Press releases

Nanometre-precise positioning for high-tech applications

SIOS and IMMS combine expertise from research and industry in the new MC_NPS project

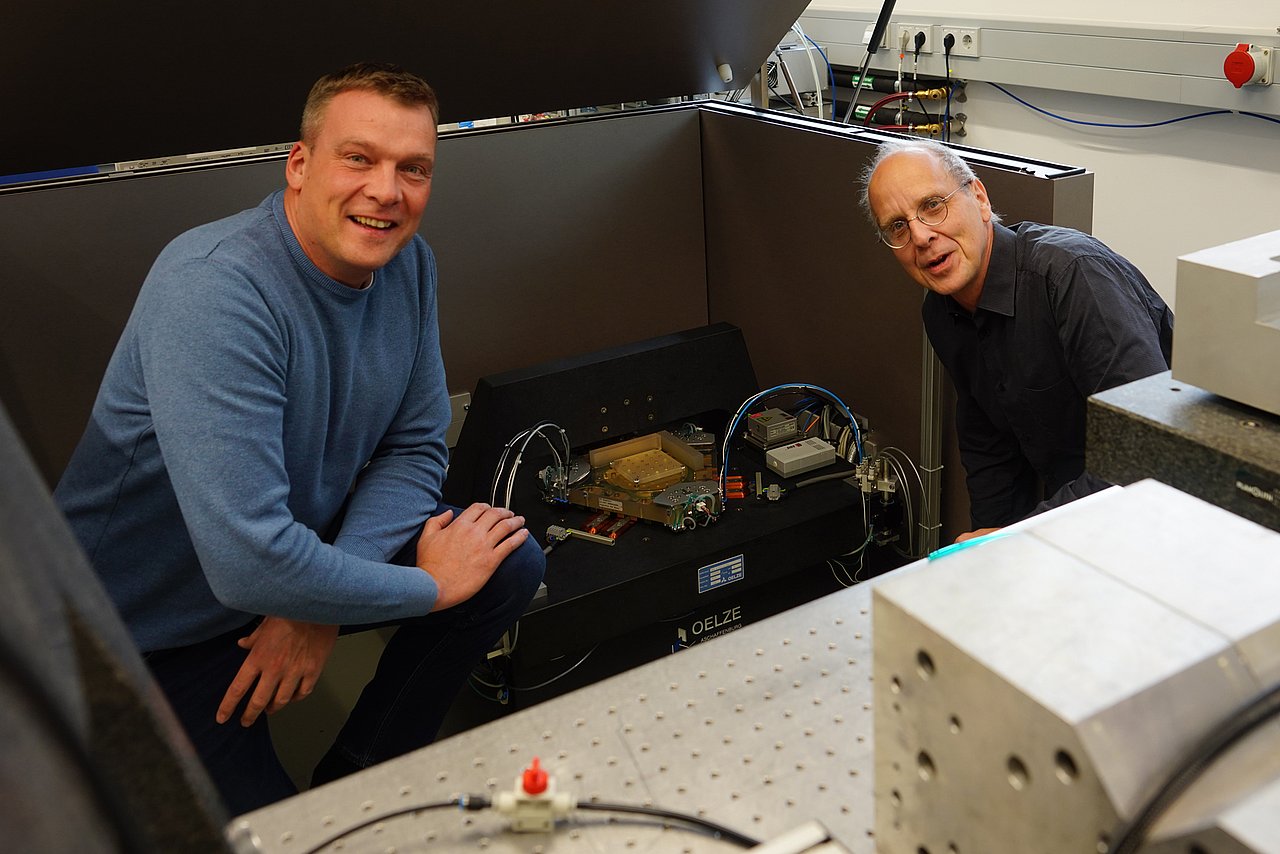

On 5 November 2025, SIOS Meßtechnik GmbH and IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH (IMMS GmbH) kicked off the one-year joint project ‘Motion Controller for the NPS6D100 Nano Positioning Platform’ (MC_NPS) at a kick-off meeting at IMMS Ilmenau. The project involves adapting a special control system from SIOS to a nanometre-precise positioning system with a large range of motion developed at IMMS. The aim is to use this combination to develop a market-ready high-tech product for new applications. These range from the semiconductor and optics industries to calibration and verification, medicine, aerospace technology and the future markets of photonics and quantum technology.

Tiniest structures in a vast field

Many industrial sectors require increasingly precise machines that can measure and process the smallest structures and objects with high accuracy, usually to further miniaturise technical products. Many such objects are a few millimetres to centimetres in size. However, surface features and functional elements often measure only a few micrometres or nanometres. In production, they must be positioned with an accuracy of a few nanometres, i.e. about one millionth of their size. Not only the precision of the drives needs to be improved, but their working range also allows for more applications and, last but not least, greater cost-effectiveness, the larger it can be with the same positioning accuracy.

Individual solutions for research and industry so far

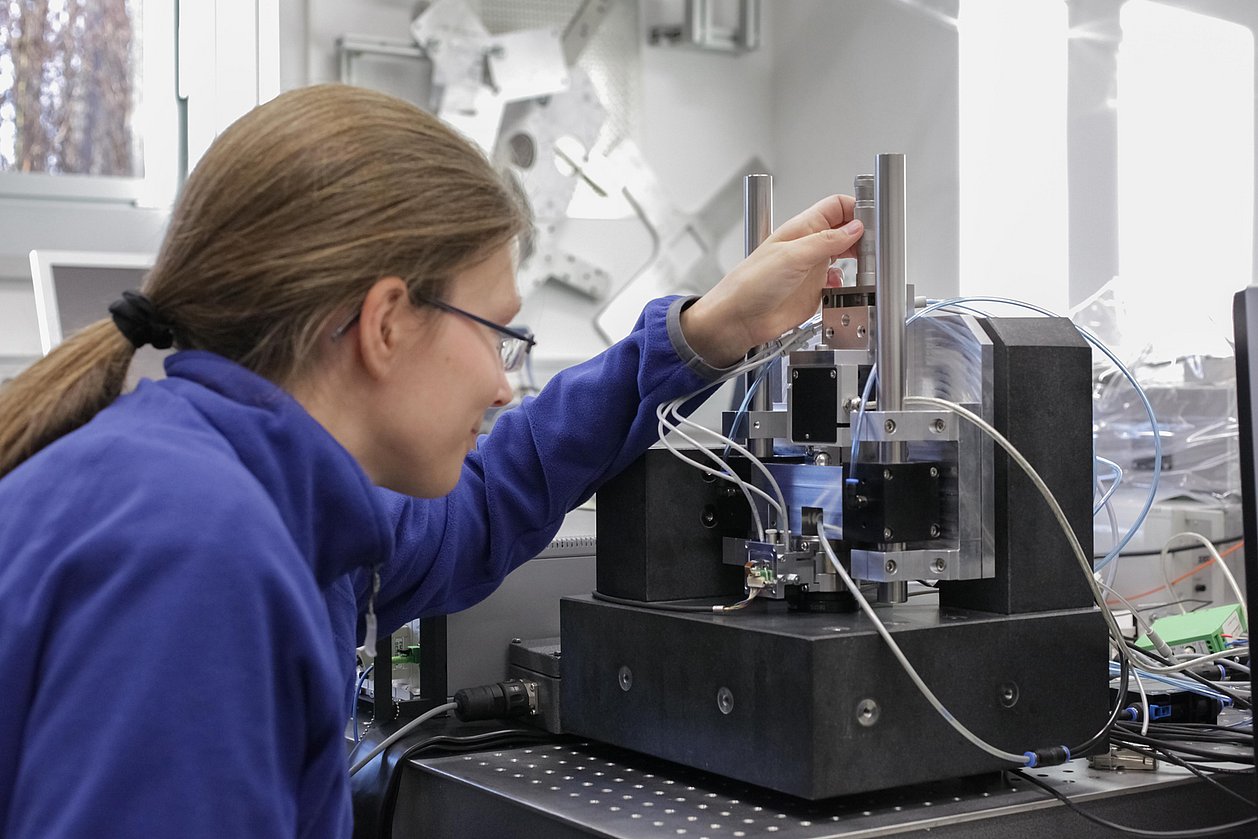

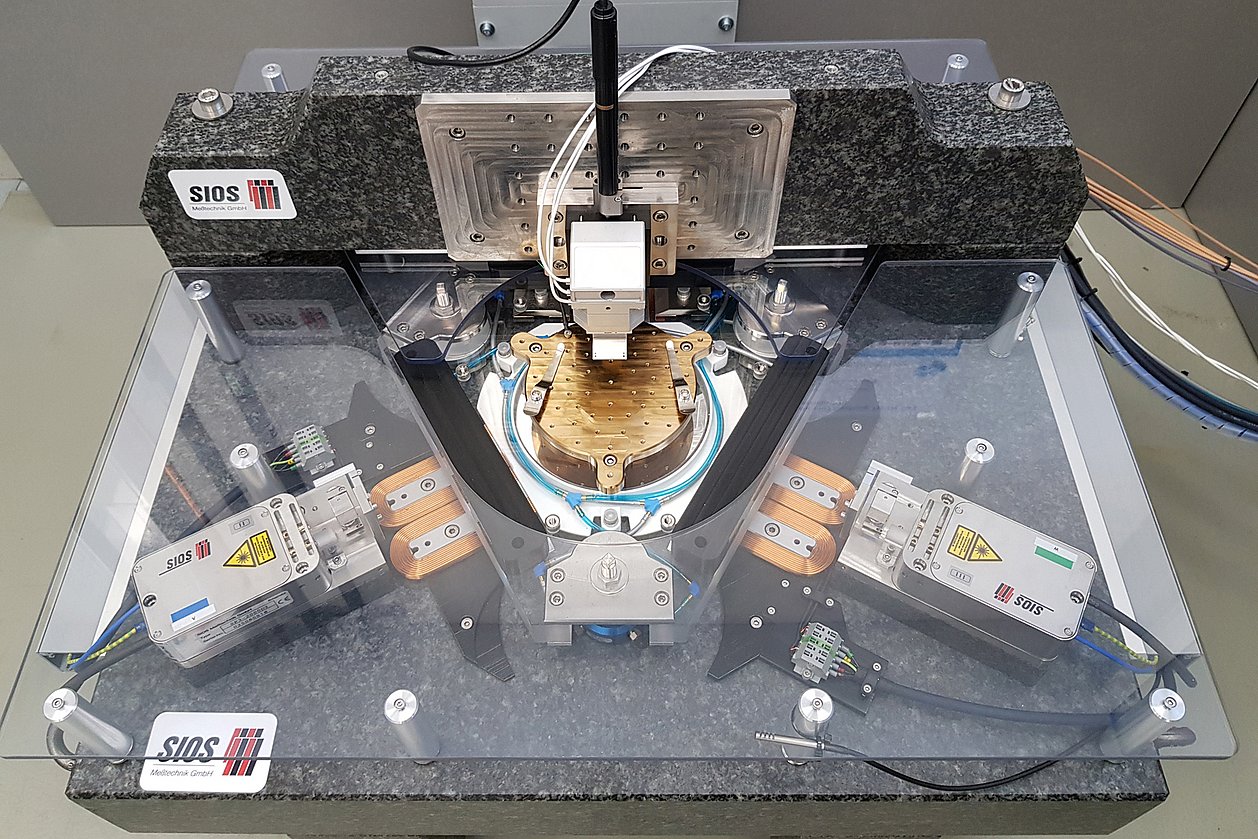

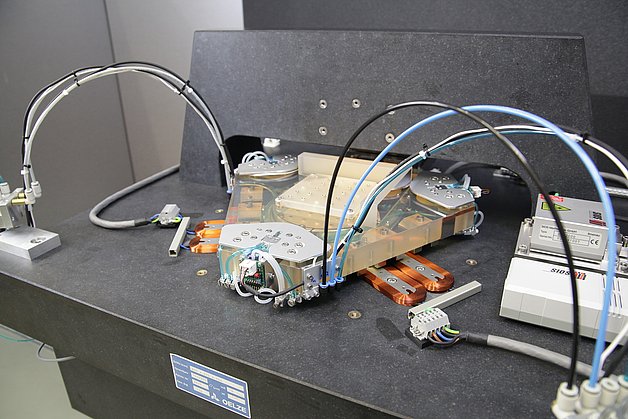

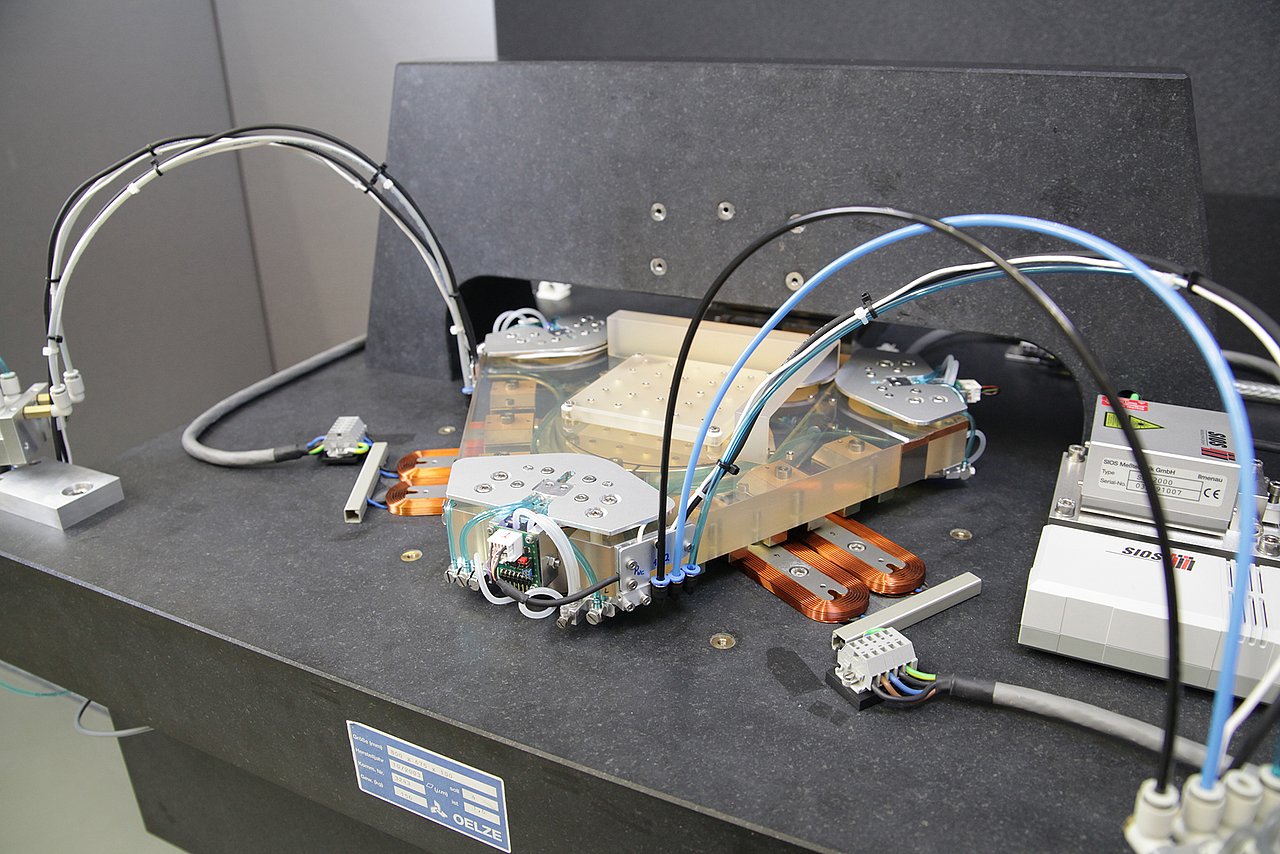

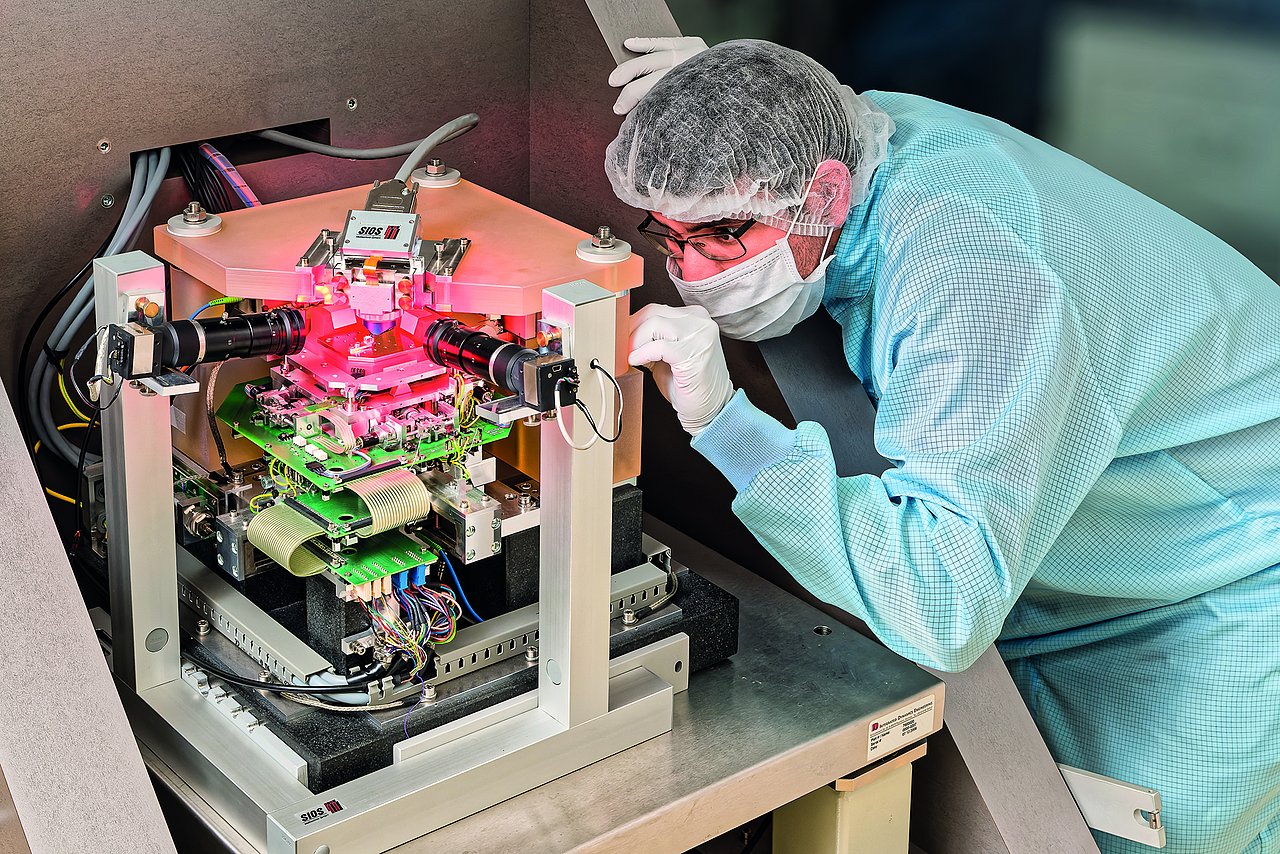

IMMS addresses precisely these requirements with its research, thereby helping to define the current state of the art worldwide: it has developed the NPS6D100 nanopositioning system, which positions objects weighing up to two kilograms within a motion range of 100 millimetres in diameter and 10 millimetres in height with a resolution of less than 2 nanometres and with 6 controlled degrees of freedom. Translated into more everyday dimensions, this would be comparable to a helicopter that can drop its load within a radius of 100 kilometres with an accuracy of less than 2 millimetres.

To open up this system for flexible industrial applications and thus for marketing, it still needs to be connected to the hardware and software commonly used for control in this field. The control hardware has to process the complex control algorithms in real time. The software must allow intuitive operation and flexible integration of different applications. None of this can be achieved with commercially available standard axis controllers.

SIOS already has industrially established and mature hardware and software for controlling its NMM-1 nanopositioning and nanomeasuring machine for such requirements. SIOS is the global market leader with the NMM-1 system. However, this control system cannot be used directly to operate the IMMS drive, as it is designed for a different drive architecture.

Industrial-grade modular complete system for wide applicability

In the MC_NPS project, SIOS and IMMS will work on a marketable solution that combines IMMS' newly researched drive with SIOS' industry-proven control system. The intended result is a system that not only covers a significantly larger working range than SIOS' current leading product, but is also modularly configurable and can therefore work with various probing systems such as focus sensors, atomic force microscopes or microprobes in different applications.

To achieve this goal, SIOS will coordinate the project and adapt and expand the motion controller of its NMM-1 machine, which is based on a special digital signal processor, for the IMMS NPS6D100 drive. On the IMMS side, the control and regulation algorithms developed for its NPS6D100 drive, which enable nanometre-level positioning, will be restructured to match the SIOS control system and finally will be ported to it.

If this fusion of ultra-precise positioning systems, efficient and cost-effective controller hardware and state-of-the-art measuring systems proves successful, it will pave the way for the marketing of the NPS6D100 as another nanopositioning system ‘Made in Thüringen’ that sets global standards.

Funding

The joint project “Motion controller for the NPS6D100 nano positioning platform” (MC_NPS) is supported by the funding programme of the German Land of Thüringen for the promotion of research, technology and innovation (RTI) as the research and development initiative Thüringen Verbund under the joint project number 1007528 , the IMMS topic “Porting and adaptation of the NPS6D100 control software to the NMM DSP controller from SIOS” under the reference 2025 VDY 0050.

This might also be interesting for you

Related content

Project

MC_NPS

Combination of a high-precision drive from research with industrial control for nanometre-precise positioning in high-tech applications

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_20200731_IMG_2732_K4PNP-INPOS_SG_1920x1280_7c70c69f8a.jpg)