Project RGBS

Development of a new retrofittable glass break sensor based on ultrasound technology with greater precision and robustness

The aim is to develop a particularly sensitive ultrasonic glass break sensor. This sensor will enable a wide variety of windows and doors to be retrofitted with burglar alarms at low cost, exceed the strict testing requirements for VdS certification and eliminate false alarms. Such sensors are needed to secure critical infrastructure and high-risk properties such as museums, IT rooms, pharmacies and other commercial, storage and production buildings.

Ahead of burglars by exceeding the standard

There is high demand for ever better and at the same time cost-effective solutions for security technology. Project partner SCHMEISSNER GmbH has already developed retrofittable glass break sensors that meet some of the VdS criteria and have established themselves on the market. The testing carried out by VdS Schadenverhütung GmbH is stricter than DIN in terms of material quality, installation and tamper protection and is required in areas with an increased or very high risk of burglary.

Im Projekt werden zwei Ansätze für bessere Sensoren verfolgt – eine sensiblere Erkennung auch im Hinblick auf potenzielle neue Einbruchsmethoden und eine höhere Robustheit gegen Falschalarme. Gerade wiederholte ungewollte Alarme können zu einem Abstumpfen der Sicherheitskräfte und letztendlich zur Deaktivierung der Sensoren durch den Betreiber führen. The project is pursuing two approaches for better sensors – more sensitive detection, also with regard to potential new burglary methods, and greater robustness against false alarms. Repeated unwanted alarms in particular can lead to security personnel becoming desensitised and finally lead to the deactivation of the sensors by the operator.

The challenge of glass break sensors

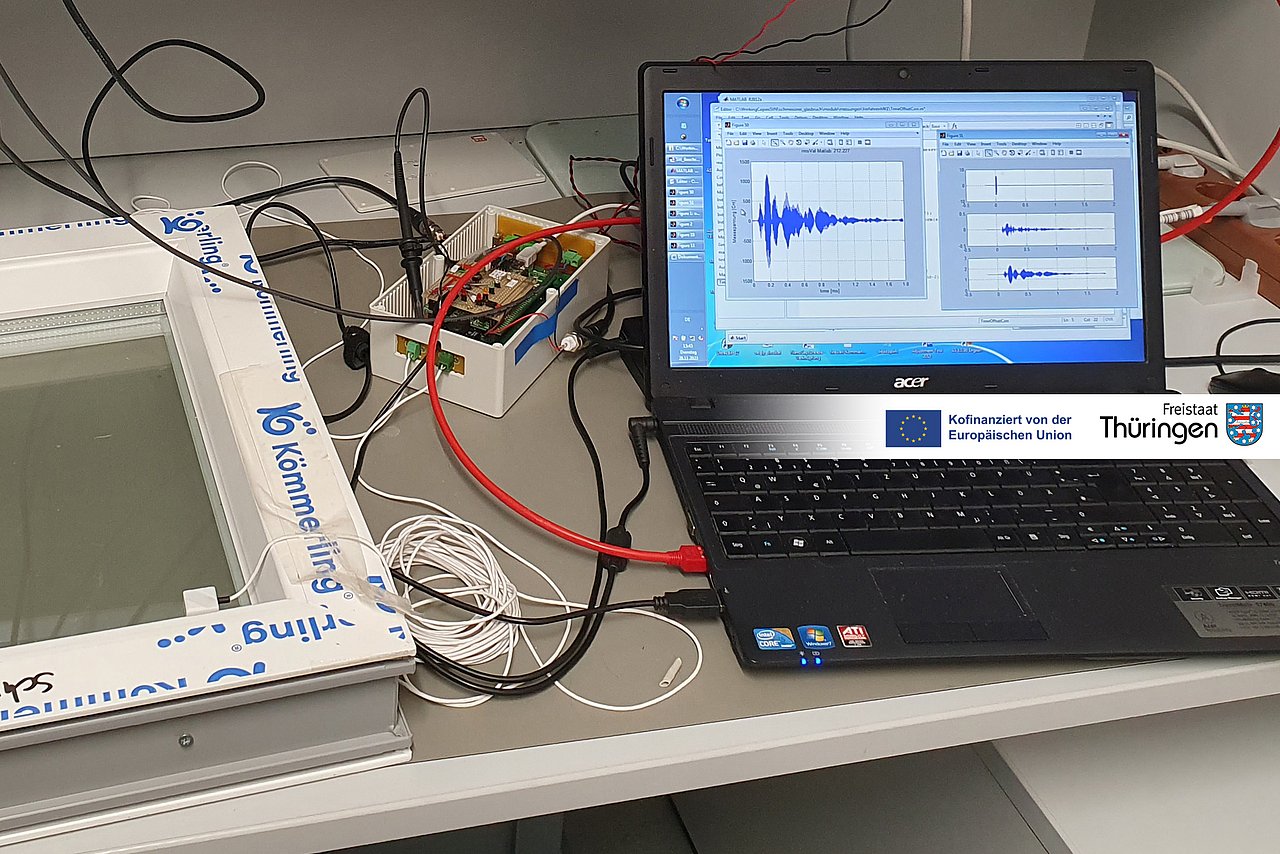

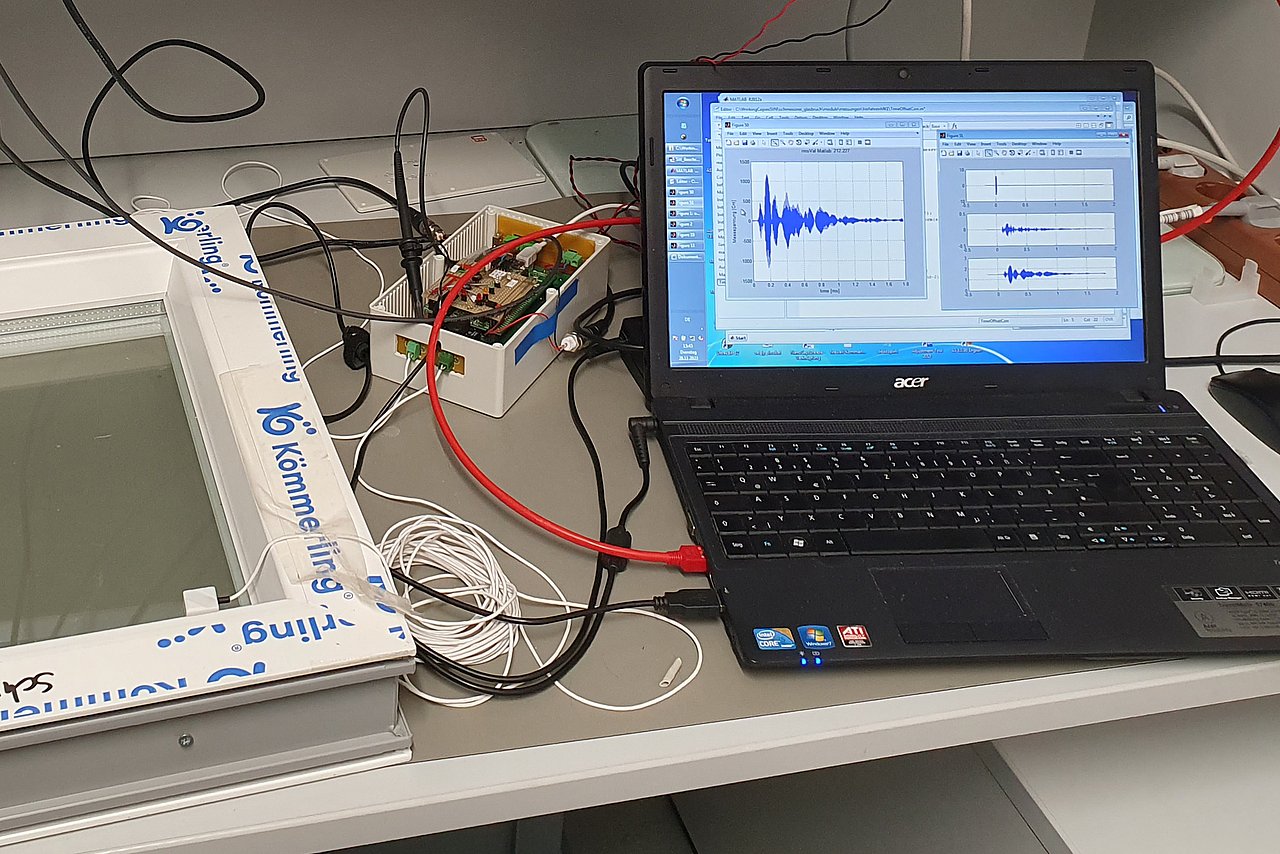

Glass breakage sensors evaluate ultrasonic signals generated by vibrations in the glass. These signals change when external influences affect the glass. Typical signals caused by normal environmental influences such as temperature fluctuations, rain, hail or stones thrown up by passing vehicles must be detected, as must signals caused by the violent breaking of the pane, the cutting out of pieces or simply stress cracks due to large temperature differences. Distinguishing between these scenarios places high demands on the sensor's evaluation algorithms. In addition, new types of break-in methods may not only require more sensitive evaluation, but may also influence the ultrasonic signals in such a way that immunity to false alarms will become even more difficult in the future.

More sensitive and robust glass break sensors targeted

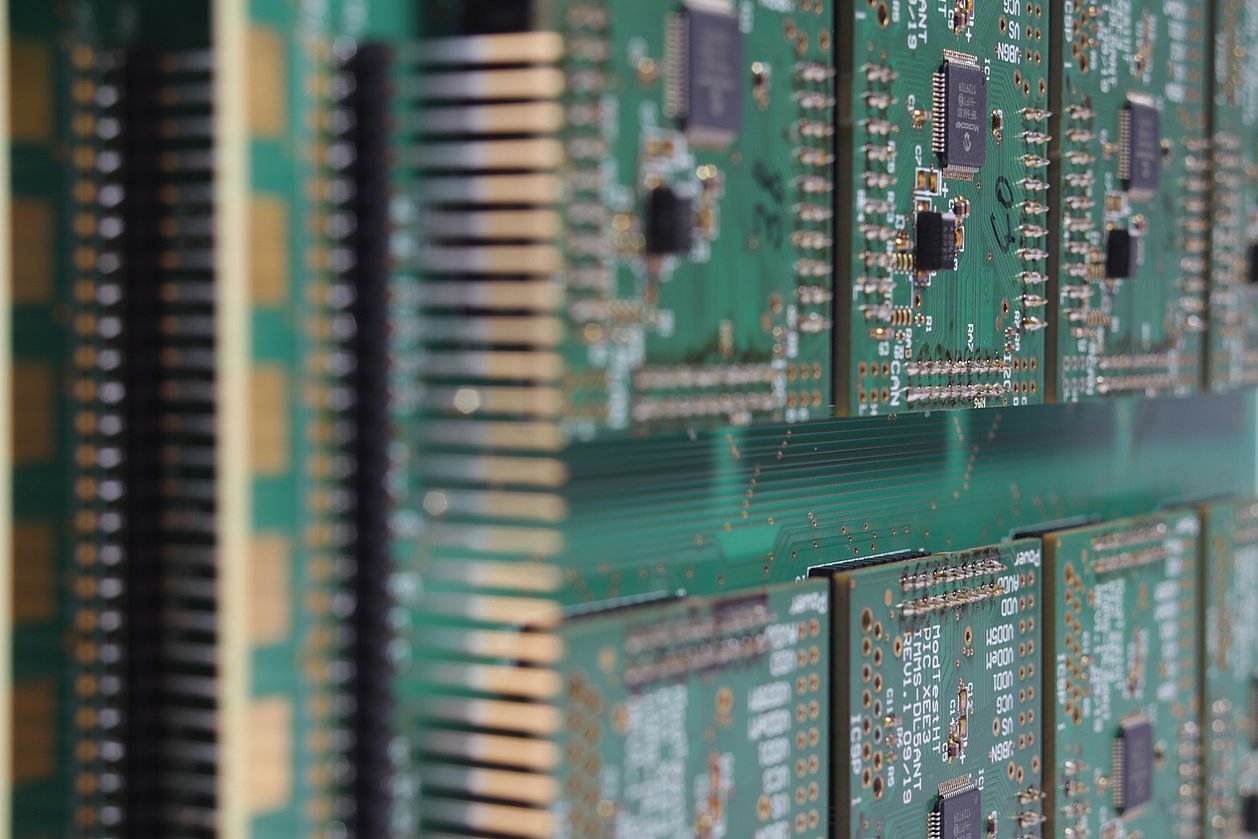

The innovative glass break sensors, which are particularly sensitive yet robust against false alarms, are to be achieved through a powerful and interference-resistant hardware design. A key component will be the application of innovative analysis and evaluation methods. Here, complex algorithms are used to clearly distinguish between fault detection and permissible impacts.

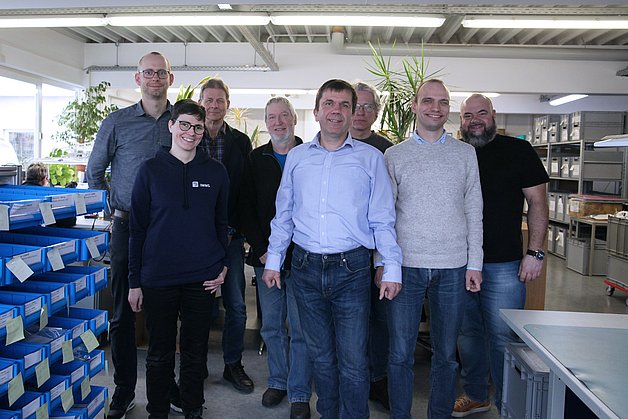

IMMS is coordinating the project and will be responsible in particular for developing the methodology and creating a more sensitive and robust fault detection system. SCHMEISSNER GmbH will primarily develop the hardware and protect it against interference, carry out validation measurements and take further preparatory steps for later product development, such as EMC simulation and testing, as well as developing the software for the user interface.

The aim is to develop an innovative yet inexpensive retrofit solution that meets the growing demands of customers and users of glass break sensors by contributing to the highest level of property security and that strengthens the competitiveness of Thuringian companies in this field of application.

Acronym / Name:

RGBS / Integration of novel signal processing methods and design solutions for robust glass breakage detectionDuration:2026

Application:

|Burglary protection| security technologyResearch field:Smart distributed measurement and test systems

Partner

Related content

Press release,

Project launch for new glass break sensor with greater precision and higher robustness

Schmeissner and IMMS aim to surpass existing sensor standards

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Förderung

The joint project “Integration of innovative signal processing methods and design solutions for robust glass breakage detection“ (RGBS) is supported by the funding programme of the German Land of Thüringen for the promotion of research, technology and innovation (RTI) as the research and development initiative Thüringen Verbund under the joint project number 1007968, the IMMS topic “Development and implementation of innovative signal processing for highly sensitive breakage detection in glass panes” under the reference 2025 VDY 0061.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/7/csm_20130223_dcSen_ProberEF_MM_MG_3325_1920x1280_588e478d86.jpg)