Press releases

2019 annual report online

Here you can find the contents in brief and the entire report which is linked to further information, related articles and videos.

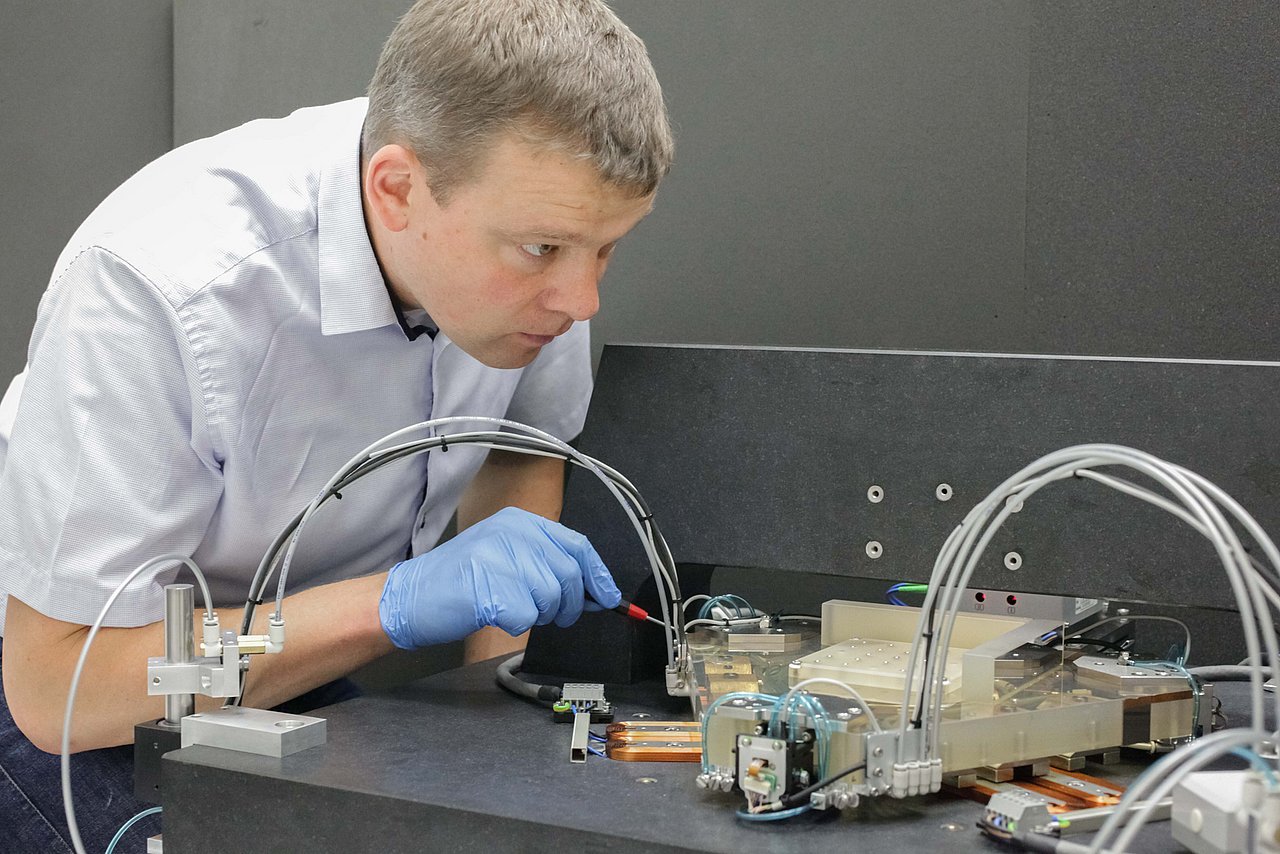

INPOS – 6D integrated direct drive moving objects through nanometre spaces. In semi-conductor manufacture, direct drives position wafers etc in one plane with great accuracy. But so far they have only been able to raise objects on the nanometre scale over a surface of a few square millimetres. In partnership, IMMS has developed a 6D direct drive capable of positioning objects anywhere in an area of ∅ 100 mm while raising or lowering them through 10 mm under active control on the nanometre scale.

INSPECT – Proving and quantifying presence of PSA for point-of-care prostate cancer diagnosis with immunoassay on CMOS biochip. To measure PSA (the prostate-specific antigen) without recourse to laboratories, IMMS has created a mobile readout device containing an exchangeable opto-electronic CMOS biochip. Together with Senova as partner, IMMS has succeeded in quantifying PSA directly on the chip using an immunoassay while fulfilling the clinical directives for PSA testing.

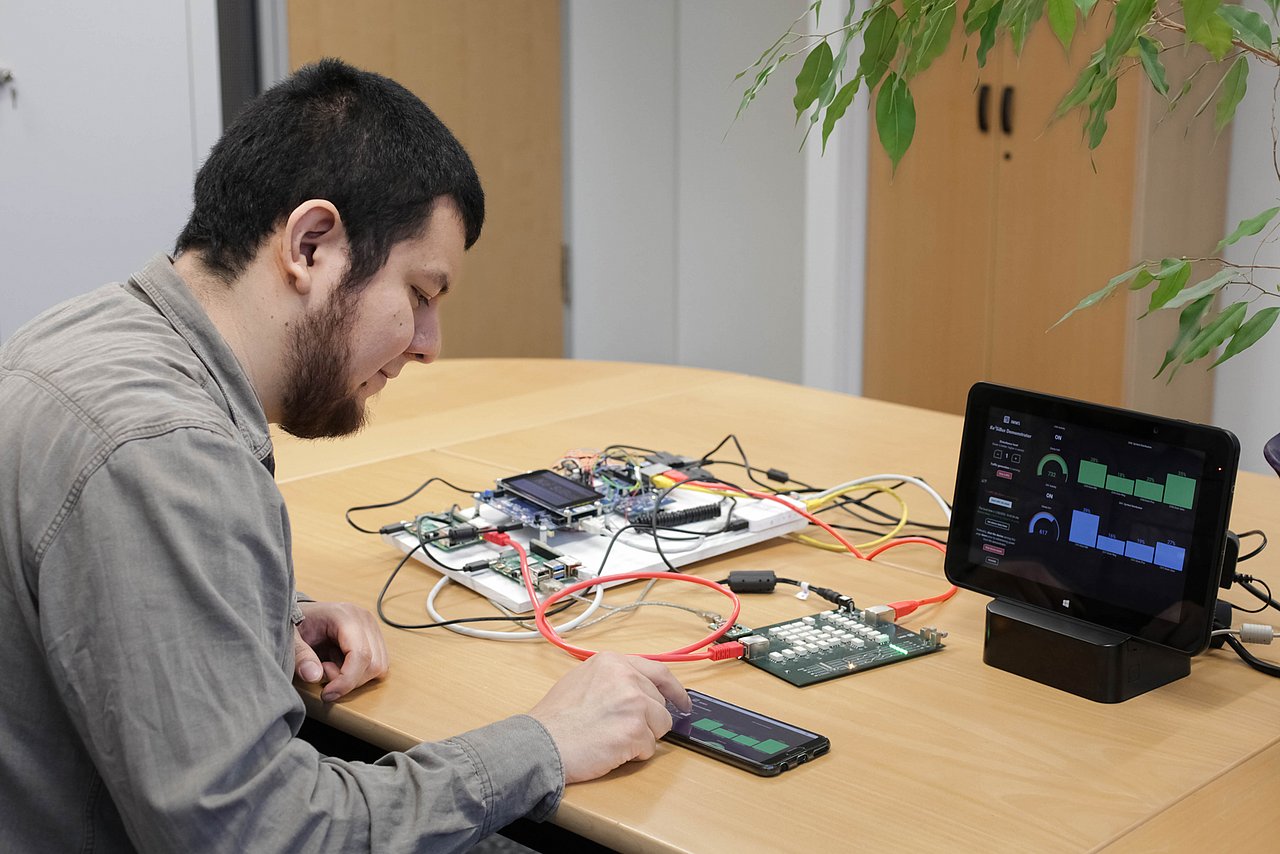

ADMONT – RFID chip supporting battery-free operation of off-the-shelf sensors for diagnostics and analytics. The IMMS RFID chip supplies energy to individual commercial sensors with an I2C interface and transmits their measured data to an NFC-capable smartphone or other RFID readout device, contact-free. The integrated energy management system and I²C master enable energy-intensive measurements to be taken at low cost using NFC. The data is processed with an Android app.

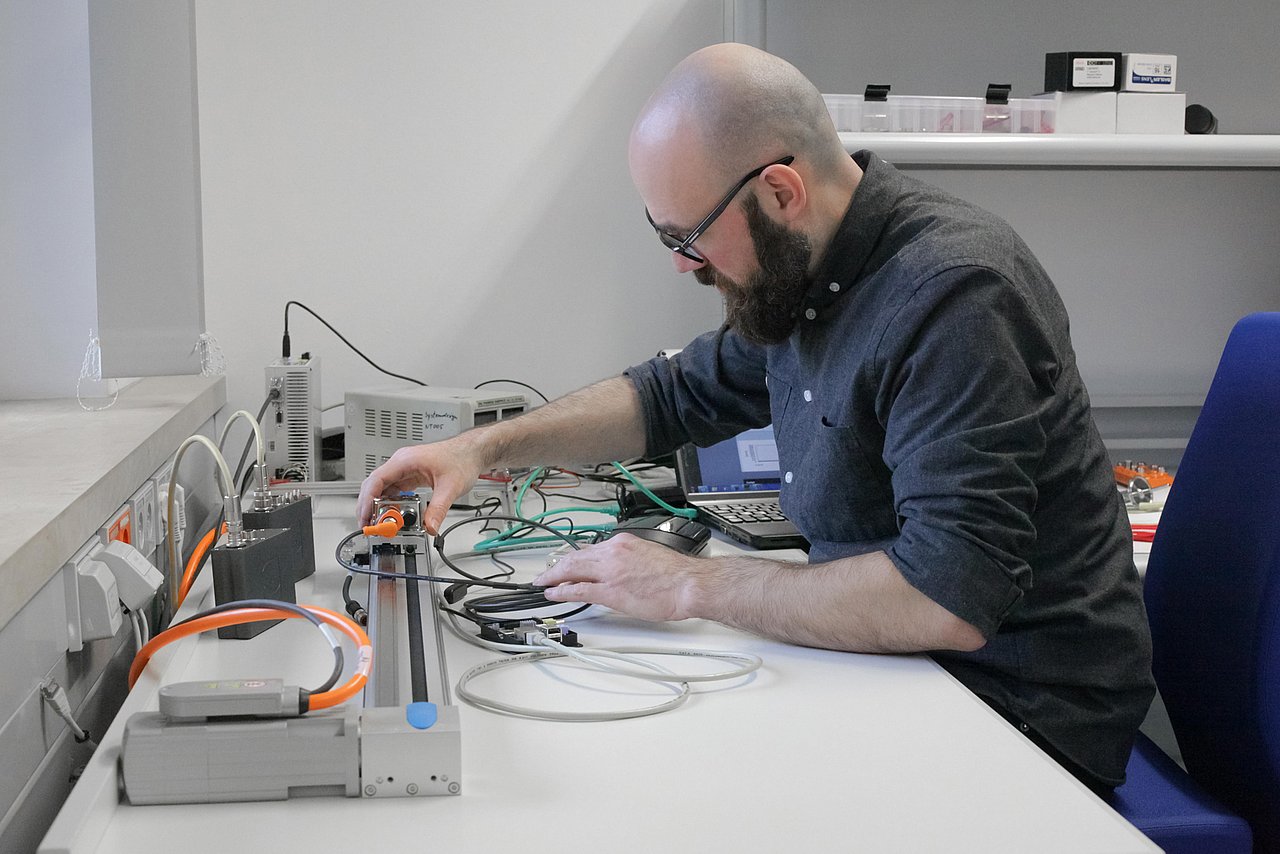

Ko²SiBus – Continuous, cost-effective signal analysis for Ethernet-based bus systems. Continuous monitoring with Ethernet cables can prevent machine downtime in industry. However, this is not possible on a comprehensive scale for want of suitable methodology. A solution to the problem has now been developed. The Ethernet cables on a machine can be monitored cheaply and continuously during normal operation without any interference in their communications.

AgAVE – Industry-4.0 communications for an assistance system, ML-based, that autonomously analyses connected production chains. The increasing complexity of production plant has made root cause analysis in respect of errors more difficult because the message and the error are often at different sites. Fraunhofer IOSB-INA and IMMS have developed an assistance system for production chains for automatic early recognition of sources of error and anomalies, keeping fault costs to a minimum.

Digital Engineering for planning and revitalisation of city districts – use of sensors to monitor buildings. For building surveys and efficient planning of complex residential construction and renovation, innovative methods have been developed by the Bauhaus University, Weimar, research group. The system automatically captures and validates data from residential and other buildings. IMMS has contributed a means of wireless monitoring of physical features of buildings.

IRIS – A procedure for in-line inspection of encapsulated MEMS silicon components. It is common for micromechanical structures to be protected at wafer level by encapsulation. However, there has to date been no means of optical inspection of what is inside the capsule during production. Now, using partners‘ new measurement technology for inspecting capsule content, IMMS has developed a procedure for wafer-level measurements and quality assessment of encapsulated MEMS.

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.