Project in-ovo

Commissioned by Leipzig University, IMMS has created a prototype device for automatic sexing of hen eggs

For want of a cheap enough alternative, millions of male chicks are being destroyed

In the German poultry industry alone, 40 – 50 million male day-old chicks are killed each year because they neither lay eggs nor yield much meat. This killing is because the poultry industry divides domestic hens into two types, those with high egg-laying rates (known as layers) and those which put on a lot of flesh in a short time. There have been many different approaches all over the world for many years in the attempt to find a solution which might harmonise animal welfare and mass production.

Automated sex determination before hatching – one possible way out

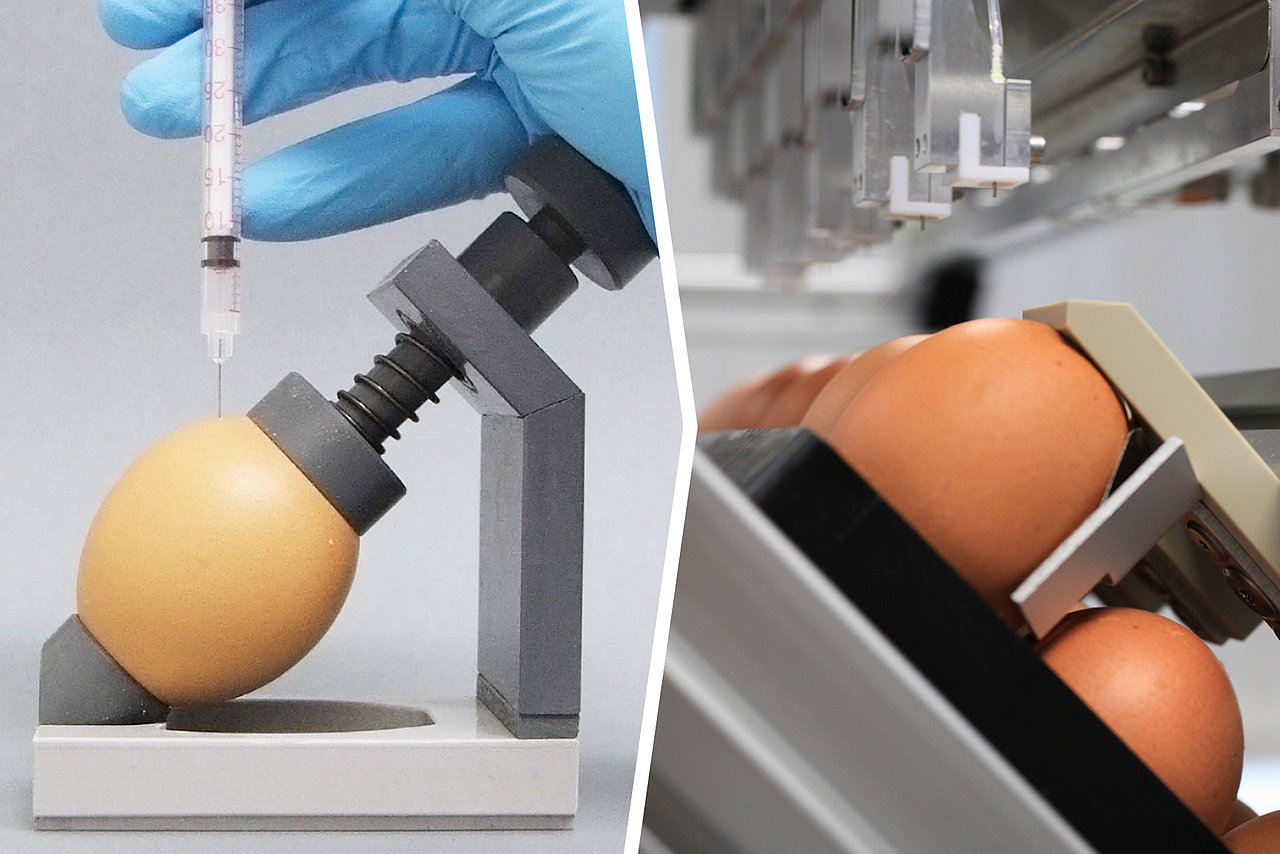

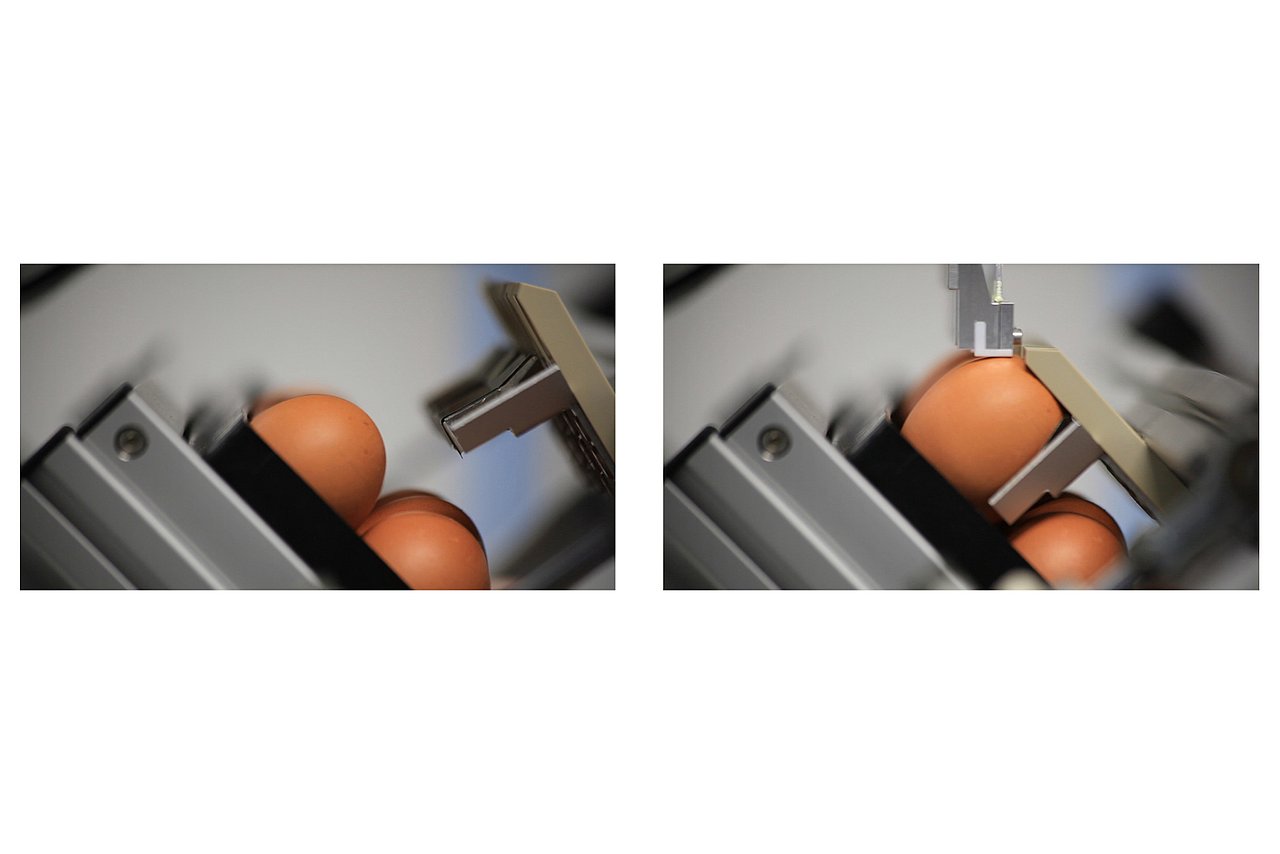

Commissioned by the VPCI (Institute of Physiological Chemistry, Faculty of Veterinary Medicine) of Leipzig University and under their instruction, IMMS has gone from the drawing board stage to proven use of a prototype device for automatic sexing of eggs. So that full automation of the hormone-based procedure developed since 2011 in Leipzig and validated in practical testing may follow. The automatic equipment is based on the experience gained by the VPCI on manual devices for individual egg testing. The central specification was that the eggs should be positioned at an angle of 45° to their longitudinal axis and that samples should be removed from above by a vertical puncture (see Figure 1, left). The IMMS prototype sampling device working automatically in parallel lines is an initial step on the road to future automatic testing of vast numbers of hens’ eggs in egg-producing factories so that male eggs can be sorted out automatically before they hatch.

The endocrinological procedure at Leipzig University

The science behind the Leipzig procedure is endocrinology. The procedure is to remove a drop of the embryo’s urine (known as the allantoic fluid) through a tiny puncture in the egg shell made with a fine canula at a stage which researchers currently believe to precede sensitivity to pain for the embryo. Sex-specific differences in the hormones of the allantoic fluid sample of nine-day-old embryos are tested for, using oestrone sulphate as marker.

If the hormone is found, the egg will develop into a female bird. If it is not present, the embryo is male and the egg will not be hatched. The hole made in the egg shell has no influence on the further development of the female embryo and does not require closure. In manual pricking and sampling of 10,678 eggs on the ninth day after laying, this procedure achieved 98 % accuracy in the predicting the sex. No significant variation in chicken body weight was detected on hatching. Breeder farm experiments confirmed all the usual egg-laying parameters.

IMMS’ Prototype 1.0

In close collaboration with Professor Einspanier of the VPCI, IMMS came up with a device and system for the automation of the hormone-based procedure, including drive mechanics and system control. The first tester, for 75 eggs per tray in the first instance, succeeded in automating the extraction of allantoic fluid from hens’ eggs and preparing it for sex determination, including full matching of sample to egg. Up to the time of writing, the tests had been carried out for 2,100 eggs by Leipzig University in cooperation with the REWE supermarket group using the prototype. The hatching rate was 86.5%, sampling success was 89.5% and for 95% of the samples the hormone-based diagnosis was correct.

Further development has been conducted on using the principle of the prototype tester to achieve higher throughput and even higher sampling success in a joint venture (known as SELEGGT) between REWE Group and the Dutch HatchTech company.

.

Acronym / Name:

in-ovo / Prototype device for automatic sexing of hen eggsDuration:2014 – 2016

Application:

Automation technology and Industry 4.0|Life Sciences|Automation| in-vitro diagnostics| sex determination| sexing| hatchery| laying hen farm| poultry farmingResearch field:

Partner

Related content

Contact

Contact

Dr.-Ing. Ludwig Herzog

Head of Mechatronics

ludwig.herzog(at)imms.de+49 (0) 3677 874 93 60

Dr. Ludwig Herzog will provide detail on our research on magnetic 6D direct drives with nm precision for the nm measurement and structuring of objects. He supports you with services for the development of mechatronic systems, for simulation, design and test of MEMS as well as for finite element modelling (FEM) and simulation.

Funding

IMMS produced Prototype 1.0 for automated sampling of hens’ eggs to enable endocrinological sex determination on being commissioned to do so by the VPCI (Institute of Physiological Chemistry in the Faculty of Veterinary Medicine) of Leipzig University. The project was funded by the BMeL (Federal German Ministry of Food and Agriculture) under the code 313-06.01-28-1-33.031-07.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)