Press releases

Extended service life for self-teaching wireless sensors for industrial maintenance

IMMS patent for edge AI solution wins bronze medal at iENA 2025

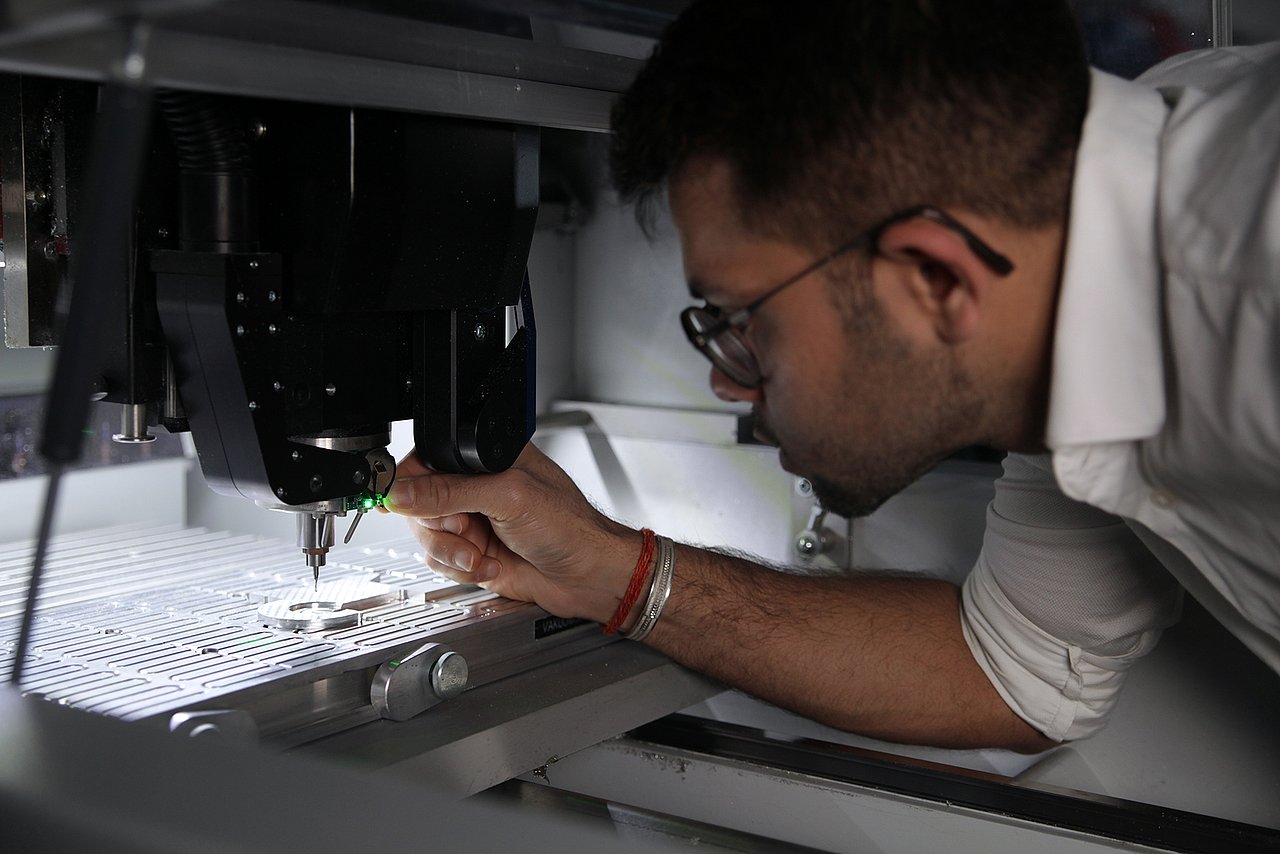

The IMMS patent ‘Method and sensor arrangement for monitoring the function of a machine component’ was awarded a bronze medal on 11 December 2025 at the Thuringian award ceremony of PATON | Landespatentzentrum Thüringen (Patent Centre of the German Land of Thüringen) at Technische Universität Ilmenau in the competition at the iENA inventors’ fair. At the beginning of November, PATON submitted the work to the competition at iENA in Nürnberg, Germany, on behalf of the inventor Rick Pandey. Core to the patent is a new method for data-reduced communications between wireless sensor nodes and monitoring systems, which significantly reduces the energy consumption of wireless sensors. This allows users or manufacturers of wireless sensors to use them for industrial maintenance with condition monitoring and predictive maintenance, even in large quantities and in hard-to-reach places, for years to come.

Energy consumption of wireless sensors and large amounts of data critical

Machines and industrial plants are often monitored and analysed in real time using wireless sensors to detect potential problems or deviations from normal operating conditions at an early stage and predict maintenance requirements. However, this can lead to limitations: if the sensors are located in many or hard-to-reach places and are required to operate reliably for years, their energy consumption is critical in terms of battery life. The sensor technology used for monitoring also generates a large amount of data. To date, this data can only be transmitted to the central monitoring device at high energy costs. In addition, defects in machines occur very rarely or not at all during normal operation, and certain fault conditions, such as defective bearings and machine parts, cannot be easily reproduced.

New algorithm learns good conditions – wireless sensor only transmits deviations

With the patented Edge AI solution, data is processed directly on the sensor node and reduced for radio transmission, which lowers its energy requirements and thus increases its service life. Interference data and error states no longer need to be recorded in advance.

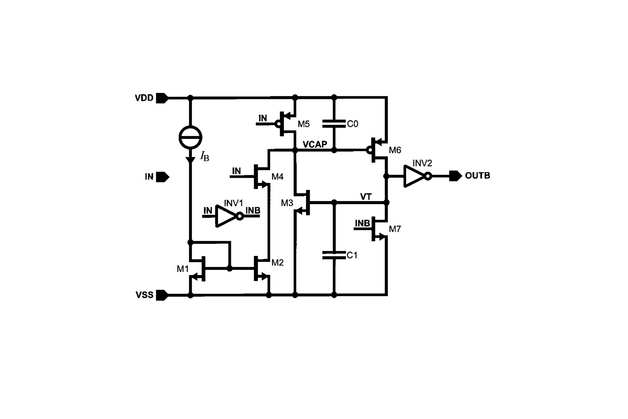

The much-cited term ‘edge AI’ combines edge computing and artificial intelligence. This allows algorithms and machine learning to be executed directly on interconnected wireless sensors – locally or with an internet connection. While edge computing enables data to be stored close to machines and systems, AI algorithms process the data directly at the edge of a network or at the interface to the higher-level network and can provide real-time feedback on the machine status.

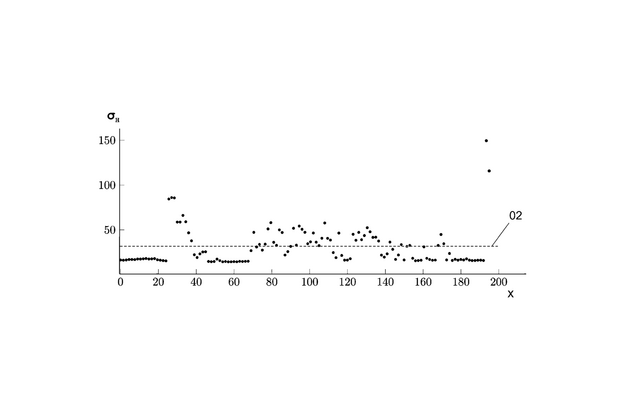

The new algorithm developed at IMMS collects data and learns normal machine behaviour patterns directly on the sensor, largely without supervision. The regular behaviour patterns of a plant and certain novelty criteria that indicate deviating behaviour are learned from the data recorded on the wireless sensor. Data is only sent to a central monitoring system if the calculated novelty value deviates from the normal criteria for ‘healthy behaviour’. This completely eliminates the need to transfer raw data to a central monitoring system. This on-device learning and subsequent retraining make the algorithm generalisable for various industrial scenarios and robust against possible data drift. The method for recognising the novelty value of data combines mathematical procedures in a specific sequence for ongoing condition monitoring and predictive maintenance over many years.

On-device data reduction through singular value decomposition and correlation

To this end, the proper operation or good condition of, for example, a bearing or a machine is first recorded, its characteristics are automatically determined by singular value decomposition, and a threshold value is determined on this basis to be able to detect deviations. This threshold value is then further improved by learning certain anomalies and conditions.

To reduce the data set on the sensor node so that as little data as possible needs to be transferred to the monitoring system, only a certain number of the dominant singular values are used with their associated information. In the application, newly recorded vibration values are analysed using canonical correlation analysis. Changes in condition are qualitatively recorded based on the differences between the learned characteristics of the good condition and the newly recorded ones.

The process can be implemented in various applications for machine monitoring and is available for licensing.

German patent: DE 10 2024 100 703 B3, IP available, patent applicant/holder: IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH (IMMS GmbH), inventor: Rick Pandey.

Funding

The HoLoDEC project on which this report is based was funded by the German Federal Ministry of Research, Technology and Space (BMFTR) under the reference 16ME0703. The author is responsible for the content of this publication.

This might also be interesting for you

Related content

Project

HoLoDEC

IMMS researches ultra-low-power architectures (ULP) and circuit concepts as well as energy-efficient edge-AI systems with overall system energy…

Patent

DE 10 2024 100 703

Method and sensor arrangement for monitoring the function of a machine component

Event,

SMACD 2025

International Conference on Synthesis, Modeling, Analysis and Simulation Methods, and Applications to Circuit Design

Event,

InnoCON 2025

Innovation policy flagship event of the German Land of Thüringen. Topic “Key technologies: Paving the way for the world of tomorrow“

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.