Project PMS380

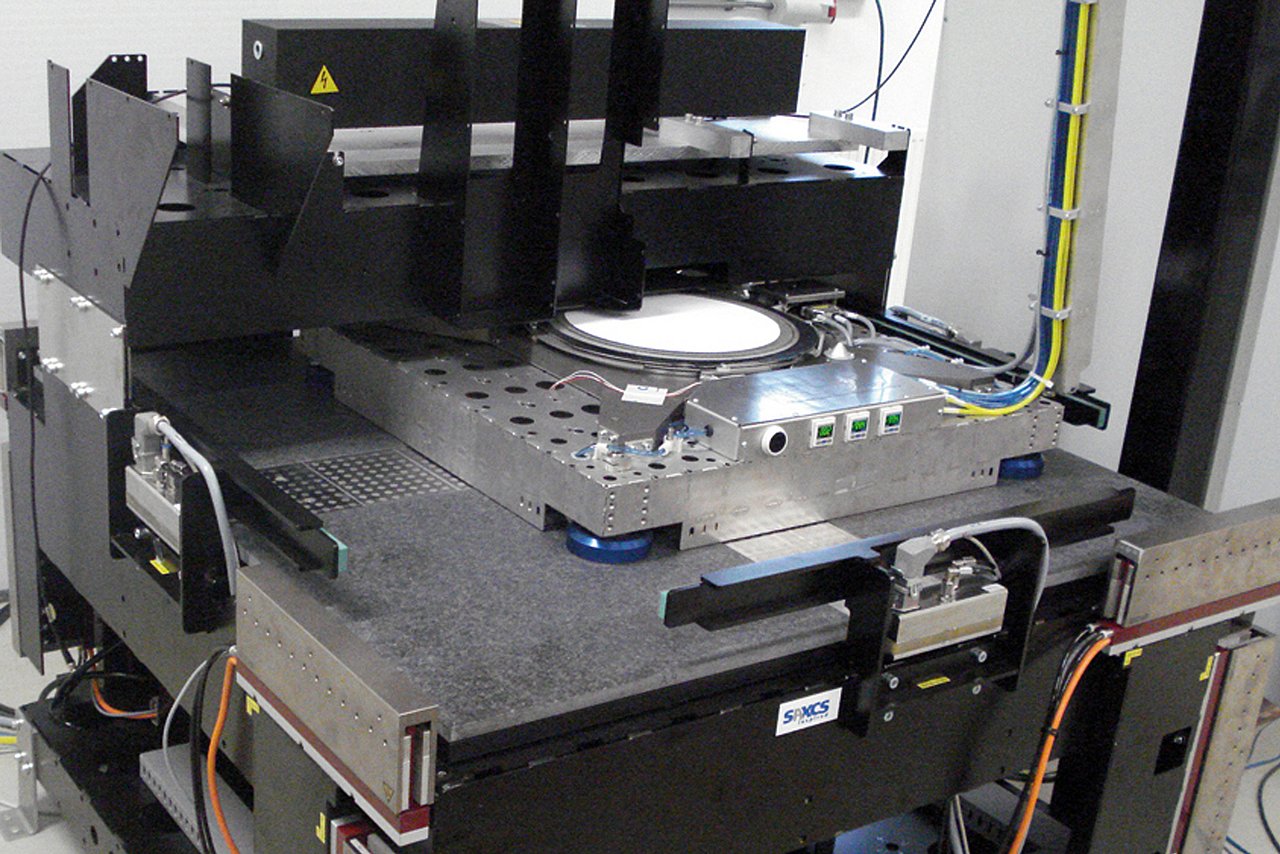

Thanks to the planar drive system developed by IMMS microelectronic chips are separated from 12” wafers in semiconductor production worldwide.

In the project a laser dicing system was developed, with which microelectronic chips are separated from thin 12” semiconductor wafers. Compared to conventional mechanical sawing processes the novel system allows a productivity improvement of up to 500 per cent. Savings from wafer surfaces through much narrower cutting paths bring additional benefits.

The potentially high speed of laser separation processes can only be effectively used if the wafer is guided under the beam with highest precision and dynamics.

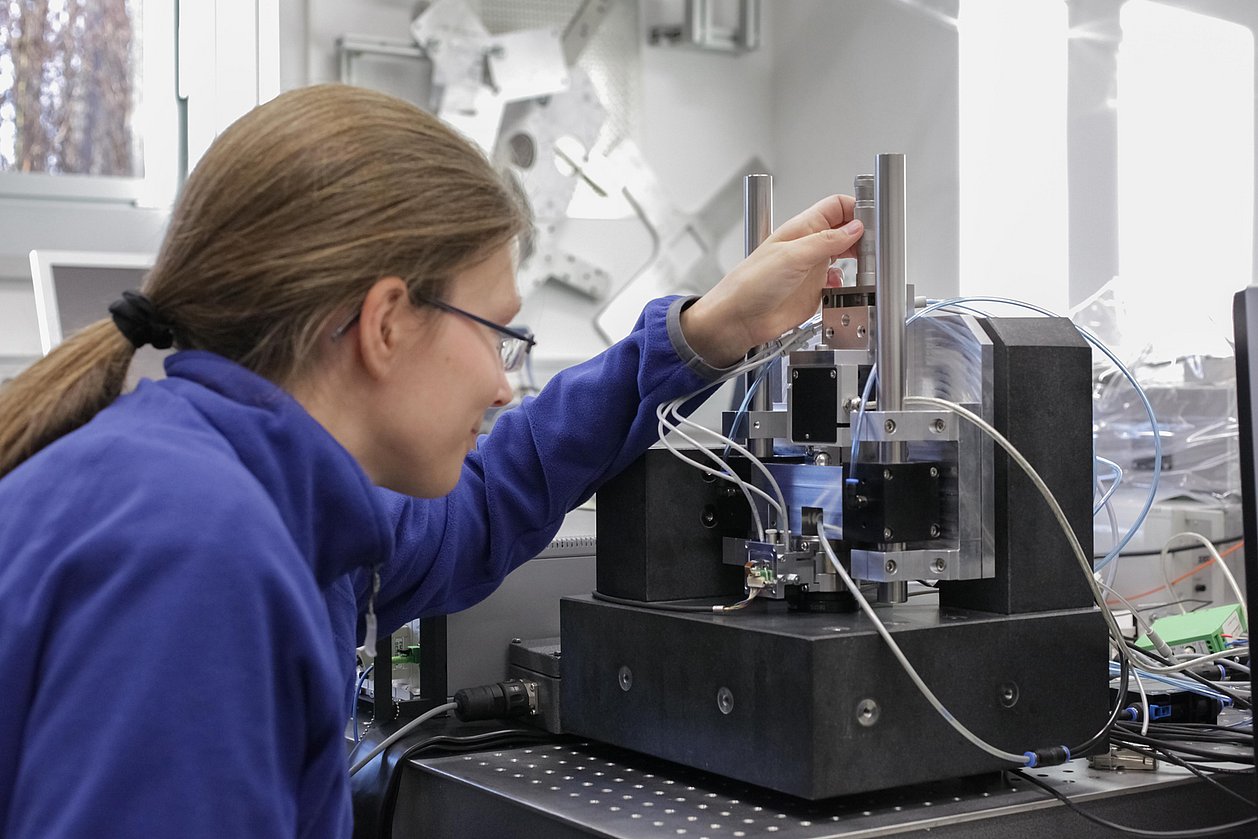

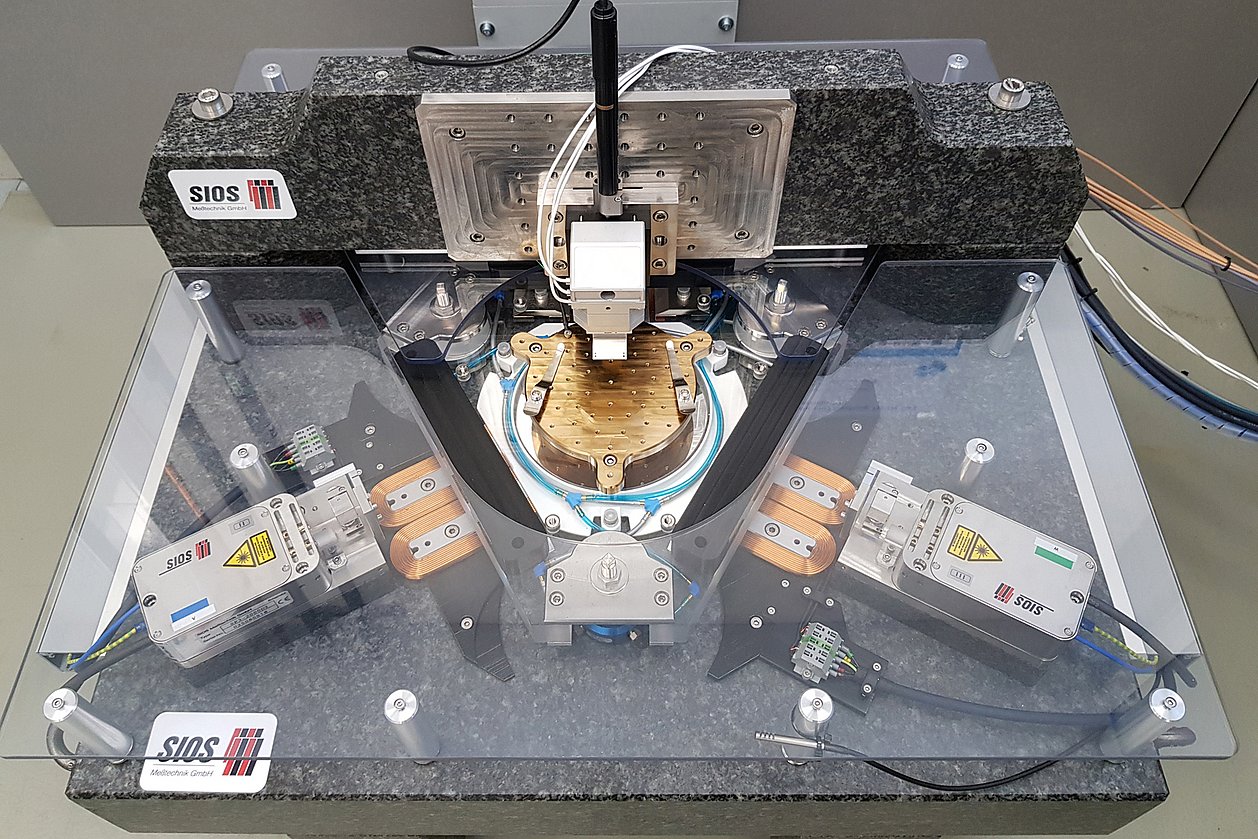

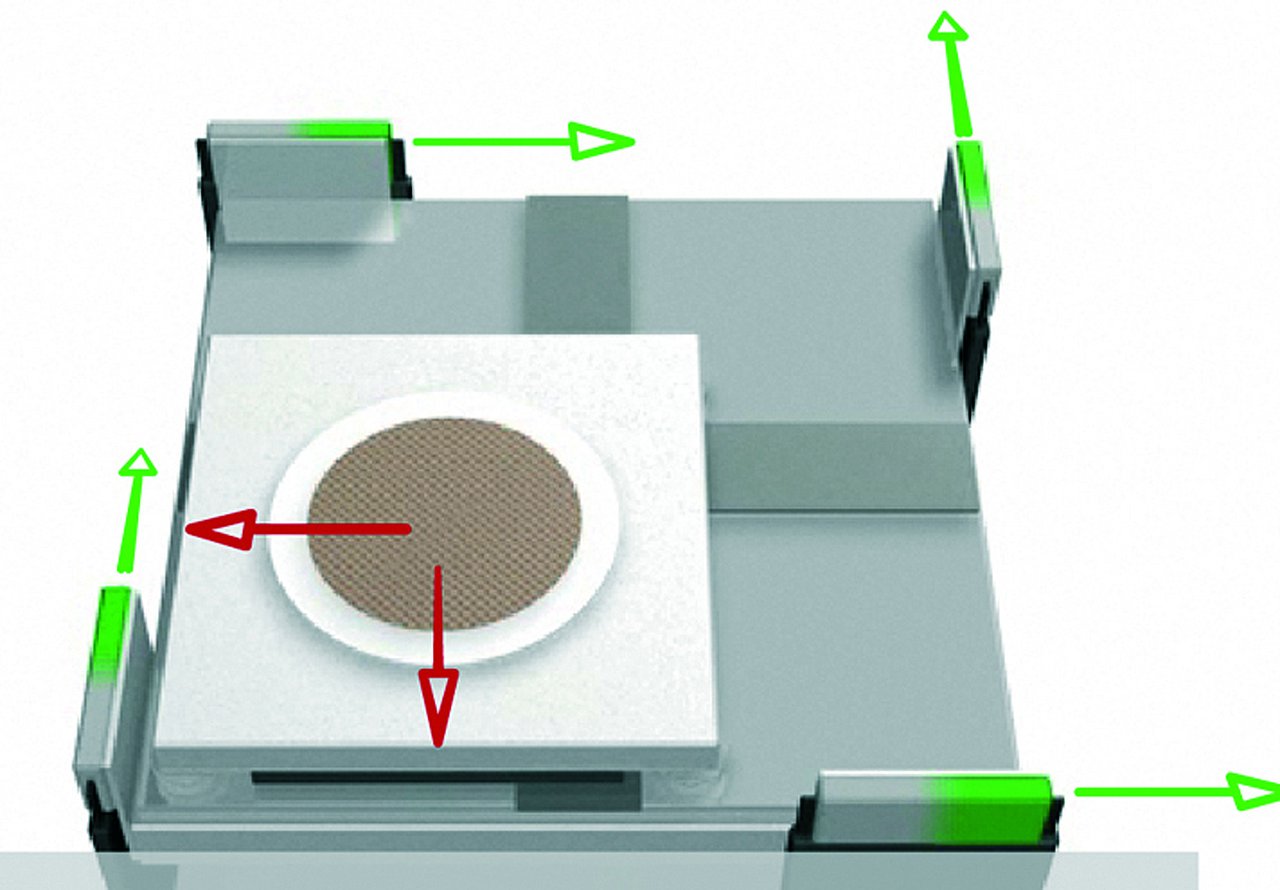

IMMS was in particular responsible for the planar drive system of the wafer stage and its control. The precision drive system consists of a two-dimensional planar magnetic direct drive. The motor glides on air bearings over a highly flat steel/granite sandwich, whereby friction independence and high durability is achieved. A special cooling system of the drive coils ensures precise temperature control of the assembly groups and maintenance of flatness. Also through an additional integrated magnetically acting twist lock, a completely contact less and frictionless guidance of the wafer stage is as such ensured.

Distortion and vibration caused by high accelerations in dicing processes lead to imprecisions against which the integrated active mount system works. According to the wafer stage movements linear actuators generate timely synchronised opposing forces in the machine frame, in order to minimise the inherent vibration. Besides, these actuators eliminate vibrations from external interference sources on the system.

Our partner ALSI has been producing the system in series since 2010.

Acronym / Name:

PMS380 / 300mm integrated stage platformDuration:2007 – 2009

Application:

Research institutions and ultra-precision mechanical engineering|Semiconductor| High-precision drives| Laser dicing of semiconductor wafersResearch field:Magnetic 6D-direct drives with nanometre precision

Related content

Reference

Peter Chall, ALSI

”The achieved extreme precision, reproducibility and productivity of the laser dicing technology are at the forefront of international excellence. The close cooperation with IMMS leads to innovative developments, which is a basis that we can count on to expand our position as a leading technology provider.“

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Funding

The work was funded by the government of the Netherlands as PointOne project under the reference PNE06007.

![[Translate to English:] Von ALSI hergestelltes Laser-Dicing-System. Foto: ALSI.](/fileadmin/_processed_/4/2/csm_03_PMS380_ALSI_ProductLarge15996_7ded454660.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)