Project THERMULAB

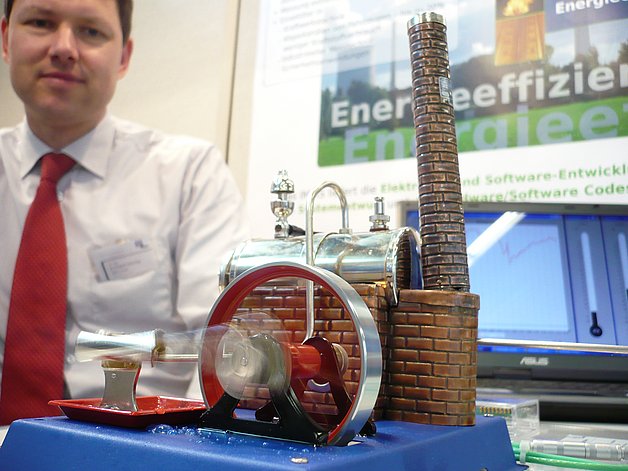

The developed highly accurate sensor system, operating at 150°C, improves the efficiency of industrial plants and combustion engines.

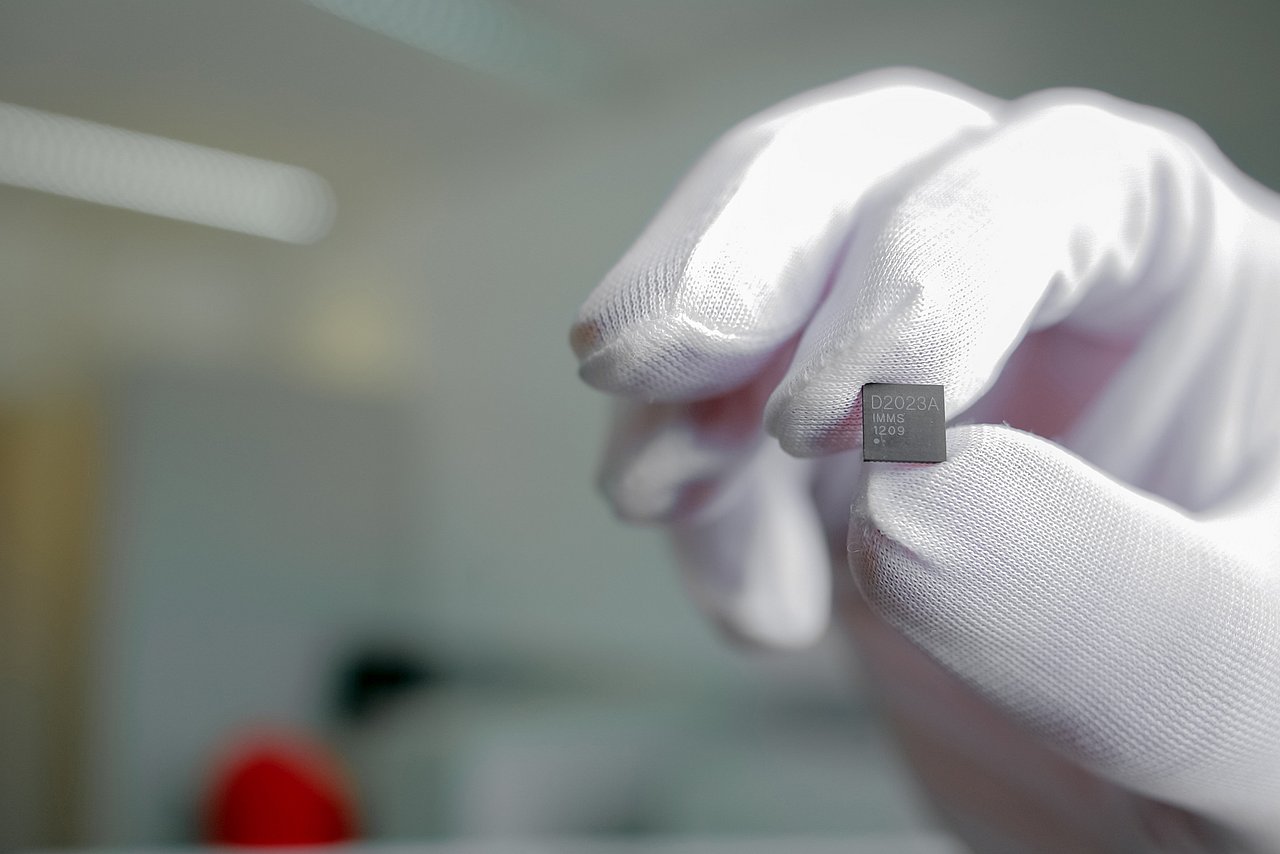

To achieve high thermodynamic efficiency in gas power stations or combustion engines, the working temperatures are raised almost to the thermal limit of the materials contained in the equipment, reaching up to 1200°C, so that highly accurate measurement of the temperature at various points is required to avoid breaching of that limit. IMMS has thus developed an ASIC for a compact intelligent high-temperature sensor system. This microchip, operating at 150°C, supports temperature measurements with a thermocouple to an accuracy tolerance of 1°C in the range from -40°C to 1200°C.

Networking is simplified by the use of a digital data bus which, also, because there are fewer cables means lighter weight and lower cost. The data from the sensors can be processed on a distributed basis, significantly improving energy efficiency. Sensor merging and data compression achieve much lower data rates, again resulting in lower energy consumption.

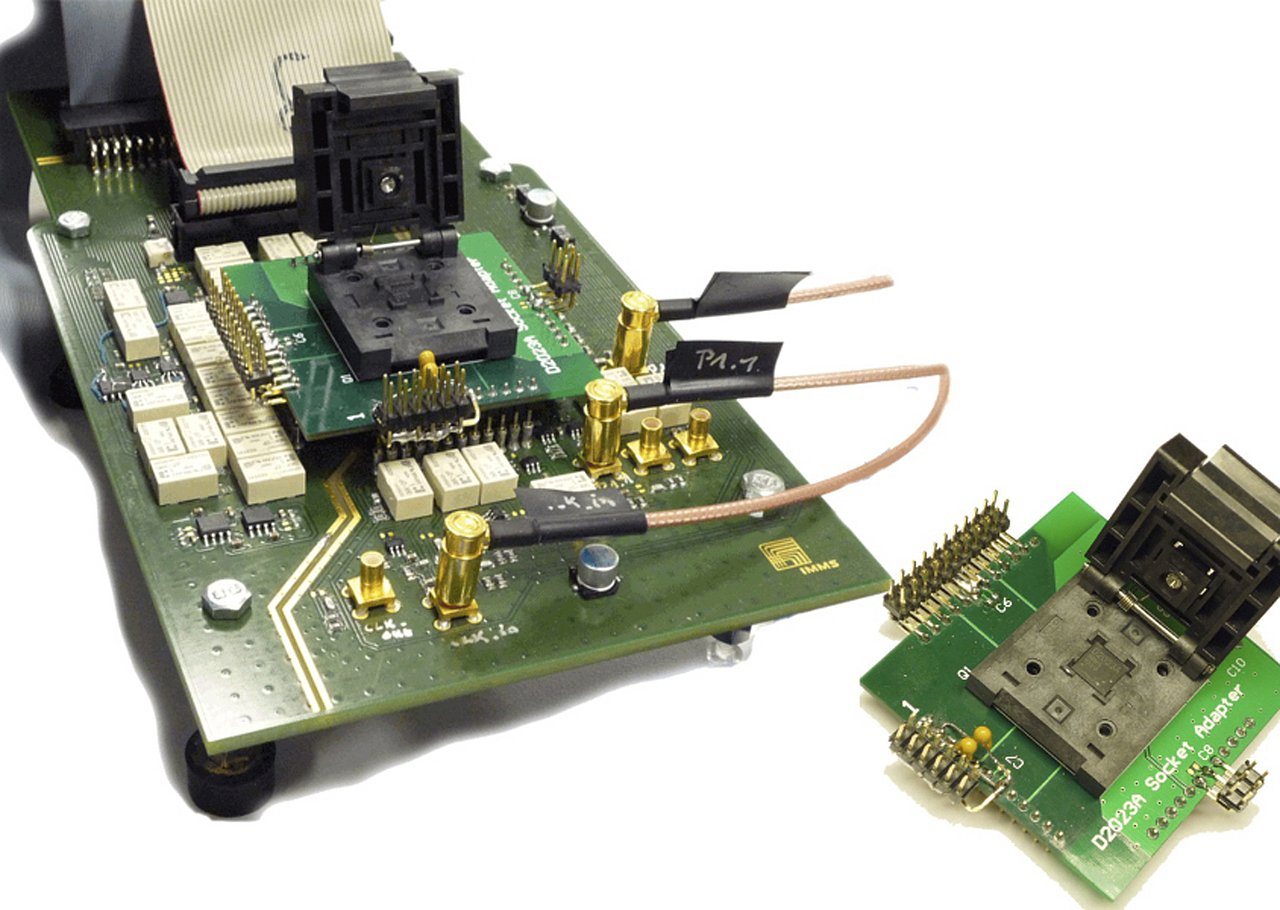

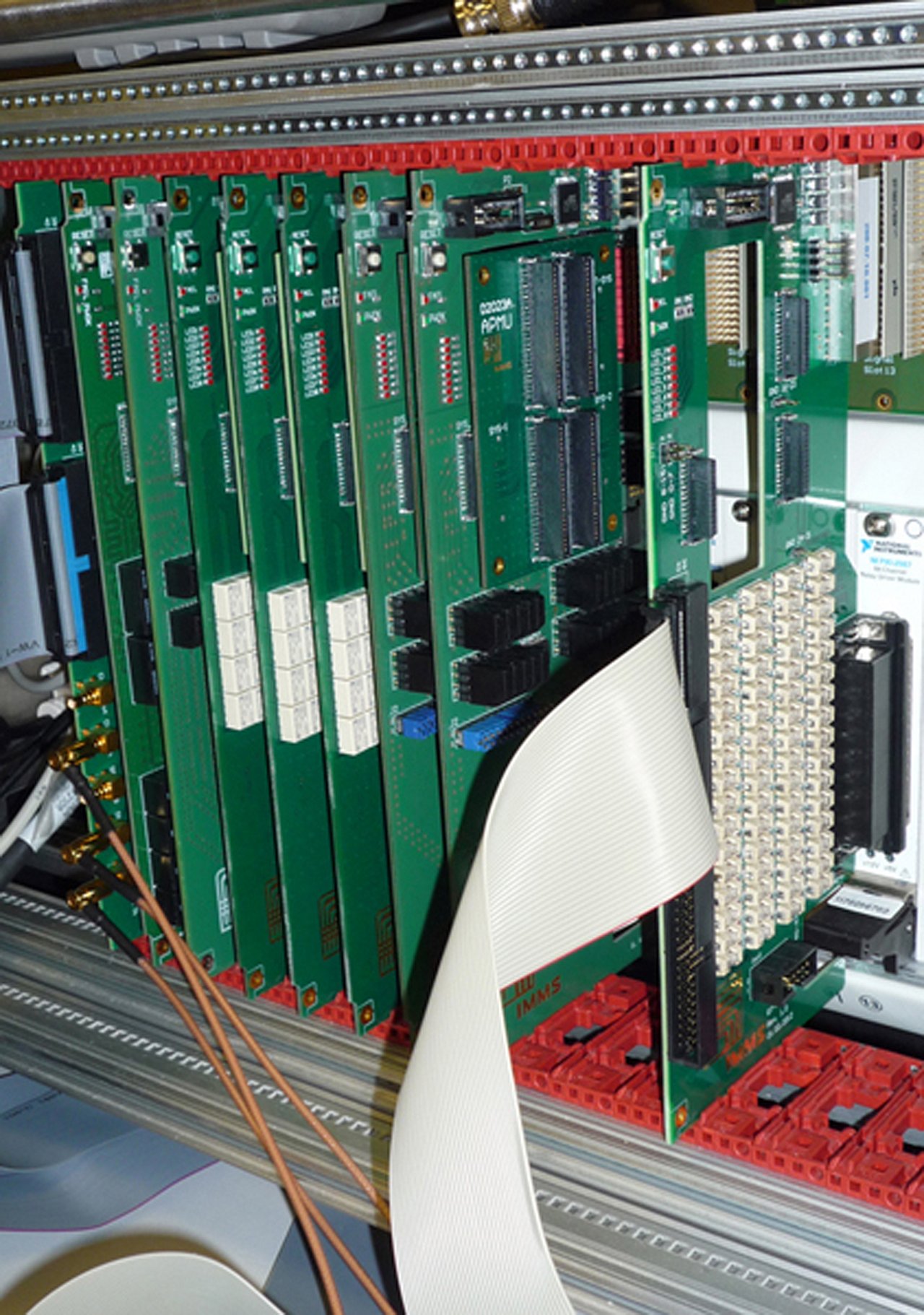

The complex demands on the microchip – wide temperature range, large digital blocks and highly accurate analogue components – involved great effort for the test setup.

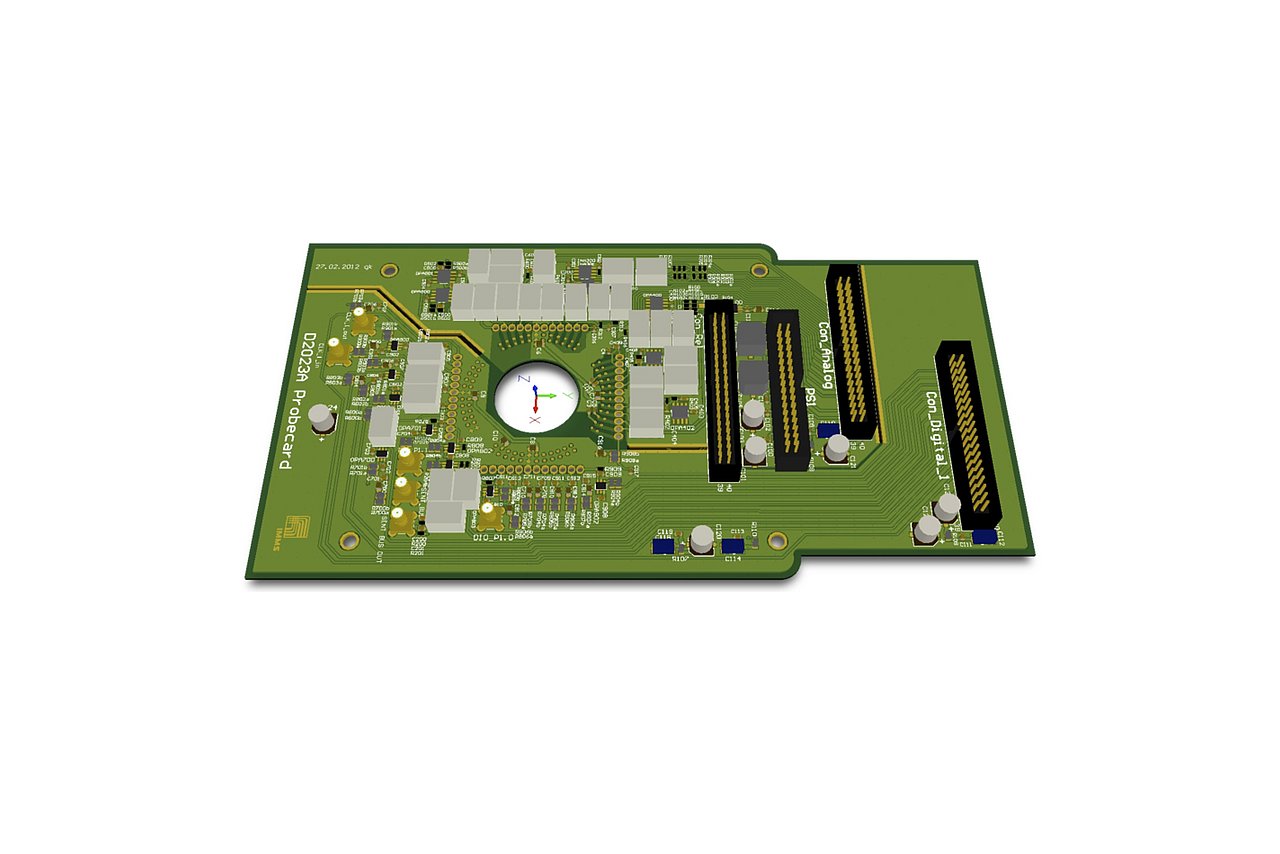

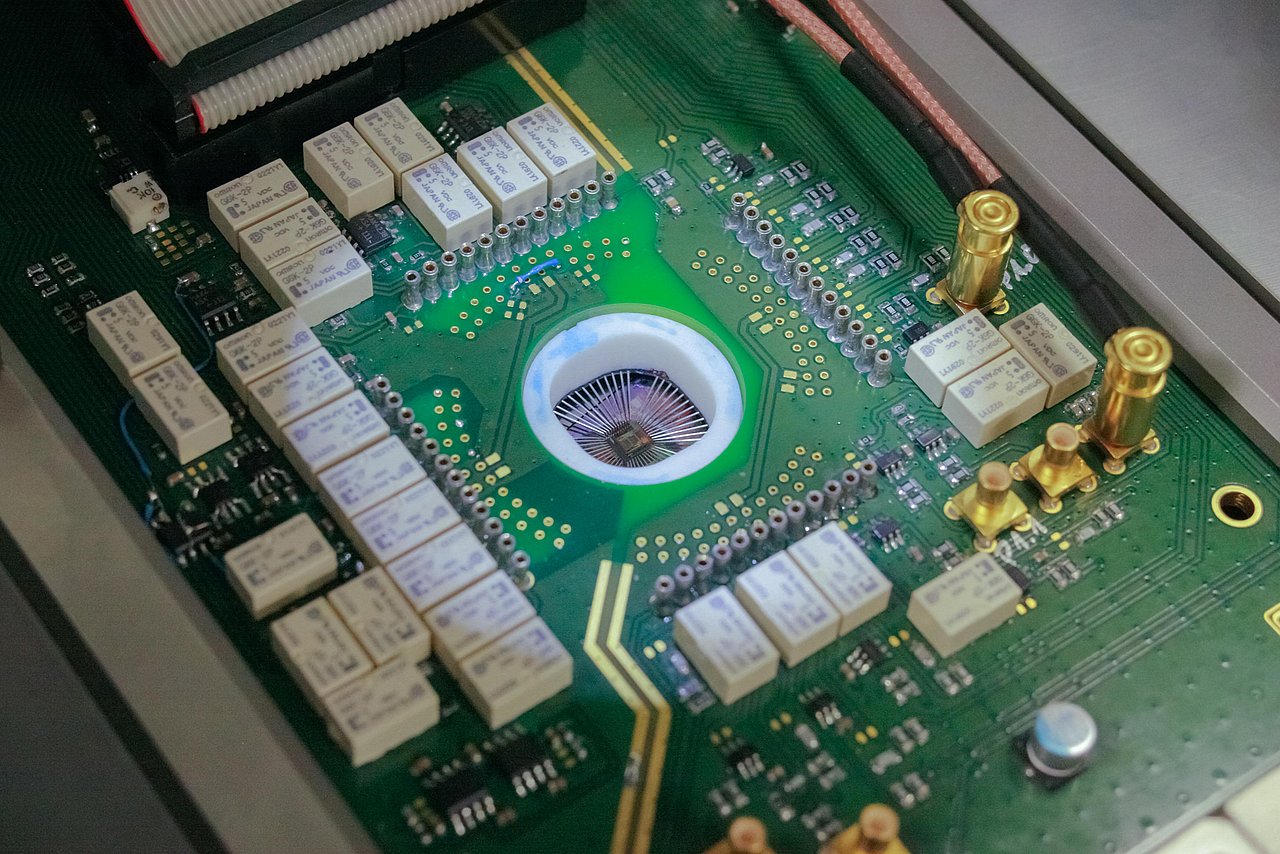

IMMS verified and characterised the microchip at the stage when it was on the semiconductor wafer. For the testing card the research group created the circuit diagram, simulated the circuit, designed the layout and constructed the PCB in four layers. Among the items contained on the PCB are connections to the testing system and 30 relays to put the specified tests into practice.

Acronym / Name:

THERMULAB / Thermodynamic Multi-Sensors for the Monitoring of High-Temperature-Processes, especially in flue ducts – Smart Sensor Interface Applicable for High TemperaturesDuration:2010 – 2012

Application:

|High-temperature electronics| temperature measurement technology| industrial measurement technologyResearch field:Integrated sensor systems

Related content

Reference

Lutz Langelueddecke, Melexis

”IMMS modelled and verified a mixed-signal IC with a controller for Melexis. Their high technical competence confirmed once more how well and enjoyably we have been able to collaborate with IMMS over recent years.“

A Digitally Trimmable Wide Temperature Range 0.35-µm CMOS On-Chip Precision Voltage Reference

Jun Tan1. Marco Reinhard1. Dirk Nuernbergk2. Eckhard Hennig1.13. ITG/GMM-Fachtagung: Entwicklung von Analogschaltungen mit CAE-Methoden (Analog), Aachen, 04.03.2013 - 06.03.2013

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau. 2FH Jena, Fachbereich Elektrotechnik und Informationstechnik.TalkA Digitally Trimmable Wide Temperature Range 0.35-µm CMOS On-Chip Precision Voltage Reference

Jun Tan1. Marco Reinhard1. Dirk Nuernbergk2. Eckhard Hennig1.13. ITG/GMM-Fachtagung: Entwicklung von Analogschaltungen mit CAE-Methoden (Analog), Aachen, 2013, CD-ROM, ITG-FB 239, ISBN 978-3-8007-3467-2

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau. 2FH Jena, Fachbereich Elektrotechnik und Informationstechnik.ArticleHW/SW-Co-Entwurf einer intelligenten Sensor-Schnittstelle mit Hilfe eines schnellen, Zyklenzahl-genauen, RTL-nahen Befehlssatz-Simulators

Gregor Nitsche1. Eckhard Hennig1. Georg Gläser1.15. Workshop Methoden und Beschreibungssprachen zur Modellierung und Verifikation von Schaltungen und Systemen (MBMV), 2012, Kaiserslautern, 05.03.2012-07.03.2012

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau.TalkAnwendung modellbasierter Verfahren beim Entwurf eines Smart-Sensors

K. Agla1. S. Engelhardt1.11. Microcontroller-Applikation/eingebettete Systeme-Workshop. Wissenschaftliche Zeitschrift der Hochschule Mittweida Nr. 2/2011. S. 43-45

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau.Article

Press release,

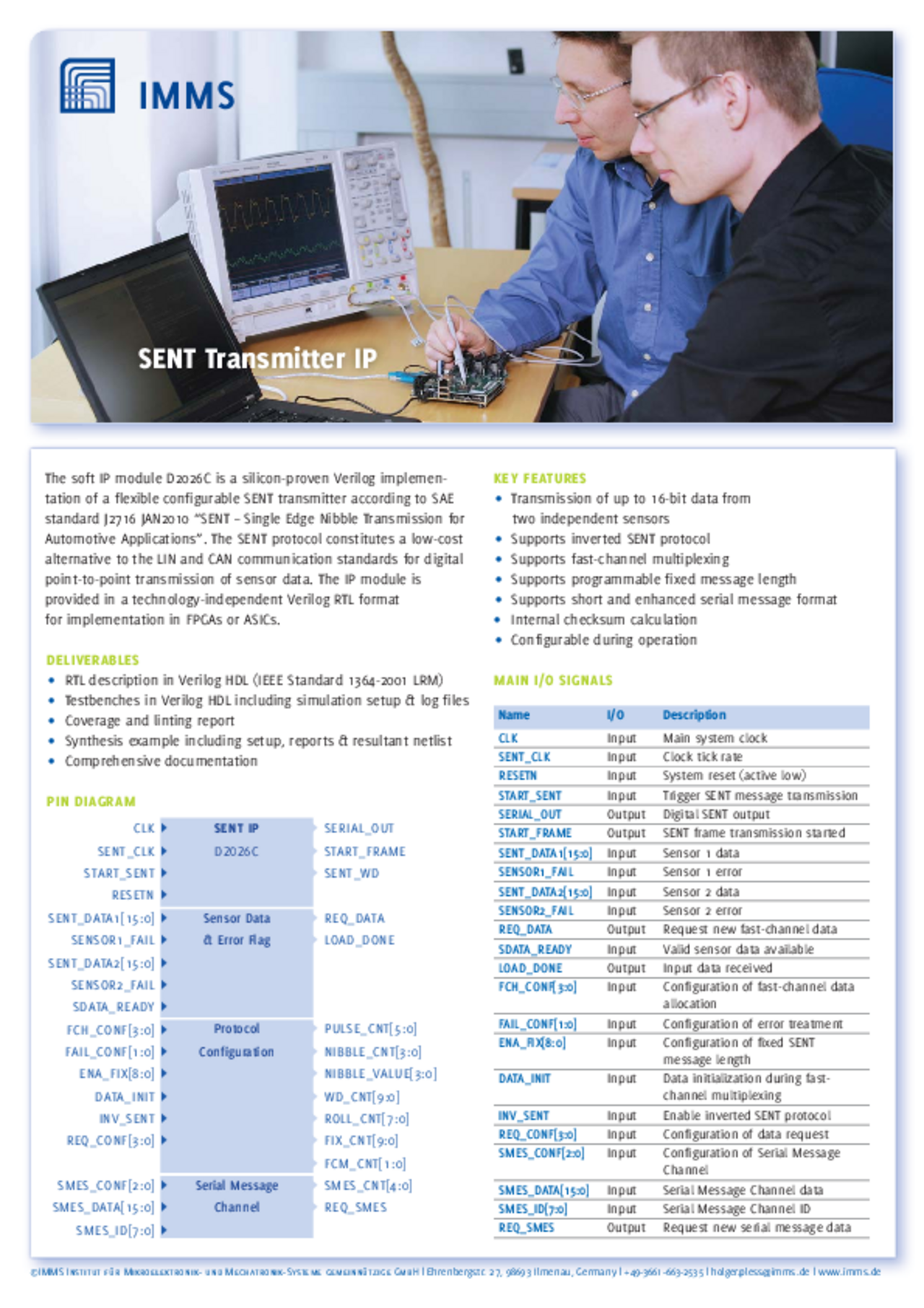

IMMS released a new version of its SENT transmitter IP for next-generation smart sensors in automotive applications

SENT is a digital point-to-point communication scheme for use in applications where high-resolution sensor data needs to be transmitted from a sensor to a control unit. It constitutes a low-cost alternative to the LIN and CAN bus standards for the automotive industry, e.g. for the transmission of the exhaust temperature to the engine control unit (ECU). IMMS’ newest release of its SENT transmitter IP “D2026C” now supports the transmission of up to 16-bit data from two independent sensors. The…

Contact

Contact

Eric Schäfer, M. Sc.

Head of Microelectronics / Branch Office Erfurt

eric.schaefer(at)imms.de+49 (0) 361 663 25 35

Eric Schäfer and his team research Integrated sensor systems, especially CMOS-based biosensors, ULP sensor systems and AI-based design and test automation. The results are being incorporated into research on the lead applications Sensor systems for in-vitro diagnostics and RFID sensor technology. It will assist you with services for the development of Integrated circuits and with IC design methods.

Funding

The work of the Thermulab project received funding from the “Land” of Thüringen and the European Union (European Regional Development Fund (ERDF, German EFRE) under the reference 2009 FE 9086.