Press releases

MEMS design methodology honoured with the EDA Achievement Award 2015

IMMS and Ilmenau TU’s methodology opens up cost-efficient MEMS developments and novel applications.

On 21st May, 2015 at the edaWorkshop15 in Dresden, Germany, researchers of IMMS and Ilmenau University of Technology, Germany, were honoured with the EDA Achievement Award by the German “edacentrum” for their work on schematic-driven design of MEMS/ASIC systems as outstanding research and development contribution to electronic design automation (EDA). The awarded solutions were primarily accomplished within the MEMS2015 project.

MEMS (micro-electro-mechanical systems) are one of the keys to innovative manufacture of plant and equipment. As such, they are an element of the Industry 4.0 strategic project. MEMS are being developed at enormous rates with quantities and revenues going into the billions worldwide. One of the aims of the MEMS2015 project is the combination of the design processes for the mechanical and the electronic components to create a comprehensive design methodology which can be expected to enable SMEs to compose their own individual, tailor-made solutions using a flexible MEMS and electronics construction kit so that they can capture a share of the MEMS boom.

For this purpose, the tried and trusted modular principle from microelectronic design has been adopted by the researchers and transferred to mechanical systems and to MEMS. The two design procedures have been combined into a systematic start-to-finish procedure. As a result, MEMS can now be simulated and verified as an entire system, which means that errors can be recognised and remedied early.

One outcome is a special design tool that supports XM-SC, the SOI technology of X-FAB AG, by providing a sensor design system for computer-aided design of the electromechanical unidimensional sensors known as accelerometers. The tool works by using a mathematical algorithm developed at IMMS to compute the various design possibilities that might match the customer’s requirements. The tool is, furthermore, a source of sensor models which the user can integrate into the design tools made by our research partners Coventor and Cadence. It will generate the necessary mechanical layouts for the manufacturing stage.

These implementations in conjunction with a comprehensive and model-based design flow for heterogeneous systems are now the basis of work on the transfer of the methodology to systems of greater complexity. Examples for such multi-facetted systems are 3D or 6D accelerometers, energy-harvesting modules as developed by the GreenSense research group of IMMS and RF-MEMS being investigated by the MUSIK research group in which Ilmenau University of Technology and IMMS are cooperating.

Group lead by Prof. Dr. Ralf Sommer:

V. Boos, A. Frank, S. Hampl, E. Hennig, A. Jäger, D. Karolewski, J. Klaus, D. Krauße, B. Leistritz, S. Michael, J. Nowak, R. Pevgonen, B. Saft, E. Schäfer, R. Sommer, J. Tan

Related content

Project

MEMS2015

The IMMS tool automatically generates mechanical designs. MEMS can be simulated and verified as an entire system.

Event,

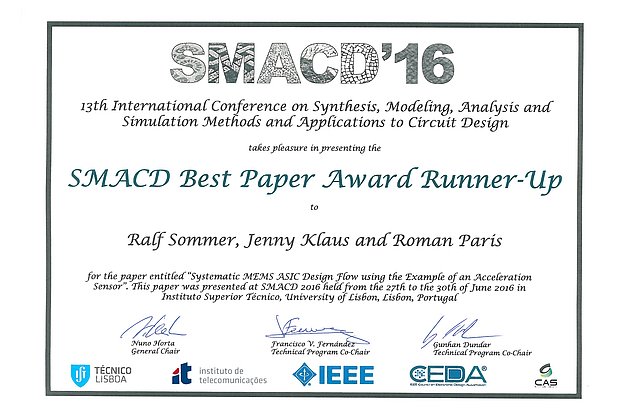

SMACD 2016

13th International Conference on Synthesis, Modeling, Analysis and Simulation Methods and Applications to Circuit Design

Event,

TuZ 2016

Two presentations at the 28th GMM/GI/ITG Workshop on test methods and reliability of circuits

Event,

edaWorkshop 15

Lecture: "Design of Acceleration Sensors Using a Systematic MEMS-ASIC Design Flow"

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.