Project iHUB

Start-up support for innovative ideas – how start-ups and young companies can benefit from research

What is iHUB?

As part of the Leistungszentrum InSignA (InSignA performance centre), IMMS is also involved in the iHUB ideas competition as a research partner. This provides start-up support for innovative ideas on the topics of sensor technology, digitalisation and assistance systems. In a competition, the ideas are presented to a jury from science, business, public institutions and venture capital companies. The best ideas are then selected for funding and supported with research services from the partners involved. There are various objectives for advancing the idea, from demonstrators and prototypes to market analyses and feasibility studies. The projects are carried out by members of the performance centre for up to six person-months, including access to experts, laboratories and material resources.

In 2024, IMMS was able to take part in the competition as a partner for the first time. The jury selected a total of three project ideas in which IMMS is involved:

iHUB projekt LPT – Process monitoring during pulverisation

Task and partners: Lean Plastics Technologies GmbH (LPT) produces fine powder grains by cutting a long plastic strand with knives. The knives are mounted on a rotating cutter head, which is located in a cutting chamber from which the powder is evacuated. Currently, the cutting process is largely a black box from a process monitoring perspective. Particularly interesting information on the cutting process would be real-time images of the cut itself, e.g. using a high-speed camera, as well as the temperature profile of the components involved in the cutting process, especially the knives, to be able to optimise the process later. The optical solution was developed by Fraunhofer IZFP, while IMMS focussed on temperature measurement.

IMMS solution: To measure the knife temperature, it was first checked whether sensors could be attached directly to the blade. Due to the rotation of the cutter head, only a very small wireless system can be used for this. RFID sensors are the only way to measure there. However, the tested system is not able to transmit the data in real time, which would be necessary for control.

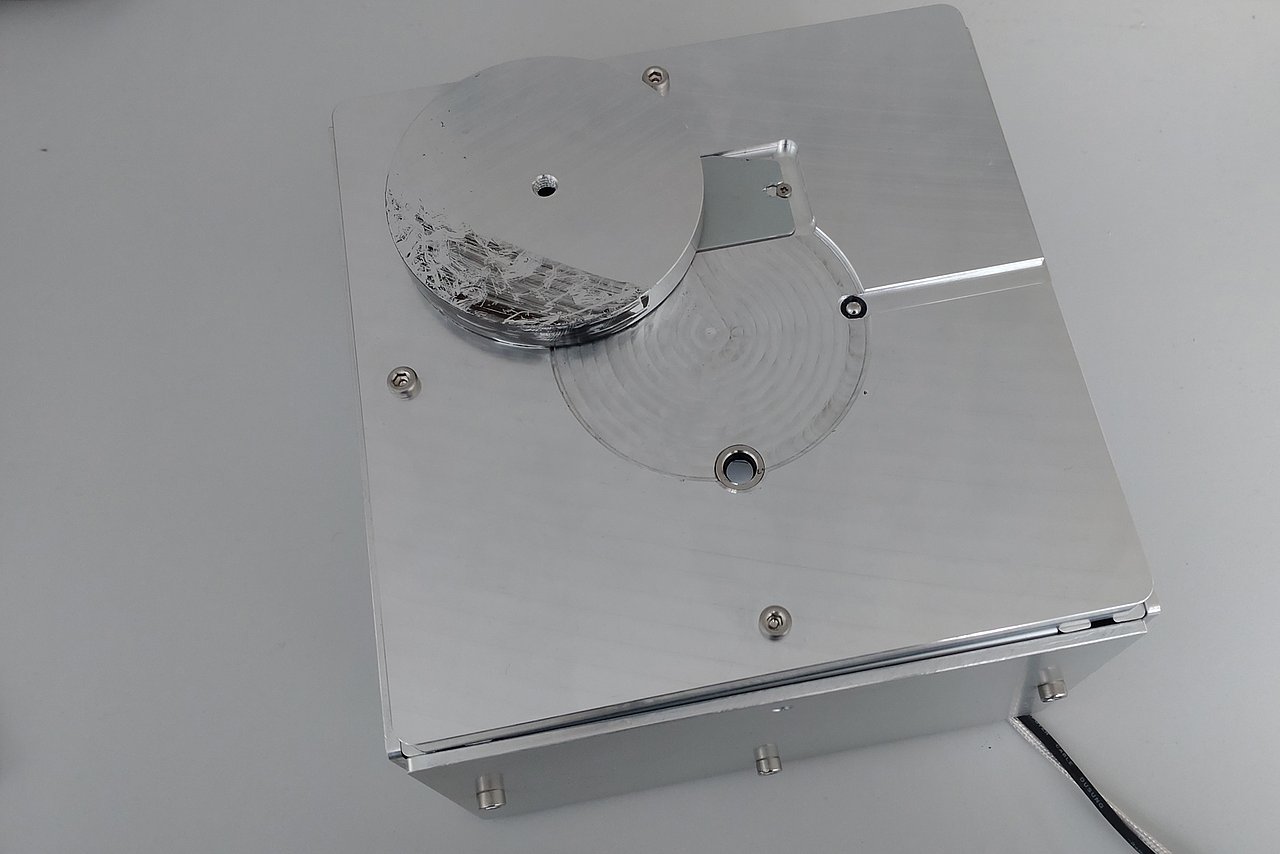

Alternative measurement concepts were therefore developed. Three further options for indirect measurement were identified, two of which were tested on a specially constructed test stand at IMMS, see photograph. The temperature of the test objects could be successfully tracked in the laboratory using both methods.

The infrared sensor has proven to be a good option here if positioning in the area of the chamber is possible. Similar properties should be achievable with a fast thermistor. This made it possible to develop a recommendation for measuring the process parameters.

iHUB project KitchenGuard – a new cooking experience with embedded AI

Task and partners: KitchenGuard‘s vision is to make cooking safer with intelligent sensor technology installed on the oven by using AI to determine what is happening in the cooking pot from acoustic data to prevent fires from starting by switching off in time. The iHUB project aimed to take a first step towards realisation. Fraunhofer IDMT was responsible for designing the microphone arrangement and selecting suitable microphones, while IMMS was responsible for designing the embedded data processing platform.

IMMS solution: The system is to be based on a microcontroller for processing the audio signals. Various options were investigated and the key data compared. The limited resources of embedded systems (MCUs) pose a major challenge when implementing AI models. In particular, the available memory (RAM and flash) and the available computing power must be taken into account. Some variants of current microcontrollers have integrated hardware accelerators for the calculation of neural networks, which should improve capacity. There are also options for reducing the size of the networks and the complexity of the calculations – ideally without negatively impacting accuracy. To investigate this, various AI models were tested on an NXP MCXN947 MCU and a more powerful NXP iMX8 CPU with Google TPU and their performance evaluated.

The results show that the hardware accelerator can speed up the calculation time of the neural network by a factor of 8 to 38, depending on the size and structure of the network. The best-performing system with the i-Mx8 application processor offers a strong acceleration (up to 60 times) in the calculation of large networks.

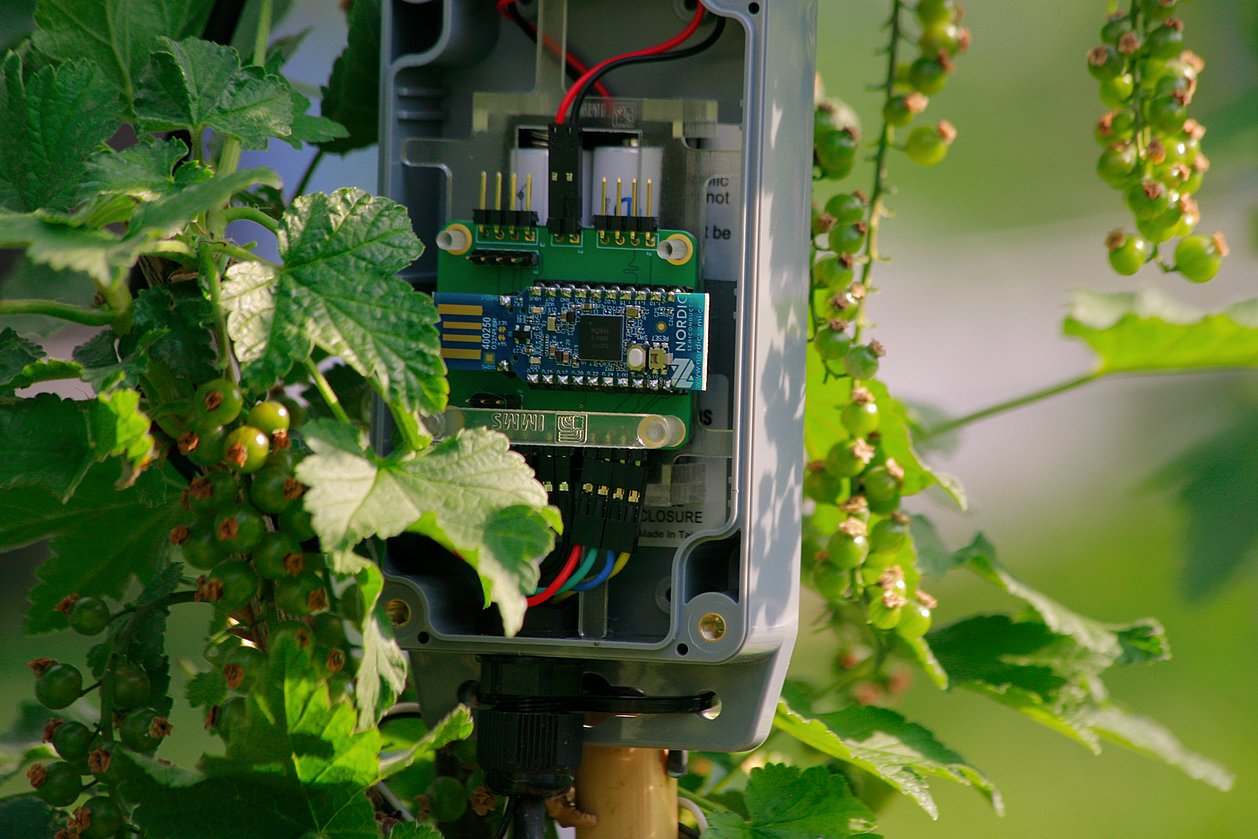

iHUB project PerfML – edge measurement system for distributed signal acquisition in industrial ML applications

Task and partners: seioTec already has an edge platform for ML applications on embedded systems in the form of the datAIndustry app. However, the demand for solutions for vibration and ultrasonic sensor technology and the associated high sampling and data transfer rates is increasing, particularly in distributed systems. The iHUB project therefore aimed to create the conditions for a corresponding system as a proof of concept. In addition to seioTec and IMMS, Fraunhofer IDMT was also involved. The task of IMMS was to design the data transmission efficiently.

IMMS solution: The partners first developed a suitable system architecture for an edge-capable measurement system for distributed multi-channel signal acquisition and integrated data pre-processing for industrial machine learning applications. The focus was on the communications interface between the measurement platform and the datAIndustry app. After analysing available technology and protocols in detail, the gRPC framework was chosen as the basis for the data interface between the components. Initial benchmarks have already been carried out with a test configuration consisting of a PC client and server implemented as the respective communications counterparts for the two systems. This proved that the transmission of data from several sensors via gRPC over Ethernet is possible without any problems. Packet sizes that are too small have a disadvantageous effect on throughput. Packets that are too large generate a high system load and can lead to problems with the datAIndustry app when storing the data in the internal database. These findings allow seioTec to further optimise its own software. It was also shown that multi-channel measurements with a high sampling rate can be processed by the system and further analyses can be carried out on this basis.

Next iHUB pitch in 2026

In three very different projects, IMMS was able to contribute various competences to support start-ups and young companies in realising their ideas. The institute is ready for the next challenges that companies bring to the iHub competitions. Ideas for the next pitch in February 2026 can be submitted until January 2026: https://ihub.leistungszentrum-insigna.de/pitch.

Acronym / Name:

iHUB / InSignA Innovation HUB (iHUB)Duration:2022 – 2027

Project website:https://ihub.leistungszentrum-insigna.de

Application:

Research field:Smart distributed measurement and test systems

Related content

Reference

Frank Seiferth, seioTec GmbH

”In our solution-oriented collaboration with IMMS, we were able to benefit in particular from the expertise of IMMS employees in sensor and embedded systems technology.“

Contact

Contact

Dr.-Ing. Tino Hutschenreuther

Head of System Design

tino.hutschenreuther(at)imms.de+49 (0) 3677 874 93 40

Dr. Tino Hutschenreuther will answer your questions on our research in Smart distributed measurement and test systems and the related core topics Analysis of distributed IoT systems, Embedded AI and Real-time data processing and communications, on the lead applications Adaptive edge AI systems for industrial application and IoT systems for cooperative environmental monitoring as well as on the range of services for the development of embedded systems.

Funding

The ‘InSignA Innovation HUB (iHUB)’ is a project supported by the German Land of Thüringen that promotes start-ups and spin-offs in the field of intelligent signal analysis and assistance systems in Thüringen and beyond.