Press releases

Project launch of ECo-Harvester – ambient energy for decentralised sensor applications

First co-design of mechanics and electronics for electrodynamic vibration harvesters

Ilmenau/Villingen-Schwenningen, 16 February 2021. Hahn-Schickard-Gesellschaft für angewandte Forschung e.V. and IMMS Institut für Mikroelektronik- und Mechatronik-Systeme gemeinnützige GmbH (IMMS GmbH) started work on their three-year DFG research project “ECo-Harvester - Design methodology for the co-design of mechanical structure and interface circuitry of electrodynamic energy harvesters” in a virtual kick-off meeting on 15 February 2021.

Energy harvesters convert ambient energy into electrical energy in order to operate, for example, energy-autonomous wireless sensor nodes for monitoring tasks in industrial environments and to minimise the necessary maintenance and installation costs. Energy harvesters thus have a high potential to become a key technology for the decentralised distribution of sensor applications.

In the ECo-Harvester research project, a computer-aided design methodology for the co-design of mechanics and electronics for electrodynamic vibration harvesters is to be developed to derive the optimal harvesting system depending on given requirements.

“We don't want to simply assemble two components, but aim for an overall system design. The optimum of the overall system is not always the optimum of the subsystems,” explained Prof. Dr. Ralf Sommer, scientific director of IMMS. This overall system view is necessary so that the efficiency of the system can be increased, i.e. it delivers more power or can be built smaller with the same power, Sommer continued. Such an approach expands the state of the art, as currently the components are often developed separately from each other.

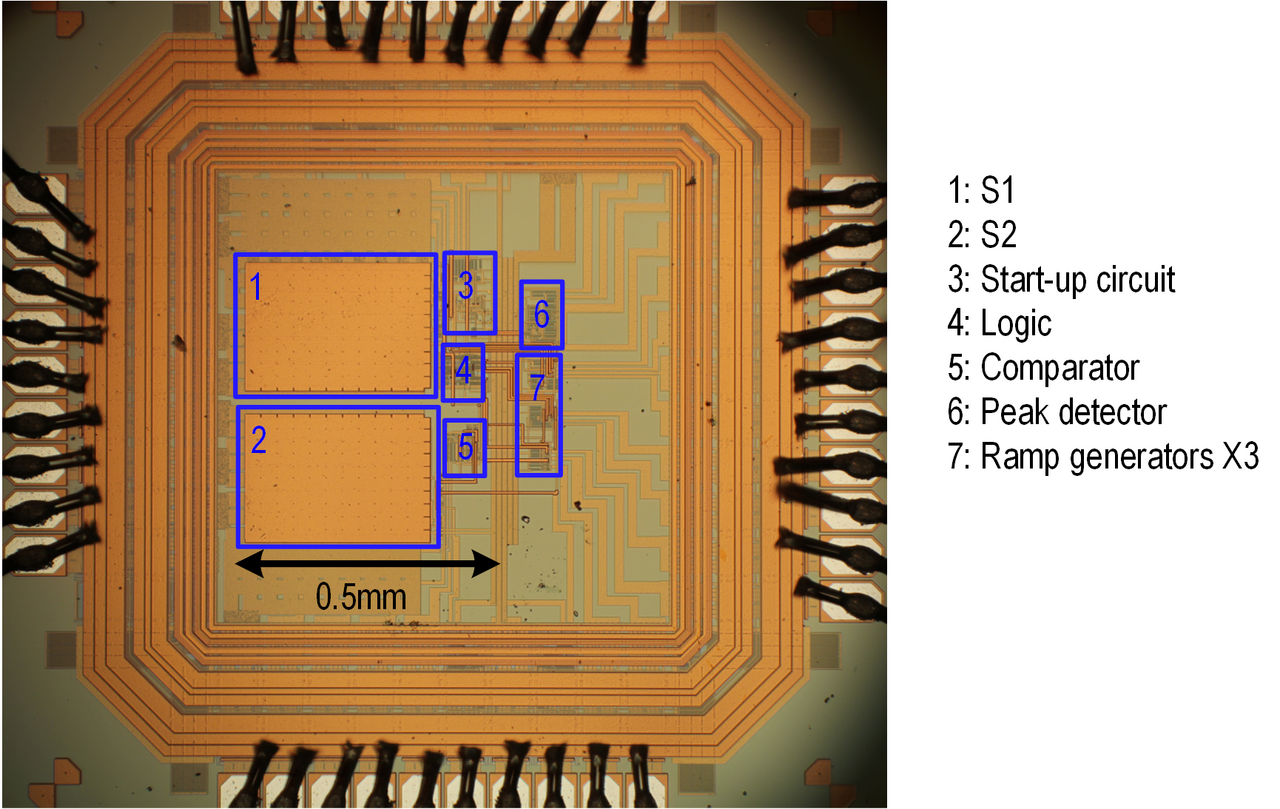

IMMS will focus on mechanical modelling including magnetic fields and mechanical damping of energy harvesters, which are used to extract energy from vibrations. Hahn-Schickard will focus on the front-end circuits with high efficiency or low losses in order to provide the energy from the harvester mechanics in a suitable form for sensor systems.

“However, since both partners are looking beyond their main areas of focus, especially at the interaction of harvester design and interface circuitry, we can exploit synergy effects,” said Dr.-Ing. Thorsten Hehn, group leader for electronic systems at Hahn-Schickard. By appropriate modelling, an optimal overall concept for given framework conditions, such as signal shape, frequency and amplitude of the excitation, size of the harvester, etc., can be generated from the topologies for the harvester and the interface circuit, including parameter determination. This not only enables a cost-effective design, but also extended application scenarios through improved system properties.

“The challenges lie in the fact that there are a large number of basic topological structures on the part of the mechanics and, for example, many voltage ranges on the electronics side,” Hehn summarised. “The exciting question is what is best for the overall system. We look forward to the answers we will provide together.”

Funding

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) – reference number 452215927.

Related content

Project

ECo-Harvester

In the project, the methodology for the co-design of mechanics and electronics of electrodynamic energy harvesters is being developed.

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.