Project ANUBIS

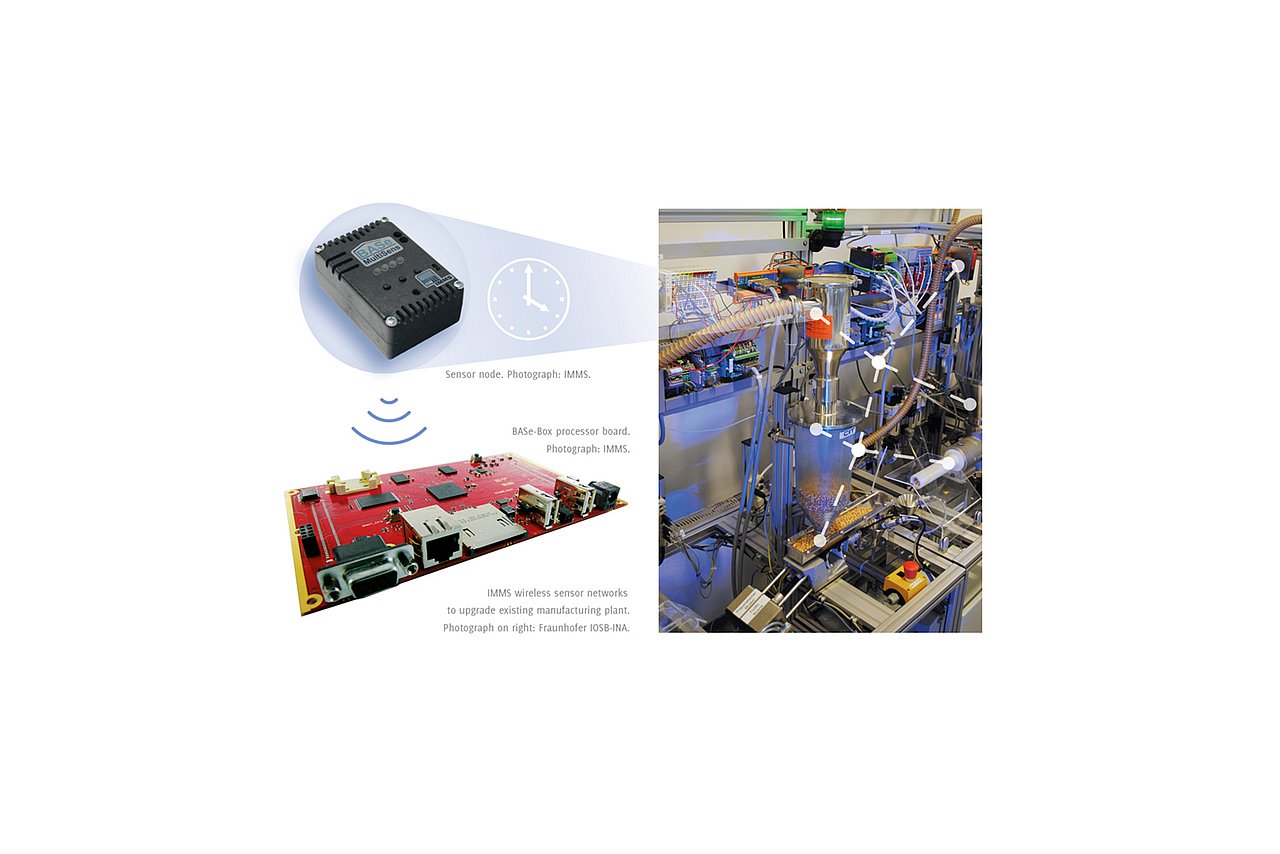

For efficient processes the developed synchronised wireless sensor nodes capture energy data of industrial plant.

For the protection of the environment and to maintain Germany's international competitiveness through efficient manufacture it is necessary that energy should be saved in production processes. To this end, the politicians have set standards and issued directives such as ISO 50001, requiring automatic equipment to make energy savings which must be proven by detailed recording of energy consumption. The ISO 50001 standard applies equally to older plant, which tends to be rather less automated. Here the relevant data are often unavailable as they are not included in the process image of the communication infrastructure, if such an infrastructure even exists.

IMMS has designed a wireless sensor network and achieved the practical acquisition of the relevant data under the harsh conditions obtaining in industrial production. The data is then transmitted for processing. This wireless network can be added to existing plant, in particular, enabling it to capture the information required by the standard. The system can be installed without affecting the productive operation of the plant.

The wireless sensor network and the automation system are connected via the BASe-Box. It receives the data from the sensor network and transmits it to the automation system, acting not only as gateway for the data but also undertaking the synchronisation. The items synchronised include the BASe-Box itself, further data loggers and other components of the automation system, such as servers. The synchronisation uses Ethernet and its associated protocols. The Institute has developed software that makes this common time basis available in the sensor network.

Acronym / Name:

ANUBIS / Analysis and monitoring of energy consumption in process and production technology, taking into account the business issues detection and prevention of suboptimal energy balances in productionDuration:2012 – 2013

Application:

Automation technology and Industry 4.0|Industry 4.0| Energy| Environment| Energy-efficient systems (CPS)| Embedded Systems| Industrial AutomationResearch field:Smart distributed measurement and test systems

Partner

Related content

Intelligente Lösungen für Industrie 4.0 - Diagnose und Überwachung in industriellen Anlagen

Tino Hutschnreuther1.2. Maschinenbautag, 15.06.2016, Erfurt

1IMMS Institut für Mikroelekronik- und Mechatronik-Systeme gemeinnützige GmbH, D-98693 Ilmenau, Germany.Zeitsynchronisation in drahtlosen Sensornetzwerken – Verfahren und Anwendungen

Stefan Schramm. Michael Rink. Marco Götze.IWK Mittweida, 5.11.2014 - 6.11.2014, Vortrag

A Software Architecture for the Analysis of Energy- and Process-Data

Björn Kroll1. Sebastian Schriegel1. Stefan Schramm2. Oliver Niggemann1.18th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Cagliari, Italy, 10.09.2013-13.09.2013

1Fraunhofer IOSB-INA, Application Center for Industrial Automation, Lemgo, Germany. 2IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau.Talk

Contact

Contact

Dr.-Ing. Tino Hutschenreuther

Head of System Design

tino.hutschenreuther(at)imms.de+49 (0) 3677 874 93 40

Dr. Tino Hutschenreuther will answer your questions on our research in Smart distributed measurement and test systems and the related core topics Analysis of distributed IoT systems, Embedded AI and Real-time data processing and communications, on the lead applications Adaptive edge AI systems for industrial application and IoT systems for cooperative environmental monitoring as well as on the range of services for the development of embedded systems.

Funding

The ANUBIS project was funded by the German Federal Ministry for Economic Affairs and Energy (BMWi) as part of the programme to support “Industrial Community Research and Development” (IGF) under the reference 16419 BG/2.