Patent DE 10 2015 119 969

Arrangement for operating and/or measuring the generating power of a capacitive energy harvester

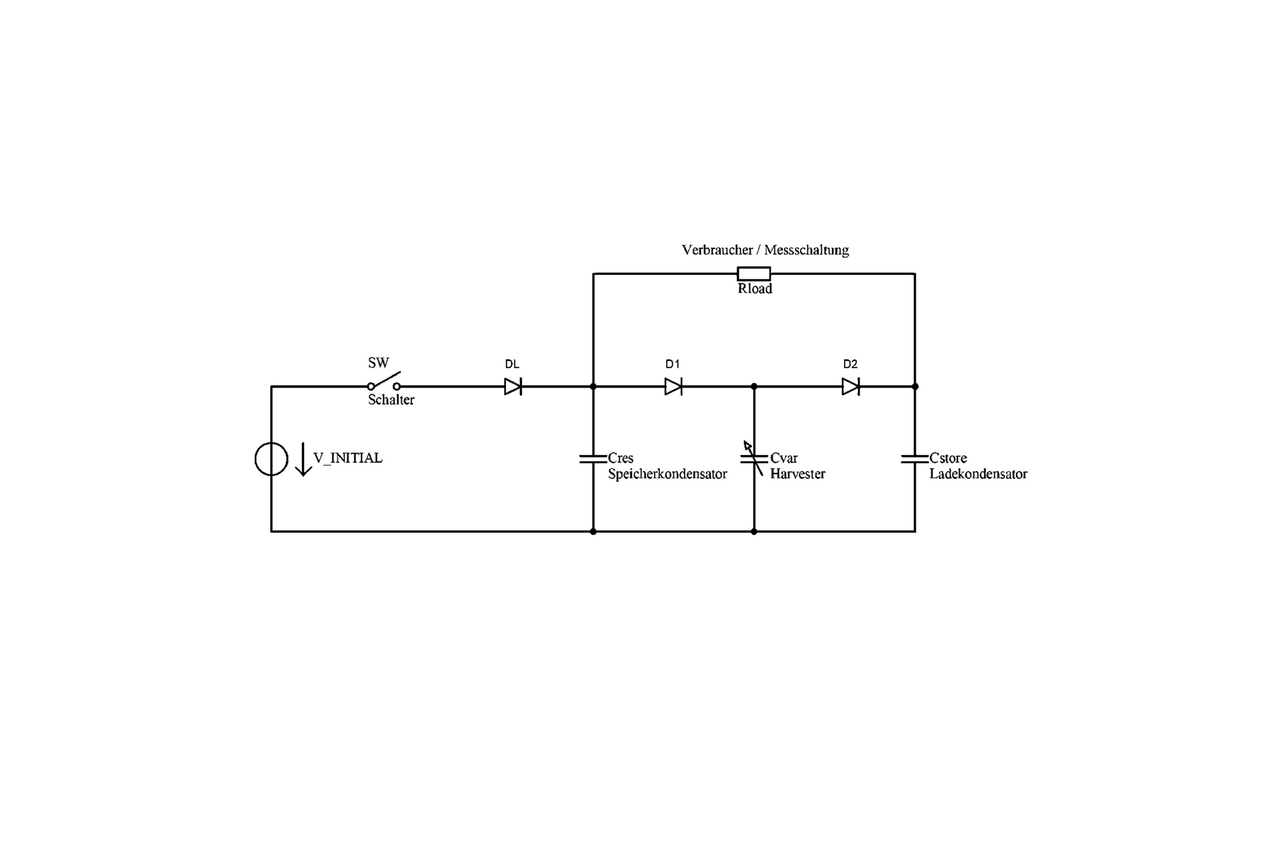

An arrangement for measuring the generating power of a capacitive energy harvester, comprising the following elements:

- a capacitive harvester capacitor (Cvar), the first and second electrodes of which are movable relative to each other in order to cause a change in capacitance when an excitation movement occurs;

- a storage capacitor (Cres), the second electrode of which is connected to the second electrode of the harvester capacitor (Cvar);

- a first diode (D1) whose anode is connected to the first electrode of the storage capacitor (Cres) and whose cathode is connected to the first electrode of the harvester capacitor (Cvar);

- a second diode (D2), the anode of which is connected to the first electrode of the harvester capacitor (Cvar);

- a voltage measuring device connected between the cathode of the second diode (D2) and the anode of the first diode (D1); and

- a charging capacitor (Cstore) connected between the cathode of the second diode (D2) and the anode of the first diode (D1).

Patent No.:DE 10 2015 119 969

Inventor:Björn Bieske. Gerrit Kropp

Application:

Characterisation of electrostatic capacitive energy harvesting systems| measurement of the performance of capacitive energy harvesters under different load conditions| comparison of harvester realisationsResearch field:Smart distributed measurement and test systems

granted patent

Application date:18 November 2015

Date of first publication:18 May 2017

Date of publication of grant:16 May 2019

Contact

Contact

Dipl.-Ing. Michael Meister

Head of Industrial Electronics and Measurement Technology

michael.meister(at)imms.de+49 (0) 3677 874 93 20

Michael Meister is your contact for testing services, the development of test methodologies, and long-term measurements. He answers your questions on Modular and mobile test systems that we develop in our research in Smart distributed measurement and test systems as well as about testing and characterisation of integrated sensor systems. He is responsible for the test equipment at IMMS and will support you in the validation of ASIC and MEMS developments.