Friedrich Becker, TURCK Electronics GmbH

“With its experience in the spheres of signal processing and integrating communications and systems for industry, IMMS contributed significantly to the execution of the science which the partners in Chemnitz and Offenburg derived from theoretical principles in cable diagnostics and communications interfaces.”

”Turck is one of the leading manufacturers in industrial automation. As specialists in sensor, fieldbus, connection and interface technology, RFID systems and Human-Machine Interfaces(HMI), we offer development and manufacture of highest-level automation electronics which increase efficiency and open up options for the machinery of many industries. In the search for the best possible solution to our customers’ automation needs, we are in constant touch with them.

Many of our customers are in search of predictive defect detection in Ethernet cables. In manufacturing, these data transfer cables connecting different machines are at times under heavy mechanical strain, sometimes to breaking point. While engineers search for the elusive faults and problems and carry out repairs, long hours can be lost with processes stopped. As chair of the committee accompanying the Ko2SiBus project I had the chance to advise and help on the development of solutions that might ensure these mechanical faults were foreseen so that downtime was avoided. The project united the efforts of IMMS, Offenburg University and Chemnitz University of Technology (TU) to solve how to provide continuous, affordable signal monitoring for industrial bus systems.

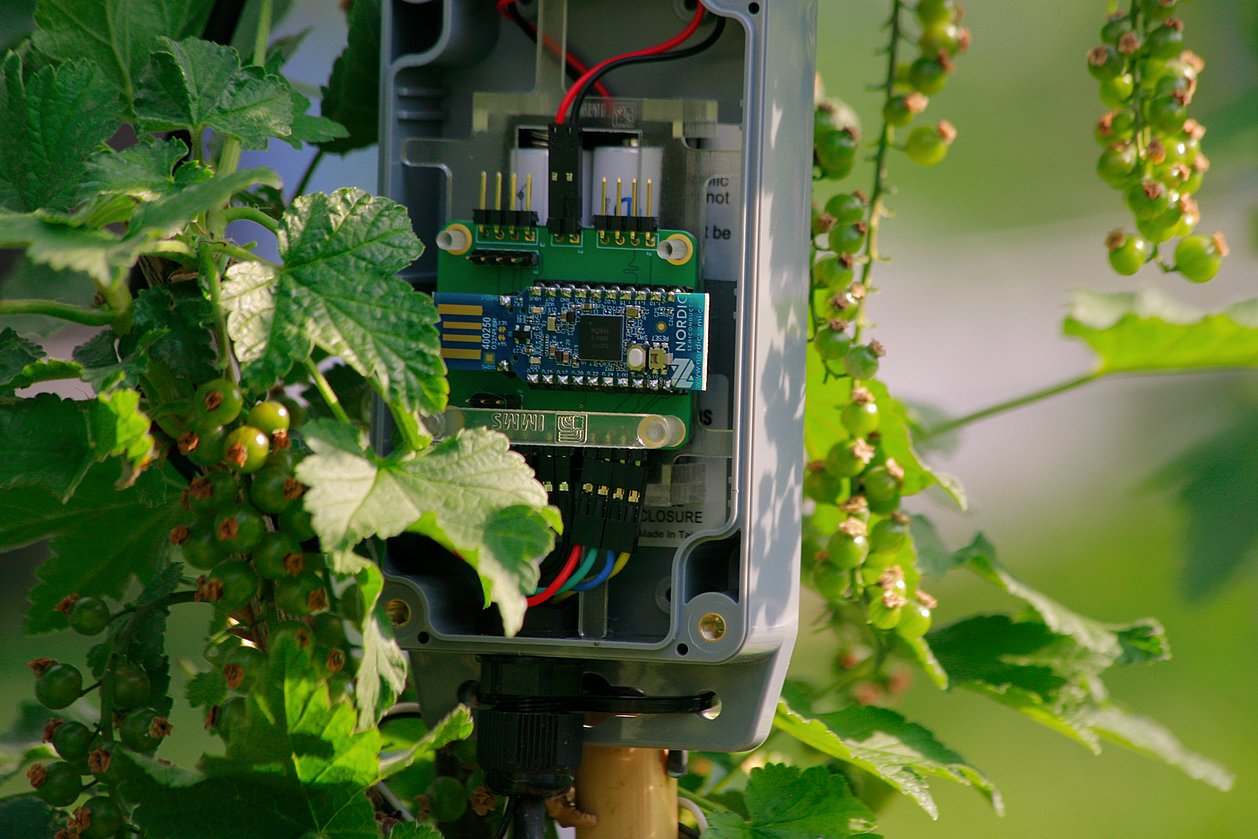

With its experience in the spheres of signal processing and integrating communications and systems for industry, IMMS contributed significantly to the execution of the science which the partners in Chemnitz and Offenburg derived from theoretical principles in cable diagnostics and communications interfaces. The role of IMMS was to design an embedded system and develop the appropriate circuit concepts. The outcome is a system able to track physical signal parameters in the Ethernet cables. It uses integrated analogue and digital components, reporting deviations to a monitoring centre – a system which has been proven in a demonstration model built jointly by IMMS and the other partners.

I see the project results as highly promising and shall continue to accompany the partners through the next stages, when the system is incorporated into industrial plant and subjected to evaluation. In my view, there is huge potential in integrating these concepts directly into Ethernet-based fieldbus devices. I also view IMMS’ style of working as having great potential. The IMMS developers think through the entire production chain from the pure science to the industrial application and they come up with convincing solutions. This means that IMMS is a valuable partner in innovative work extending well beyond the Ethernet problems here considered. I intend to enter into further joint work with IMMS, including projects of the DFAM.1“

1 DFAM: Deutsche Forschungsgesellschaft für Automatisierung und Mikroelektronik e.V., the German research council for automation and microelectronics.

The reference is related to:

Contact

Contact

Dr.-Ing. Tino Hutschenreuther

Head of System Design

tino.hutschenreuther(at)imms.de+49 (0) 3677 874 93 40

Dr. Tino Hutschenreuther will answer your questions on our research in Smart distributed measurement and test systems and the related core topics Analysis of distributed IoT systems, Embedded AI and Real-time data processing and communications, on the lead applications Adaptive edge AI systems for industrial application and IoT systems for cooperative environmental monitoring as well as on the range of services for the development of embedded systems.