Press releases

The 2016 Annual Report is available

Here you can find the contents in brief and the entire report which is linked to further information, related articles and videos.

The smart jacket with knitted switches and washable, energy-efficient electronics for better daily living. The smart clothing is to use as a wearable remote control. IMMS’ role has been to design, create and integrate the energy-efficient electronics, selecting energy-saving components and optimising their interaction. In association with these tasks, the Institute has produced solutions for the power supply, radio link, and configuration by smartphone.

ENTOMATIC – Automatic monitoring of olive fruit flies for more crop and less pesticide. In in the EU, olive fruit flies cause crop losses of 2.6 € billions a year. Hitherto, farmers use excess pesticide prophylactically to protect their harvest. IMMS has contributed to a novel monitoring system. The wireless network of opto-acoustic sensors will enable critical concentrations of olive fruit flies to be counted rapidly and safely in the olive plantations and will help to keep the pests under control.

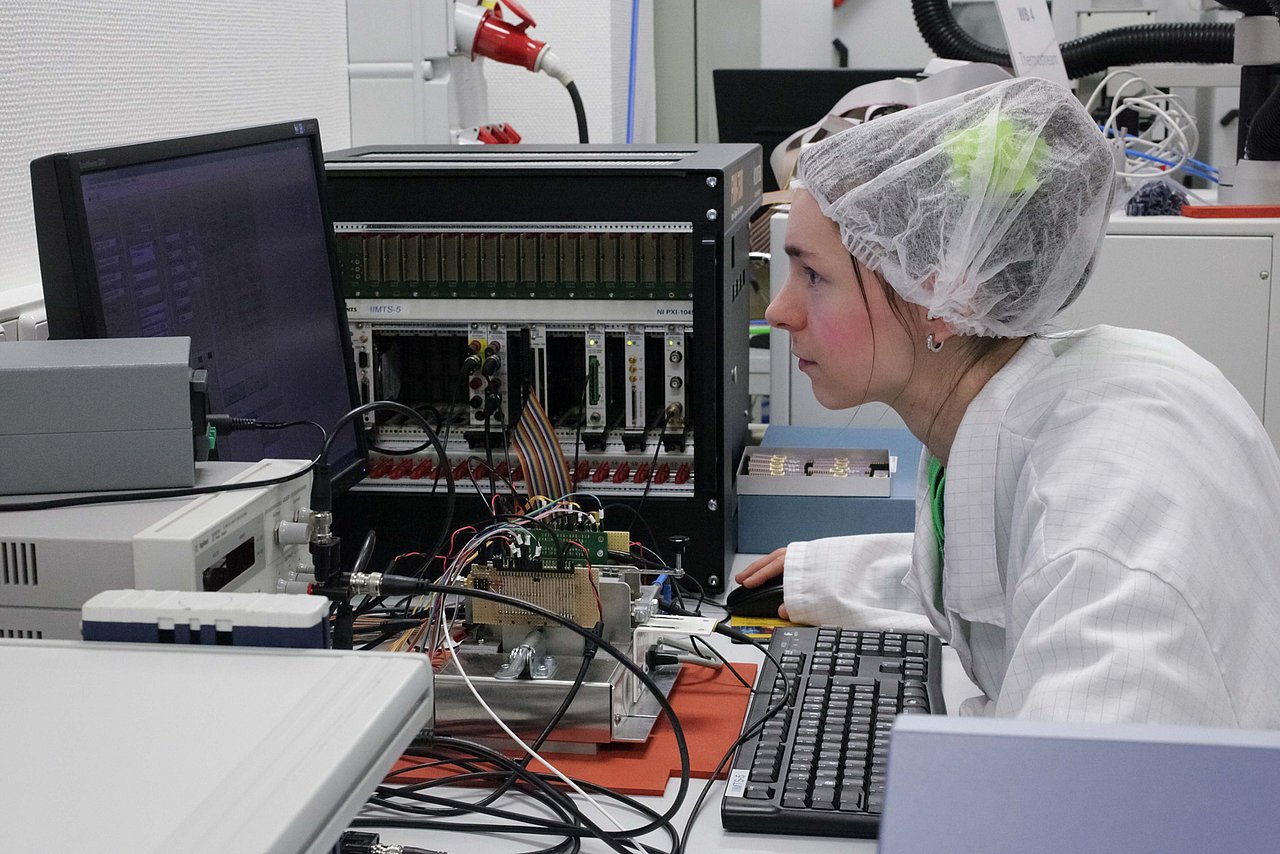

KOSERNA – Compact Satellite Receiver Systems for Robust Navigation Applications. Satellite signals are transmitted more than 20,000 kilometres, are very weak on arrival and are susceptible to GNSS-jamming being a hundred times stronger. For safety-critical autonomous navigation purposes, a compact and fail-safe receiving unit with 16 channels has been developed. IMMS has created the frontend circuits which prepare the weak signals for interference suppression.

HoTSens – An ASIC for extremely precise measurement at 300 °C to support industrial efficiency. IMMS has developed integrated sensors and electronics as a system solution, which will measure pressure and temperature with deviation of less than +/- 2 % either way when the ambient temperature is as high as 300 °C. This is sensor technology which is vital in industrial situations where data must be captured despite extraordinarily high ambient temperatures.

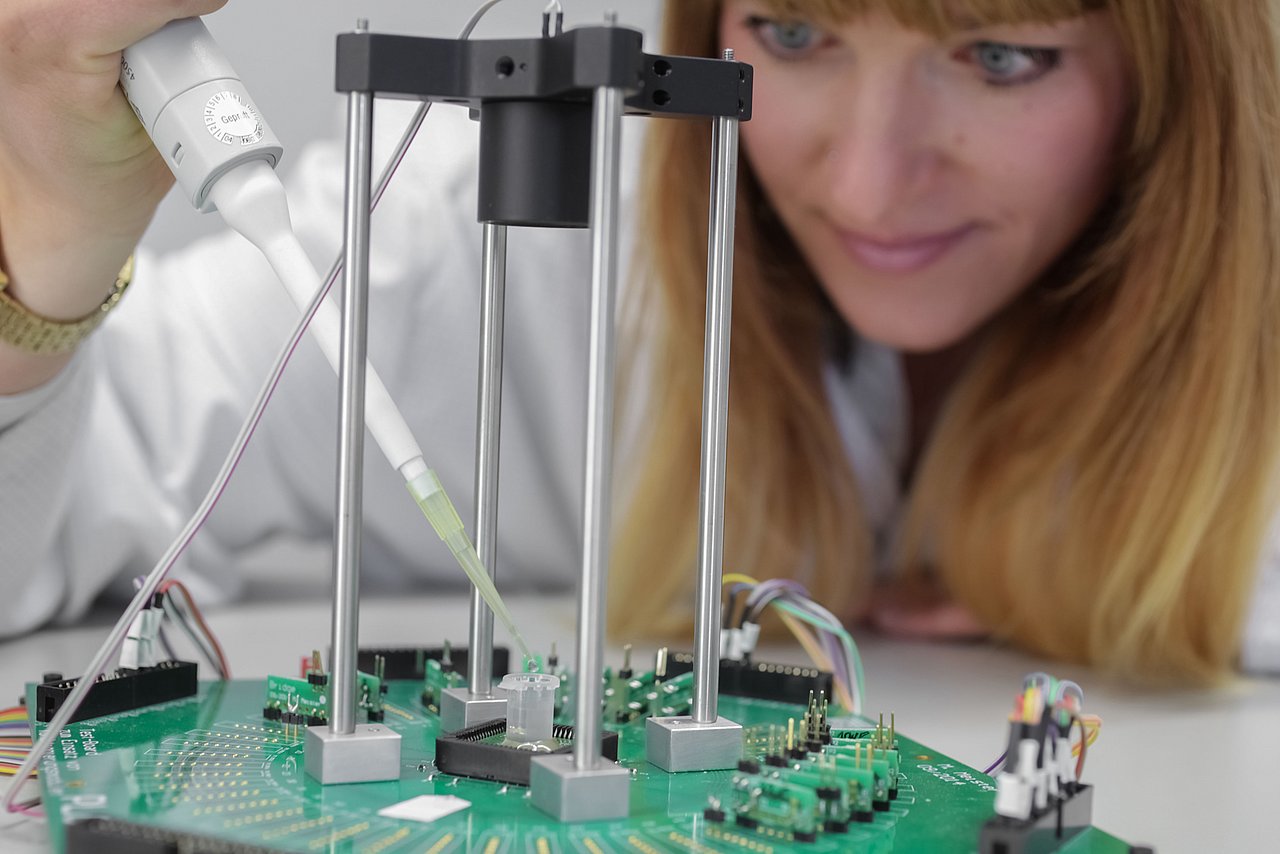

INSPECT – Microelectronics to recognise cancer early. Present rapid tests are no more than qualita tive and produce results confined to ”yes“ or ”no“. For cancer to be diagnosed at a very early stage, a chip coming into direct contact with a sample must be capable of recognising concentrations of antigens in the range of one nanogram per cubic centimetre. IMMS has investigated the technical feasibility of achieving this level of accuracy as the foundation for a new chip development.

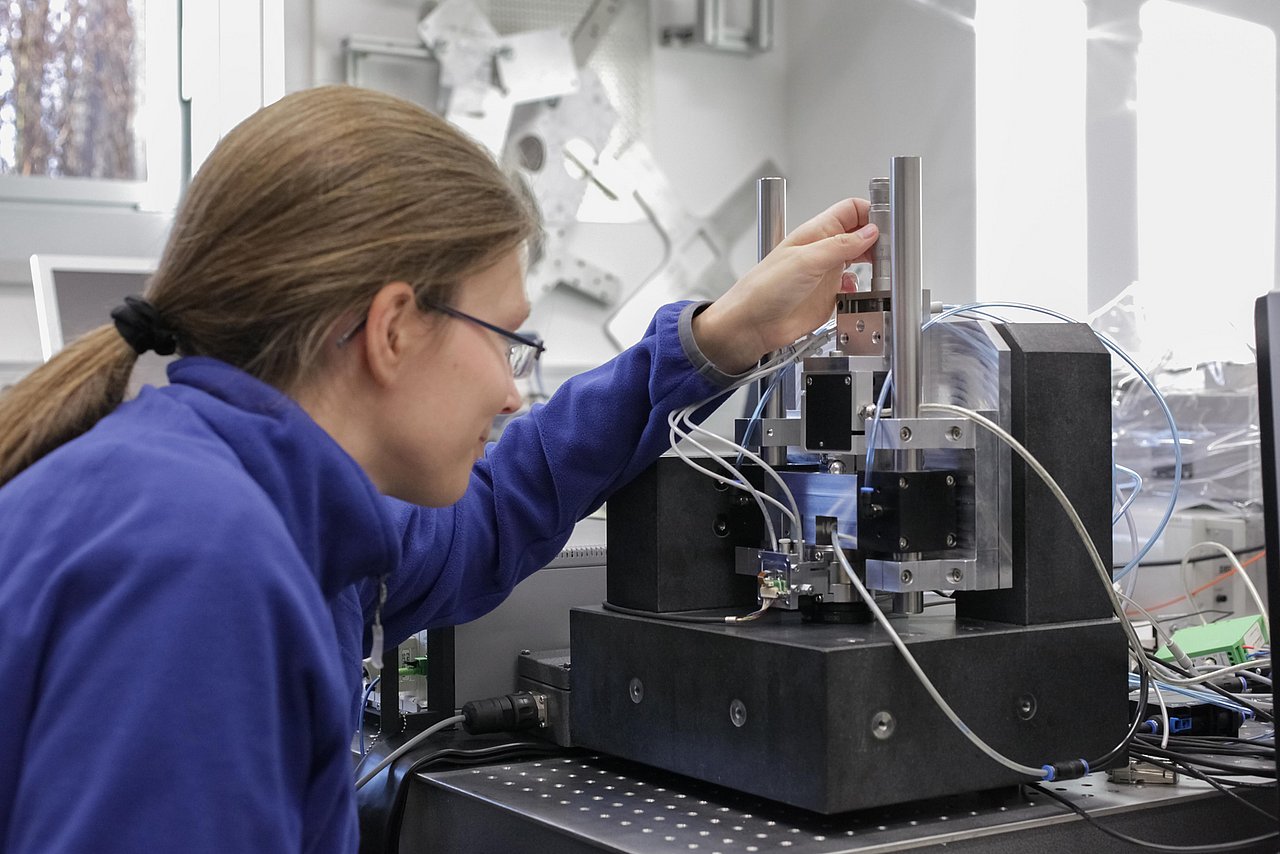

AFiA – Using air pressure and milliamp current to get a load to hover with nanometre accuracy. In semiconductor industry wafer layers with a thickness of a few nanometres have to be processed; an entire wafer may have a thickness between 0.7 and 0.9 mm. For such and other applications, IMMS has developed a vertical drive to raise or lower objects with nanometre precision and active control through a range of 10 mm. The drive can be integrated into many existing precision drive systems.

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.