Project Current Clamp

The clamp developed by IMMS registers and evaluates parasitic currents of data cables in industrial plant without interrupting production.

Expensive downtime in complex industrial plant is often attributable to malfunctioning of the closed- and open-loop control technology. These malfunctions are, in turn, often caused by unwanted interaction between the electricity supply and the control system. The effect is that communication between components is impaired. It is not always possible to apply the classic error analysis methods in the search for the causes of such interference.

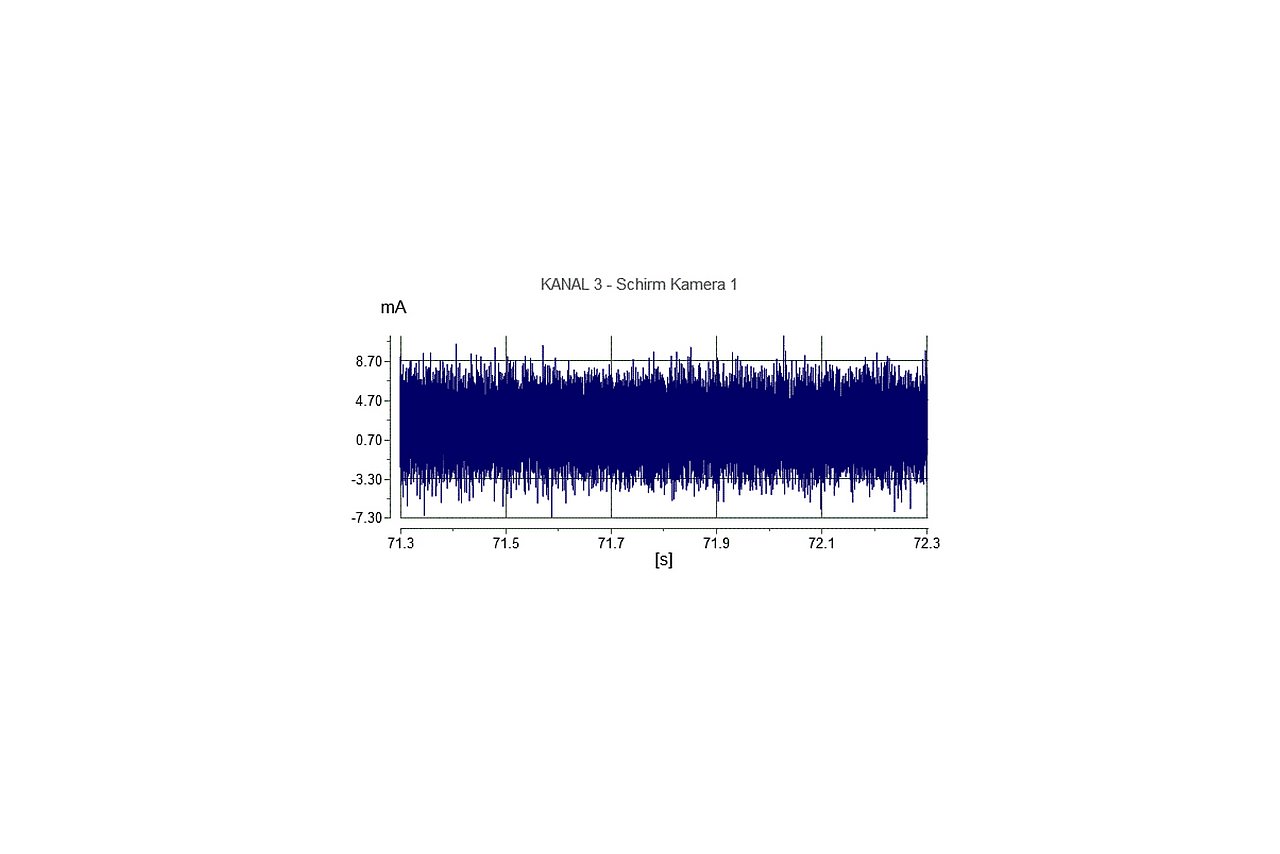

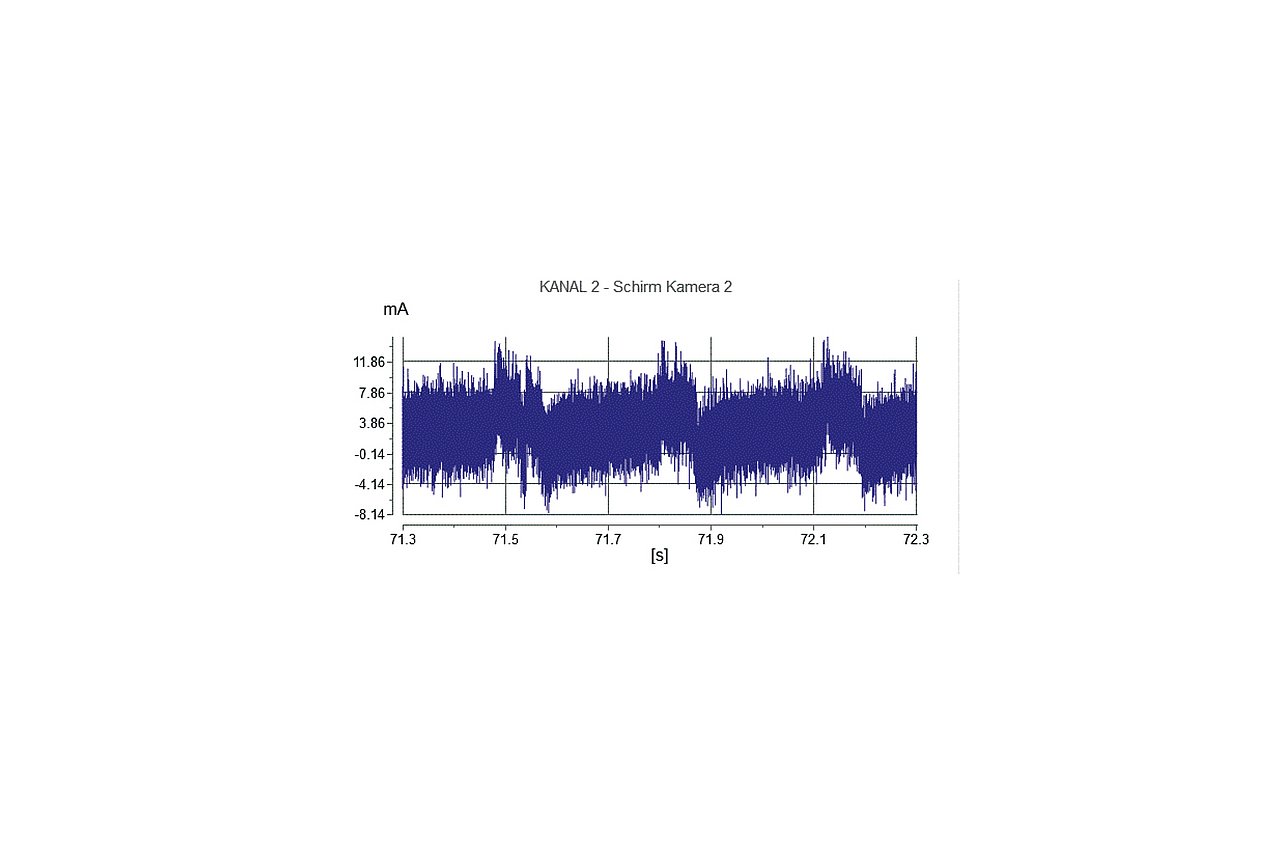

For these reasons, IMMS has developed a compact, smart current clamp for Indu-Sol to manufacture. It is a mobile device, energy autonomous, which will register automatically and continuously the true RMS level of parasitic current in a wire of the communication bus system in industrial plant for a period of 14 days, recording this on an SD card for later detailed analysis. The energy for its operation is stored in six LR6 mignon batteries supplying a total of approximately 20 Wh. The clamp recognises the parasitic currents from threshold values and is able to register values across a wide range, between 10 mA and 30A, at up to 40 kSa/s, digitising them at 16-bit resolution. It will display the root mean square value (RMS) of the current parasitics in either numerical, graphic or spectral form and can be easily and intuitively operated. If the owners of industrial plant use several clamps at once they can establish the site of the parasitics, thus greatly reducing the effort required for analysis.

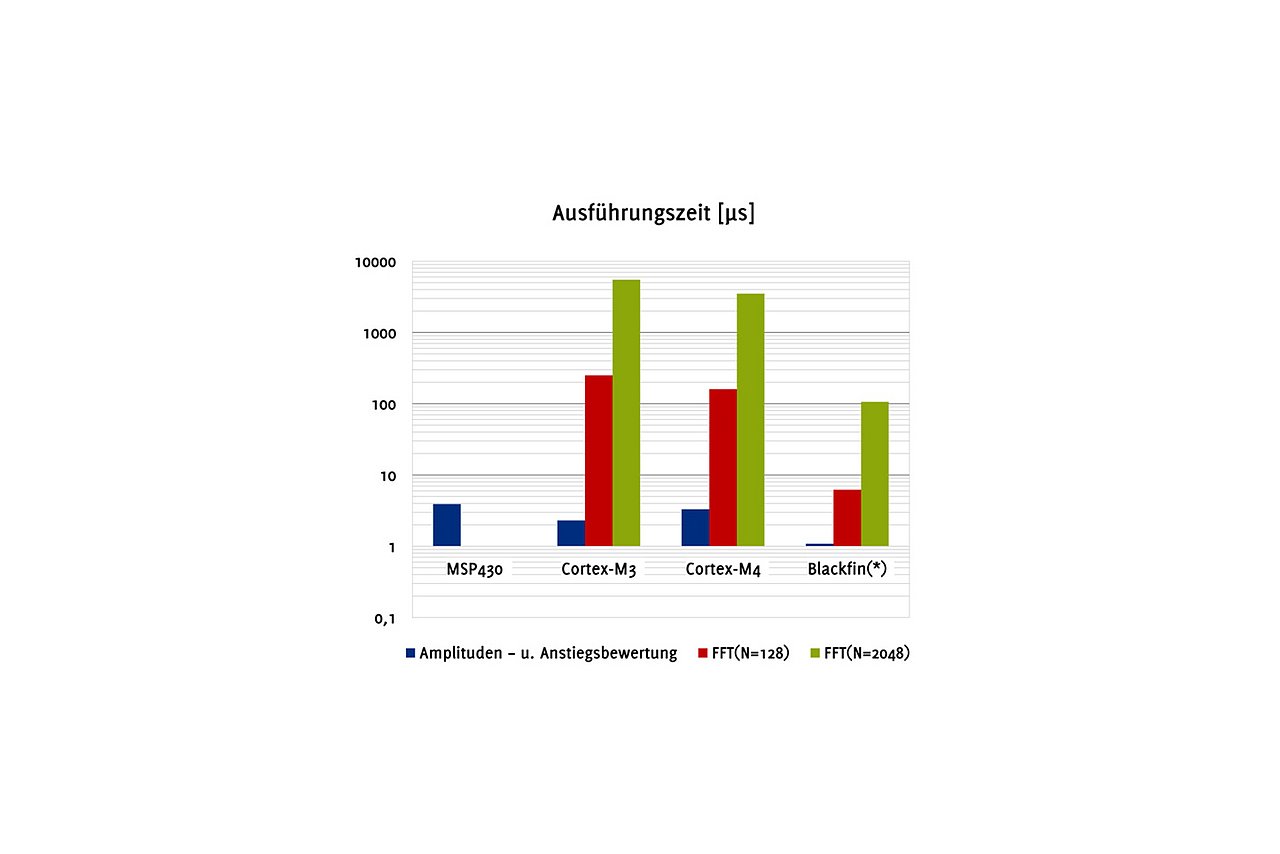

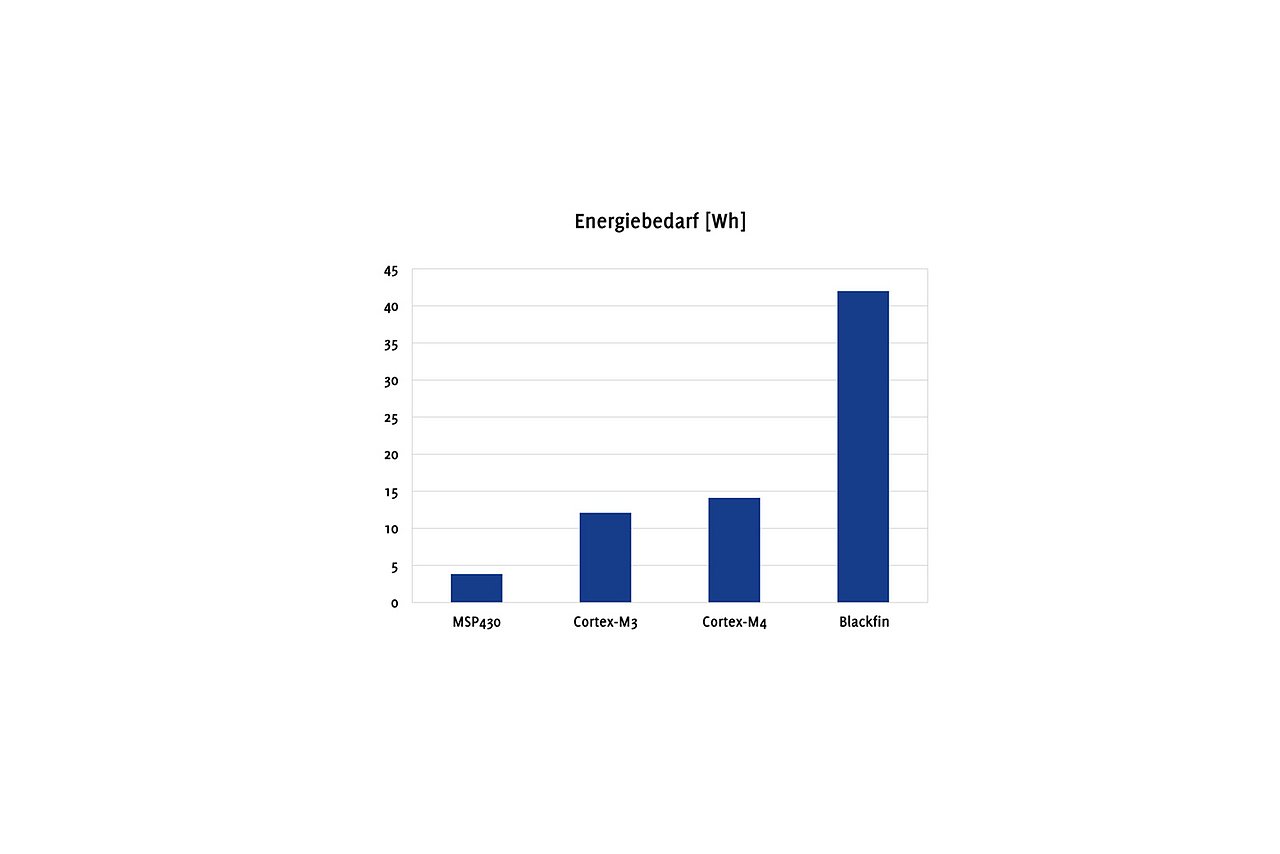

The Institute took many serial measurements for energy consumption by a variety of microcontrollers and for the time they took to go through certain algorithms. To set optimum dimensions for the batteries with the necessary capacity, IMMS identified the current consumed by the system in each operational cycle. The peak values were also identified for the supply current during the measurement procedures and the order in which the process was carried out was optimised in the software to avoid too much stress on the batteries during operation. The software to carry out the initial evaluation of the data in the current clamp was likewise made at IMMS and then implemented.

The IMMS has supported the development of the current clamp up to production transfer. It is marketed by Indu-Sol under the name EMCheck® ISMZ I.

Acronym / Name:

Current Clamp / Smart current clamp EMCheck IMSZ IDuration:2012 – 2014

Application:

Automation technology and Industry 4.0|Industrial plantResearch field:Smart distributed measurement and test systems

Partner

Related content

Reference

René Heidl, Indu-Sol

“IMMS with its many years of experience in energy-autonomous systems and in developing integrated hardware and software complemented our own work perfectly and developed us a battery-operated current clamp for us. We are more than happy with the product, which is now being mass-produced and is a valuable addition to our range.”

Intelligente Lösungen für Industrie 4.0 - Diagnose und Überwachung in industriellen Anlagen

Tino Hutschnreuther1.2. Maschinenbautag, 15.06.2016, Erfurt

1IMMS Institut für Mikroelekronik- und Mechatronik-Systeme gemeinnützige GmbH, D-98693 Ilmenau, Germany.Autarke Strommesszange schützt vor Produktionsausfällen

Tino Hutschenreuther1. Hendrik Härter2.in Elektronik Praxis, September 2015, Seite 38 - 39, online: www.elektronikpraxis.vogel.de/messen-und-testen/articles/504598/

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau. 2Redakteur, Fachzeitschrift Elektronik Praxis.Realisierbarkeit eines tragbaren Erfassungssystems fur leitungsgebundene Störströme in Industrieanlagen

Peter Kornetzky1. Martin Sachs1. Stefan Schramm1.Deutsche Gesellschaft für die Anwendung der Mikroelektronik e.V. (DFAM), Studie Nr. 8/2012, ISBN 978-3-8163-0622-1

1IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH, Ilmenau.Article

Press release,

Intelligent measuring clamp detects parasitic currents in industrial plant

Presented by IMMS at the embedded world 2015, Hall 4, Booth 160 (OSADL joint booth).

Event,

embedded world 2015

Contact

Contact

Dr.-Ing. Tino Hutschenreuther

Head of System Design

tino.hutschenreuther(at)imms.de+49 (0) 3677 874 93 40

Dr. Tino Hutschenreuther will answer your questions on our research in Smart distributed measurement and test systems and the related core topics Analysis of distributed IoT systems, Embedded AI and Real-time data processing and communications, on the lead applications Adaptive edge AI systems for industrial application and IoT systems for cooperative environmental monitoring as well as on the range of services for the development of embedded systems.

Funding

The ZIM project entitled “Intelligente Strommesszange EMCheck IMSZ I” was funded by the Federal Ministry for Economic Affairs and Energy (BMWi) under the reference KF2534508 DB2.