Project ANCONA

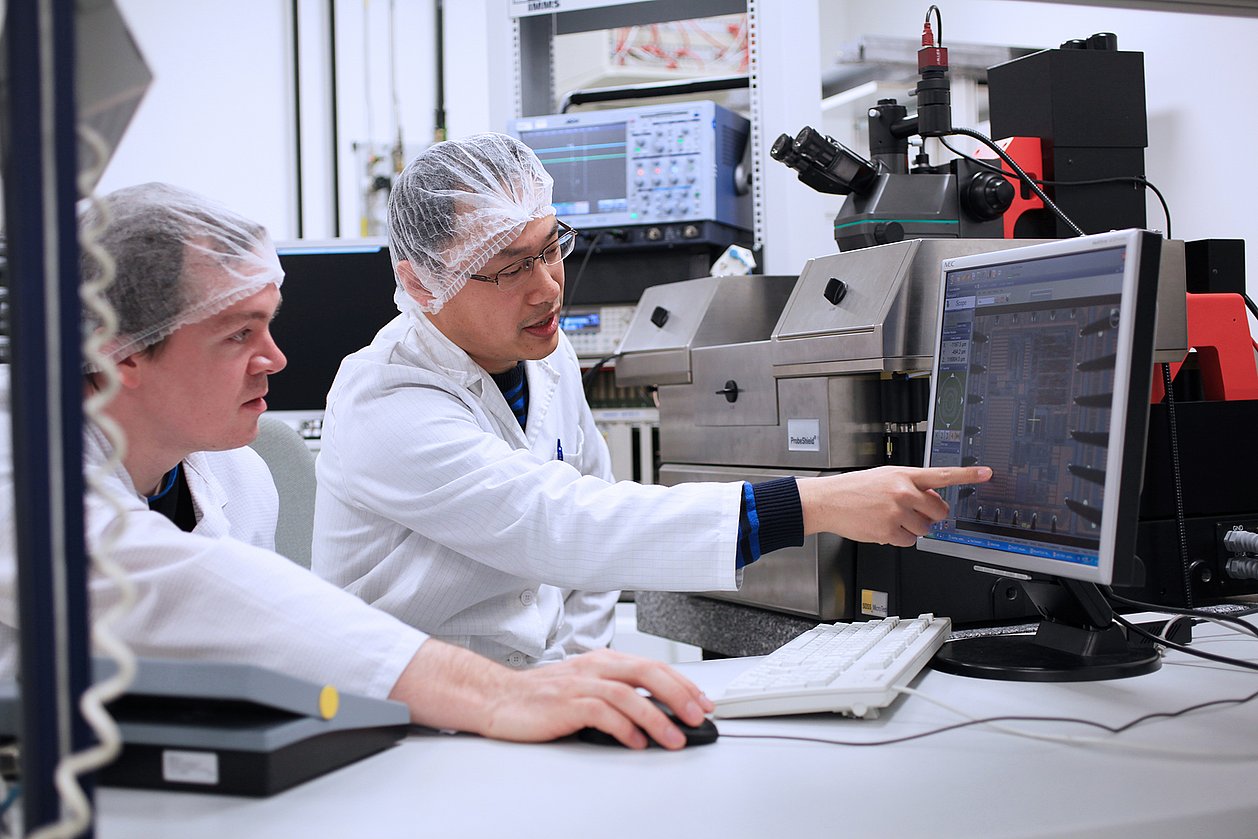

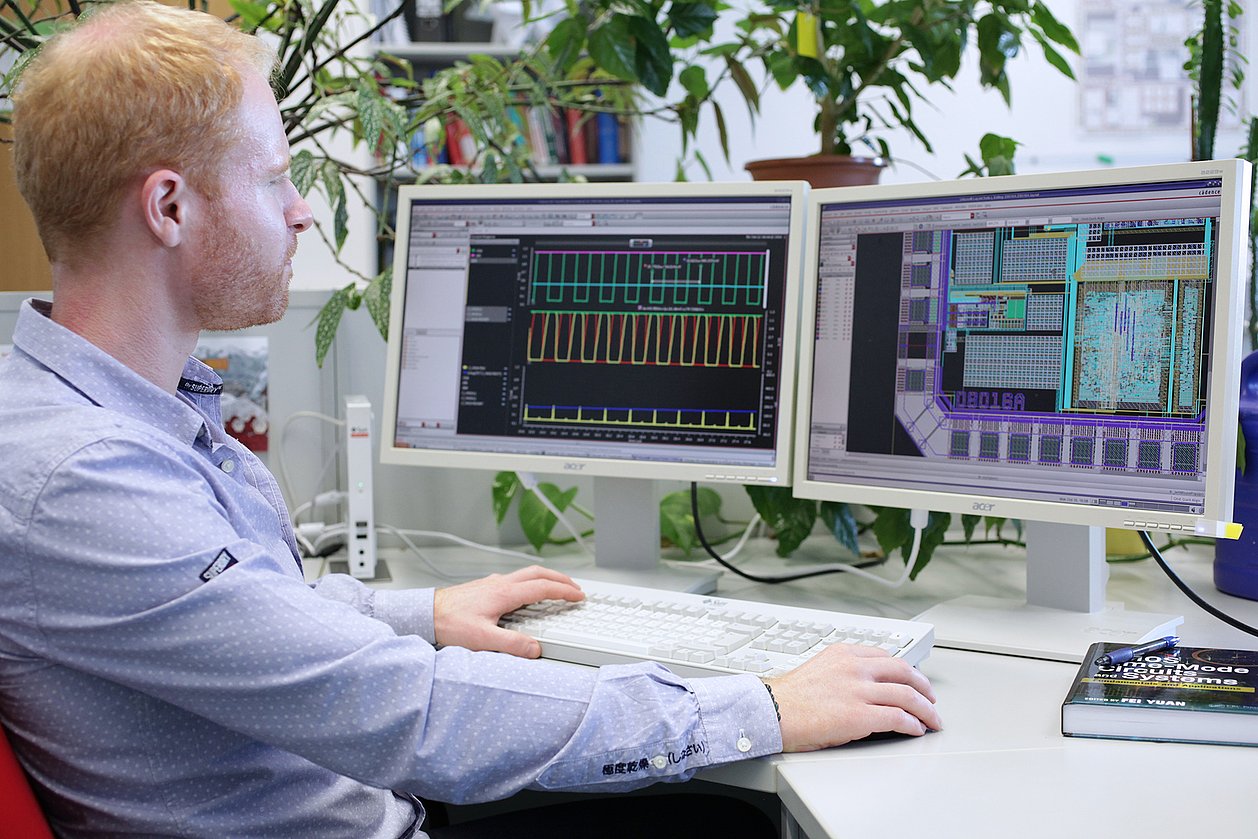

Computer-aided verification methods have been developed to accelerate the design of Industry 4.0 applications.

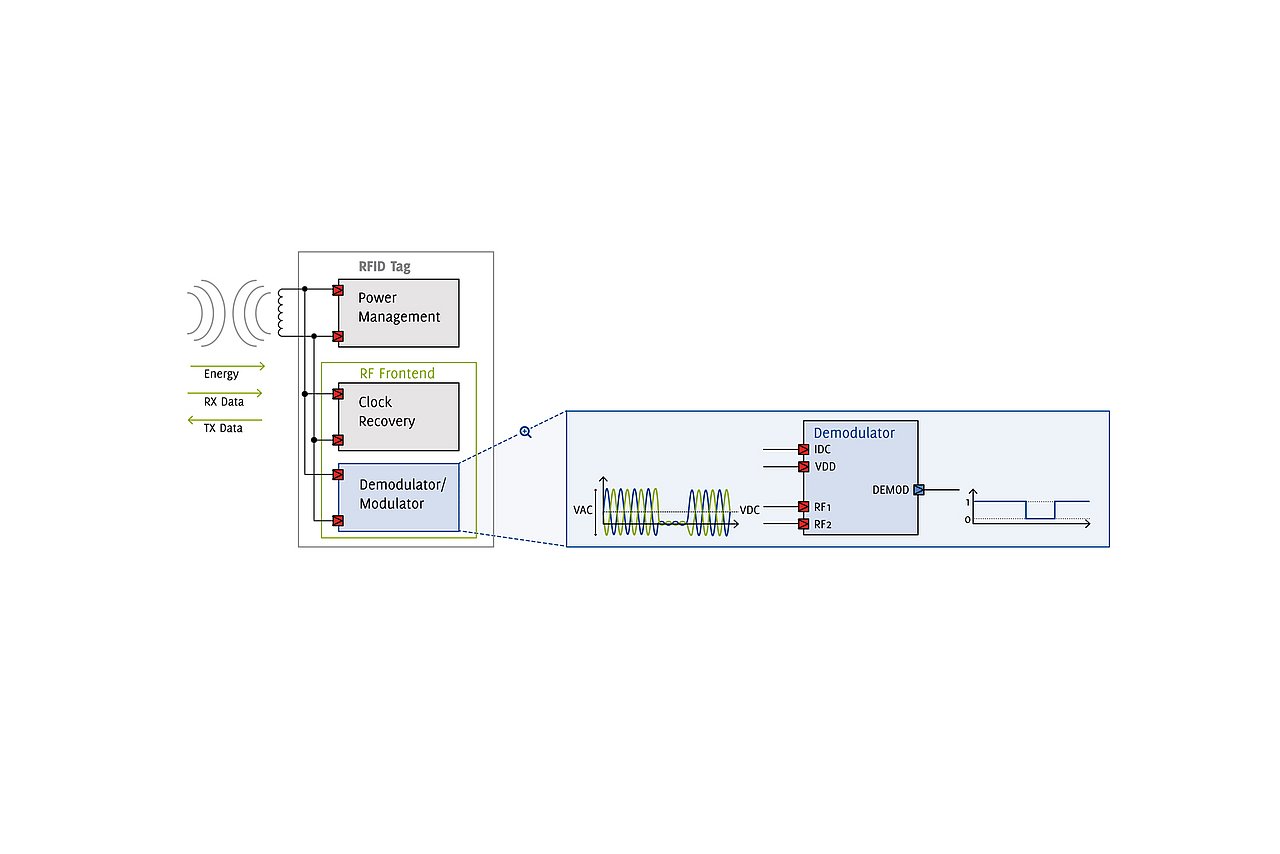

At the basis of all the smart systems which can function as part of the Internet of Things and of all the high performance applications needed in Industry 4.0 lies the technology contained in complex, highly integrated micro-electronic chips. System-on-Chip (SoC) technology comprises numerous elements and functions, both analogue and digital, into the narrowest of space, crowding together sensors, actuators and signal processing.

Any errors in the design of the integrated circuits may impact on turnover to the tune of several hundred million dollars. They can cause costly downtime and, far worse, highly expensive product recall, repair and replacement. In order to keep such risks to a minimum, designers strive to recognise any faults as early as possible in the design process. In the context of Industry 4.0, also known as the fourth Industrial revolution, there is a further imperative: to design yet smarter and thus even more complex systems to meet new demands. Research is focussing on the development of many new system components for the future. How these will interact with current methods can as yet only be tested in experimental setups.

In anticipation, the ANCONA project partners have worked on computer-aided procedures which will provide reliable testing of complex systems even at the design stage and prove their functionality. These procedures are intended to simplify and significantly accelerate the design process for integrated circuits. They will boost innovation potential and give their user a competitive edge.

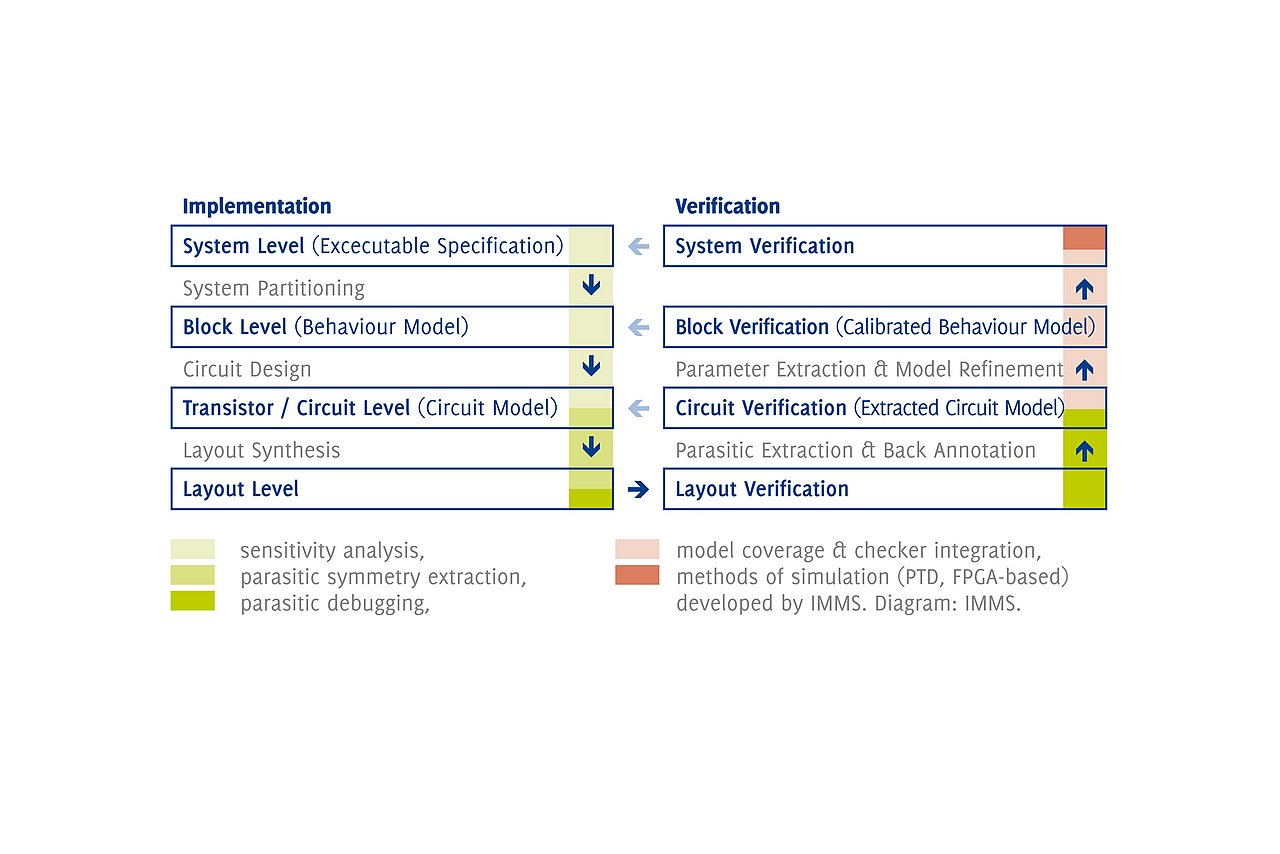

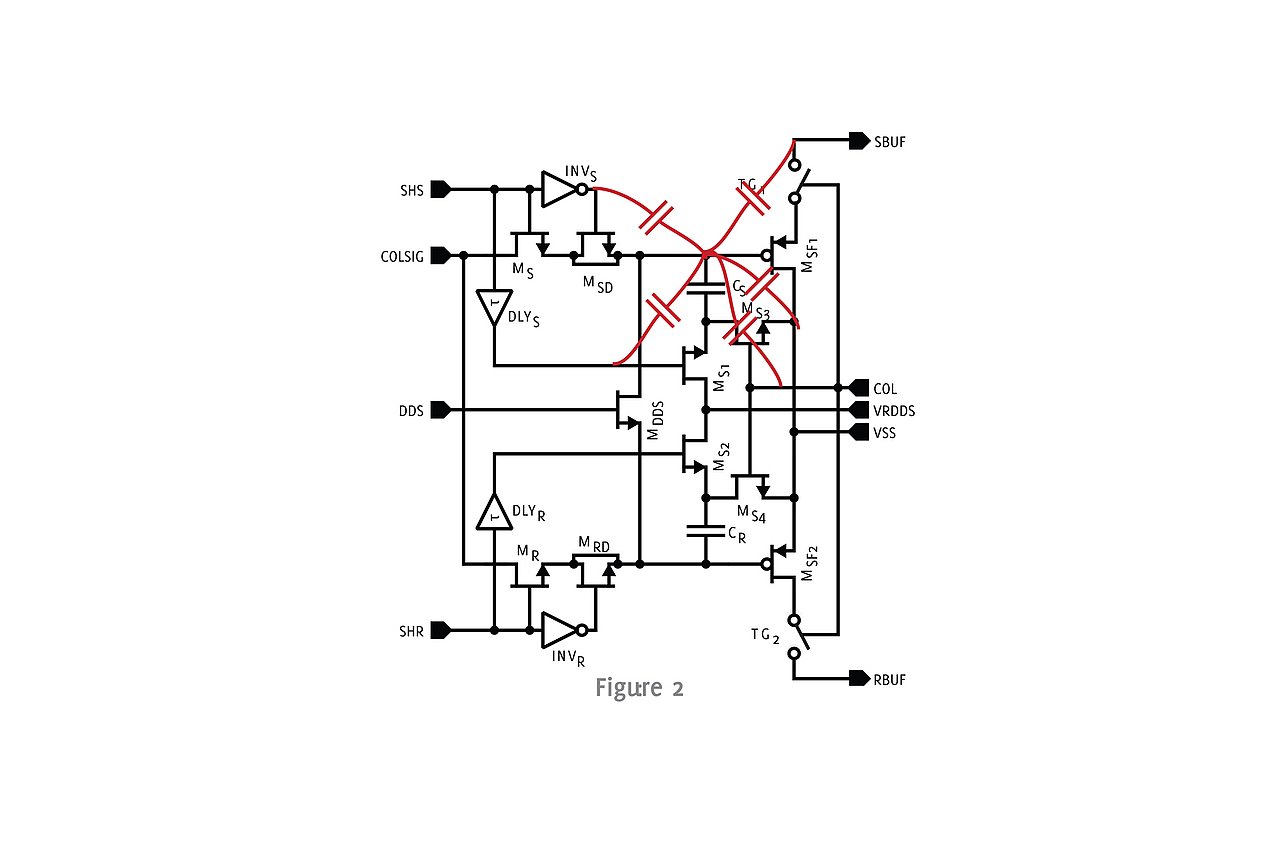

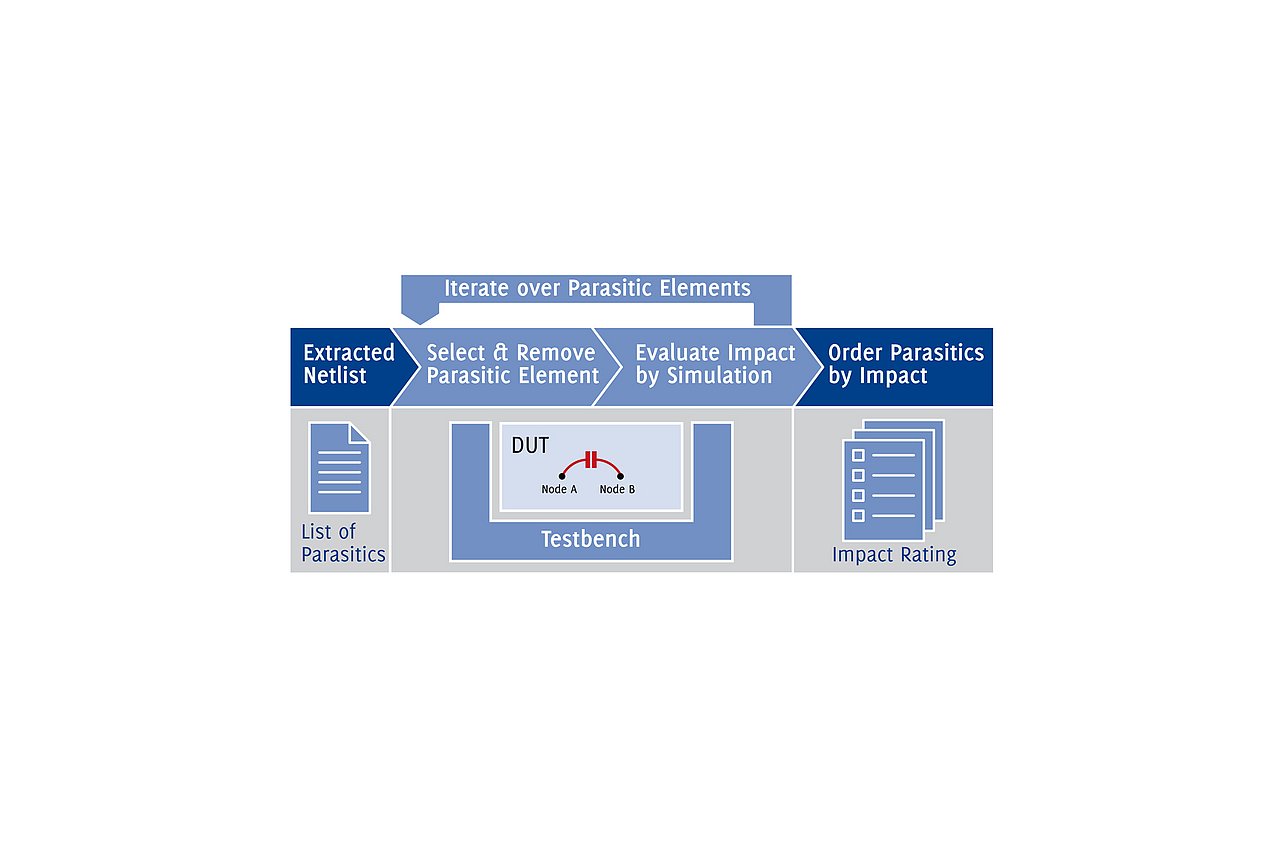

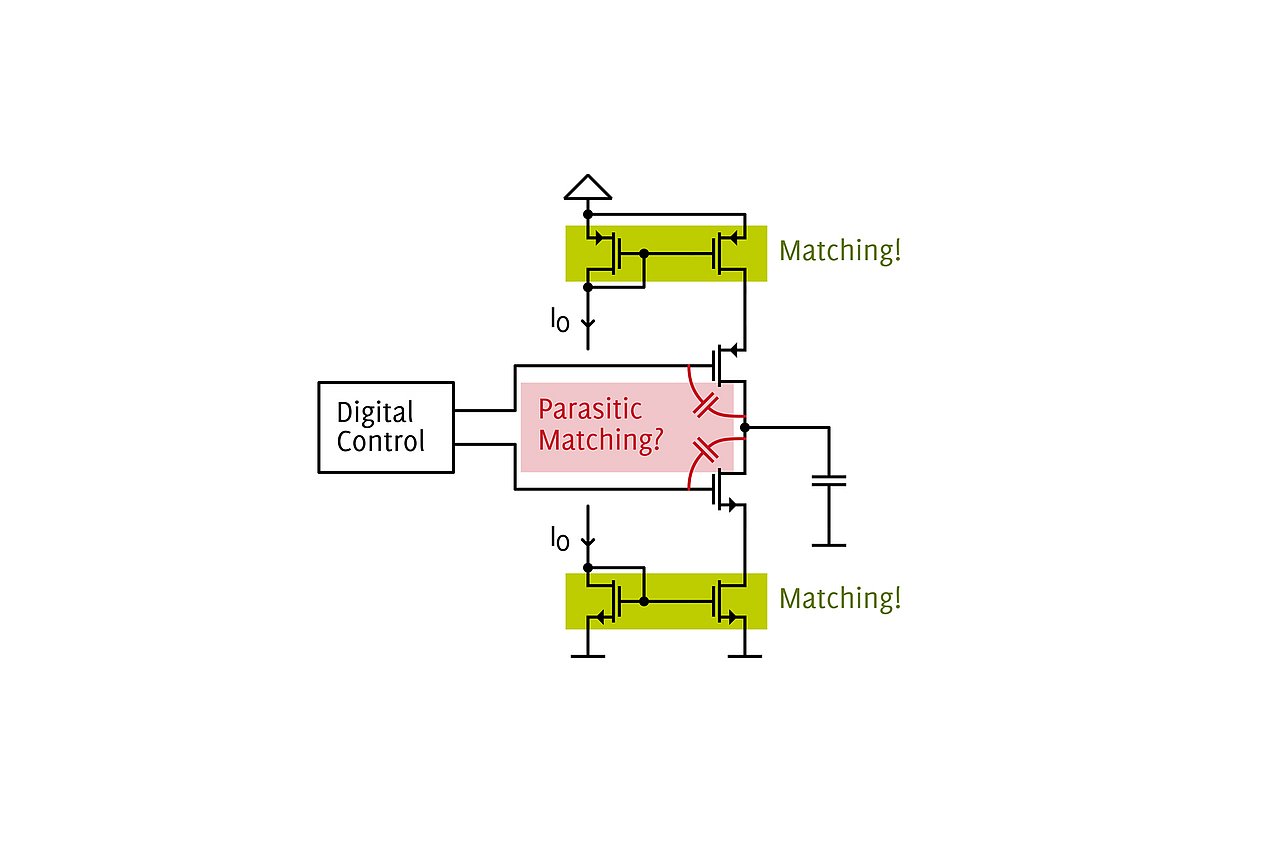

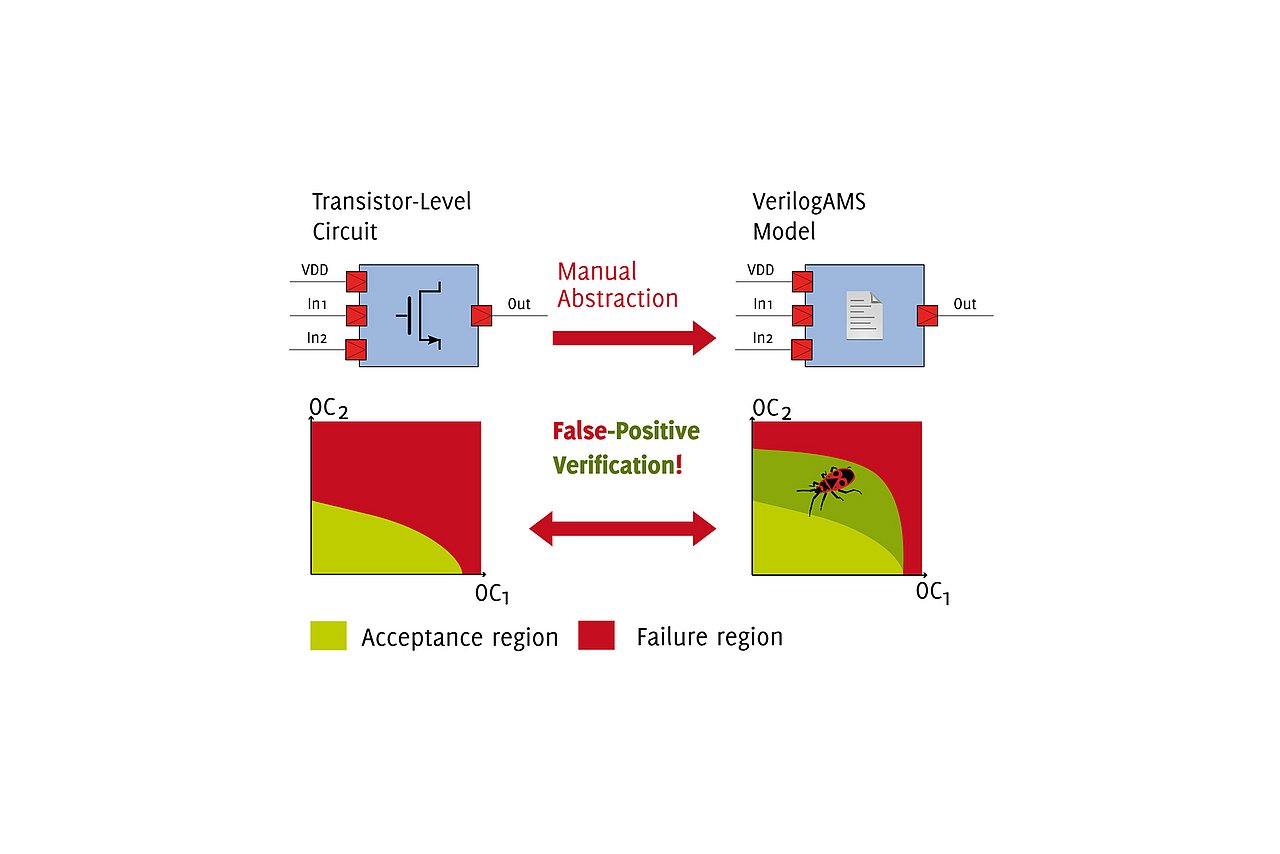

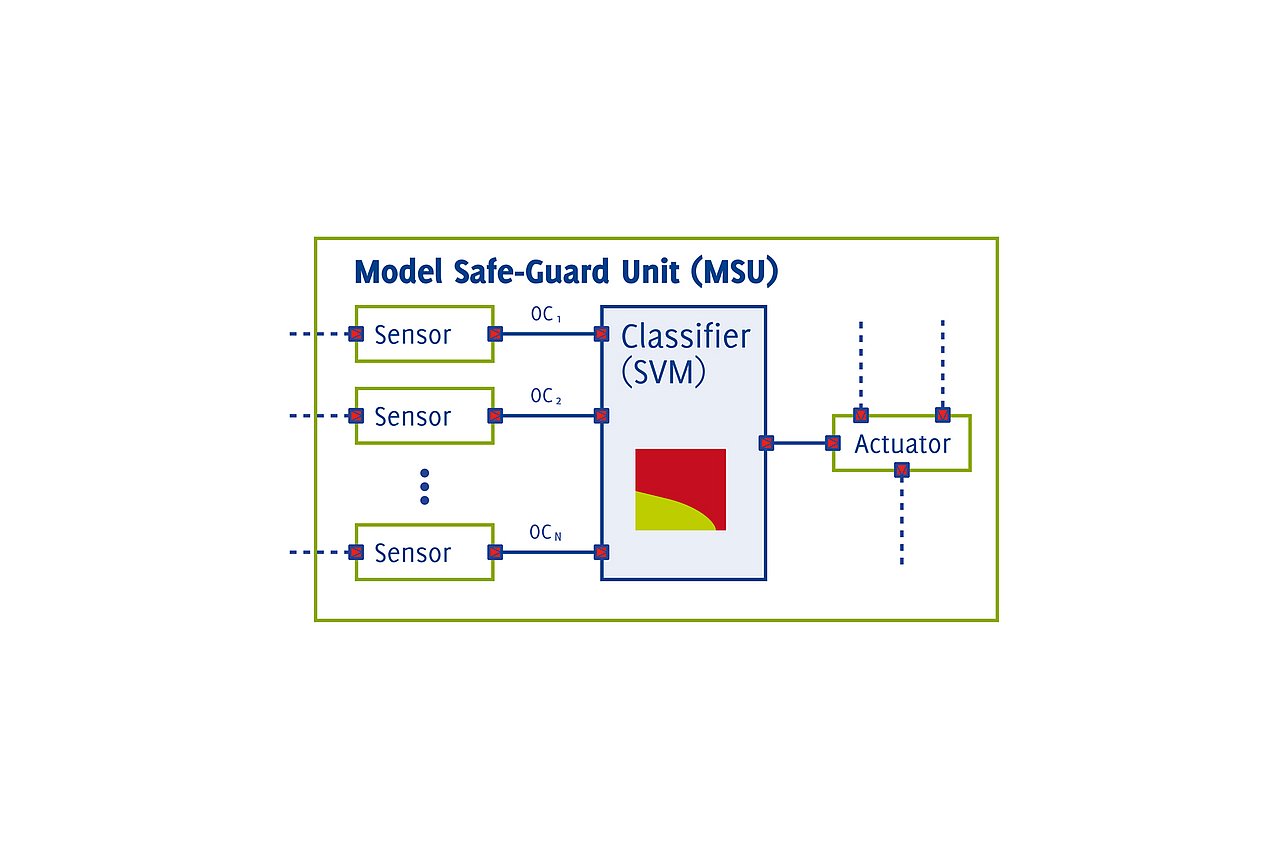

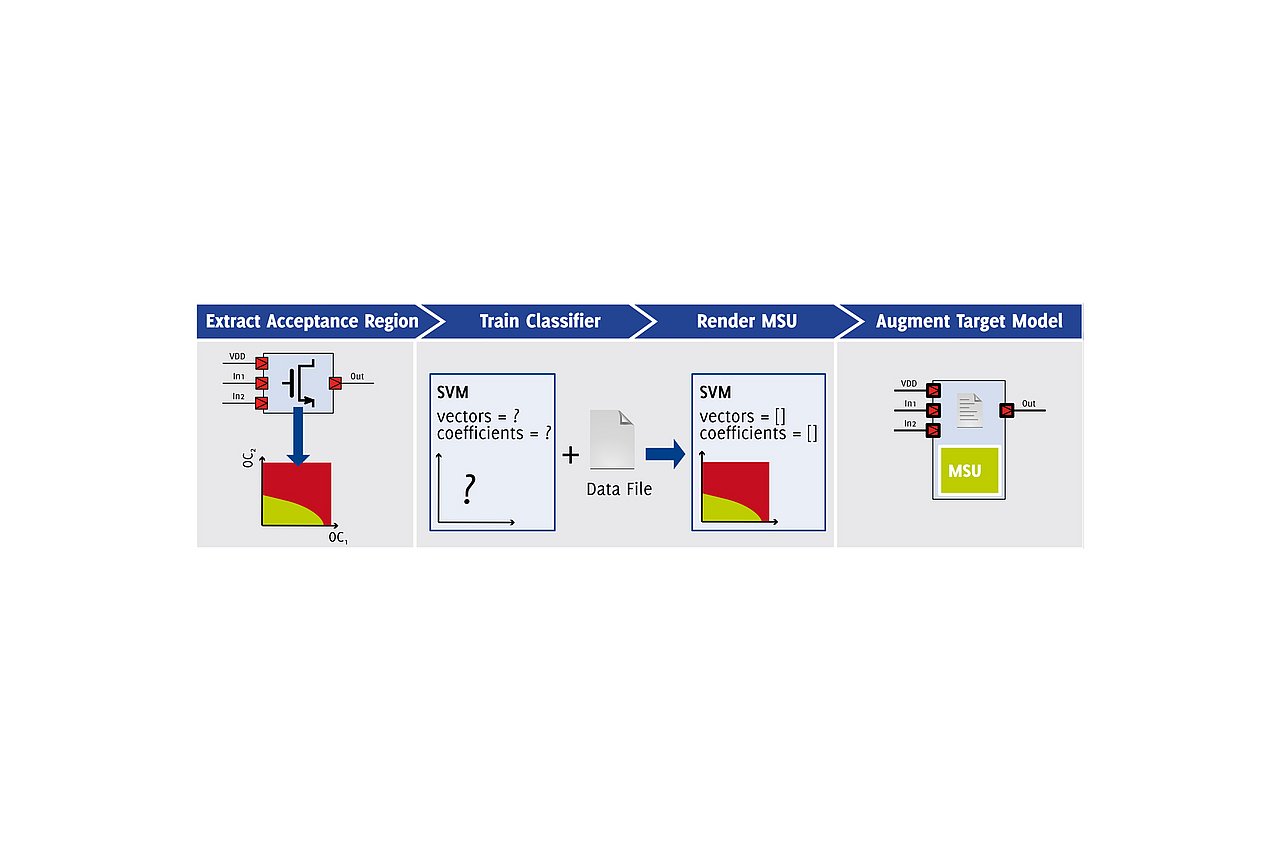

IMMS has developed various specialised methods at IMMS. On the one hand, they can be used to automatically locate the layout-related effects, evaluate them in terms of their concrete influence and thus identify potential for optimisation. On the other hand, the methods allow the integration and efficient simulation of the interaction of complex system components into system models. In addition, IMMS has created new methods with which the system behavior can be analysed before production even under still unknown operating conditions.

The methods have been successfully applied in research and industrial development projects and are being further developed.

Acronym / Name:

ANCONA / Analog Coverage in NanoelectronicsDuration:2014 – 2017

Project website:Project coordinator edacentrum e.V.

Application:

|Analog/Mixed-Signal VerificationResearch field:Integrated sensor systems

Related content

Reference

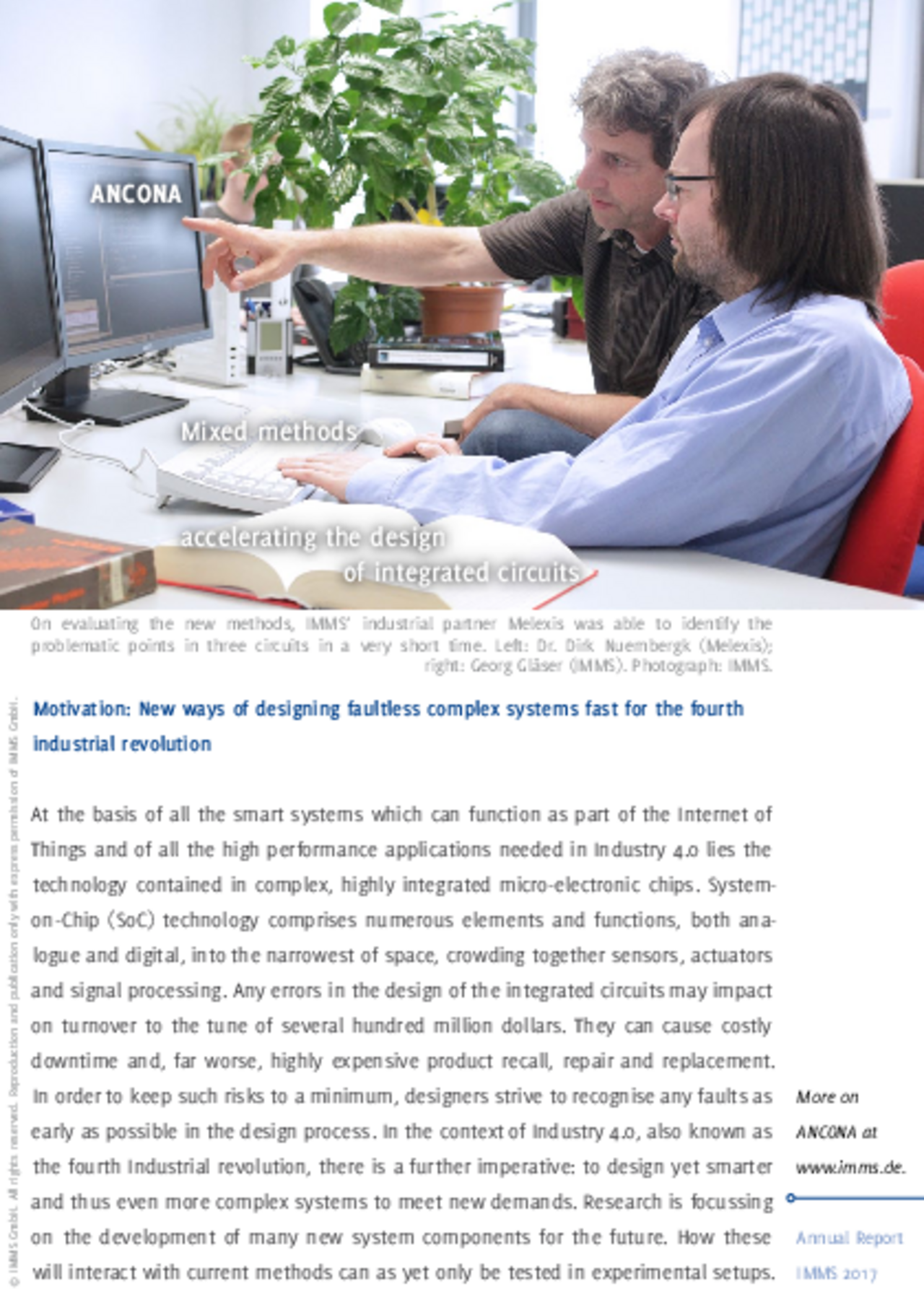

Dr.-Ing. Dirk Nuernbergk, Melexis

“The institute has developed and implemented a program that automatically finds and evaluates critical parasitics even at the design stage. In consequence, layout optimisation, which normally takes so long, is massively accelerated. In a very short time, we were able to identify the problematic points in three circuits.”

Reference

Dr. Dieter Treytnar, edacentrum

“The idea became the edaBarCamp, a ‘non-conference’. As its name suggests, it was to be the first BarCamp in the field of EDA. It was organised by the edacentrum, IMMS and OFFIS. Thanks to the support given by IMMS on organisation and content, the first edaBarCamp was so successful that everybody agreed to repeat it in future years.”

Reference

Prof. Dr.-Ing. Erich Barke

“The Erfurt branch of IMMS is involved in finding methods by which models can be efficiently simulated. Not only the excellent collaboration but also the publication success bring me much pleasure.”

From Constraints to Tape-Out: Towards a Continuous AMS Design Flow

Andreas Krinke1. Tilman Horst1. Georg Gläser2. Martin Grabmann2. Tobias Markus3. Benjamin Prautsch4. Uwe Hatnik4. Jens Lienig1.A. Krinke et al., 2019 IEEE 22nd International Symposium on Design and Diagnostics of Electronic Circuits & Systems (DDECS), Cluj-Napoca, Romania, 24 - 26 April 2019, pp. 1-10.

1Technische Universität Dresden, Institute of Electromechanical and Electronic Design, Dresden, Germany. 2IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 3Heidelberg University, ZITI, Computer Architecture Group, Heidelberg, Germany. 4Division Engineering of Adaptive Systems, Fraunhofer IIS/EAS, Institute for Integrated Circuits, Dresden, Germany.From Low-Power to No-Power: Adaptive Clocking for Event-Driven Systems

Georg Gläser1. Benjamin Saft1. Dominik Wrana2. Arthanasios Gatzastras2. Eckhard Hennig2.2018 Forum on Specification & Design Languages (FDL), Garching, 10-12 September 2018, pp. 5-16.

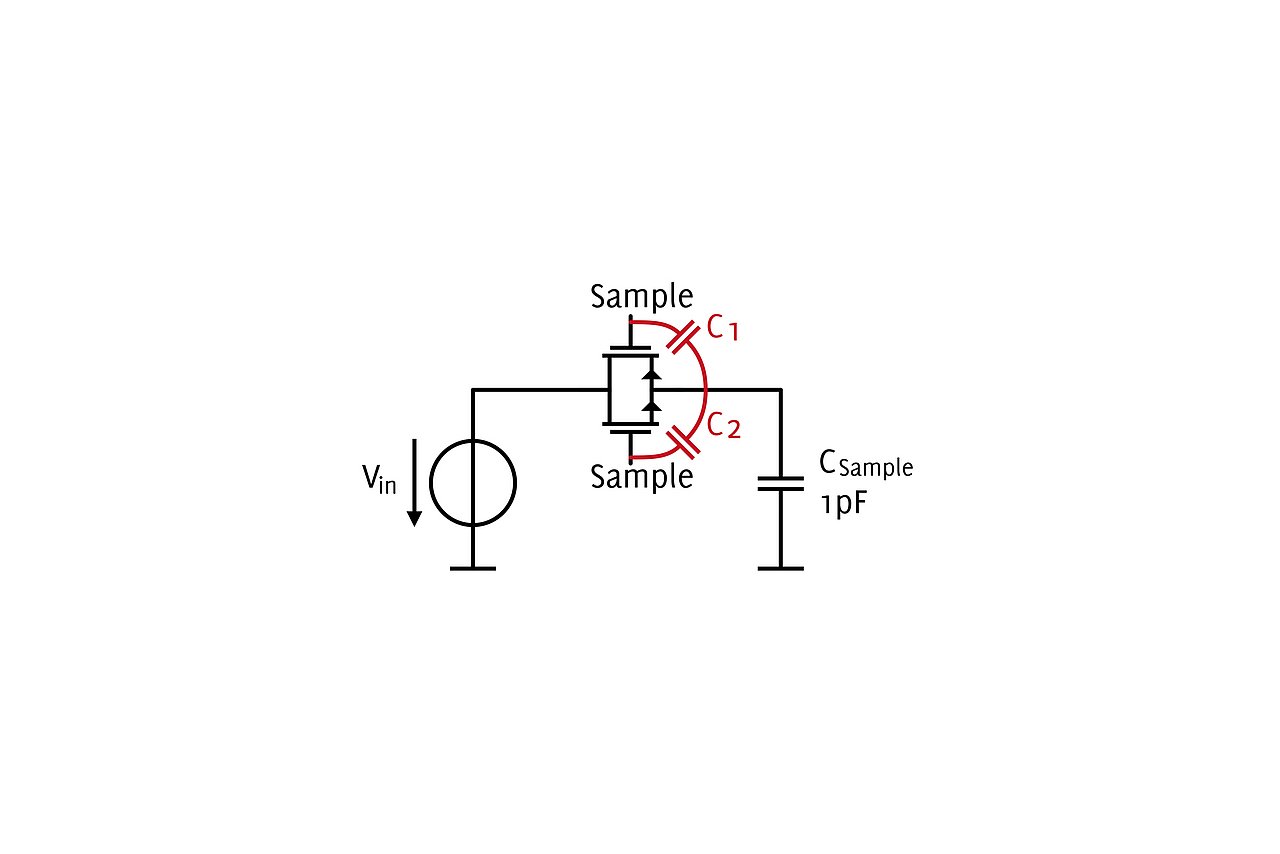

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 2Reutlingen University Reutlingen, Germany.Impact Rating of Layout Parasitics in Mixed-Signal Circuits: Finding a Needle in a Haystack

Georg Gläser1. Martin Grabmann1. Dirk Nuernbergk2.2018 15th International Conference on Synthesis, Modeling, Analysis and Simulation Methods and Applications to Circuit Design (SMACD), Prague, 2-5 July 2018, pp. 149-152.

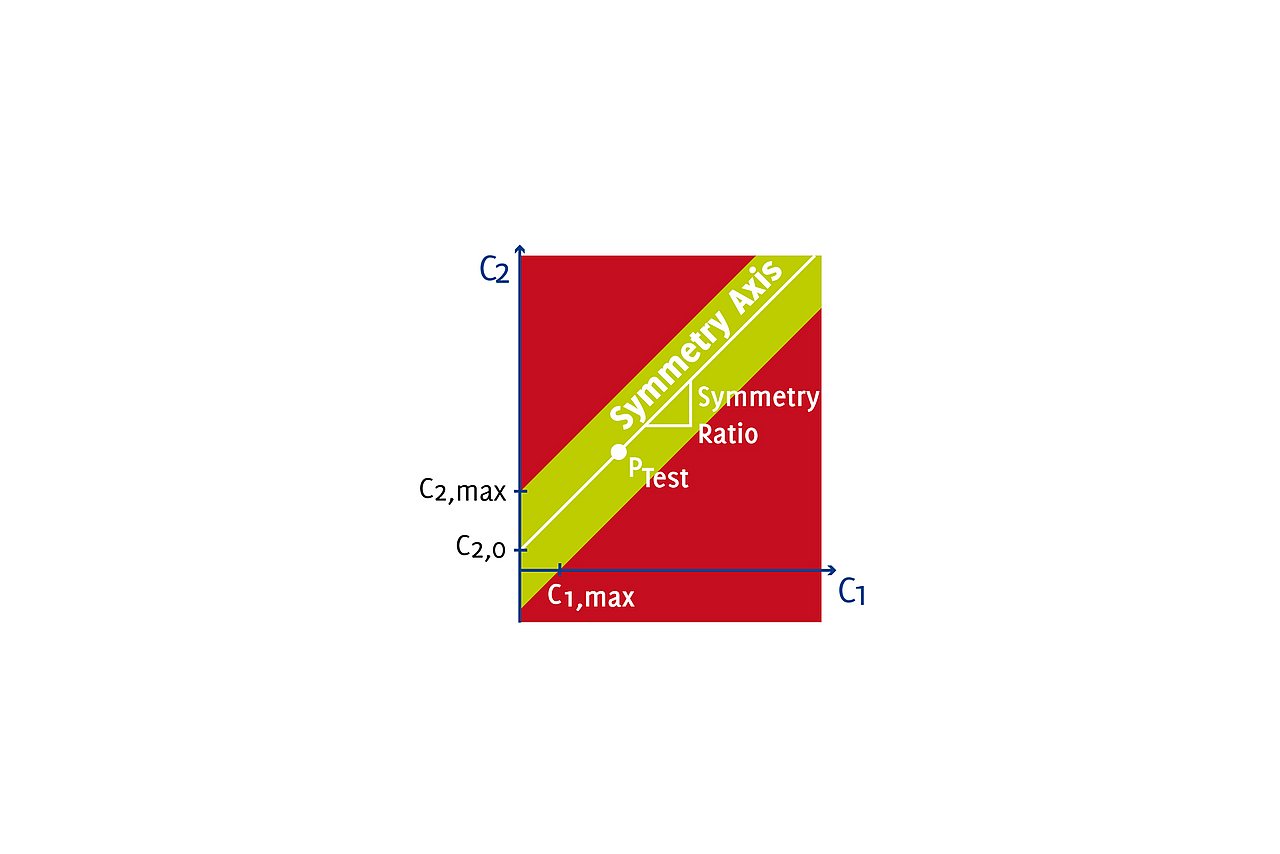

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 2Melexis GmbH, Erfurt, Germany.There is a limit to everything: Automated AMS Operating condition check Generation on System Level

Georg Gläser1. Martin Grabmann1. Gerrit Kropp1. Andreas Fürtig2.Integration, Volume 63, 2018, Pages 383-391, ISSN 0167-9260, DOI: doi.org/10.1016/j.vlsi.2018.02.016

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, 98693 Ilmenau, Germany. 2Institute for Computer Science, Goethe Universität Frankfurt a. M., Germany.

Press release,

Reliable and faster chip designs through invasive and parametric simulation methods

Dissertation on new methods for automation in integrated circuit design

Press release,

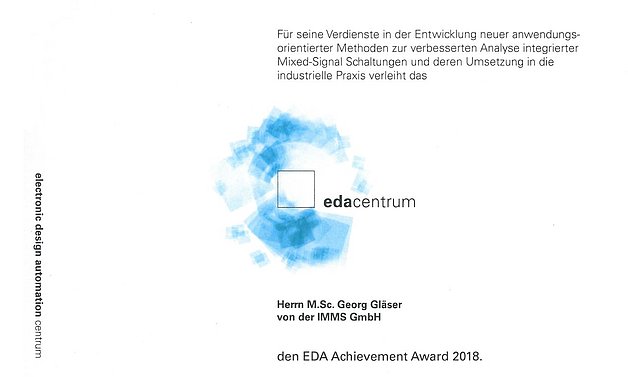

EDA Achievement Award 2018 für Methoden des IMMS zum Entwurf integrierter Schaltungen

Neue Methoden ermöglichen schnelle und fehlerfreie Entwürfe komplexer Industrie-4.0-Lösungen

Press release,

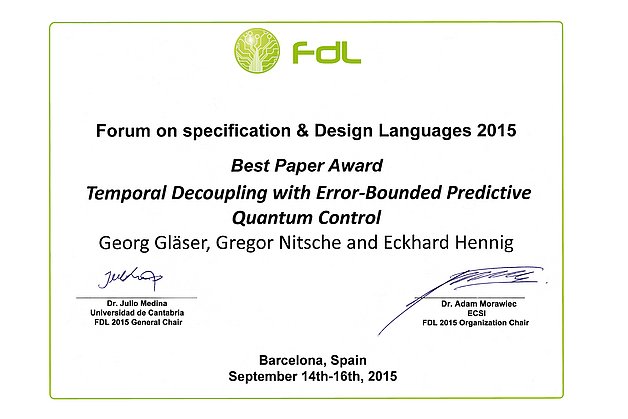

Best Paper Award goes to IMMS for work on computer-aided verification methods

Novel approach as fresh impetus for the development of Industry 4.0 applications

Event,

edaBarCamp -- may the 4th be with you!

Originating from our PhD meetings in a german research project, we gained the idea of starting an open research meeting based on the barcamp-concept.

Event,

FDL 2018

Lecture at the conference ”Forum on specification & Design Languages“:

Session 1, Event-driven Modeling and Simulation, Monday 10, September 2018, 15:00 pm - 16:30 pm

From Low-Power to No-Power: Adaptive Clocking for Event-Driven Systems

Authors: Georg Gläser1 , Benjamin Saft1, Dominik Wrana2 , Athanasios Gatzastras2 , and Eckhard Hennig2

1IMMS Institut fürMikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau, Germany

2Reutlingen University, Reutlingen, Germany

Event,

SMACD 2018

Lecture at the 15th International Conference on Synthesis, Modeling, Analysis and Simulation Methods and Applications to Circuit Design

Contact

Contact

Eric Schäfer, M. Sc.

Head of Microelectronics / Branch Office Erfurt

eric.schaefer(at)imms.de+49 (0) 361 663 25 35

Eric Schäfer and his team research Integrated sensor systems, especially CMOS-based biosensors, ULP sensor systems and AI-based design and test automation. The results are being incorporated into research on the lead applications Sensor systems for in-vitro diagnostics and RFID sensor technology. It will assist you with services for the development of Integrated circuits and with IC design methods.

Funding

This work has been funded by the BMBF (Federal German Ministry of Education and Research) in the IKT 2020 programme as part of the ANCONA project (funding reference 16ES021) and has also been supported by industrial partners, Infineon Technologies AG, Robert Bosch GmbH, Intel AG and Mentor Graphics GmbH.