Prof. Dr.-Ing. Patrick Mäder, Technische Universität Ilmenau

”For us, the cooperation shows how important IMMS is for a transfer of results from basic research into practice.”

”Our Data-intensive Systems and Visualization Group (dAI.SY) at the Institute for Applied Computer Science at Technische Universität Ilmenau and IMMS have collaborated in the Thuringian IntelligEnt research group to improve design automation for integrated circuits and systems by applying machine learning algorithms.

Together with IMMS, we have implemented circuit processing by learning algorithms for the design of analogue/mixed-signal circuits. Integrated into the design software, algorithms are used to support the circuit designer with novel functions such as the recognition of untypical structures during the design process. The circuit representation and learning procedure developed for this purpose enable neural networks to learn the function of circuit blocks implicitly. In addition, IMMS has developed new solutions for modelling, layout, simulation and verification as well as for testing and characterising integrated circuits on the basis of our AI support.

In addition to design automation, we have developed a method for machine-learning-based measurement data analysis for ASICs together with IMMS. Our developed method independently analyses extensive and numerous signal courses for potential and unknown faults and automatically creates groups of related fault types. Practical tests with industrial partners showed a ten- to 30-fold reduction in the otherwise enormously time-consuming and expensive effort for the analysis of measurement data.

It was a great pleasure for us to see the goal orientation and commitment with which the colleagues from IMMS worked with their sound application know-how to open up the methods and tools we researched and the immense potential of machine learning for microelectronics design. To do this, IMMS used requirements and data sets from industry that were contributed by companies on the project’s advisory board. This enabled not only the validation of the methods, but also the successful demonstration of their great benefit. For us, the cooperation shows how important IMMS is for a transfer of results from basic research into practice. In our view, the solution-oriented, agile and collegial way of working contributes to this, in addition to the deep technical understanding.

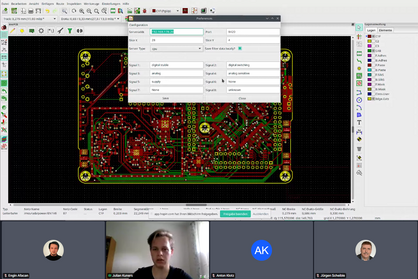

In addition, we worked together with IMMS on the AnoPCB software project. There, students jointly supervised by us developed a plug-in for the PCB design software KiCad based on the IntelligEnt results for circuit layout. The solution was awarded the EDA Competition Award for young scientists by the IEEE Council on Electronic Design Automation (CEDA). This success in the competition on the occasion of the international conferences on methods for the design of integrated circuits SMACD 2021 and PRIME 2021 clearly shows the thrust with which IMMS combines the promotion of young scientists with research and development.

We count on continued good joint supervision of students and look forward to the next opportunity to collaborate on R&D topics on electronic design automation and AI.”

The reference is related to:

Contact

Contact

Eric Schäfer, M. Sc.

Head of Microelectronics / Branch Office Erfurt

eric.schaefer(at)imms.de+49 (0) 361 663 25 35

Eric Schäfer and his team research Integrated sensor systems, especially CMOS-based biosensors, ULP sensor systems and AI-based design and test automation. The results are being incorporated into research on the lead applications Sensor systems for in-vitro diagnostics and RFID sensor technology. It will assist you with services for the development of Integrated circuits and with IC design methods.