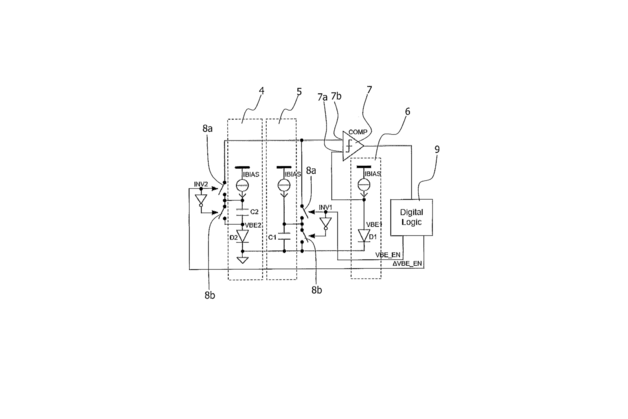

IMMS created a new digital CMOS temperature sensor for application in energy-autonomous integrated sensor systems. For this purpose, IMMS developed integrated microelectronic sensor components, manufactured cheaply with CMOS technology and optimal energy saving features, which will measure and provide electronic evaluation of various physical dimensions.

The new digital CMOS temperature sensor operates across a wide temperature range from –40°C to 125°C with high energy efficiency. The accuracy of the sensor is absolute and systematic between –0.1 °C and +0.5 °C. The temperature is measured and digitised using only 3.5 μW of electric power, which would facilitate the use of a sensor operable without interruption for at least a 10-year period from a mignon battery with a typical capacity of 1000 mAh.

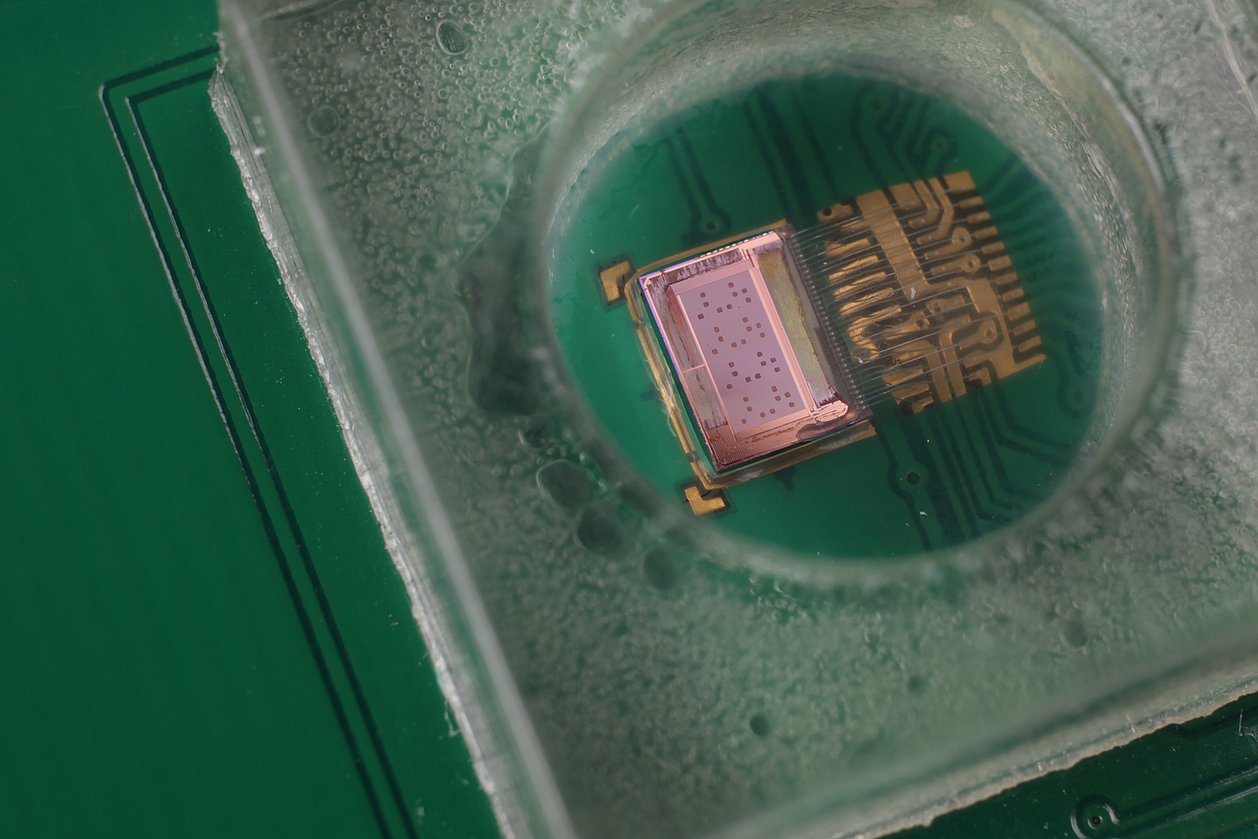

On this basis, IMMS designed and created a passive 13.56-MHz RFID multisensor ASIC, which registers, wirelessly, any changes in the temperature and pH of aqueous solutions and can be used for biological analysis.

Micromechanical energy harvesting solutions for energy-autonomous operation of wireless sensors

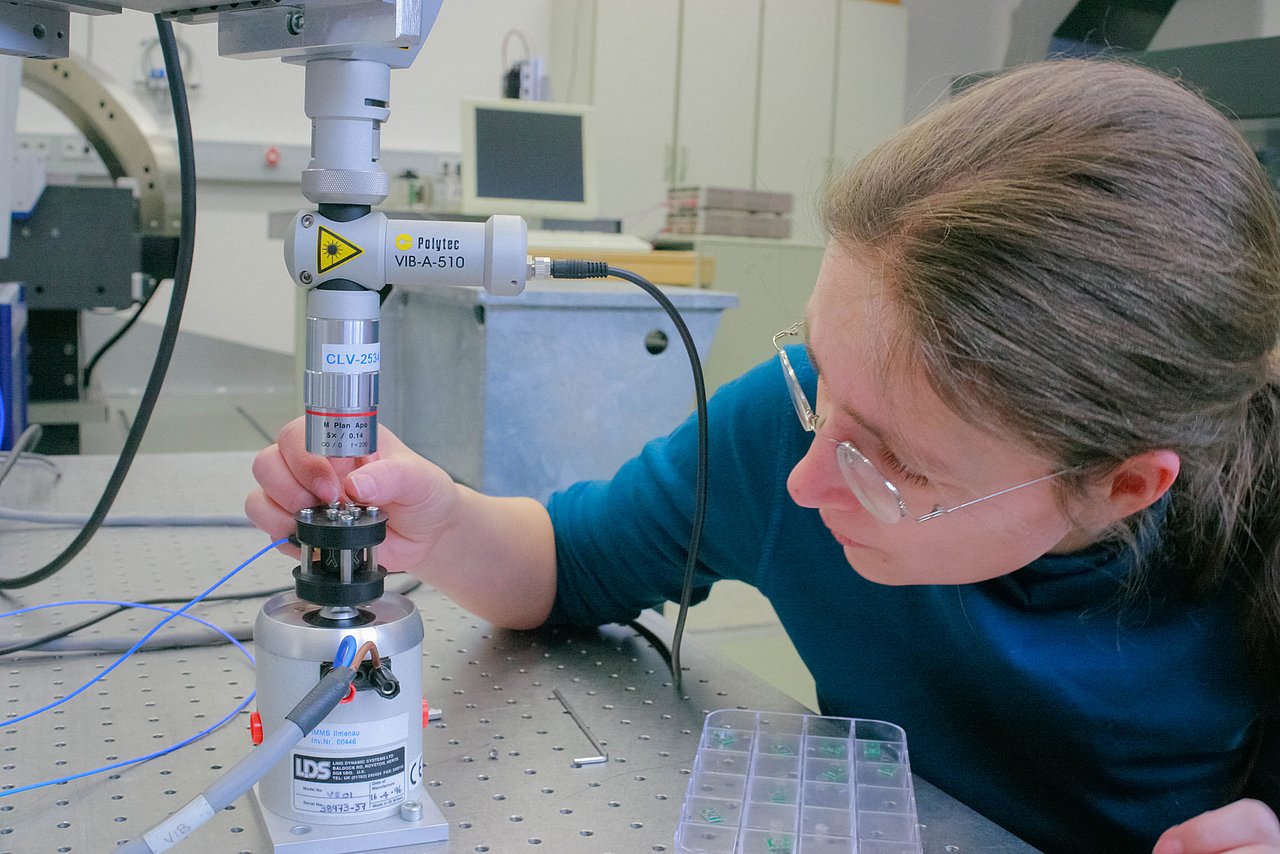

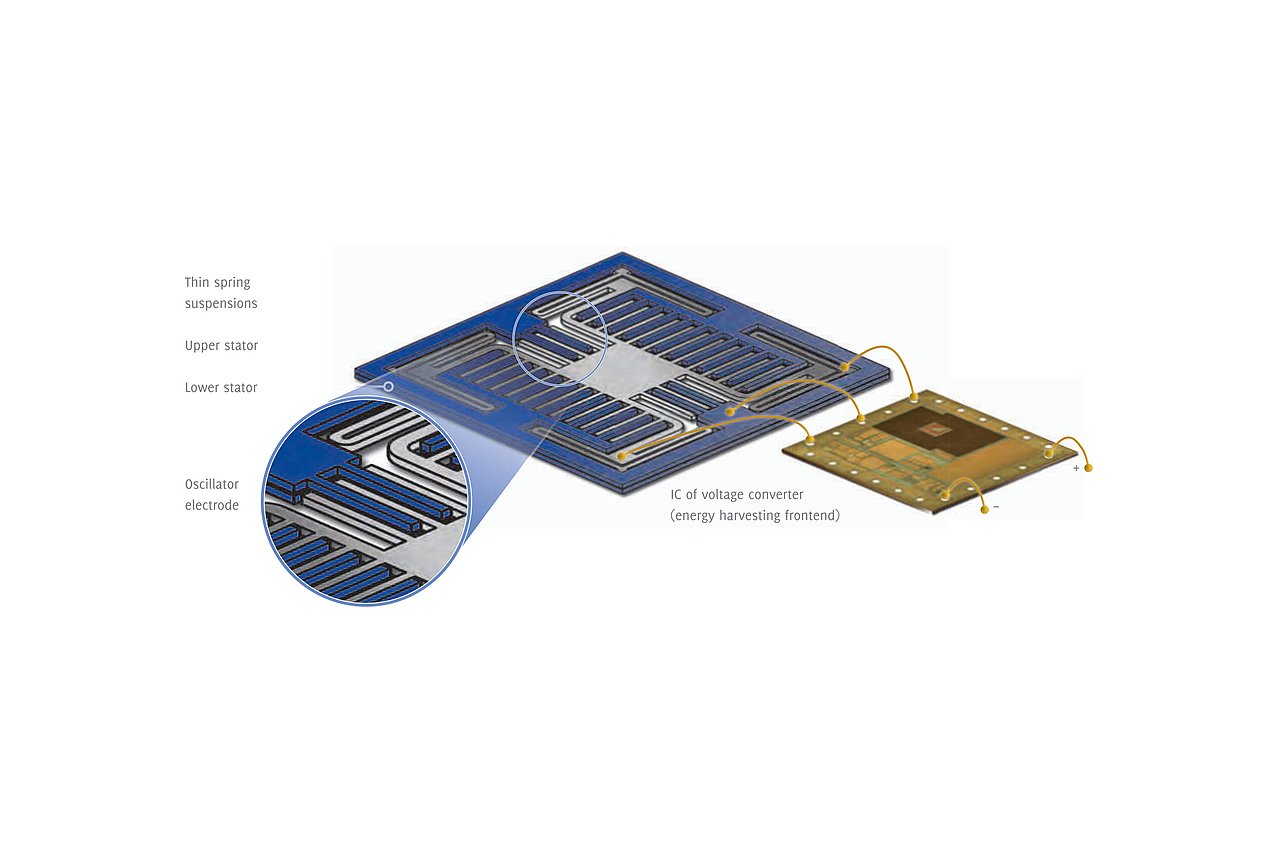

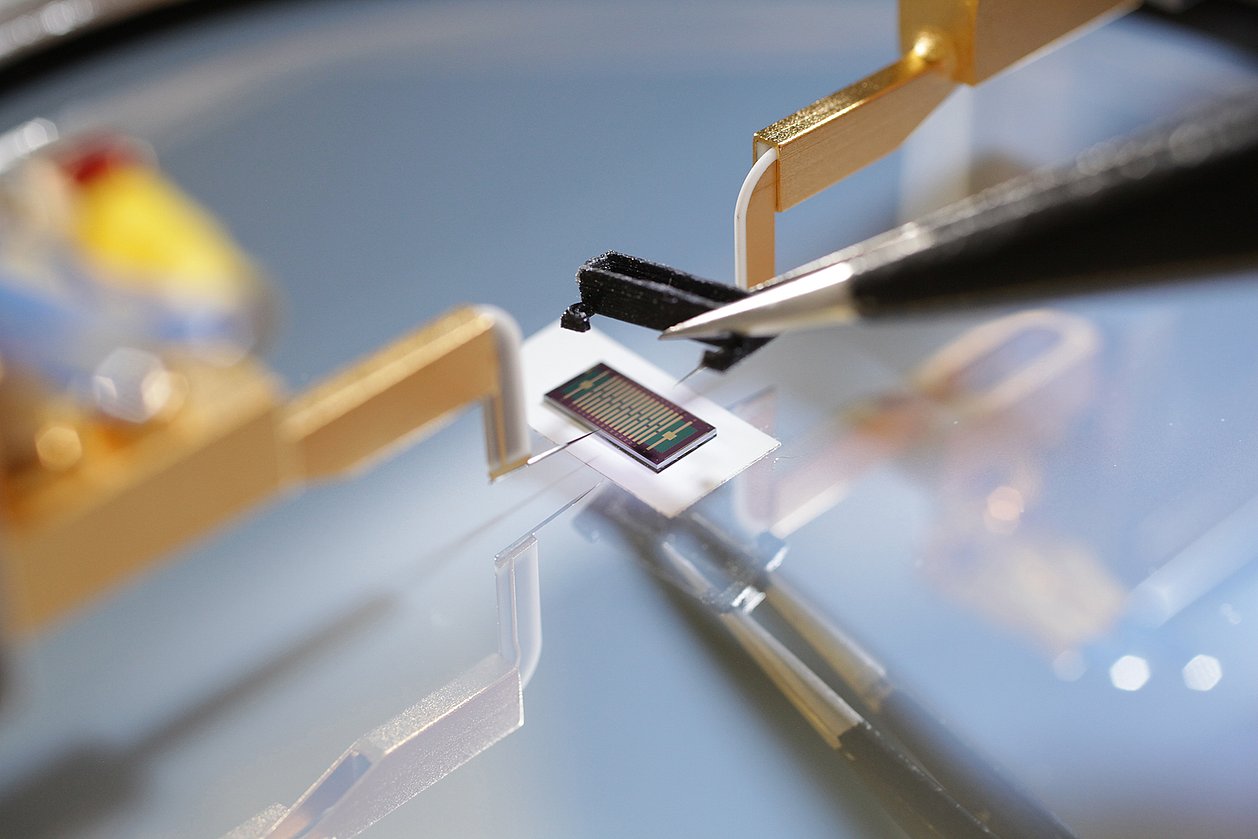

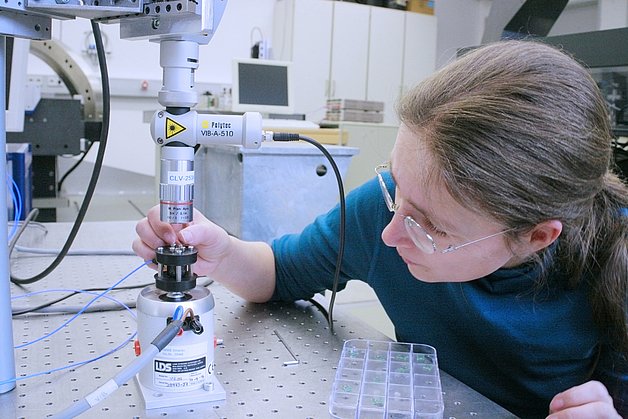

Energy harvesting is a means whereby systems are supplied with energy from their environment. IMMS has developed micromechancial energy convertors that produce continuous output power at around 10 μW. Such a wattage is enough to supply, for instance, an integrated low-power CMOS temperature sensor which is energy-efficient and provides the signal data for RFID readout. The aim is to convert energy from very low-frequency vibrations such as are created by human movement.

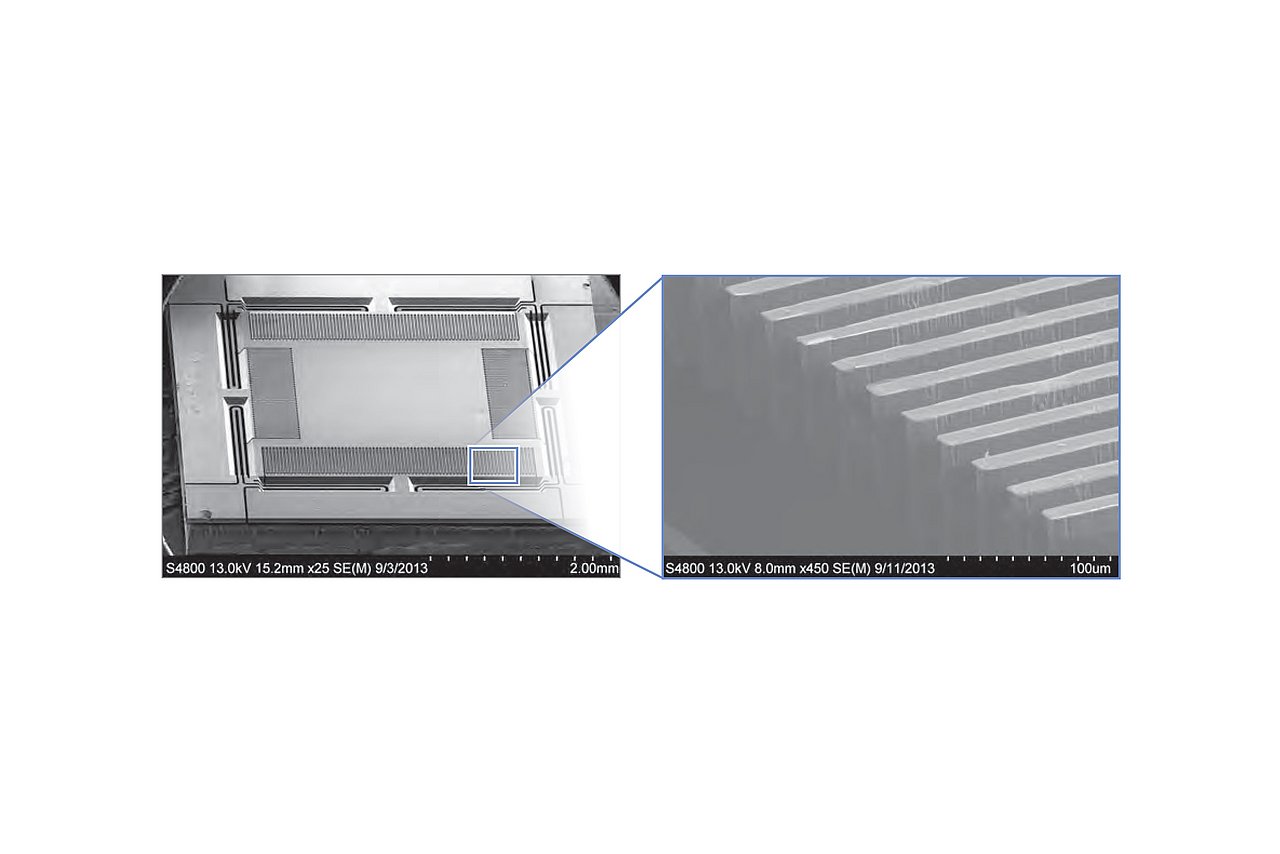

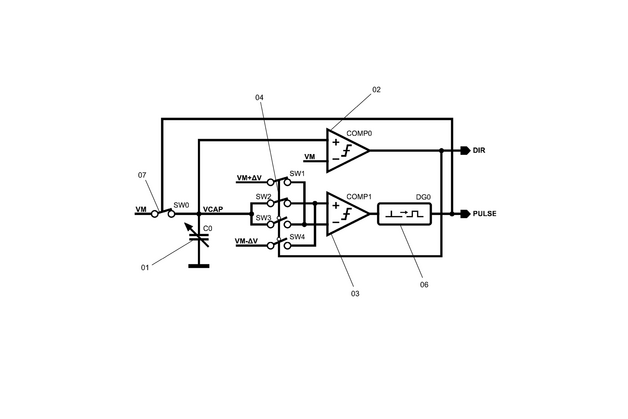

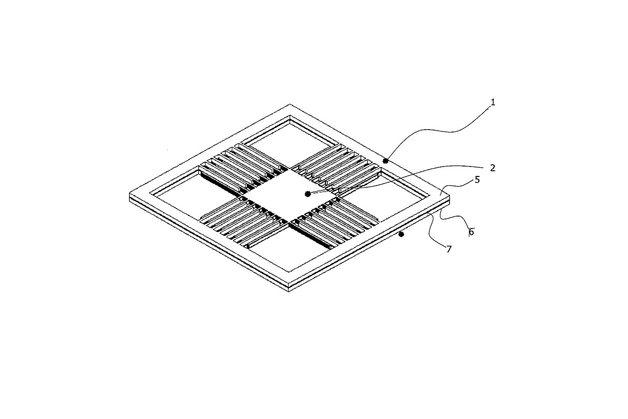

The basic principle in the system is that of moveable electrostatic comb structures. The main challenge was to achieve low eigenfrequency, capacitance at the highest level possible and a marked change in capacitance when the structures vibrate, all on a tiny chip area.

To meet the challenge, IMMS has put into practice a new idea for MEMS harvesters and applied for a patent on the design and electronics, which rely on an out-of-plane oscillator. This name refers to the fact that the central proof mass is in oscillation outside the wafer plane.

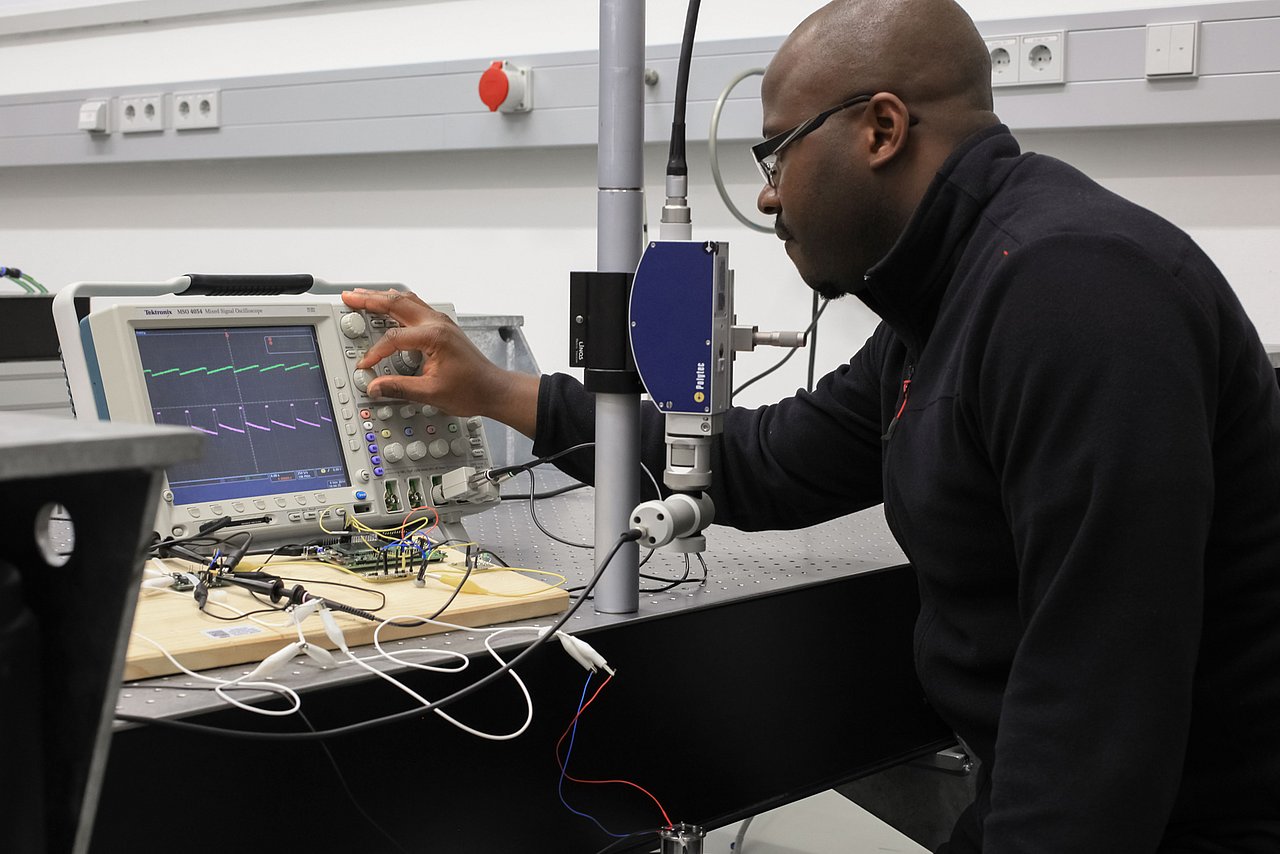

The system architecture for the MEMS energy harvesting module received the Best Paper award at the Analog 2014 conference.

Energy-efficient sensor and radio module to set up energy-autonomous wireless sensor networks

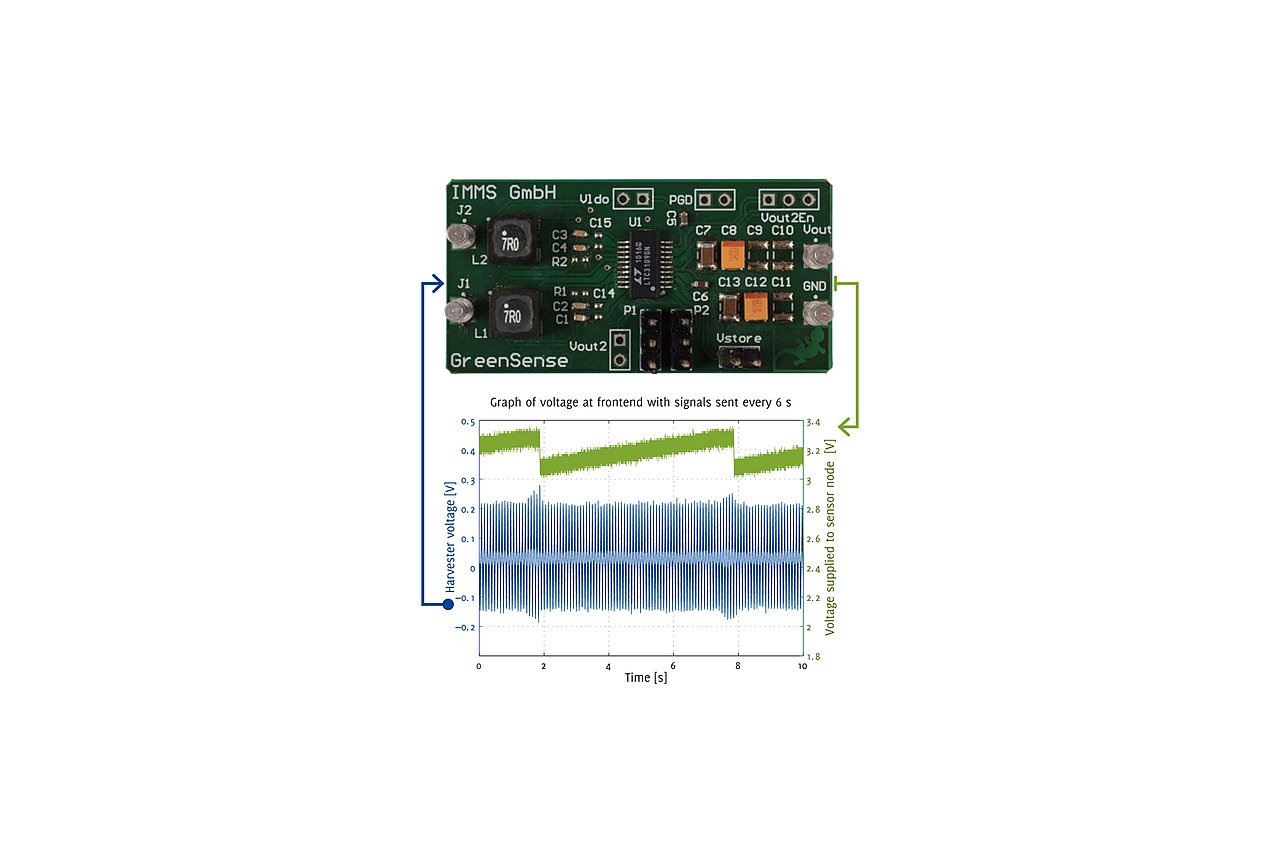

Systems which have a power output of a few microwatts cannot be used for the acquisition and transmission of rapidly changing data and cannot be used to transmit over great distances. A sensor platform in such situations may well require power up to 10 mW.

With this in mind, IMMS has taken radio sensor nodes and optimised their energy properties so that they can be fully supplied from the environment. Furthermore, an energy simulator was created. It is a solution that constitutes an innovation in the service of circuit design for PCBs, permitting estimation of the electrical consumption of complex microcontroller-based systems before they are combined into the hardware. It also enables the designer to evaluate the energy aspects if peripherals are replaced and the interfaces change. Such details are essential to optimum design of energy-autonomous radio sensor nodes. The modular wireless sensor platform which has been created on this basis can be used for a range of sensors and energy can be harvested from the environment.

IMMS explored and constructed a variety of circuits for the connection of an electromagnetic harvester. The circuits were given the appropriate dimensions and optimised so as to obtain from the harvester the maximum energy possible. The optimised harvester circuits will function with alternating voltage at the relatively low effective figure of less than 100 mV.

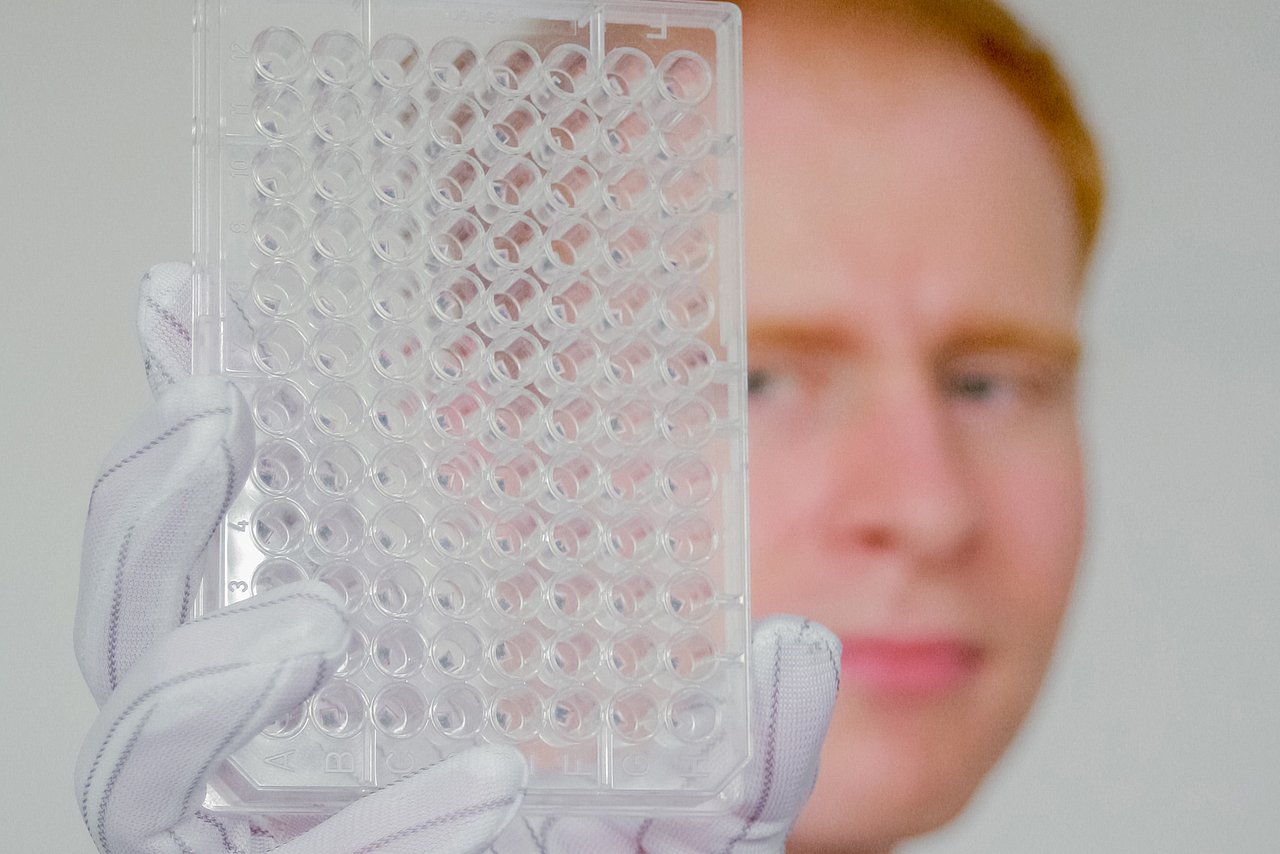

CMOS-based sensor technology for the detection of biomarkers

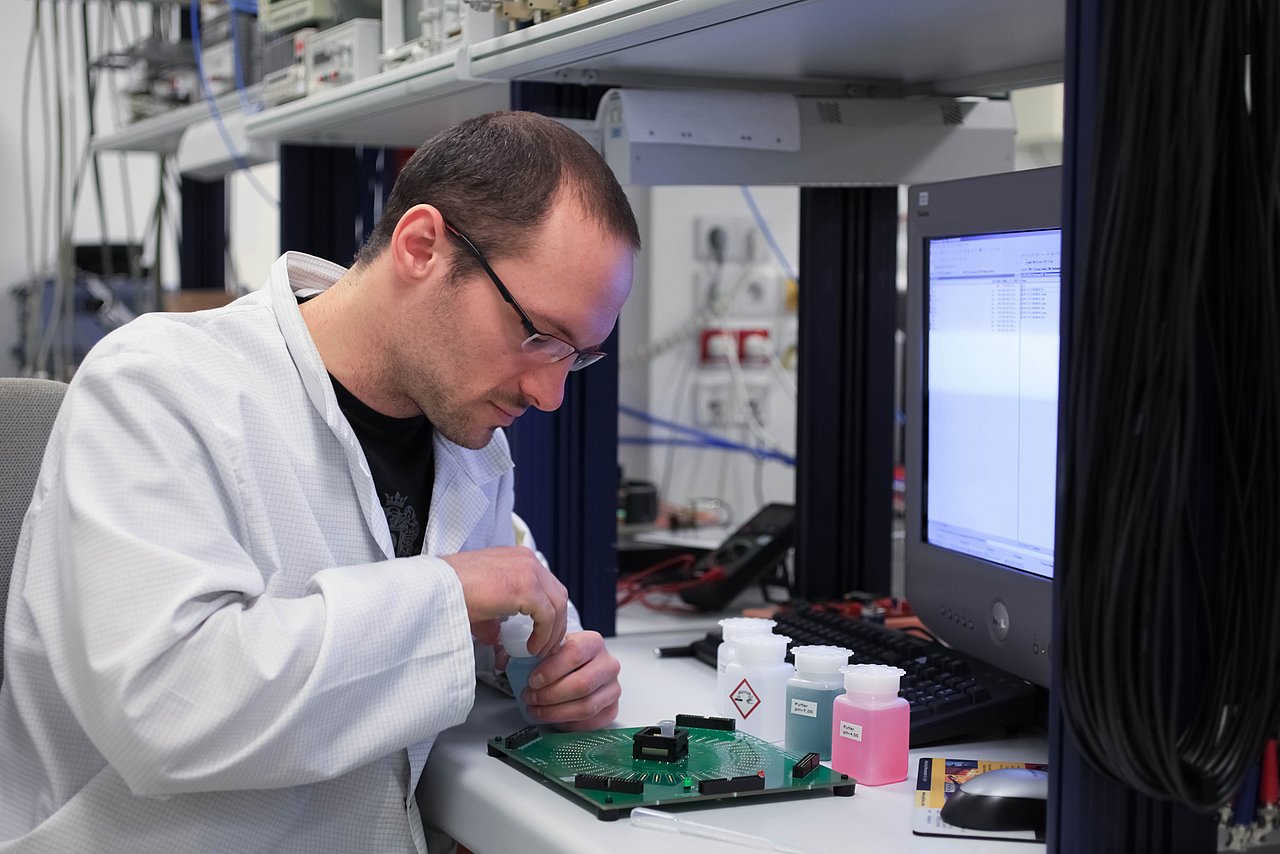

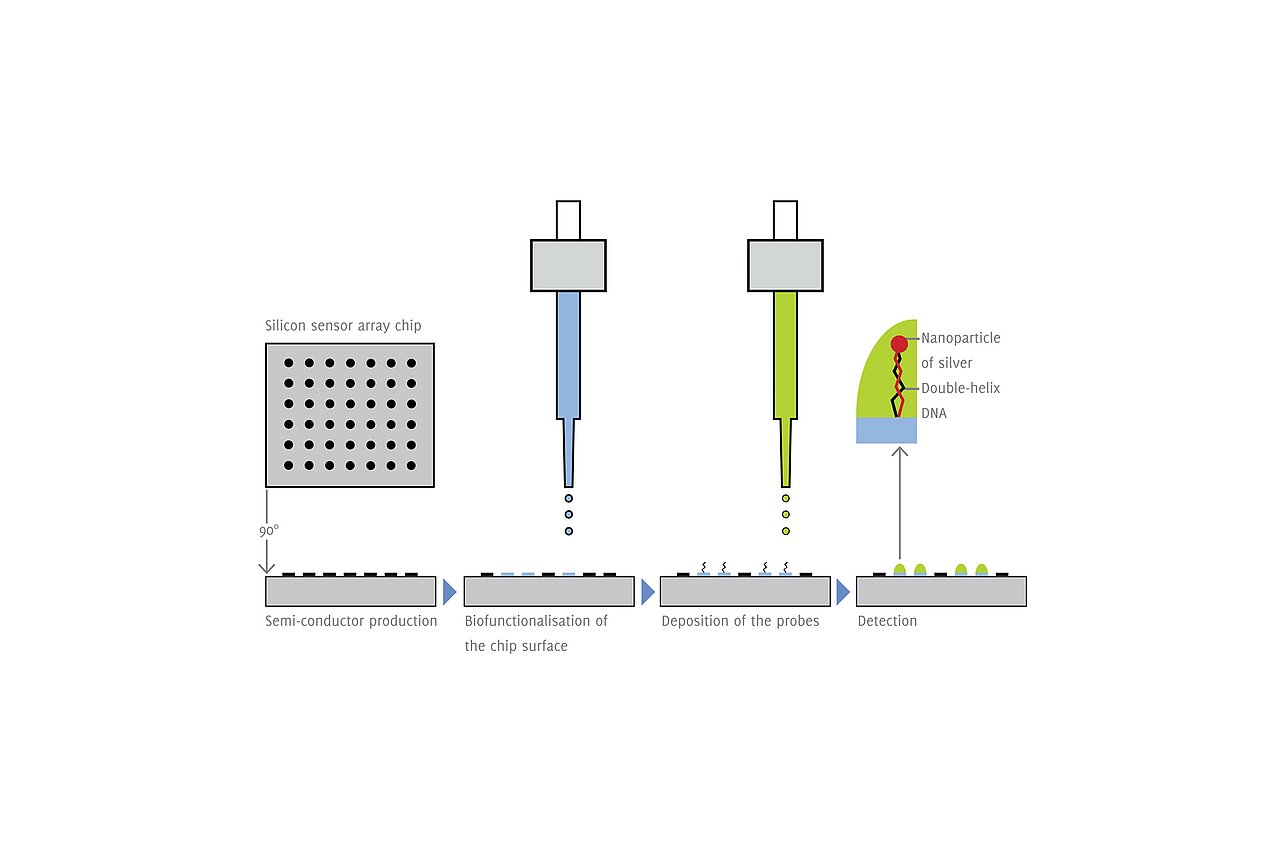

IMMS has joined forces with IPHT Jena to develop the means whereby epizootic disease can be readily diagnosed. The idea is that a portable electronic device should enable samples from farm stock to be examined for pathogens automatically and rapidly. The affected animals can then be isolated and treated at an early stage, eliminating any risk to consumers, protecting the healthy animals and limiting financial loss.

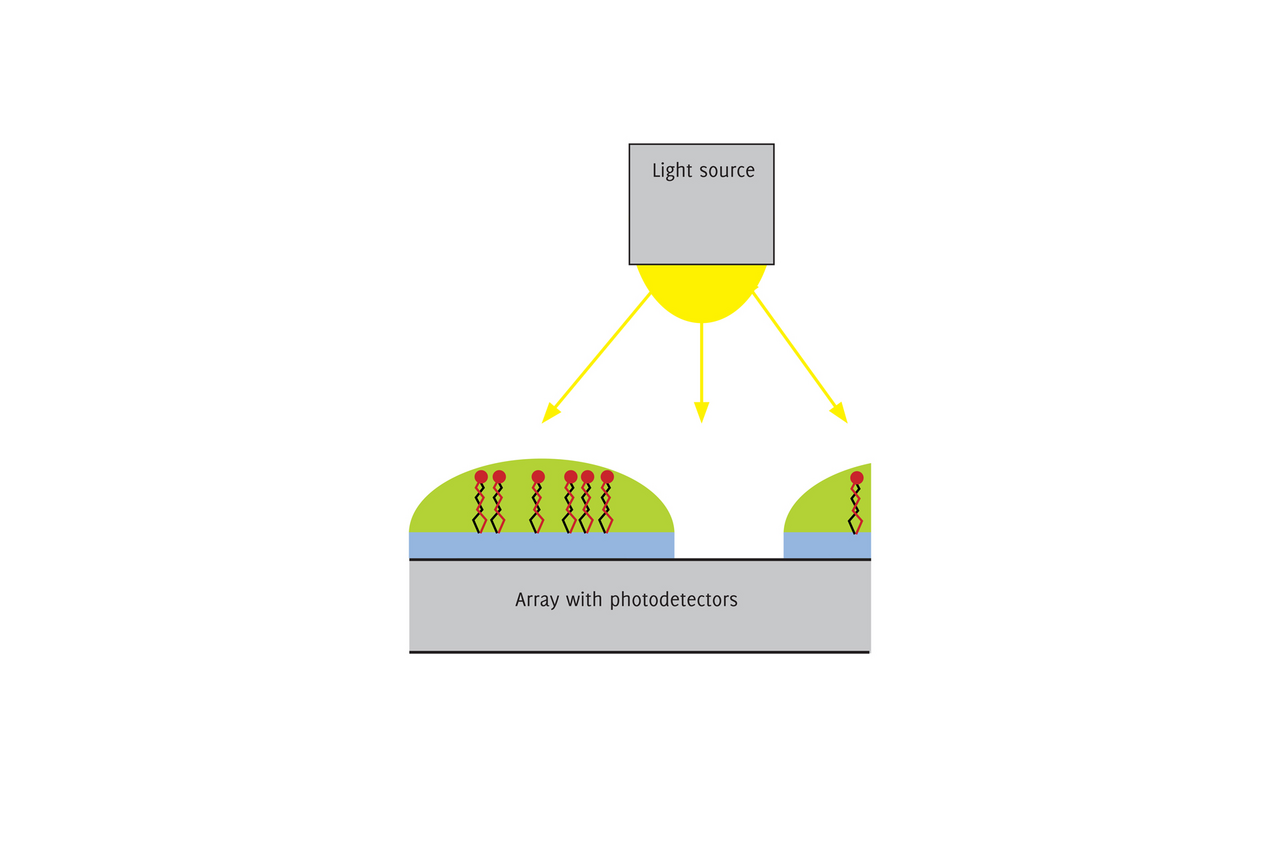

The IMMS contribution follows the principles of a diagnostic procedure developed by Jenaer BioChip Initiative (JBCI, IPHT Jena) which has enabled foot and mouth disease (FMD) and other diseases to be detected from samples on glass chips. As the procedure relies on a simple and fast evaluation of the electrical conductivity and optical properties of samples, it can be incorporated into a compact on-site diagnostic system.

The IMMS contribution follows the principles of a diagnostic procedure developed by Jenaer BioChip Initiative (JBCI, IPHT Jena) which has enabled foot and mouth disease (FMD) and other diseases to be detected from samples on glass chips. As the procedure relies on a simple and fast evaluation of the electrical conductivity and optical properties of samples, it can be incorporated into a compact on-site diagnostic system.

The microelectronic approach offers additional measurement options as an alternative to the original glass plate-based platform. The aim is to use the new devices to keep track on the reactions taking place during diagnosis and to unify the three types of measurement on a single semiconductor biochip.

Acronym / Name:

GreenSense / Enabling technologies for resource- and energy-efficient smart sensor networksDuration:2012 – 2014

Application:

Environmental monitoring and smart city applications|Automation technology and Industry 4.0|Life Sciences|Logistics| industrial process measuring technology| bio-analysis| building automationResearch field:Integrated sensor systems

Related content

Reference

Reinhard Jurisch, microsensys

”IMMS, being the sole research institute in Thüringen for microelectronic applications, has a central role for enterprises like ours in the region, acting as technology partner and coordinator for joint industrial research with public funding.“

Reference

Dr. Jörg Weber, Analytik Jena

”The work offers great potential for industrial applications, but also for growing markets in life science and medical technology, where we see a rising demand for intelligent microelectronic sensors.“

Adaptiver Frontend-ASIC für elektrostatische Energy-Harvester

Benjamin Saft1. Eric Schäfer1. André Jäger1. Alexander Rolapp1. Eckhard Hennig2.8. GMM-Workshop „Energieautarke Sensorik“, 25.02.216 – 26.02.2016, Renningen (Robert Bosch GmbH) Germany

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, D-98693 Ilmenau, Germany. 2Hochschule Reutlingen, D-72762 Reutlingen, Germany.An Ultra-Low Power Capacitance Extrema and Ratio Detector for Electrostatic Energy Harvesters

Benjamin Saft1. Eric Schäfer1. Alexander Rolapp1. Eckhard Hennig2.41th European Solid-State Circuits Conference ESSCIRC, 14-18 Sept. 2015, Pages 245 - 248, DOI: dx.doi.org/10.1109/ESSCIRC.2015.7313873, ISBN: 978-1-4673-7470-5, Graz, Austria

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, D-98693 Ilmenau, Germany. 2Hochschule Reutlingen, D-72762 Reutlingen, Germany.Vibration energy generators for low-frequency spectral excitations

Bianca Leistritz1,2. Michael Katzschmann1. Hannes Toepfer1,2.EUROSENSORS 2014, the 28th European Conference on Solid-State Transducers, in Procedia Engineering, Volume 87, 2014, Pages 420 – 423, www.sciencedirect.com,

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, D-98693 Ilmenau, Germany. 2Technische Universität Ilmenau, D-98693 Ilmenau, Germany.A Low-Voltage Low-Power CMOS Time-Domain Temperature Sensor Accurate To Within [-0.1,+0.5]˚C From -40˚C To 125˚C

Jun Tan. Alexander Rolapp. Eckhard Hennig.12th IEEE Asia Pacific Conference on Circuits and Systems (APCCAS 2014), Session Sensor Systems and Emerging Memory Technology, pp. 463 – 466, IEEE Catalog Number: CFP14APC-USB, ISBN: 978-1-4799-5229-8, Ishigaki Island, Okinawa, Japan

Patent

DE 10 2013 113 378

Method and electronic circuit for determining the time instant of an extremum of a time-varying capacitance

Patent

DE 10 2012 215 600

Capacitive energy converter and method of operating a capacitive energy converter

Press release,

Highly accurate and battery-free measurement via RFID

IMMS PhD candidate defends dissertation on precise passive RFID sensor technology

Press release,

IMMS receives iENA silver medal for energy-efficient solutions in integrated circuits

Approach to be used in energy-efficient biological analysis and Industry 4.0 applications.

Press release,

IMMS Receives Best Paper Award For Work On Energy-Efficient Sensor

The CMOS temperature sensor was presented at the APCCAS 2014 and is designed for energy-autonomous sensor systems with power supply from MEMS energy harvesting modules.

Press release,

IMMS receives Best Paper Award for MEMS Energy Harvesting Module

Ilmenau, 22.09.2014. On Friday at the ANALOG 2014 conference in Hannover, Germany, IMMS researchers received the Best Paper Award for their article and lecture "A System Architecture for an Integrated Electrostatic MEMS Energy Harvesting Module". This work on the development of miniaturized energy harvesters will establish innovative supply options for self-powered wireless microsensor networks.

The presented topic was part of the the GreenSense research project which started in 2012.…

Contact

Contact

Eric Schäfer, M. Sc.

Head of Microelectronics / Branch Office Erfurt

eric.schaefer(at)imms.de+49 (0) 361 663 25 35

Eric Schäfer and his team research Integrated sensor systems, especially CMOS-based biosensors, ULP sensor systems and AI-based design and test automation. The results are being incorporated into research on the lead applications Sensor systems for in-vitro diagnostics and RFID sensor technology. It will assist you with services for the development of Integrated circuits and with IC design methods.

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Funding

The GreenSense project has been funded by the “Land” of Thüringen (Ministry of Economics, Labour and Technology) and the European Social Fund (ESF) under the reference 2011 FGR 0121.