Press releases

Development of an inline cleaning system for washing media in resin-based 3D printing production

Inline3D project launched to minimise pollutants and costs in 3D printing

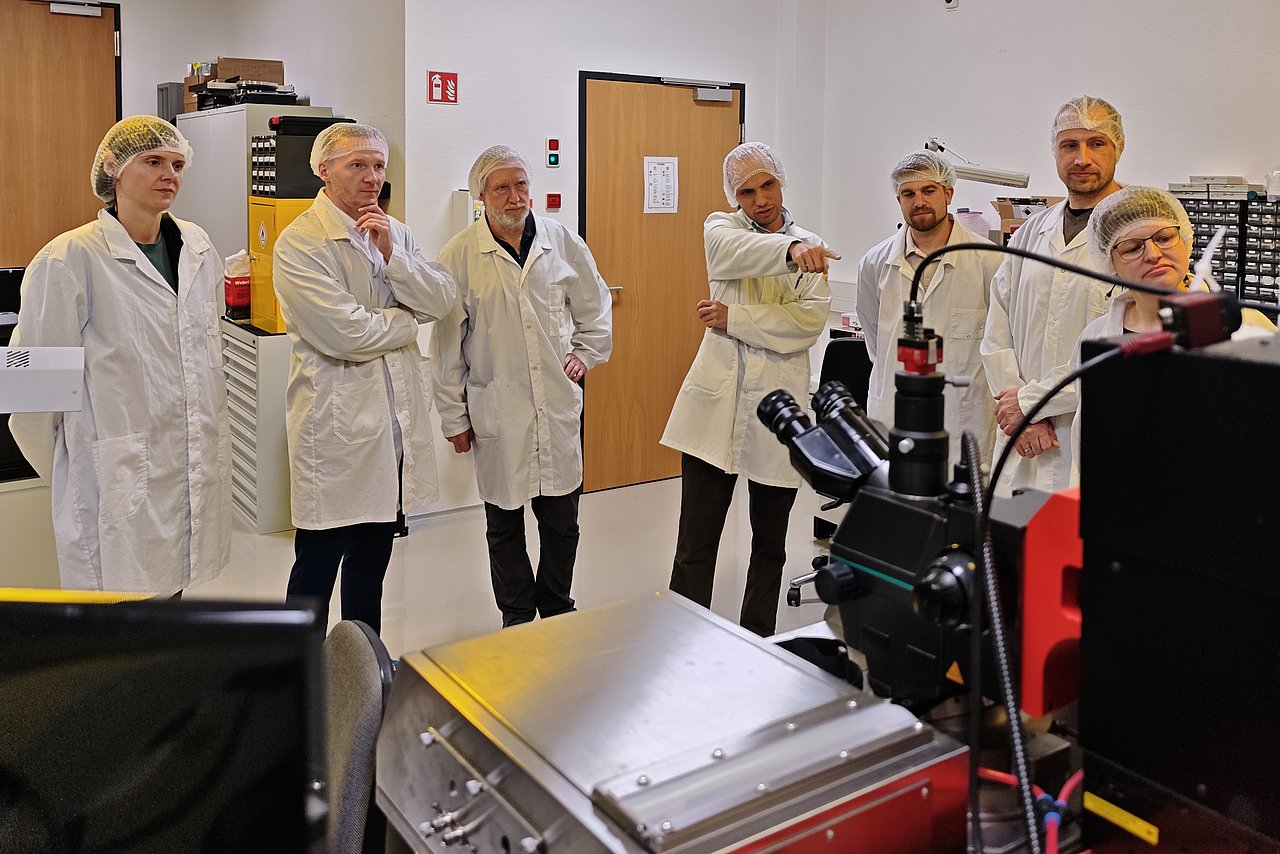

On 11 September 2025, IMMS, IL Metronic and BURMS presented details of the Inline3D project, which is funded by the German Land of Thüringen and the EU and was launched in June, to the Thüringer Aufbaubank in Erfurt. In this project, which will run for almost two and a half years, sensor technology, cleaning and fluidic modules are being developed to clean washing media in resin-based 3D printing production inline – directly in the manufacturing process – for the first time. The aim is to minimise the use of environmentally and health-damaging as well as cost-intensive substances in the washing media required for 3D printing.

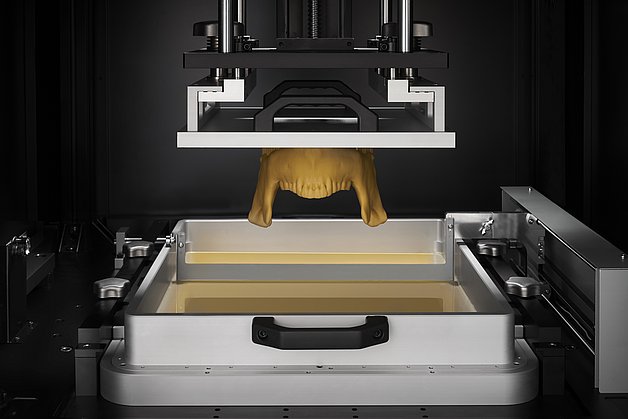

Resin-based 3D printing processes generate harmful waste

In resin-based 3D printing production, the 3D printed objects are cleaned with special washing media. These contain substances that are harmful to the environment and health and are currently often disposed after one use instead of being recycled. The reason for this is that, at present, recycled washing substances are usually not sufficient to clean the printed objects of unhardened resin.

Cost factor washing media difficult to minimise so far

The consumption of cleaning media is also a significant cost factor in the production process. So far, cleaning media is only processed on a large industrial scale. Available cleaning devices are large, unhandy, energy-intensive and can only be used ‘offline’. This means that the media to be cleaned must be transported to the cleaning system in separate process steps and later returned to the 3D printing process in some cases. Automatic cleaning during the ongoing production process with permanent monitoring of the properties of the media is not yet available.

Inline treatment allows further use of the cleaning medium

The Inline3D project is developing a treatment process for washing media that removes contaminants directly during the production process and then returns the treated washing medium to the cleaning process. This treatment converts environmentally hazardous and harmful components into harmless waste products that do not need to be disposed of as hazardous waste.

Sensor-based monitoring of the contamination level can extend the service life of the washing medium and optimise the quality of the cleaning process. The aim is to use resources more efficiently and minimise pollutants and costs in 3D printing production processes.

Thuringian partners pool expertise in sensor technology, UV irradiation technology and 3D printing

The regional alliance of the three Thuringian project partners BURMS 3D Druck, IL Metronic Sensortechnik and IMMS Institut für Mikroelektronik- und Mechatronik-Systeme promotes innovation and the further development of existing expertise in the field of 3D printing in the German Land of Thüringen.

IMMS is coordinating the project and developing a sensor-based measurement method to quantify the degree of contamination in the washing medium. IL Metronic is using its expertise in UV irradiation technology to transfer the measurement method to a sensor module and develop an irradiation module for separating out dissolved resin residues. BURMS is contributing its expertise in commercial 3D printing solutions, implementing the fluidics and process integration in the project, and ensuring device safety, disposal and biocompatibility.

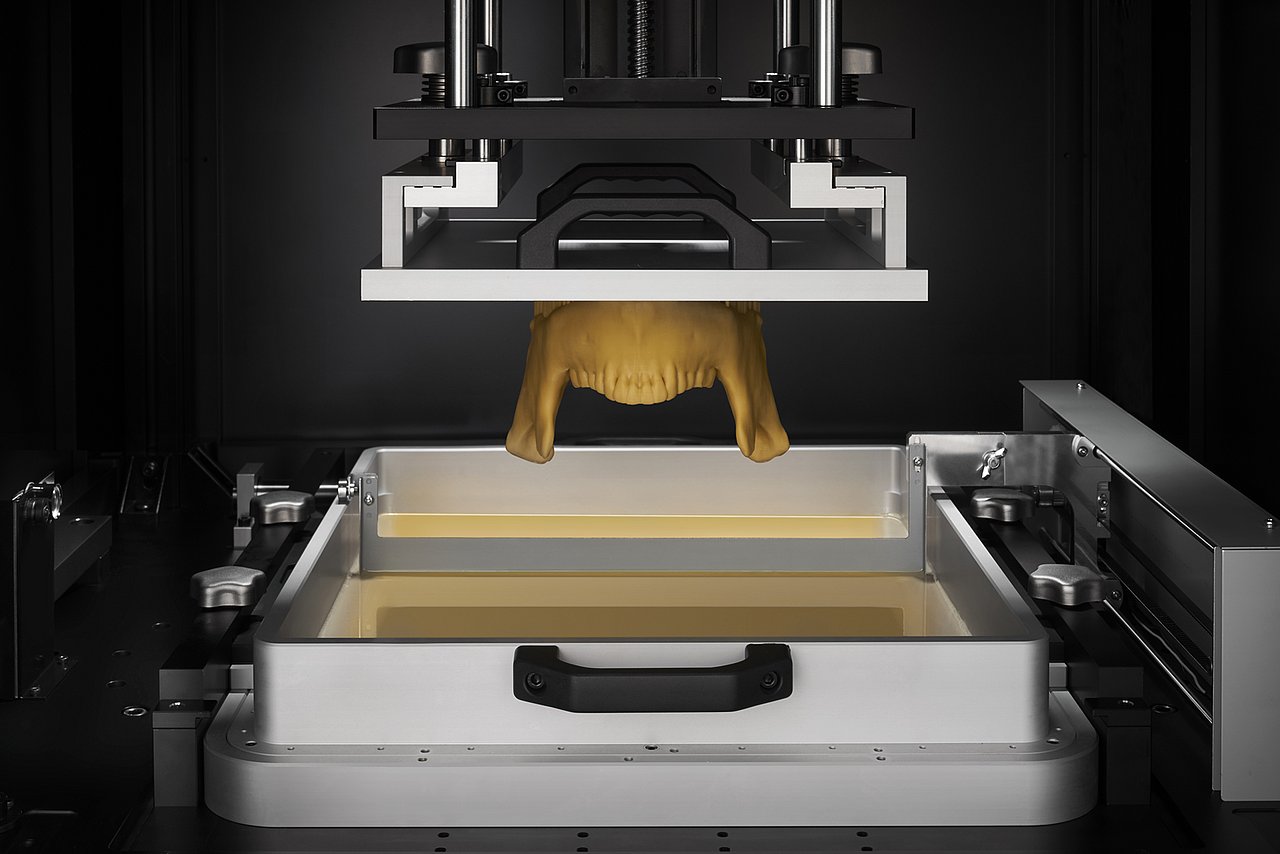

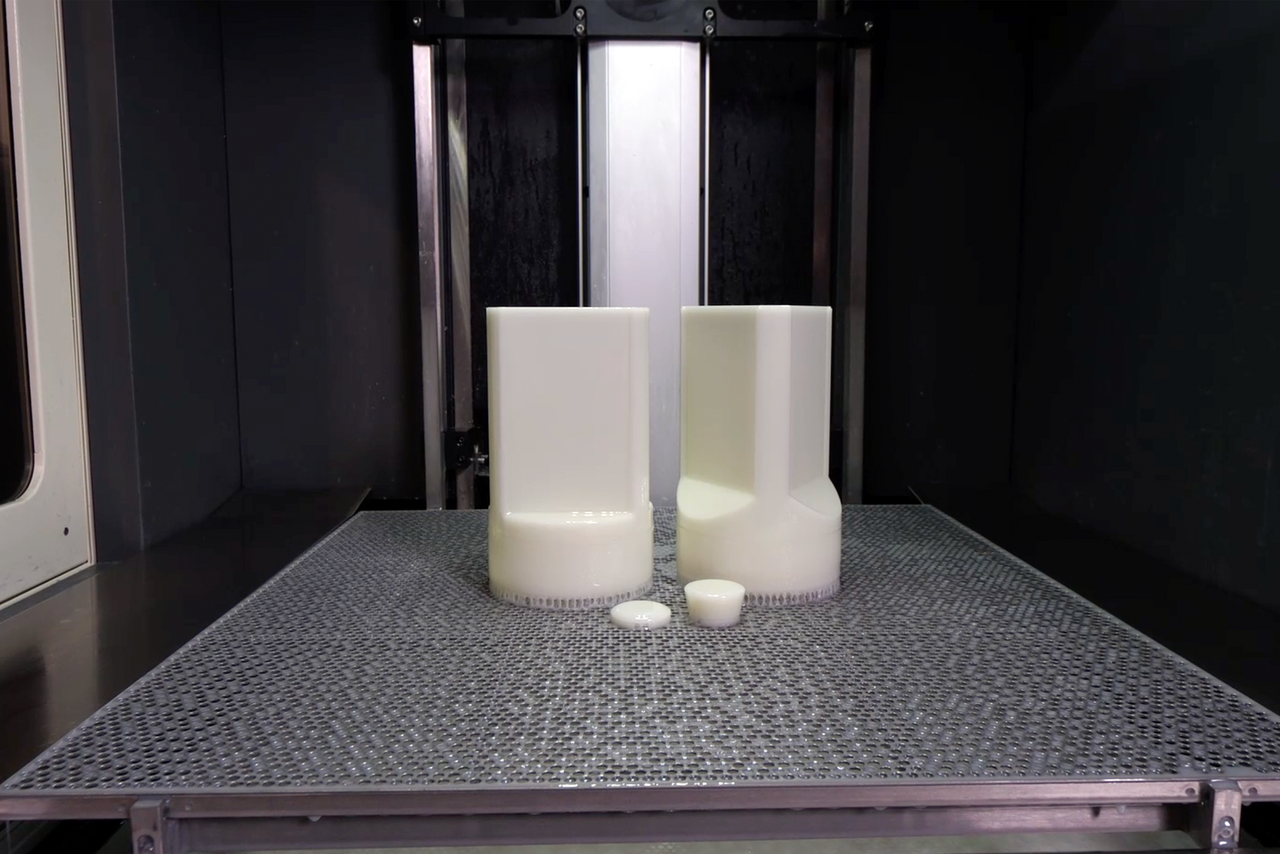

Faster production and more resource-efficient small batches possible

Due to the advantages of fast production times and application- and customer-specific customisation of individual items, growth is expected particularly in medical applications. In addition to the technological advancement of the 3D printing technologies of the partner BURMS, the aim of the project is also to use the technological findings to further develop those 3D printing systems that currently do not process the washing medium at all.

Funding

The joint project ‘Inline cleaning process for washing media in resin-based 3D printing processes’ (Inline3D) is supported by the funding programme of the German Land of Thüringen for the promotion of research, technology and innovation (RTI) as the research and development initiative Thüringen Verbund and co-financed by the European Union under the reference 2024 VFE 0113.

This might also be interesting for you

Related content

Contact

Contact

Dipl.-Hdl. Dipl.-Des. Beate Hövelmans

Head of Corporate Communications

beate.hoevelmans(at)imms.de+49 (0) 3677 874 93 13

Beate Hövelmans is responsible for the text and image editorial work on this website, for the social media presence of IMMS on LinkedIn and YouTube, the annual reports, for press and media relations with regional and specialist media and other communication formats. She provides texts, photographs and video material for your reporting on IMMS, arranges contacts for interviews and is the contact person for events.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/7/csm_20130223_dcSen_ProberEF_MM_MG_3325_1920x1280_588e478d86.jpg)